Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

3,377 -

Joined

-

Last visited

Reputation Activity

-

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

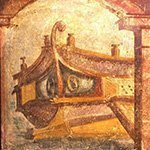

So the instructions for this kit have what I think is a major flaw. Along with the frames, there is a two-part false deck that goes within the frames. The instructions say to glue the frames to this false deck first, and then install onto the keel. That would look like this (dry-fit for demonstration purposes):

However, as pointed out by Binho for the smaller version of this kit, this has a serious flaw: The false deck is flat, while the keel is not; the latter has a clear rocker (curve) toward stem and stern. So if you glue the frames to the deck nice and square, they'll start leaning toward the center as you approach the stem and stern. This means they won't actually fit nicely with the vertical slots in the keel.

So it makes more sense to attack the frames first, then slip the false deck in. To make sure this would work (i.e. is there enough room to slide those deck pieces through the enclosed frames?), I did another dry-fit. It does work, you can slide the deck pieces in afterward:

With that confirmation in hand, I started gluing in frames using my homemade jig:

The frame is first lined up with the horizontal lines on the jig to ensure it's level, then clamped on (black clamps). I then use a square to ensure that it's even across the keel and clamp the jig's feet to the build board (silver clamps). I've done a few this way and it's worked great.

I ran into one small problem. I thought I'd been careful to ensure that the horizontal strips holding the keel in place were low enough to not interfere with the frames, but got it wrong in one place: the very next slot in the image above. I fixed this by using a small chisel to gouge out a slot for the frame to enter. This was especially easy as the cedar is soft and easy to carve:

I nicked the keel, but I don't think it'll be visible in the final model.

So now I'm just moving forward gluing each frame in place, which is slow as I like to let the glue set well before moving on to the next frame as the workspace is tight. I probably could have built a second jig to work from the other and and double my rate, but don't feel like it, so will just keep plugging away.

Thanks for reading! Hopefully this will get more interesting soon as the ship starts to take shape. Early steps are always a bit dull.

-

Cathead got a reaction from Canute in Chaperon 1884 by mbp521 - FINISHED - Model Shipways - Scale 1:48 - First Build Log

Cathead got a reaction from Canute in Chaperon 1884 by mbp521 - FINISHED - Model Shipways - Scale 1:48 - First Build Log

Ooooh, is that an ACW ironclad? Tantalizing.

-

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

I got the cylinder timbers made and installed and am working on the paddlewheel buckets next.

-

Cathead got a reaction from mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

So the instructions for this kit have what I think is a major flaw. Along with the frames, there is a two-part false deck that goes within the frames. The instructions say to glue the frames to this false deck first, and then install onto the keel. That would look like this (dry-fit for demonstration purposes):

However, as pointed out by Binho for the smaller version of this kit, this has a serious flaw: The false deck is flat, while the keel is not; the latter has a clear rocker (curve) toward stem and stern. So if you glue the frames to the deck nice and square, they'll start leaning toward the center as you approach the stem and stern. This means they won't actually fit nicely with the vertical slots in the keel.

So it makes more sense to attack the frames first, then slip the false deck in. To make sure this would work (i.e. is there enough room to slide those deck pieces through the enclosed frames?), I did another dry-fit. It does work, you can slide the deck pieces in afterward:

With that confirmation in hand, I started gluing in frames using my homemade jig:

The frame is first lined up with the horizontal lines on the jig to ensure it's level, then clamped on (black clamps). I then use a square to ensure that it's even across the keel and clamp the jig's feet to the build board (silver clamps). I've done a few this way and it's worked great.

I ran into one small problem. I thought I'd been careful to ensure that the horizontal strips holding the keel in place were low enough to not interfere with the frames, but got it wrong in one place: the very next slot in the image above. I fixed this by using a small chisel to gouge out a slot for the frame to enter. This was especially easy as the cedar is soft and easy to carve:

I nicked the keel, but I don't think it'll be visible in the final model.

So now I'm just moving forward gluing each frame in place, which is slow as I like to let the glue set well before moving on to the next frame as the workspace is tight. I probably could have built a second jig to work from the other and and double my rate, but don't feel like it, so will just keep plugging away.

Thanks for reading! Hopefully this will get more interesting soon as the ship starts to take shape. Early steps are always a bit dull.

-

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

This is how the plank extension was made by the Kyrenia ship (found by its wreckage). But that is 4th century bc.Pentconter is 12th to 11th cent.bc

-

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

I got the individual wheels of the paddlewheel painted and the styrene rings attached.

-

Cathead reacted to mbp521 in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead reacted to mbp521 in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Hello again everyone,

I'm back from a much needed vacation.

Not a whole lot was accomplished this time around, haven't had a lot of build time having to playing catch up at work but I did manage to get a few post-worthy things done.

So with my change of mind to go ahead and do some of the interior of the model, I got the bulkheads cleared out from the boiler hold. This was a task that I wish I had thought about prior to building the hull since it would have been much easier to do with all of the glued hull planks. However, I managed to get them removed without too much damage.

Here the bulkheads are removed and I am going in with the sub framing for the boiler decking. I figured that since the next forward bulkhead was further forward then the boiler hold that I would also build out the forward coal bunkers as well.

Floor planking going in.

Floor planking completed and the curved hull planking going in.

Curved hull planking completed.

Forward coal bunkers trimmed out.

And finally the deck sanded down and the boiler hold trimmed out. I am going to simulate the port and starboard coal bunker doors as closed since I don't want to cut into the false keel boards. I'm too afraid this will weaken the hull if I cut into them too much. Besides, they will be in a location where they are not easily seen.

I had started cutting out the hatchways and realized that it is very difficult to keep the framing lines straight, so one of my next tasks is going to build a cradle for the hull to sit in so that I can keep everything lined up properly. I've seen this methods done on several builds and it seems to have helped those builds. We'll see how this goes.

Until next time. Thanks for looking and all of the likes.

-Brian

-

Cathead reacted to KrisWood in Oseberg Ship by KrisWood - 1:25 - Vibeke Bischoff Plans

Cathead reacted to KrisWood in Oseberg Ship by KrisWood - 1:25 - Vibeke Bischoff Plans

I've got the inside of each strake mapped out! Next up will come fitting the curves into the rabbets and then I can start working on mapping out the internal structures.

-

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Many thanks Eamonn! I might try to find a way to make it thinner (maybe by using a chisel) but let's see... I'm more inclined to leave it as is since it seems a bit fragile

I finished making the sweep ports. This was not too bad until I realized I forgot to paint the inside of it before it was too late.. Ah well, I am liking the contrast the wood makes with the red, and the back of the ports is kind of hard to see since its so deep, so all is good!

I needed to use a bit of wider wood than the instructions called out for. Fortunately, I had saved all my scraps and used some wider pieces. After cutting each piece, I applied tung oil, then stuck them to the hull using diluted glue. Then the horseshoe shaped hinges and wire pins were also installed using diluted wood glue.

Here are some pics:

-

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Planking slow but it proceeds. The planks are very thin and break easily. Another thing is that due to the length I need more than one plank for each row.

-

Cathead reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

Cathead reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

Another 4 oarsmen complete and another 4 started, which brings us to just past halfway.

I've found that getting to halfway has a positive effect on morale. From there on there are more items complete than there are left to do, and with every new item complete the balance shifts further and further that way. So rather than being overwhelmed by how many are left to do, it becomes "only so many left". I found this with making the oarsmen, the oars,and various other things where there were a lot of identical items to do.

Also, when I mix the paint for the tunics (and the flesh colours as well), inevitably I mix far more than I need for just one figure. But as I'm doing four at a time, each one at the extreme end of the row it's in, I can paint the tunics all the same colour without it looking obvious.

-

Cathead reacted to druxey in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to druxey in Swallow 1779 by tlevine - FINISHED - 1:48 scale

As long as you wash off any excess glue before it sets, all will be well!

-

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Thank you to everyone for the likes. JD, I am using diluted yellow glue. And yes, I am gluing along the rabbet as well as on the bulkhead. I tried it with gluing just the bulkhead for fear of glue bleeding out onto the hull but that was a disaster. Waiting for the glue to become tacky has prevented any problems.

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Eric, thanks again, really appreciate it.

I found "soft grip binder clips" on amazon, a Staples brand, so I can probably find them at any office store. Great idea, whoever thought it up, I'll give it a try.

The clothespin trick is new to me as well, thanks for that. Now I'm looking around the house and wondering what other things I might have that could be useful!

-

Cathead reacted to Warnerade in King of the Mississippi by Warnerade - Artesania Latina - 1:80

Cathead reacted to Warnerade in King of the Mississippi by Warnerade - Artesania Latina - 1:80

Progress at a snails pace, but I finally finished planking the second level deck. Putting the deck nails in and the second layer or varnish next using the same method as I did in the first level deck

-

-

Cathead reacted to kurtvd19 in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to kurtvd19 in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Maybe consider a small filler strip/block only where the joint would pose a problem.

-

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Thank you, druxey. That is the only place there will be an issue. I did several layouts and this one was the least problematic unless I installed bulkhead filler blocks. This is the first POB model I have made in a long time; I really appreciate the spacing options provided by POF construction.

-

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Planking has commenced. Thanks to everyone who responded to my request for more information on clinker planking. Before any planking could be cut, the planking belts needed to be laid out. This was done with chart tape. The lowest rows of tape represent the garboard and broad strakes.

The garboard was made up of four planks. It feathers into the sternpost and keel at the deadwood and ends on the stem just above the boxing joint. On the upper part of all the planks is a rabbet to accommodate the overlapping plank. After some experimentation and based on the diagram from Goodwin's book on Alert, I decided to make the rabbet approximately one-third the width of the plank and at a 10 degree angle. The prototype had a narrower rabbet but this gave me a wider gluing surface. The rabbet was formed on the mill and cut to a depth of 2/3 the thickness of the plank at the widest part. The broad strake was made up of three planks. At the stern and stem posts the clinkering gradually tapers to a smooth surface.

The overlap of the planks is easily seen in the next pictures. The easiest place to see the planking rabbet is on the broad strake at frame "H".

These pictures illustrate the tapering of the garboard and broad strakes into the keel and stern post, and each other.

-

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

The ancient port of Amathus.... in Cyprus

-

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

I got all 4 wheels of the paddlewheel built and have them mounted on the shaft with sized spacers. The spokes of the wheels appear to be in sufficiently good alignment to allow attaching the buckets without too much fitting (thankyou cathead).

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Thanks again Eric.

Here is my meager clamp library so far. (I have more than pictured, but those are the only styles.)

The ones you pictured would probably do the trick, or in any case be handy to have. Looks like you sacrificed a binder clip in order to make two of your clamps, maybe slid some plastic/vinyl tubing over the arm?

I used hot tap water for the first try, but when I practice on the second piece I might add some hot water from a tea kettle, see what happens.

-

Cathead reacted to Louie da fly in Viking Longship by Binho - Dusek - Scale 1:72 - Model based on the 11th Century Skuldelev 2 wreck

Cathead reacted to Louie da fly in Viking Longship by Binho - Dusek - Scale 1:72 - Model based on the 11th Century Skuldelev 2 wreck

Very interesting chart, Binho. One thing I can add is that the orpiment yellow is made from lead sulphide. LOTS of lead based paints back in the day. But I don't think you need to carry the quest for historical accuracy that far . . .

-

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Making some progress on the hull details. I finished with the eyebolts, sheaves, and quarter gallery installation. I found the sheaves to be a bit of a pain, especially the aft ones. I decided to drill the holes all the way through, this overcomplicated things but I guess I did an OK job. To those who also want to drill them through, make sure to drill both sides and not only on one. The basswood will otherwise chip... I had to drill the ones at the stern all the way through from outboard because my pinvise could not fit for the inner ones. This caused a bit of a mess and had to put filler to hide the mistakes.

As for the eyebolts, I used the tip of a compass to make sure they are circular.

Enough rambling, here are some pics:

Also I have noticed some fingerprints show up on some plates... 😣 I have been so careful not to touch the copper, but there are times where my hand might have slipped to hold it 😬

I might try using a water, salt, vinegar mix to remove the fingerprints (I think I saw this pointed out by Dubz but don't remember exactly where), but I am a bit scared that it will age the copper too quick.. I am liking the new copper look.. The fingertips show much more when the ship is on a white platform, so if I decide to not touch the copper, I will end up placing it on a darker one to hide it 😅

If anyone has any other tips to remove the fingerprints, please let me know.

Oh and almost forgot, I tapered the stem knee a bit more so that I can fit the mermaid. Here are a couple of photos with the figurehead dryfitted:

Lastly, I found this slate lying around in scraps of a construction happening nearby. Not sure if too thick or not but I kinda like the look.

-

Cathead reacted to Thistle17 in New England Stonington Dragger by FriedClams - FINISHED - 1:48 - POB

Cathead reacted to Thistle17 in New England Stonington Dragger by FriedClams - FINISHED - 1:48 - POB

I have spent hours dockside in New England taking in the fishing fleet work craft. I have a special reverence for them.There isn't a one that doesn't show the ravages of toil, sea and weather. You have captured those effects perfectly and I might add your modeling talent is to be admired. Your model tells a story. Extremely well done!

Joe