-

Posts

796 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kees de mol

-

The winch took me more than 8 hours to build. I want to build more models so I wanted to make resin catings of it For both materials (silicons and resin) there is an A and a B component. You have to mix them 1:1 and then casting. I first made a silicon mould which I leave to harden for two days and then I went casting. I am very satisfied with the endresults. Only the first winch and hatches did need some more attention because I didnt removed the airbubbles the first time. But nothing serious, just some filler and sanding to make them right.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Can you put the propellorshafts trough that holes? I hope so! Looks very good anyway.

- 184 replies

-

- ruby & arthur reed

- lifeboat

-

(and 1 more)

Tagged with:

-

Very nice hull you made. I am looking forward to your updates.

- 184 replies

-

- ruby & arthur reed

- lifeboat

-

(and 1 more)

Tagged with:

-

I made this hatch and winch-thing the last few days. The winch is used for unloading the ship and the hatch (with the smaller hatch on top) is for the nethold. I tried to copy as mutch detaills as possible and some detaills are still missing because I want to make some resin copies of it later. The coin on the pictures is 25mm or 1 inch in diamter. Kind regards. Kees

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Hello Thanks for watching my buildingreport and for the support I get from you. Not only in this report but in forum as whole. Your buildings really encourage me to build. I worked on the Pelikaan again. On the wheelhouse I wanted something to watch at so I started building an interior. It's meanth to be scematic and it is not on scale. But I think it looks good later when you look trough the small windows of the wheelhouse

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Hello fellow shipbuilders, Meanwhile I made the roof and the so-called "Pet" and that makes the bridge really complete. It was very hard to find the correct shape and it took me more cardboard and ps plate than I wanted. But at the end it worked out well.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Well I believe they are. I feel honored to build the models for them. They are two hardworking fishermen on the ship. The models are very important for them. The thing is. Now I am building two... why not three? Two for the fishermen and one for me. Have to think about that

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Its for when I am drunk again. When I see double the two images of the models will blend into one

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

DIY router machine

kees de mol replied to kees de mol's topic in Modeling tools and Workshop Equipment

You should see my other hand -

Hello Jan. I see you allready found the topic I made about the tool. It's selfmade and if I can help you with more info or pics just give a shout. I added a photo to the topic.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

DIY router machine

kees de mol replied to kees de mol's topic in Modeling tools and Workshop Equipment

Ik discovered another way to use the tool. Very happy with it. -

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Hello people, I wanted to buy a router but the missis wouldnt let me spend the money so I searched the bits and peaces-bin for stuff to make on myzelf. I had an old Kinzo multitool wich I could use and the necessary parts were there too. I built a router-part which is adjustable in height, a part to make circles and a part to make straight lines. Here's the result. It works very well and I am very happy with it. Kind regards, Kees

-

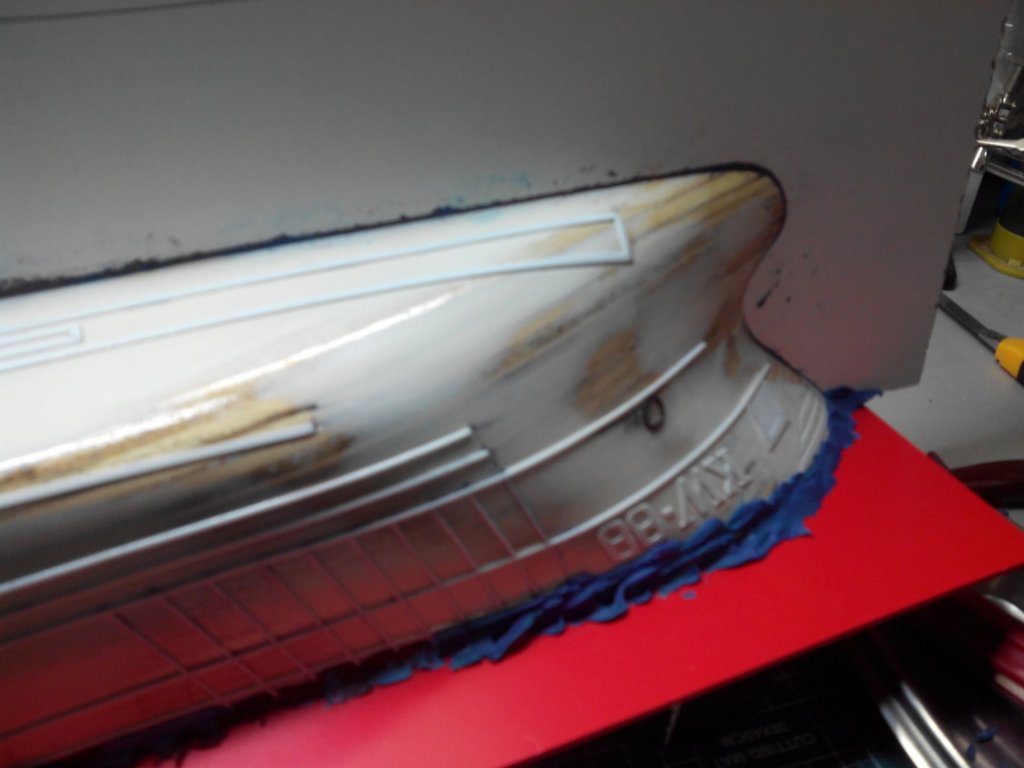

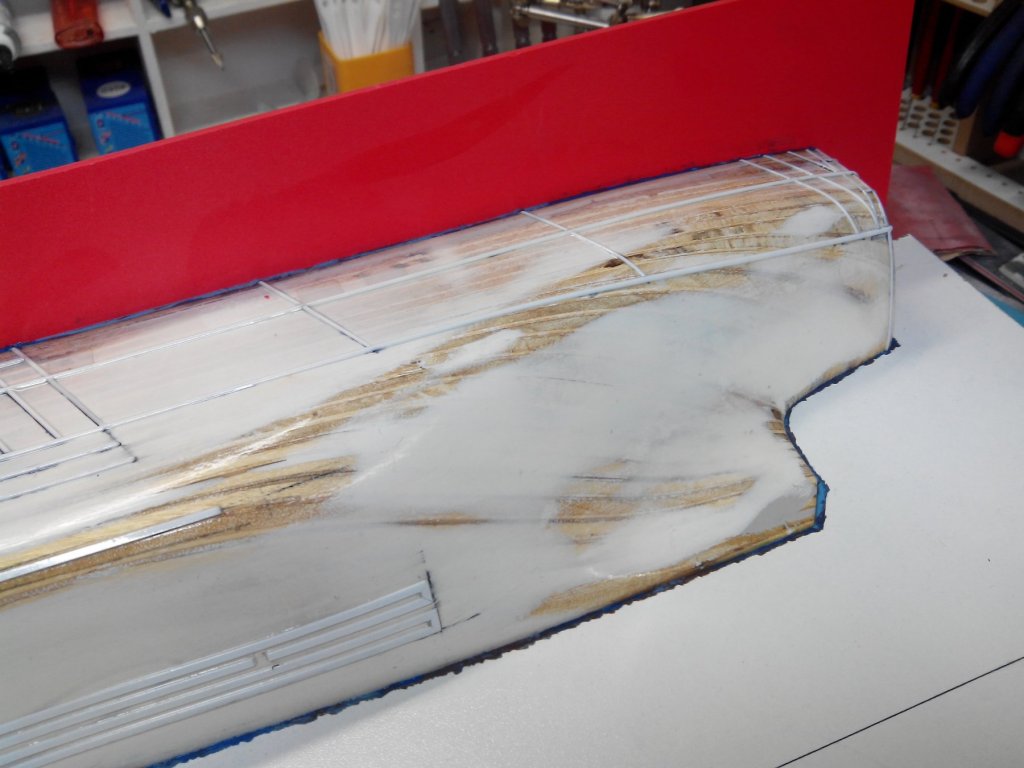

More work done on the KW88. Prepare the moulds for laminating. It will be a two part mould. First I will prepare and laminate the first half and after that I will remove the wooden plate and laminate the second half. I have never done this before so it will be exciting. It will take some weeks before I can show the results.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Was that one below the belt, Jan? I have never pretended to be an expert. When one builds form scratch one hase to make choices and take risks. I have watched orther people building moulds and after carefully considering all the pro's and con's I dicided to do it the way I do now. I have good faith that it will work but it is exciting for me too. I hope you enioy my buid and support me in my efforts to build this ship. O ja Daar bij komt nog dat ik stront, maar dan ook stront eigenwijs ben

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Only Time Will Tell. I have seen much more detailed plugs with no problems but I will report it when thing wont go like I planned. Regards, Kees

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Cooling at the outside of the hul. I also finishes the bowplate and some other things. Just decided to make a keel also before making the moulds. Than every hull will be complete with keel.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Added registration numbers and did some other jobs on the hull. Next job will be mould-making for wich I bought polyester and other stuff.

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

I am going to use a two part split mould because I saw this in building logs by other modellers. When you split the mouldparts, you start at the bow so you can turn the parts away from aech other. The transom wont give any problems this way. I hope to show you how thing turn out in the next few updates

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.89ea57fb8e3e86838aa59d34bfb1af7b.jpg)

.thumb.jpg.85c837c707c44aa6dd440beb6574b010.jpg)

.thumb.jpg.8a5e3a867050b8f181a3502ae600688f.jpg)

.thumb.jpg.6a75b39245f3bf2f3a7346db67065f92.jpg)

.thumb.jpg.655502d991c21e0bb32e55cdda7a047e.jpg)

.thumb.jpg.f1cbe135709af1590d566ea7d6a4431e.jpg)

.thumb.jpg.98eb4db2ad1101385ecab2a2bc0e7c60.jpg)

.thumb.jpg.2bd190333a83cf442a5c703de9229815.jpg)

.thumb.jpg.924eb8c8002cbca2f3f7a2b0b0a48dee.jpg)

.thumb.jpg.72dd16a03ea8e5a2495365c5a4cc2b6a.jpg)

.thumb.jpg.2077a881886e63d5cb3bac5da686e038.jpg)

.thumb.jpg.7bfa9ccc6a91f7da8a51899f8a44e35b.jpg)

.thumb.jpg.3712bdcde4b913fcd945fe2194939a77.jpg)

.thumb.jpg.093232f7b8f036ab413f752ab07ebcab.jpg)

.thumb.jpg.ee49a47df8a457b368d5893f2fd45c5a.jpg)

.thumb.jpg.5a9a9bb7296e7d5d01d6f282afe053ce.jpg)

.thumb.jpg.0633afa98f3e8e0525fc28894c071dc6.jpg)

.thumb.jpg.941b6efad041b4e3e84a3da1f195a5d7.jpg)

.thumb.jpg.b4af2717519f7d507c847d79c8ad5e05.jpg)

.thumb.jpg.0847701e0efb512fd5b37b4d6c95be7e.jpg)

.thumb.jpg.6fb88e8bce24c87b4711e670f1528f55.jpg)

.thumb.jpg.02412d6a451597d110049b6e1f8324dd.jpg)

.thumb.jpg.9e01c7f1479307f4c2c7498f5dd3a45b.jpg)

.thumb.jpg.0d1f166ba10959572f3156da50229ba1.jpg)

.thumb.jpg.30aade28ff6ae52d5a4045f607d3055c.jpg)

.thumb.jpg.de51d78100b6cacd26d4691a3df9174e.jpg)

.thumb.jpg.8692e789121ed30f54ab7b1b3ea978cc.jpg)

.thumb.jpg.5a753ca7ca88d56cafb9eec76c884a7c.jpg)

.thumb.jpg.eeedd32d27611b9a2d1c71120d4a50fe.jpg)

.thumb.jpg.f47f5d79ef2728a534e642e7f78ce77a.jpg)

.thumb.jpg.757e54f16d65d99902e0ab063829fad6.jpg)

.thumb.jpg.6f5d8827f5e2bb12f4fa229a957baedf.jpg)

.thumb.jpg.8f09051aa21e29227ea87fd48b933d4c.jpg)

.thumb.jpg.ff4058354173002c9dbd96eedce72bad.jpg)

.thumb.jpg.d8836d965fc0b24816c5232bbfc1d3c9.jpg)

.thumb.jpg.b736b8bd2f3e28ae4dcc796196ae9692.jpg)

.thumb.jpg.2244b1efc9b0add49215316a0eae18b5.jpg)

.thumb.jpg.0aff54619bbcdfbf3879ce35ffdf5e21.jpg)

.thumb.jpg.d72c49e6dea9cbd2bed8a1cf4a90de0f.jpg)

.jpg.a5a4e85ad48b1a2290f70b042eadb762.jpg)