-

Posts

1,569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ryland Craze

-

Congratulations on finishing your first wooden ship model. The boat looks great and thanks for sharing your progress with us. Also, welcome to Model Ship World.

- 12 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

I used Minwax Wood Filler in a tube that was natural in color to fill small cracks. It matched the color of the Yellow Cedar very well. I also used the wood filler to seal up some joints throughout the model that were painted over. You are making good progress and your workmanship is excellent.

- 155 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congratulations on finishing your King of the Mississippi. You did a nice job on building this model.

- 109 replies

-

- Finished

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Nice start to your Medway Longboat. This was a fun build and I look forward to following your build. Did you use the templates at the end of Chapter two for lining out the bow? They were a great help for me.

- 155 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Floyd, I did serve the loop around the mast. This was explained in my post #174. Here is a link to that post: https://modelshipworld.com/topic/19354-medway-longboat-1742-finished-124-scale-by-ryland-craze/?do=findComment&comment=775296 I have also attached a close-up picture showing the servings and seizings on my model: I studied the pictures from Chuck's build and will be glad to forward you some of the close up pictures of Chuck's model that I took at the Northeast Joint Clubs Conferences if it will help clarify things.

-

Hi Greg and welcome to Model Ship World. I look forward to seeing your work with the 3-D printer.

-

Floyd, I did exactly as Grant did. I seized the loop as I explained in my December 17th post around the mast. I seize the served line loop a little higher up on the mast so that when I slide it down the mast it tightens up. I also use diluted white glue on my seizings. I hope you and your family have an enjoyable Christmas holiday.

-

Hi Shane and welcome to Model Ship World.

-

Hi Dirk and welcome to Model Ship World. It is great that you are going to finish your Dad's model and that you shared his modeling interests. I know he enjoyed this.

-

Hi Bob and welcome to Model Ship World. It is always nice when someone acquires a ship model in progress and completes the build. The Bluejacket Smuggler builds into a nice model. Please share your progress with us.

-

Very nice and clean looking. This is going to turn out to be a very good build.

- 51 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Your Longboat is looking good. You are heading toward the finish line. I stropped my deadeyes by forming the 24 gauge wire around the deadeye. I formed the strop so that the two ends met at the top of the deadeye. I trimmed the wire so that the two ends butted against each other. I then opened up the strop, applied some CA to the underside of the strop and squeezed the strop down into the grove in the deadeye. Be sure to insert the hook on the wire strope before you permanently close up the strope.

-

Hi Ray and welcome to Model Ship World. Thank you for your service. Like you, most of us started modeling at a young age. Ask away and we will be glad to answer your questions.

-

New Member Rock Harris: An Introduction

Ryland Craze replied to rock harris's topic in New member Introductions

Hi Rock and welcome to Model Ship World. I have never built a solid hull ship model so I cannot answer your question which is best to start with, a solid hull or plank on bulkhead/frame ship model. -

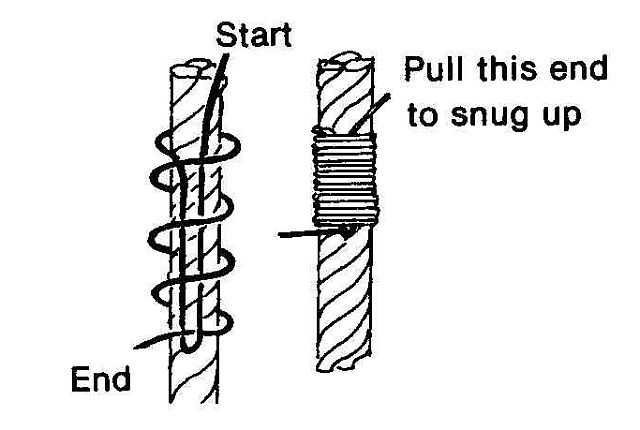

Floyd, I do my seizings the way my father taught me to tie flys to my fly fishing line. I found a picture that best illustrate this: I found the above image at this website: https://sites.google.com/site/shipwrightsfaq/smf-sn-shopnotes/smf-sn-seizing?tmpl=%2Fsystem%2Fapp%2Ftemplates%2Fprint%2F&showPrintDialog=1 I usually do six turns of cotton thread. Here is a YouTube video link of this process: Also, John Earl has an excellent article explaining his method of seizing on his website located here: https://www.modelboatyard.com/stropping.html There are many ways to do this. I use watered down white glue to coat my seizings and once dry, snip the tails of the seizing line close to the loops of the seizing. I prefer not to use CA on my rigging. Rigging was very enjoyable on my model.

-

Hi Jimmy and welcome to Model Ship World. You have some enjoyable hobbies and you have come to the right forum to help you build your wooden ship model skills. We are glad to have you aboard.

-

Hi Dan and welcome to Model Ship World. The Lowell Dory is an excellent kit to start your journey in building wooden ship models. The other kits in the series will help you build your skills.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.33d7ab1fb1b63f82351ca785b25f86f2.jpg)