-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jaekon Lee

-

Making small nails with round head

Jaekon Lee replied to Aleksei Domanov's topic in Metal Work, Soldering and Metal Fittings

Really good idea. I'm so happy to find this info at the right time. Thank you and Dr. Michael. Lee -

ancre La Salamandre by tadheus - 1:24

Jaekon Lee replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Very nice hull planking, Paul. May I ask what kind of nails did you use and how did you blacken them? -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Garboard Thank you Nils. Small update after long break. For the start of clinker type planking of port side, the garbord strakes were attached along the keel. Rabbet was scored at the upper side of strake to receive the plank strake above. Cheers, Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

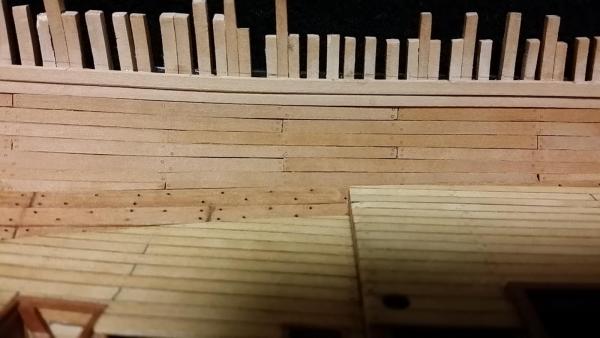

Going outside of hull By the lots of joining long stuffs, she became strong enough to work on outside of hull. First, stepped and rough starboard side surface of frame was smoothened with rasp, file and scraper was used for final finishing. Port side frame surface, where the planking will be scheduled, was only finished with rasp. The main wale was prepared with 2mm thick ebony strake. They were steam bent and joined at the same height of upper deck clamp. Next step will be the planking of port side by clinker type. Cheers, Lee . -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Treenail simulation and finishing of inner hull After removing upper deck beams, I tried treenail simulation with hypodermic syringe needle on the inner hull planking boards. It is the good place of experiment because this place will be invisible after upper deck planking. -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Hi, I always appreciate your kind words and "like"s. Alex and Nils, thank you for the kind recommends about deck beam and I agree with you. At this moment, I removed all the beams from the ship and will observe closely the shape change, however, I'm not so worry about the flattening of beams because the hull wall will act as the constraint of shape change. Anyway, this is a good chance of experiment and in the next project, I may take the method of shape cutting. Regards. Lee -

Hi, Siegfreid the Dragon fighter, I've just catch up your build log. Thank you for sharing your really great job and beautiful coloring. Lee

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

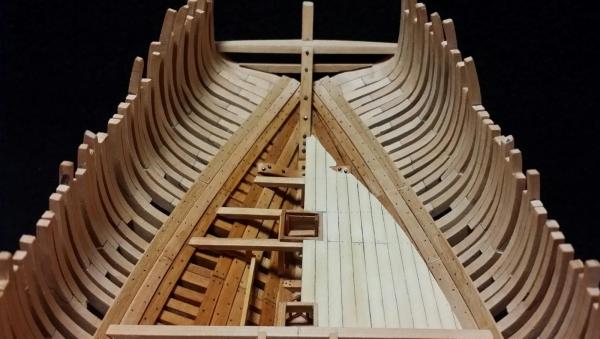

Upper deck beam Cambered upper deck beam were prepared by steam bending method and joined on the deck clamp temporarily. Bending was more simple than cutting curved beam, however, it is not easy keeping bending radius constantly for each beam. As can be seen on the following pics, some of beams are needed rectifying the curvature. After marking the position of carling, they will be removed for scoring recesses, attaching hanging and lodging knees and so on. Regards, Lee . -

Nils, many thanks for your warm words and tips. Long time experience of wooden furniture making as a hobby, woodworking for model ship building is familiar with me. But the rigging, I've never done yet, seems highlight of ship modeling. Yes, rigging of Alert will give me a good chance of experience. Fortunately, she has only one mast.

-

Fantastic work you are doing. I can not imagine I can do rigging and sail like you in the future. Lee

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thank you Wyzwyk for your interest on my building log. Thank you Druxey for your kind comments on the planking line. Though the upper thick stuff lines are much curved upward, they ended just below the upper deck hook fortunately. I think the ends should be terminated at around upper breast hook to get more reasonable result. -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Upper deck clamp, deck hook, inner hull planking between deck clamp and thick stuff. Upper deck hook was joined directly to the stem and hawse pieces at the height of upper deck line. The deck clamps were also placed at both side of inner hull following the deck plane line. Then, inner hull between clamp and thick stuff of port side was covered with normal planking boards as was done below the thick stuff. Cheers, Lee . -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Question about planking line As shown in the pictures, flat lower deck plane at the midship is almost coincide with upper thick stuff plank line, however, at the fore most deck plane is far below from the line, ie., inner hull plank line seems too much curved upward at the fore section. Is it generally right or I made mistake? In Goodwin's book, he did show very little information about inner hull planking. He only commented thick stuff placed over the chock of futtock joint. So I followed that as possible as I can. -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thank you Nils, Mark and Michael for your generous compliments and "like"s. Nils, I stumbled on small black blanket is so effective for making contrast of model ship with my mobile phone camera. No special tech. -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

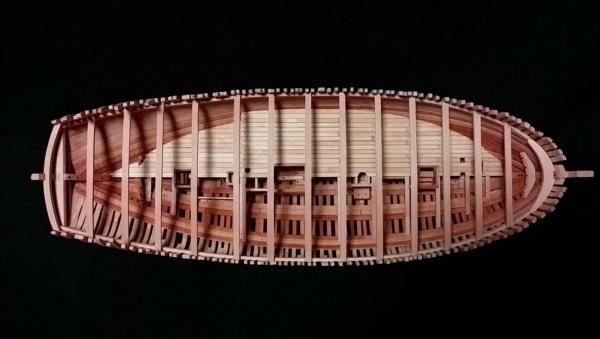

Lower deck planking Half of lower deck (port side) has covered with plank boards and oil finished. During planking, blackened glue was used between the plank boards to simulate the calking. Treenailing was disguised by pointing with awl before oil finishing. -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Thank you Antony and Nils for your encouraging words and interesting. I'm learning lots of things through this building though I made many mistakes. I hope this practice makes me better for the next project. Regards -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

I'm very happy to hear that Christian. Your work is also very helpful to me. Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lower deck beam and deck planking, pump well and shot locker Happy new year 2015! Lower deck was partly planked over the aft magazine. I'm not sure my understanding of plan around the aft clutch, some part of clutch crossed the deck plank. In this small ship, lower deck beam structure is so simple, ie., beams are not curved (no camber), no knees and a few carlings. Pump well and shot locker was installed in front of lower transverse bulkhead. Cheers. -

Hi, Giampieroricci. I just find your fantastic building log today. You are so skillful and seem to know everything of model ship building. I can get lots of tips with your log. Please look at my building log and give some advice. Thank you again. Lee

-

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Treenailing, aft magazine & lower deck beam, oiling... some progress at the inside of hull In this small scale, diameter of treenail would be about 0.5mm, however, it's not easy for me making treenail of that size. Yes, from the other's building logs, I learned how to make treenail with draw plate but I failed. I think I need more experience. So, I drilled 0.5mm empty holes without treenails on the planked board. I hope I can try again in the near future. The fitting on aft magazine was simple, light room and magazine access stair. Lower deck beams over the magazine were added. One more progress was finishing oil trial. I usually used linseed oil and wax for the finishing of furniture but they have a problem of bonding strength with glue on the oiled surface. So I tried varnish type oil and found that the result of joining strength and color was not so bad. Happy new year! Lee -

HMS Alert 1777 by Jaekon Lee - 1/64

Jaekon Lee replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Many thanks Antony for your generous words. I hope you and all visiting here have great time in New Year. Best Regards

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.