-

Posts

129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Carlmb

-

-

-

-

-

-

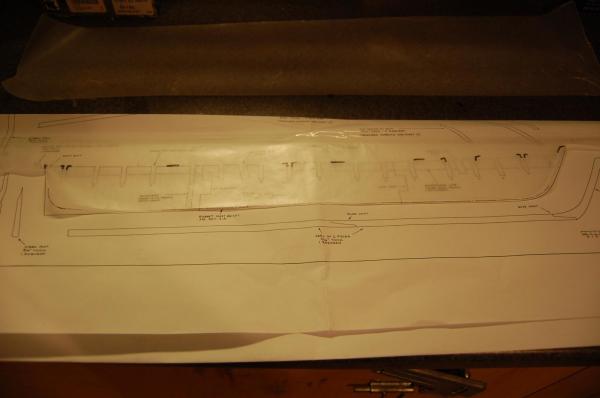

Started by cutting out all the bulkheads and pre-fitting them on to the keel assembly. It was now time to cut the bearding line from the keel. I placed a piece of wax paper over the plan and cut out the bearding line on the wax paper. Placed the wax paper over the keel and traced the line on the keel. Also using wax paper you could flip it over and do both sides of the keel. Using a compass I drew a center line down the keel so I did not sand to far. Using my handy bearding line sander I sanded with 120 till the line was complete. .

-

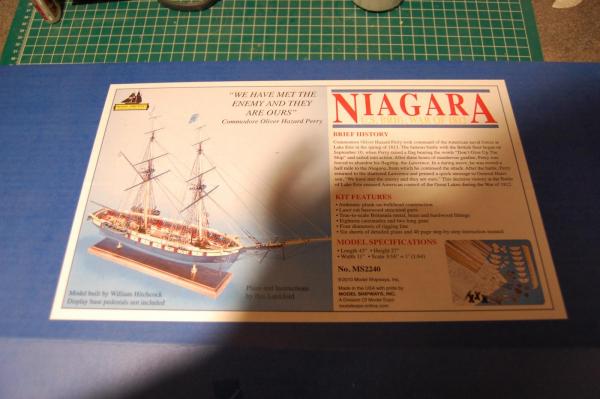

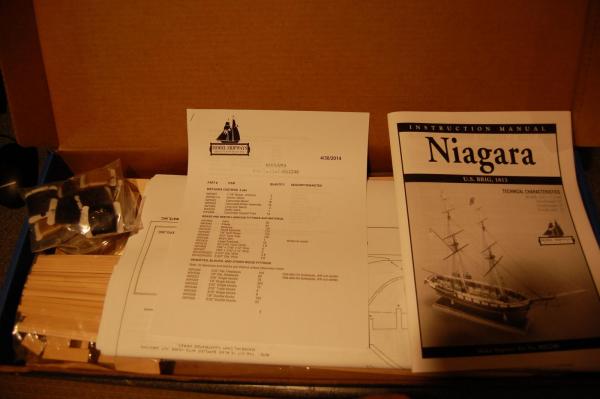

Well, it appears to be that time. I have cracked the box and going to try and make some thing that appears like a ship. I gained a little bit of experience building the New Bedford Whaleboat but this is a whole different animal. Checking off the items now and looks like a whole lot of laser burn removal in my future. Made a build board for this part but I am wondering if I should buy a keel clamp or make something similar. Anyone have any thoughts on what is best to build and plank?

I know a lot of people have completed or in the process of building a Niagara so I will have plenty of questions. Will continue to update as I go. Thanks for everyone's help.

p.s. I did a search for adding completed builds to login and could not find it. Any help would be appreciated.

-

- dgbot and GrandpaPhil

-

2

2

-

-

-

- dgbot, CaptainSteve and Duanelaker

-

3

3

-

- CaptainSteve, dgbot and Keith_W

-

3

3

-

Thanks Michael. I previously looked at your Pilot cutter and 1/500th posts. Beautiful builds.

-

-

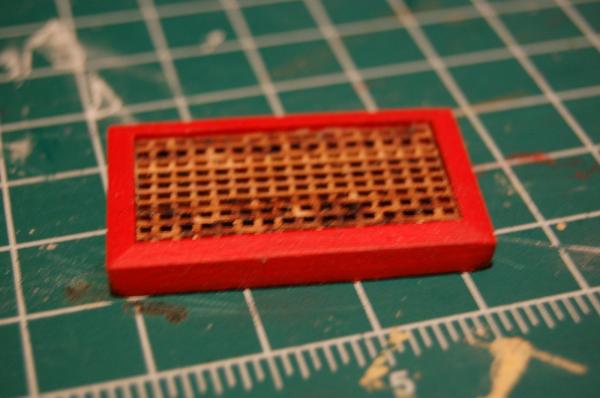

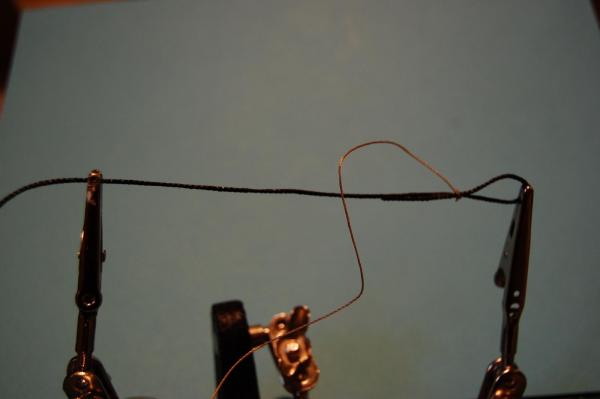

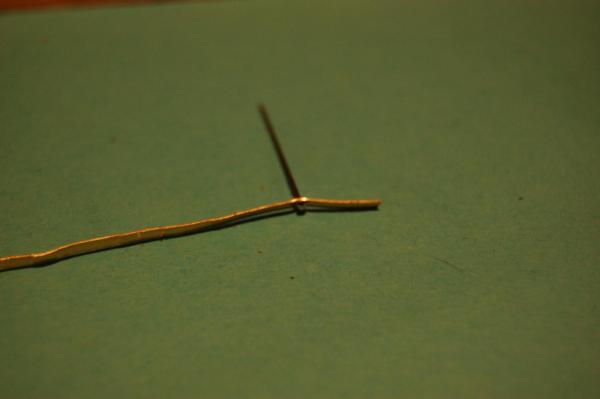

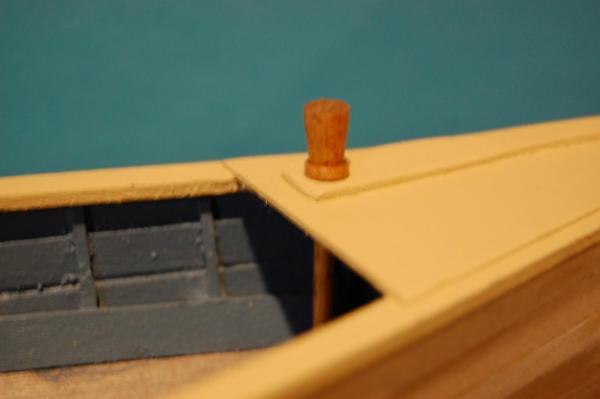

Some prefabbed planks and tops and bottoms were supplied with the kit. After being assembled I treated the wood with weather-it which is a cool wood ager I had used years ago when train modeling. I then cut some brass sheets into 1/16 strips that I fit around the drums and soldered. I then treated the strips with blacken it and CA'd them on.

-

Great job Alex! Keep up the good work.

-

- michael mott, russ and dgbot

-

3

3

-

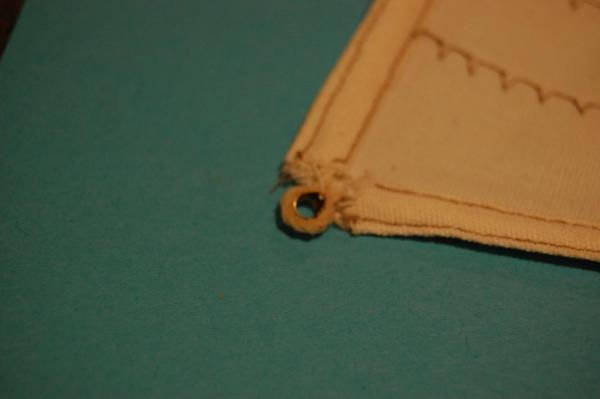

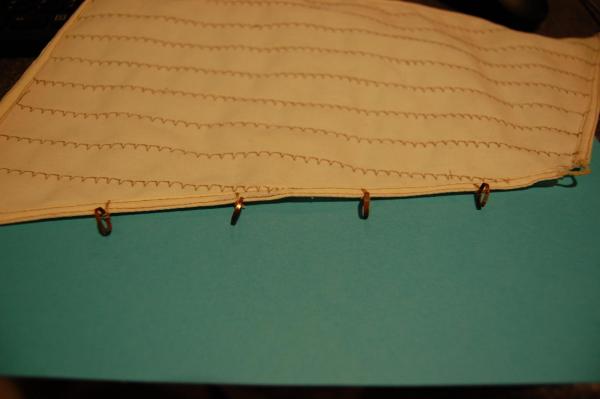

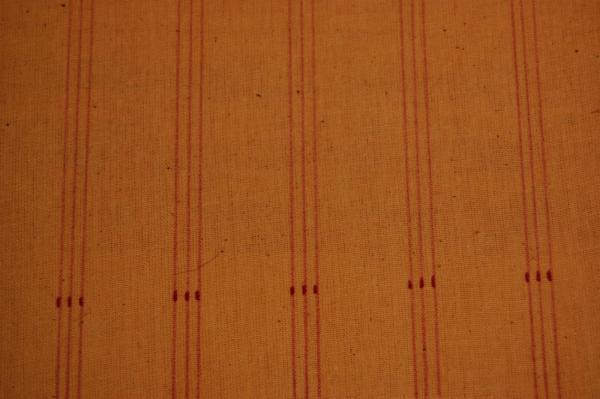

So last night I decide it must be time to make the sail. (not necessarily in order but a good distraction) I do a search for making sails and a few categories pop up but 1 by Nils on using the wife's sewing machine to make sails pops up. I contacted Nils and he was awesome responding to me with a new thread.

So I do a quick craigslist search and there is a $30 Kenmore 10 miles from me. I grab it and following some good instructions and sewing machine 101 I am able to whip something up.

I followed the instructions to build the New Bedford sail and didn't like the way it turned out (new sewing machine does not make small enough cross-stitches). Made a new one and I'm much happier. Time to make the masts now.

- dgbot and michael mott

-

2

2

-

- michael mott, CurtisW and dgbot

-

3

3

-

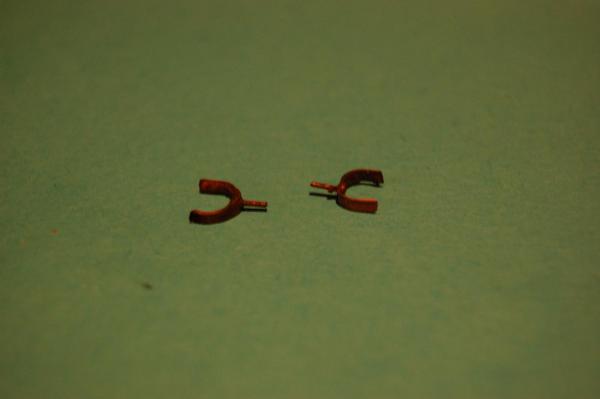

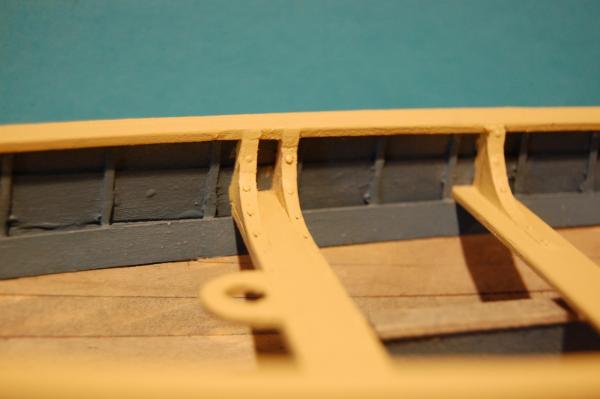

As shown on the Beetle site there are bolts holding down the thwart knees. This is a great site with some awesome pics of a complete full size whaleboat build. It can be seen at www.whalingmuseum.org/programs/beetle-whaleboat-project

I figured the best way to make these bolts was cut the heads off a #17 dress pin. I drilled the knees with a #65 drill and inserted the heads with a dab of glue. These are going to be painted over with a Light Buff acrylic.

- dgbot, Duanelaker and CurtisW

-

3

3

-

-

Great start and description.

-

-

Hanson Hobby is a small store that carries something for everyone. Mostly RC car stuff. I bought some wood there a couple days ago. He has a decent wood supply but it has just been there to long, very brittle. A few wood kits but expensive.

Thanks for the welcome. Anyone know of any ship modeling clubs in Mass.?

-

Niagara by Carlmb - Model Shipways - 1/64

in - Kit build logs for subjects built from 1801 - 1850

Posted

Thanks for the offer Laxet, I have been watching your build. One thing I have found in the instructions is that they do not list specifically what strips go to what. On my previous whaleboat build they listed what the strips fit.

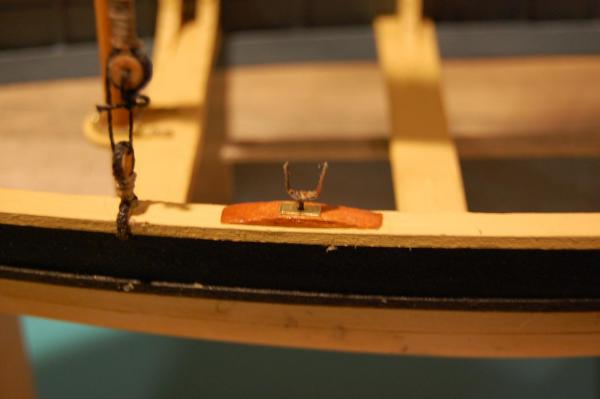

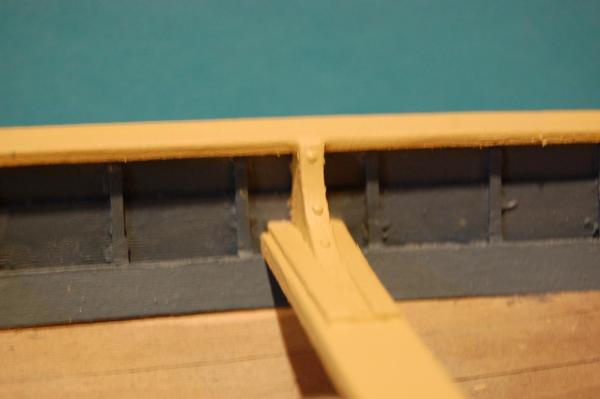

Just finished adding the supports between the bulkheads and working on carronades and structures in between.