-

Posts

3,986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

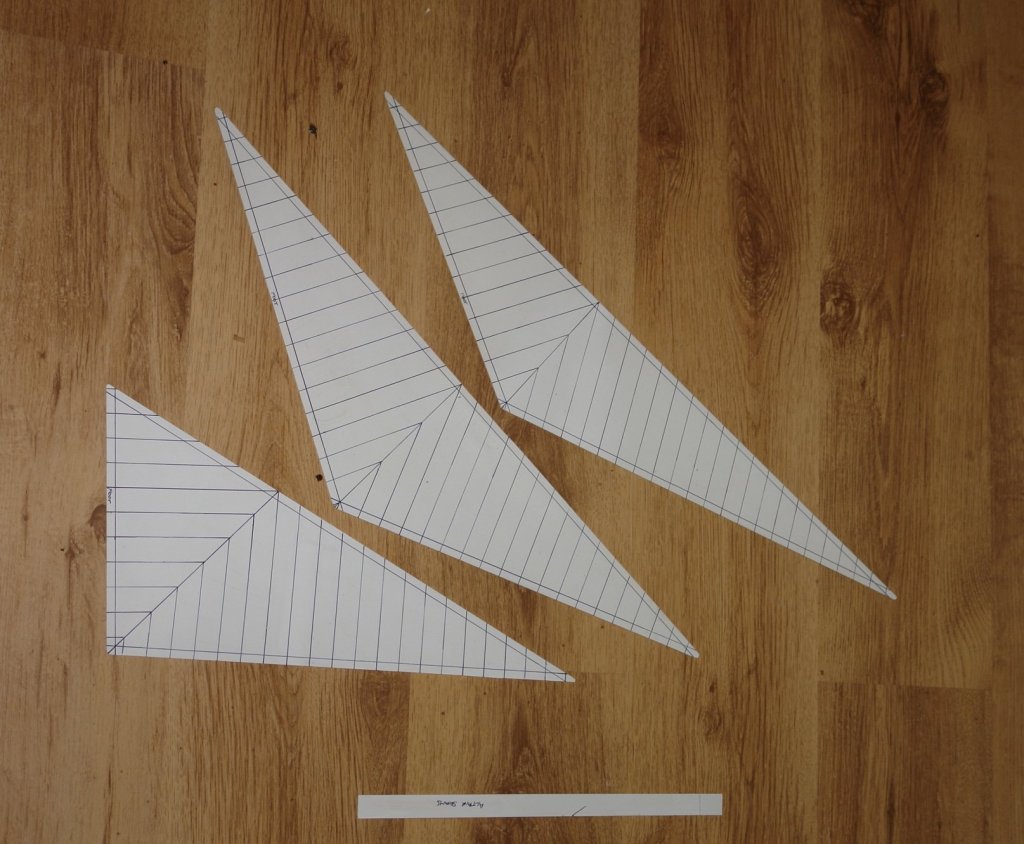

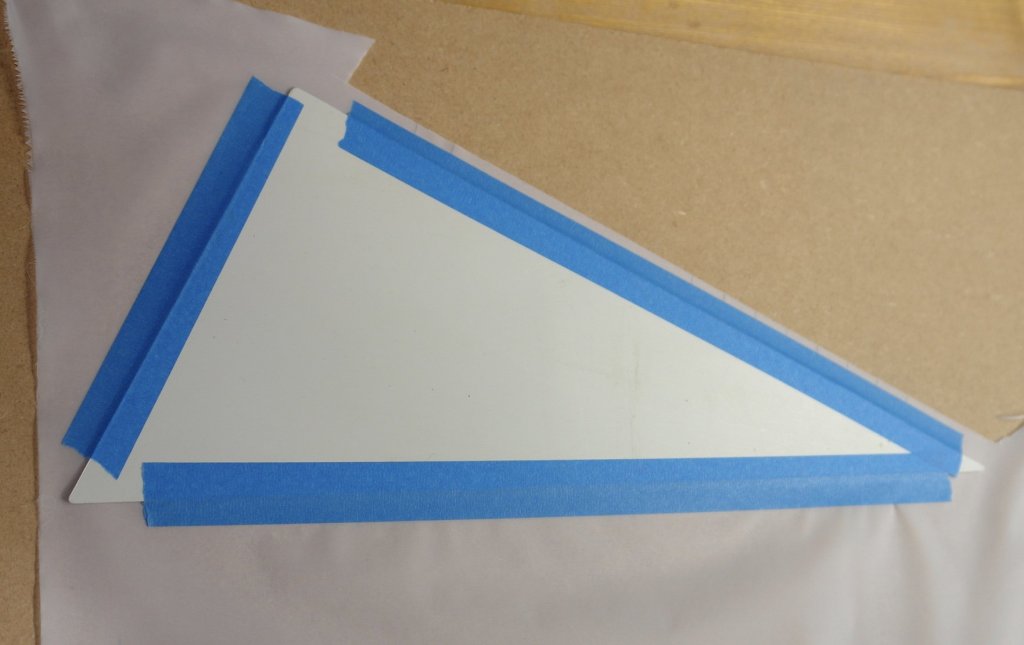

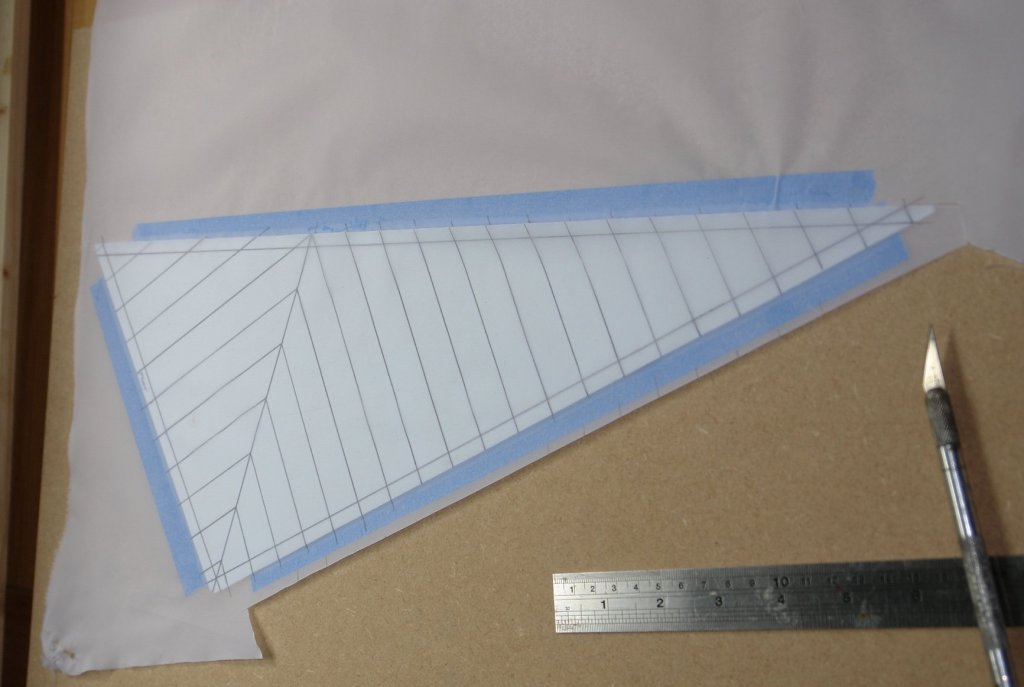

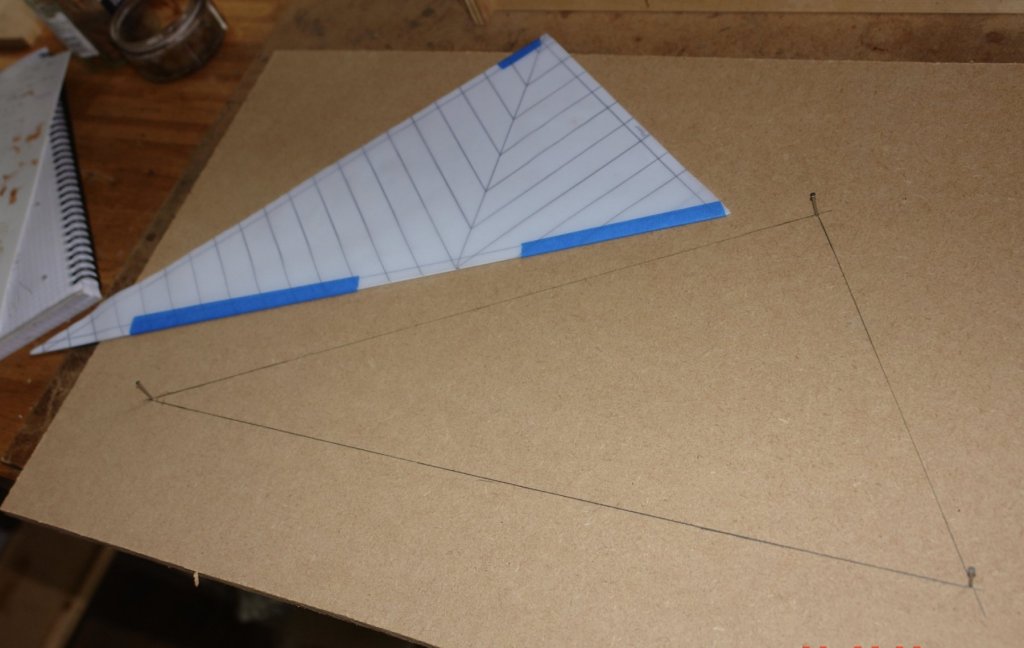

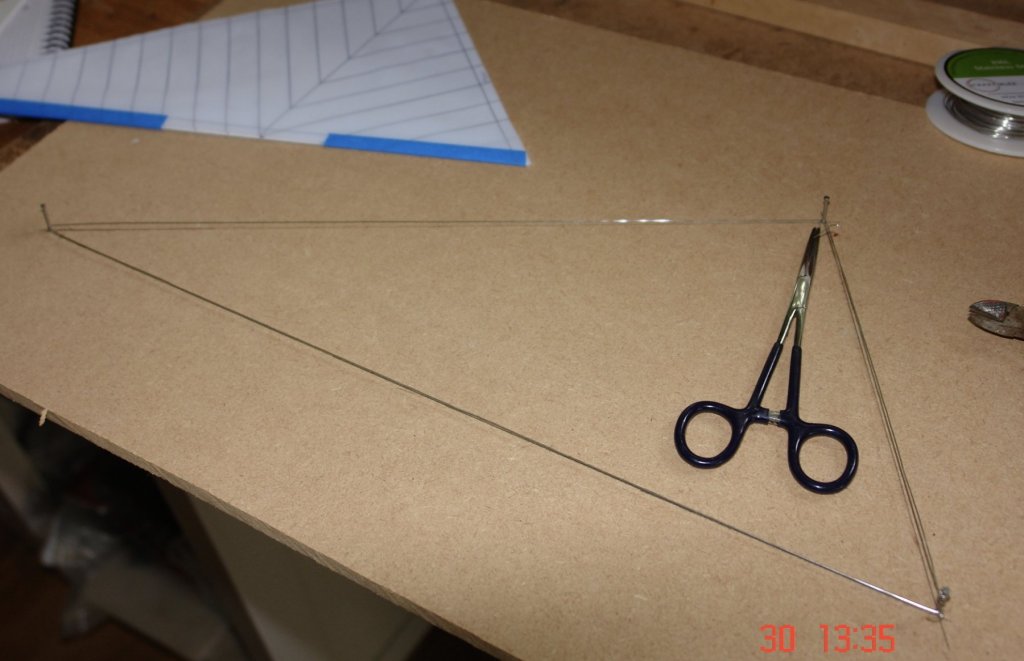

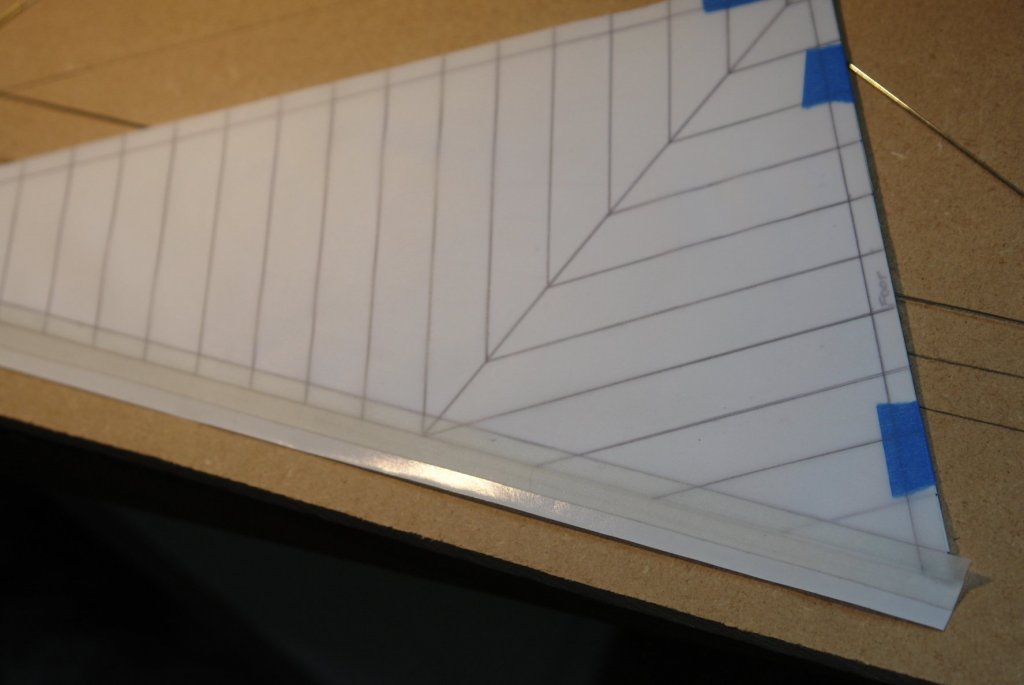

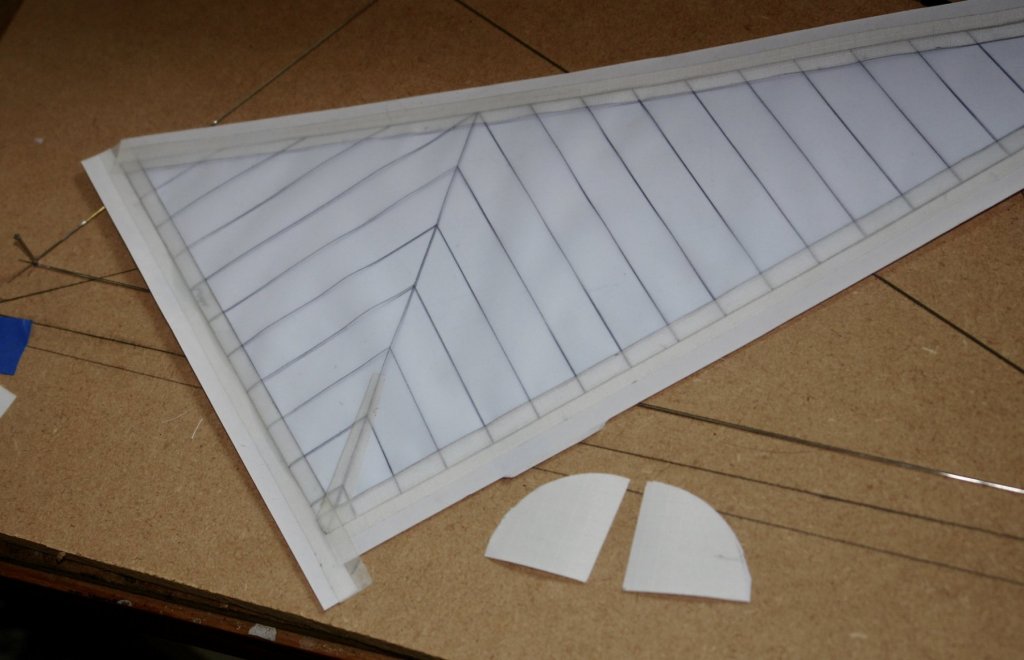

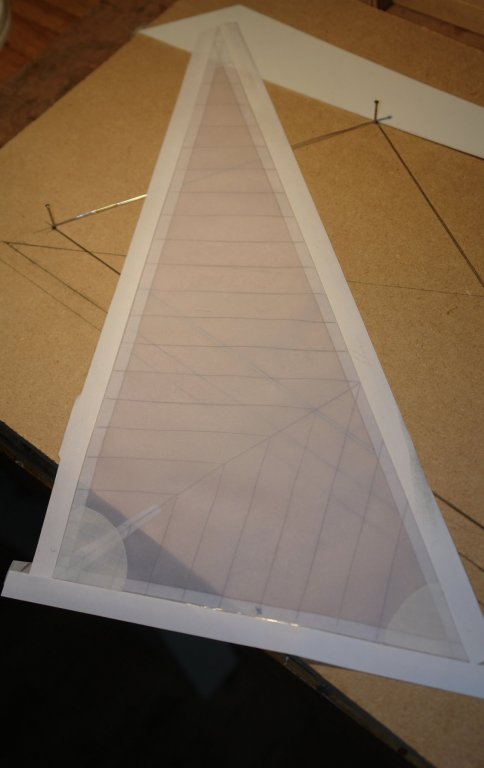

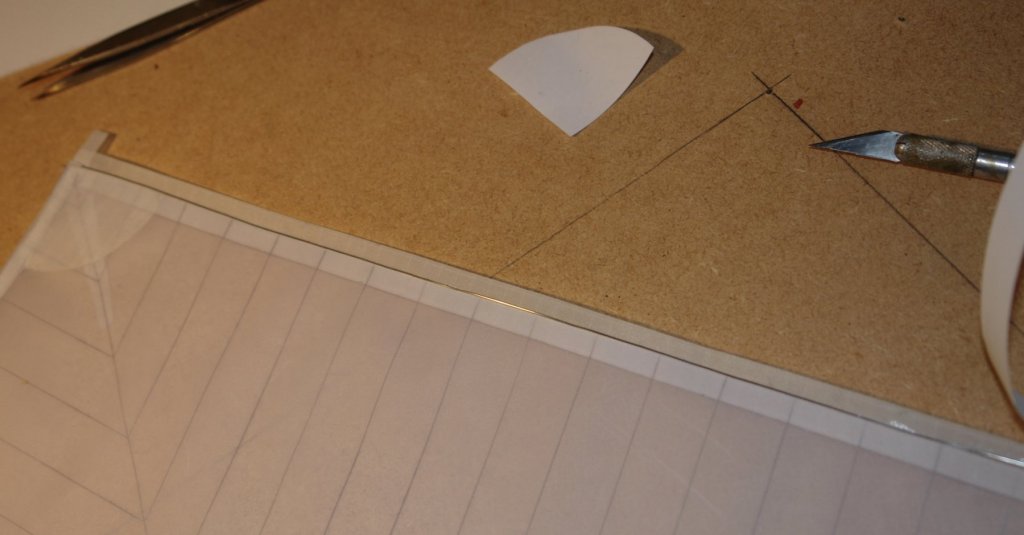

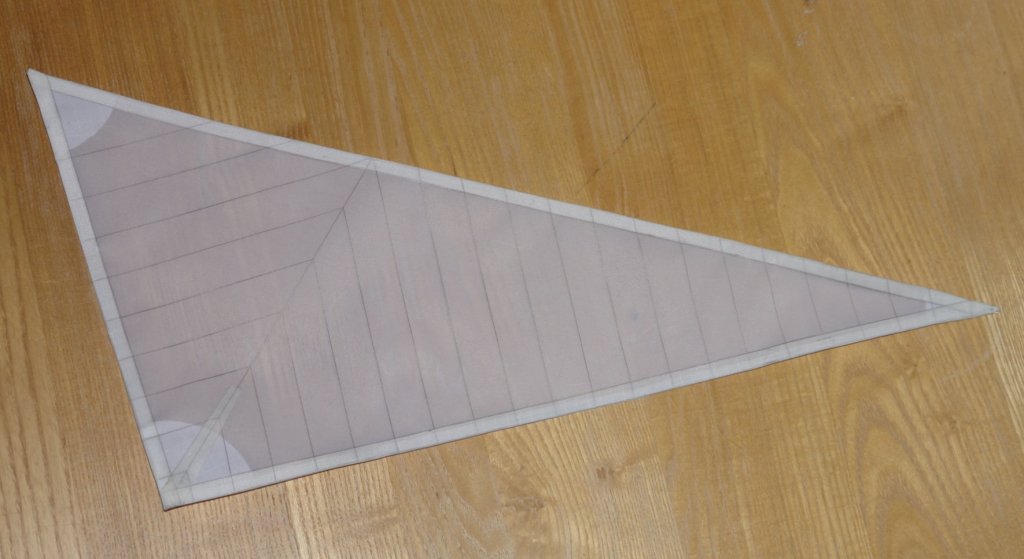

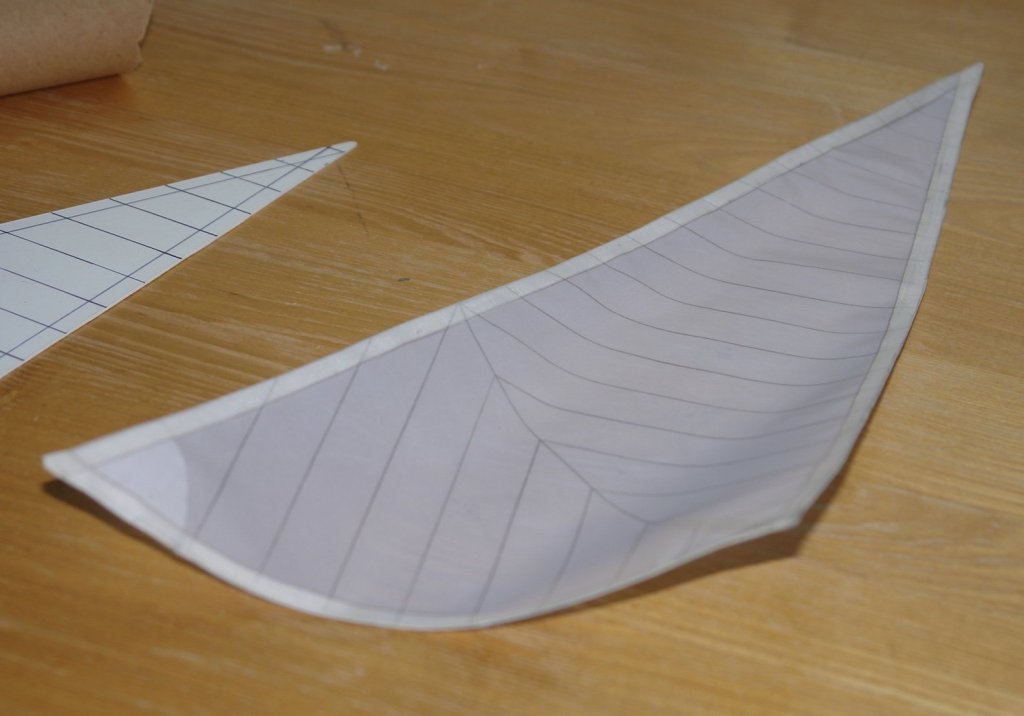

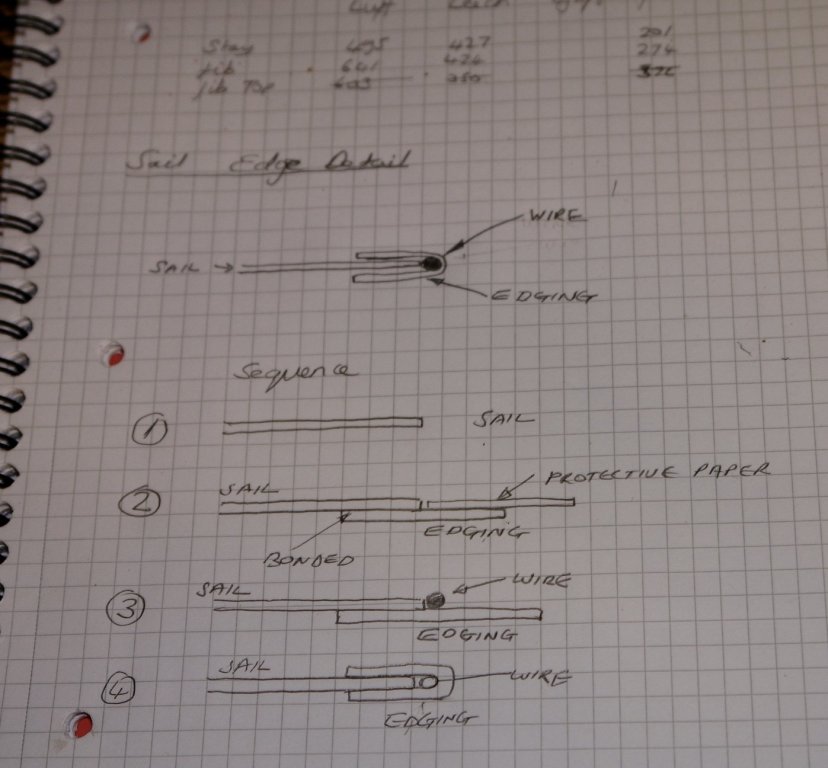

So today I made the first sail. I didn't follow convention so an apology to all you purists and perfectionists, you might want to skip this section. I wanted to make the sails in a way that would allow me to create some shape in the finished form. Flat / floppy sails in my view can spoil an otherwise excellent models. I decided I would try incorporating steel wire into the edges of the sails as a way of creating something which could be shaped. The following sketch illustrates what I decided to do. I had previously prepared the sail cloth - now with 2 coats of 50% PVA and water. It took about 24 hours to dry. I started by cutting templates for the sails. Cut from .040" plastic sheet. On to this I marked out the position of all the seams. The templates were attached to the back of the sail cloth with masking tape. The seam lines were then transferred to the cloth using pencil. No stitching for me - the scale stitch size would be much too small and my needlework skills just aren't up to it. The cloth was then cut by following the edge of the template. Additional making tape was applied to keep the cloth on the template. The template was then used to make the sail profile on a piece of MDF. Nails were place at the corners. .020" annealed stainless steel wire was then wound tightly run the nails. It was tight - pinged like a guitar string. The wire was doubled on one of the sides of the triangle. Both wires were parted by a single cut and the butt ends were joined by inserting them in a small bore tube and soldering. Half inch wide edging tape strips were cut from rip stop tape (self adhesive, very thin and very strong). These were placed 1/4 inch over the sail edge and the overhang was protected temporarily by reapplying the backing strip. The sail reinforcing detail was then added, again using the rip stop tape. At this stage the sail was offered up to the wire and the overhanging tape edges were folded over. I then tried a bit of experimental shaping. I think I might be able to simplify and possibly improve the wire insertion. I will have a go and report the results next time.

-

Nice progress Nils - I like the spindles.

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

KeithAug replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Very nice Pawel -

Byrnes table saw questions

KeithAug replied to alde's topic in Modeling tools and Workshop Equipment

Al, I don't think it your technique. I think what happens is the the pressure between the fence and the thin slitting saw blade deflects (bends) the blade away from the fence very slightly. This causes the a wedge effect which gets worse as the cut progresses. The rule relieves the sideways pressure allowing the slitting saw to run true. At least thats what I think. -

Kees - It took me a while to understand it was a plug. I should have known from your last build.

- 193 replies

-

- wilhelmina vii

- fishing

-

(and 1 more)

Tagged with:

-

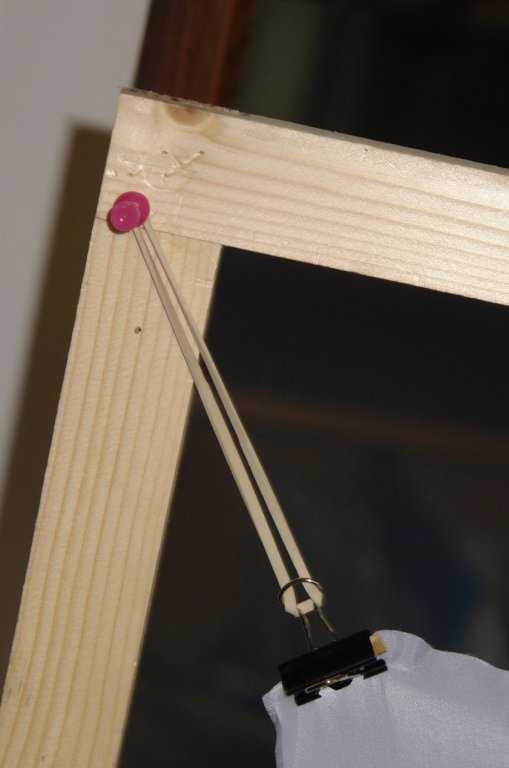

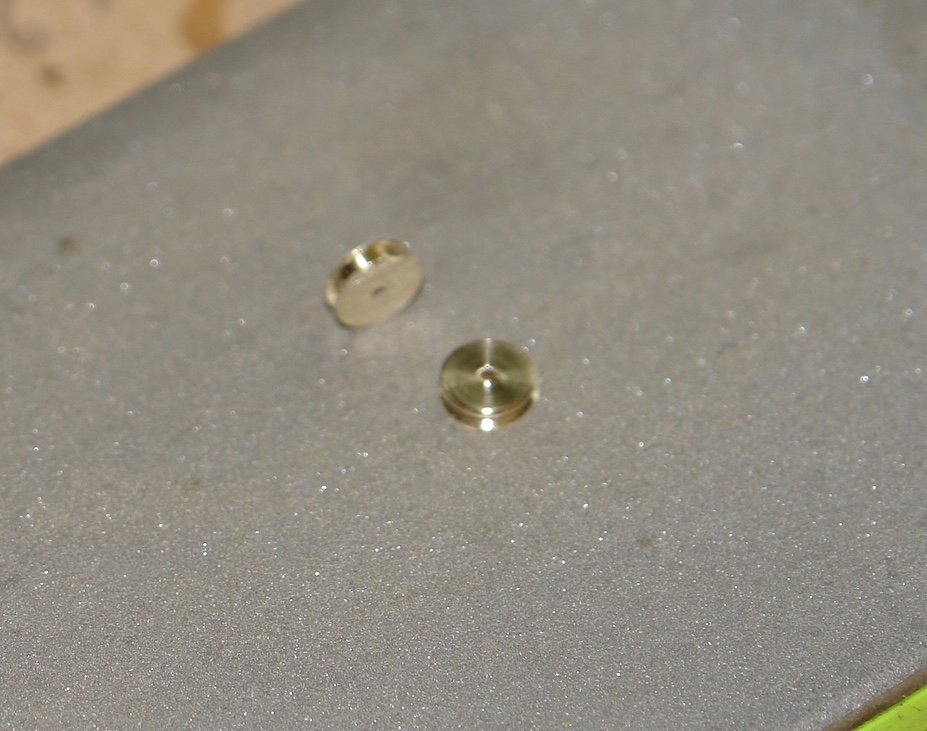

Sometimes progress feels like running up a sand dune. A couple of days ago I found a small note on the plans which required holes to be drilled horizontally through the tops of the upper masts to take the halliards for the top sails. On the face of it not a problem, that is if you ignore the fact that the holes should be slots and within the slots should be sheaves. So I spent a few days ignoring the problem of forming neat slots at the flexible and fragile ends off the masts. In the end I drilled a row of .030" holes and removed the webs with a x-acto knife. The inside of the slot was then cleaned up with a sacrificial needle file - ground thinner and narrower to get it started in the slot. I kept expecting the mast to fall apart under the cyclic load but my luck held and the job was done. The sheaves are .175" diameter by .050" wide. I rigged the lower main mast backstays - twice!! The pulleys worked - but a little too well. With a mechanical advantage of 8 (less friction) the small upper pulley was put under a load it wasn't designed for and parted with an annoying ping. I repeated the error once more before deciding the rigging didn't really need to be a taught as a guitar string. I decided I couldn't do much more rigging without mounting some of the sails so I started the process of sail making. I had a good look round at fabric options but in the end I decided to stick with the devil I know - Amati modern yacht sail cloth. I use the diluted PVA glue stiffening method and stretch the cloth on a frame to apply the liquid. I hold the tension with rubber bands. The cloth expands when wet and contracts as it dries. I find the rubber band tensioning produces a reasonably flat result. I will probably find tomorrow that this time it didn't work.

-

Byrnes table saw questions

KeithAug replied to alde's topic in Modeling tools and Workshop Equipment

Al, the carbide blade is good but because it is wider it's a little more wasteful than the .030 slitting saw blade that I typically use to rip planks. The slitting saw blade also produces a superior finish. You might want to try the slitting saw blade with the attached rule trick some time. But for now I'm pleased you are ripping good planks. -

Kees - I do find you construction approach very interesting. I looks good.

- 193 replies

-

- wilhelmina vii

- fishing

-

(and 1 more)

Tagged with:

-

Any model steam engine builders here?

KeithAug replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

Moxis It makes up into quite a nice and interesting model. The pistons are double acting which mean it self starts. The valve allows the steam and exhaust ports to be reversed which means the engine can be reversed. The valve also allows the engine speed to be adjusted between dead slow and very fast. Have fun - a build log would be good as I am sure you will get a lot of interest. -

Any model steam engine builders here?

KeithAug replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

Moxis You can find all the instructions here:- http://www.machinistblog.com/bogstandards-paddleduck-engine-plans/ -

Any model steam engine builders here?

KeithAug replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

Moxis - I dont think you need to be as good as 1/100 mm. Half that is fine 1/1000 inch in my way of working. Bores can be finished with a reamer which easily gives this accuracy. Here is one I did earlier:- -

Byrnes table saw questions

KeithAug replied to alde's topic in Modeling tools and Workshop Equipment

The table has an accurately aligned table and fence but the front fence locking thumb wheel must always be tightened first and without any side pressure on the fence -

Any model steam engine builders here?

KeithAug replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

Moxis. The difficulty really depends on the type of machinery you have available and what experience you have of using it. Do you have access to a metal working lathe and milling machine and the tooling that goes with them? Rather than go straight to the expense and complexity of a kit compound engine I would suggest you try something simpler like a wobbler first to build up your skills. You can find designs on the web. Alternatively you can try something a bit more complex like a "paddle duck". Good designs and build instructions are also available on the internet. -

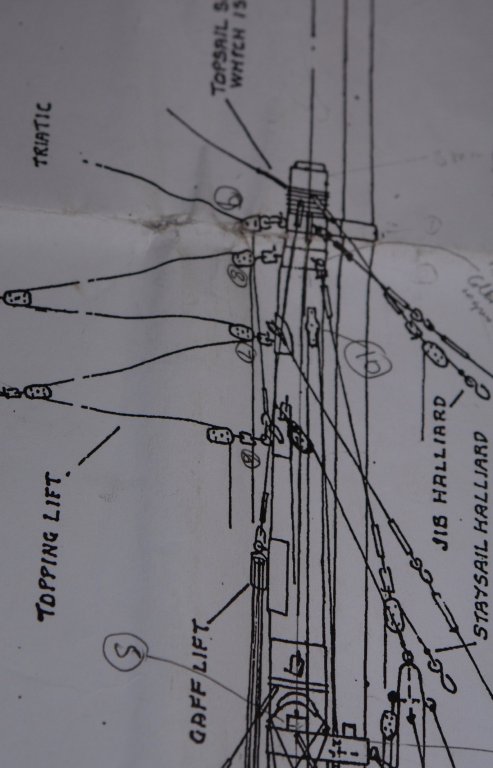

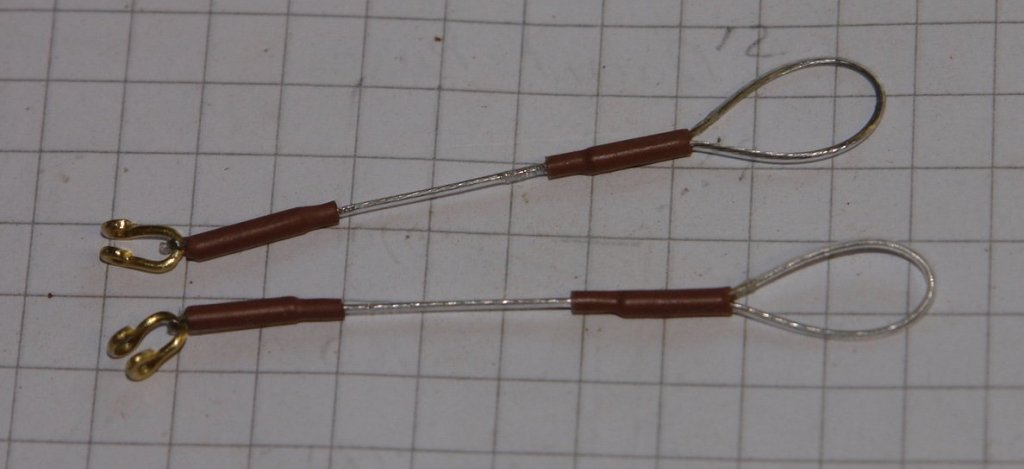

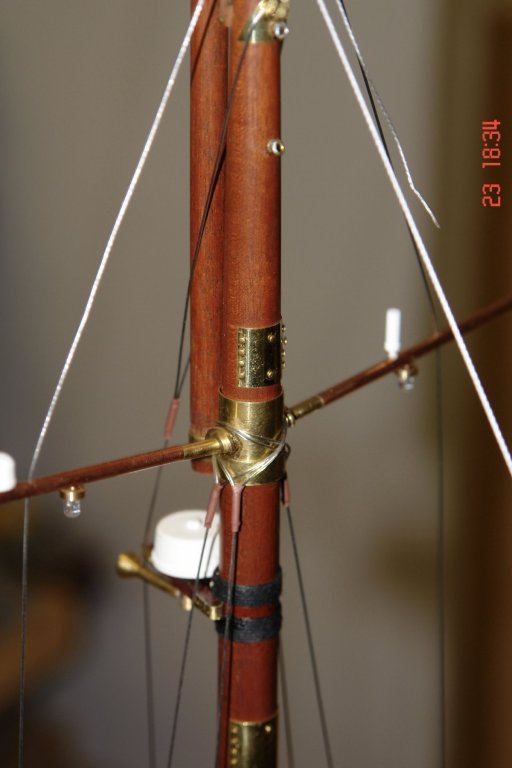

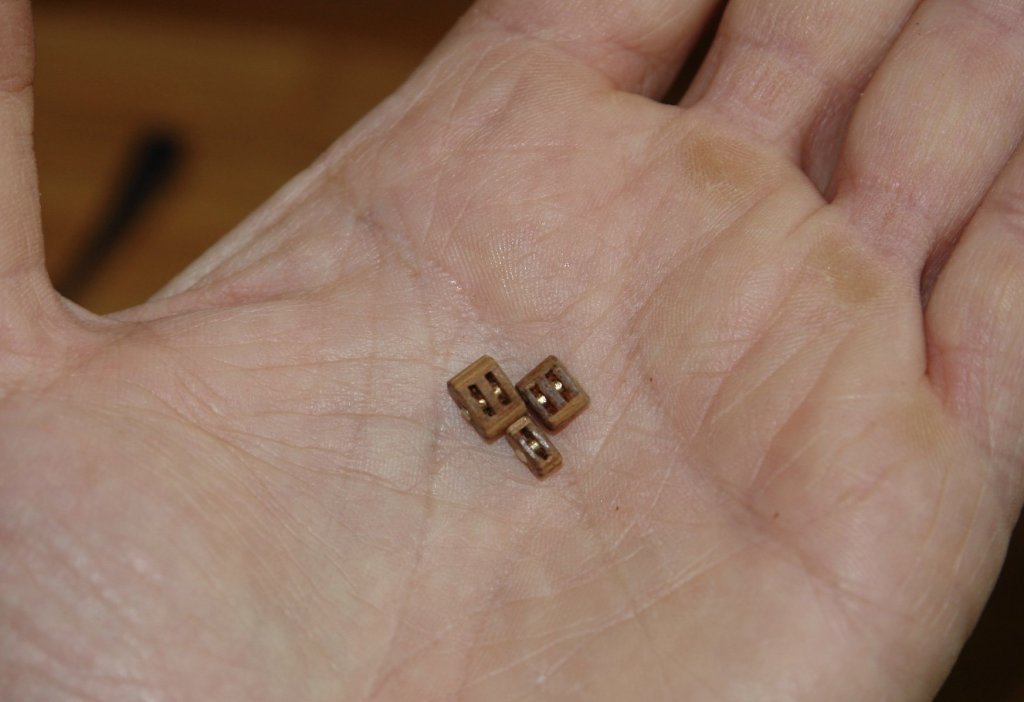

And so back to rigging. I had to give a bit of thought to the sequence of rigging the stays. I wanted to make sure that I didn't lock in any unwanted distortions due to rigging tension before all stays were in place. I started by rigging the boom stay. This had a few elements to it which gave interest. Having braced the boom I then used fishing line thread to put temporary stays in place to brace the fore and main masts. I then checked the that the masts were parallel using the previously made gauge stick. I taped this in place while I rigged the triatic and spring stay. The triatic fixing to the fore mast is to my mind a bit odd as it passes through a block before attaching a few inches lower. I don't really see what this achieves other than to obstruct the lower attachment points. I suspect someone will know why its designed like this???? The bracing shroud in front of the main mast was installed next. This passes through the front of the "A" frame which supports the radar and terminates at a turnbuckle at the base of the mast. Finally a close of the strops for the lower main mast back stays. About 1.250 inches long. The shackles are about 1/8" high Despite my block production of the previous day I hadn't made up the smallest blocks, and of course today this was the only size I needed - for the triatic block.

-

Seren, It looks like an interesting and challenging model. Welcome aboard and good luck with the build.

-

Byrnes table saw questions

KeithAug replied to alde's topic in Modeling tools and Workshop Equipment

Al, another option is to try the following:- The fence has a slight taper from middle to back to allow the cut plank to move slightly away from the saw. When using slitting blades on some woods I find this isn't enough so I increase it by attaching a thin 6" rule to the fence with double sided tape. The end of the rule nearest the blade overlaps the front edge of the blade by about 1/2" -

JD sorry my mistake - reference should have been to Page 21 - 6th August. Page 11 is an earlier version which was a bit over complicated, particularly for the smaller blocks. Richard - thank you - I have thought about an alternative method which I might try at some time. Per - thanks for the feedback

-

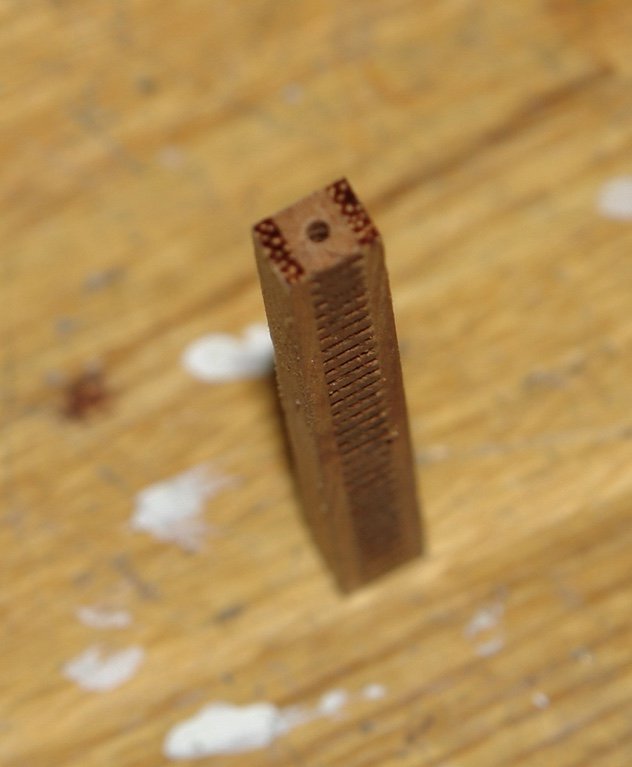

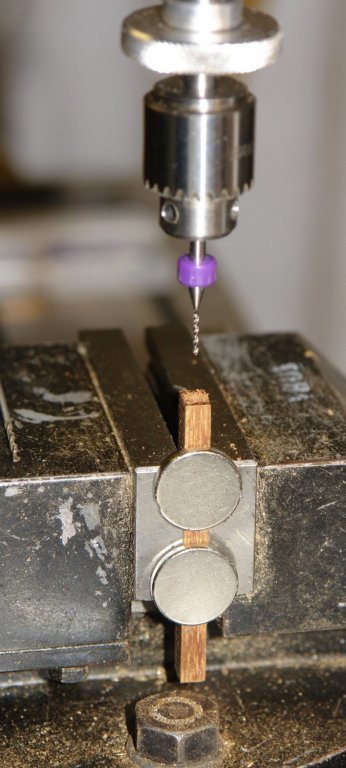

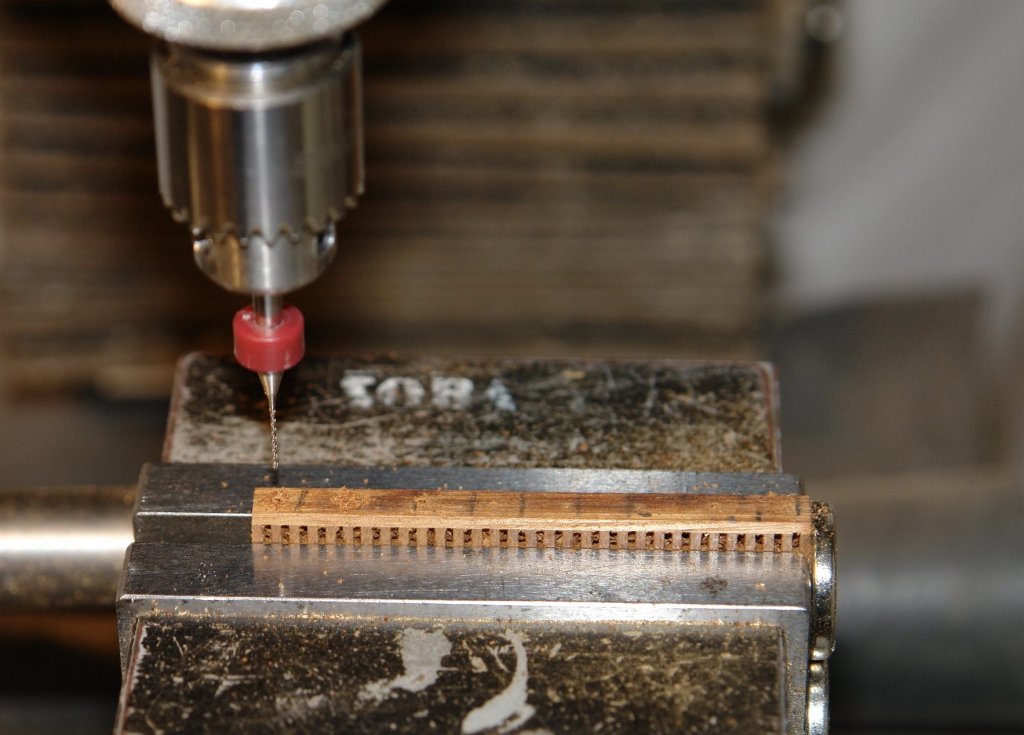

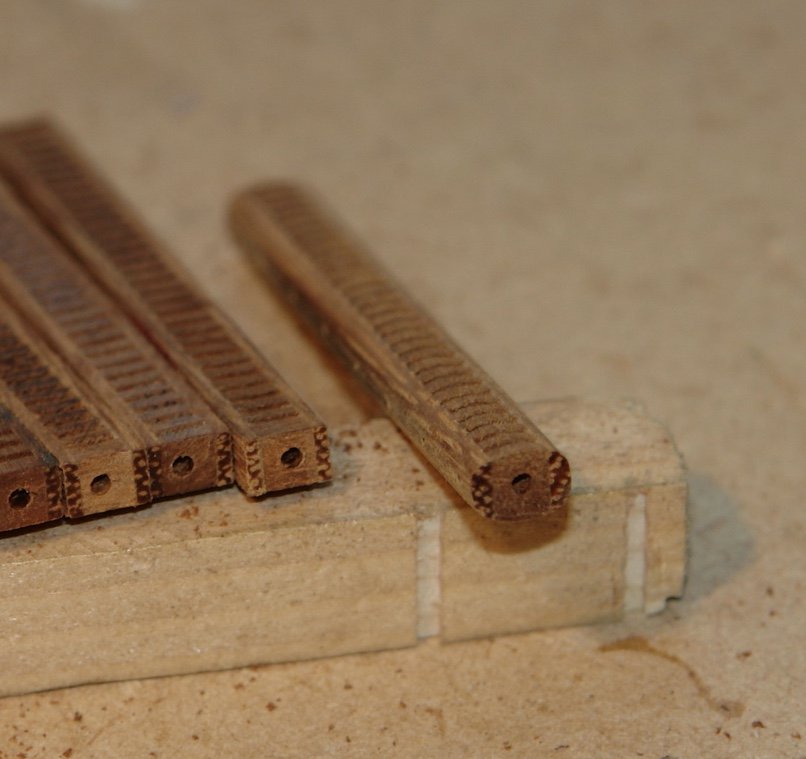

Today I started a production run on blocks. Large size doubles and medium size doubles and singles. The method was much the same as explained on page 19 so I won't go through that again. I will however explain a few of my learning points, techniques and tools. I found it important when laminating up the sandwich to apply plenty of PVA glue. It was very easy to get areas which were not bonded and some blocks fell apart when they were cut down to finished size. Having crated the sandwich the "block strips" were sliced off using the table saw and a .031" slitting saw blade 3" diameter 108 teeth. The length of the strips was just long enough to be able to drill along the length (from both ends) using my longest .062" twist drill. The hole was first bored using a .040 micro drill before being extended and opened out with the twist drill. This method helped the hole run true. All the drilling for each size of pulley was done on one setting (drilling head relative to vice). Rare earth magnets were used to create a positive end stop for locating the block strips. Drilling from both ends worked better than I had expected with the alignment being good as witnessed by the rod passed through the hole. I did however get 2 that drifted unacceptably off from the centre. 2nd and 3rd from the right. Holes for the block eyes were drilled while the blocks were still in the strip. A .031" micro drill was used. These are great for accuracy and cleanness of cut but very fragile. One was attracted by the rare earth magnet which applied enough force to break it. For double blocks I needed to drill through the web of the block. The occasional mis location here caused the drill to break out from the web and inevitably this caused it to break. 3 broke in total. Shaping of the blocks into ovals then followed. I had previously made a concave sanding block which is good for repeatably shaping the blocks. I compromised on the sheaves. Making the shaft small and installing sheaves proved very fiddly even on the largest blocks. I decided to make the shaft larger and dispense with the sheaves, when the rope is in you can't see them anyway. The blocks were then parted from the strips using the bench saw and .031" slitting saw blade. Supporting the back of the strip with a sacrificial piece of wood was essential to stop splintering of the blocks. The sharp edges on the cut blocks were softened by hand sanding with 120 grit paper followed by 400 grit wet and dry. I found that putting the brass shaft through the block eased handling during the sanding operation. The shaft was glued in with CA and then the shaft was parted off using a piercing saw and cleaned up with the wet and dry. The 3 blocks types are in the following picture. Large double, medium double and single. Large is .280" high and medium is .240" high. It took 6 hours to make the following:-

-

I seem to be in one of those phases where lots of stuff is getting in the way of ship building. I did however find a bit of time today to rig the shrouds on the main mast. The piece of dowel between the masts is spacer holding the masts parallel while I do the rigging. The next job is the running back stays bur for these I need blocks. I previously made the "stock" for the smallest blocks. To proceed furthrer I needed to progress to medium and large blocks. Accurate slitting on the saw took a while.

-

Kees, A novel approach, but it seems to work quite well.

- 193 replies

-

- wilhelmina vii

- fishing

-

(and 1 more)

Tagged with:

-

It looks a bit like the creature from the film The Blob.

- 193 replies

-

- wilhelmina vii

- fishing

-

(and 1 more)

Tagged with:

-

Nils, in the past I always used a hand held jig saw but I recently bought a scroll saw. I'm sort of hoping it makes cutting out frames easier.

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

Dan. Remarkably good looking finished model.

- 295 replies

-

- amatsukaze

- halinski

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.