-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jaekon Lee

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Attaching rudder Thank you Nils and Bob. ;-) Four set of pintle and gudgeon braces were fixed on the rudder and stern post with brass nail. The nail heads were blackened after hammering. I think this work seems one of the hardest part to get neat result. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

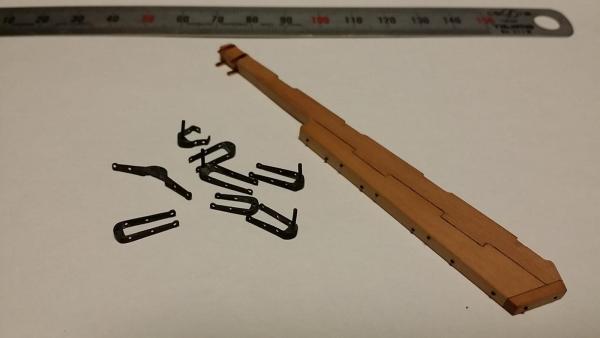

Rudder, pintle & gudgeon brace Hi, friends. Thank you for the generous comments and likes. Small progress during last weekends. Rudder and hinge assembly were prepared. Pintle and gudgeon brace parts were made with copper plate and brass wire and then blackened chemically. Cheers Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

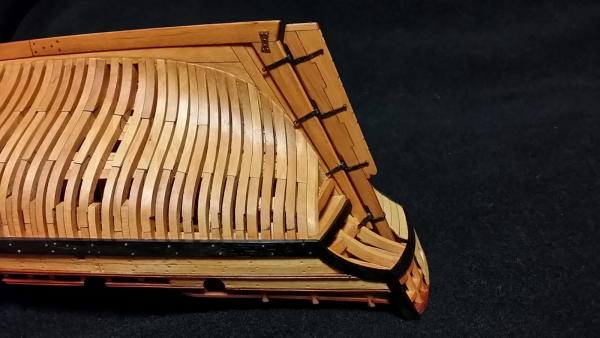

Copper plate & bolting on the keel Thank you friends as always. ;-) Horse shoe and fish tail copper plates were attached on the both sides of the keel. Brass wire was used to fix them on the keel. After finishing bolting work, keel, frame and outside planking strakes were oiled with the mixture of linseed oil and turpentine oil. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Stern planking and fitting of cathead, channel, shot racks...nailing and bolting... Many thanks friends for the warm words and likes. Now, I'm on the way of nailing to the wale with brass wire. Nail heads will be blackened later. Cheers, Lee -

Beautiful progress of your journey, Nils. Your workshop looks also very nice. :-)

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

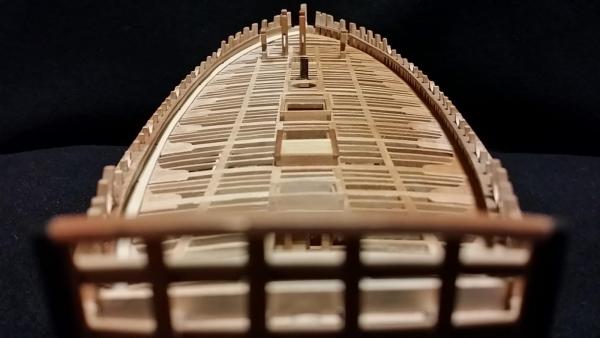

Main deck planking Planking of port side main deck has been finished at the breast center line. Though it is hard to see at this moment, treenails were simulated with syringe needle tip. I hope they will be more visible after oil finishing. : ) Windlass spindle, jeer bitt and several standards for them were attached and bolted. Small windlass will be added between the jeer bitt pins. Cheers, Lee -

THE 74-GUN SHIP by Jeronimo

Jaekon Lee replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Great start Karl!!!! So excited to follow your build.- 194 replies

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thanks Nils, Antony, Coleman, Tadheus, Tom and Alex for your compliments and likes. Tom, yes I mixed carbon black into the normal white glue to blacken it. To make uniform mixture, I made carbon black slurry with small amount of water and then mixed it to glue with small agitator. Drop of bonding strength was negligible. Cheers -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

-

It's a great pleasure to follow your building progress, Nils. Will you do planking the hull? One more question is that you built hull with series of blukhead to support the hull shape (so it would be plank on bulkhead, 'POB') but you write "POF" in the title. Am I incorrect? Lee

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

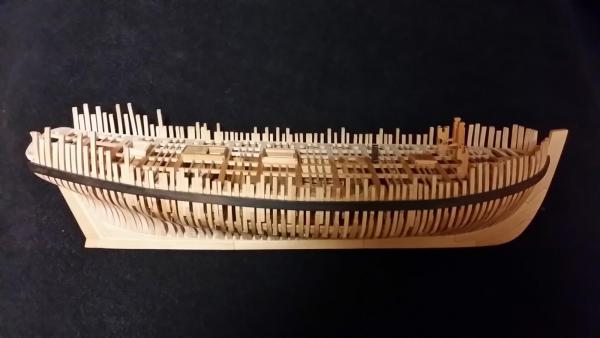

Draft rail and rough tree rail Hi, Nils, Christian, David and Mike. Many thanks for your compliments. Long break and little progress due to busy work and trip. Draft rails on the top timbers and gun ports were joined with glue. Nailing seems to be required to reinforce the joining strength. At the aft hull side, rough tree rails were placed between extended top timbers over the draft rail. Now I'm ready to install deck planking. ;D Cheers, Lee -

Hi, Nils. What a great start and progress!!!

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Waterway, spirketting, plank sheer and scupper Thank you Nils and Bob as always. Welcome Jim on my build log. To Nils; I drilled smaller holes and chiseled them to square hole. Next will be adding rough tree rail on the top timber ends. For the color contrast, I'll make it by ebony strake. Cheers, Lee -

Mary Rose 1545 by tarbrush - Scale 1:72

Jaekon Lee replied to tarbrush's topic in - Build logs for subjects built 1501 - 1750

John, I'm so sad to hear that accident. I hope your fast and full recovery . -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Progress on bulwark area. Hi! David, Nils, Clare and Rao. Many thanks for your compliments. To start upper deck planking of port side, waterway was attached. Plank sheer rails were also tried. Making small square holes for the top timber passage through the rail was somewhat tricky. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Trimming the top timbers and adding gunport sill, upperwork side planking on both side of hull. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Antony, thank you always. ^^* -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Many thanks all friends for the warm words and likes. You make my heart beat increase. ^^* -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Stern transom and timber structure Due to the complex shape of stern structure and lack of information, many trials were needed to make this part. Though it is not clear with the drawing, side counter timber was formed as double layered with recess to receive the outer top side planking boards. Outer side counter timber was made by ebony to match the color of wale. Curved shape of transoms and tafferal were formed by steam bending method. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thanks Rao, Nils and Bob for the kind words. Bob, I will do half planking (in and out side of port side) See you soon~~~ -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

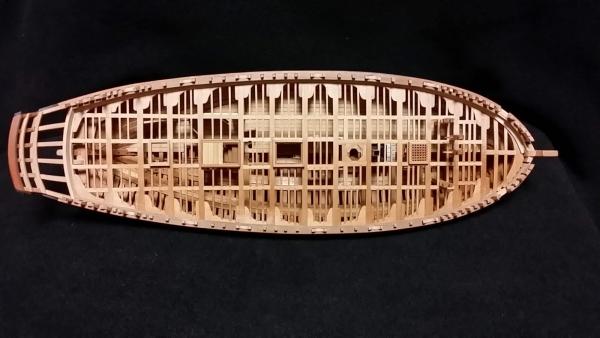

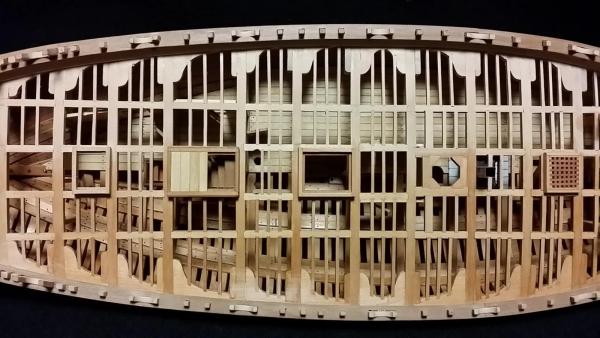

Upper deck beam structure Though it was tedious, with installing the last deck beam, called as deck transom, upper deck beam structure was finished. It is hardly seen but captain's room and bread room bulkhead was fitted below the deck beam structure. ^^* Next work will be stern timber structure and port side deck planking. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thank you all for the compliment and likes. Christian, you looks so busy now a days. David, I have slow hands rather than patience. ^^* -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

One more deck beam and wardroom, bulkhead and doors Little progress of deck structure. I left some pics of interior because they will be covered with deck planks and become invisible soon. ^^ Cheers, Lee

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.