Per

Members-

Posts

77 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Per

-

Hi Harley, You could try "Ordnance Instructions for the United States Navy, 1866" at Project Gutenberg: http://www.gutenberg.org/files/19058/19058-h/19058-h.htm#Page_A_46 P. 46 onwards should give you all the information you need. On p. 55 you will find instructions how to house lower-deck guns in different weather. Per

-

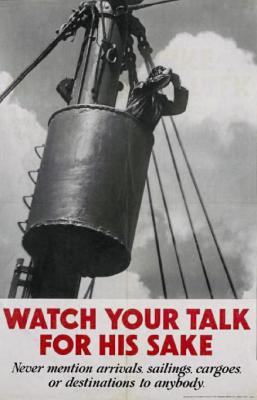

I also found this British wartime propaganda poster. It clearly shows a ladder bolted to the mast and, once you got that far, rungs bolted to the outside of the barrel. Per

-

I found this - Ogden's 1927 whaling cigarette cards: http://www.coolantarctica.com/Antarctica%20fact%20file/wildlife/whales/whaling_cards.htm Kester's bad weather barrel as well as a more minimalistic southern type. Per

-

Now this is what I call a lathe! Ok, not quite up to date and perhaps a tad overpriced, but boy would I want one! http://tinyurl.com/qb5y5qw Per

-

I was going to suggest a Dremel diamond cutoff disc. Hypodermic needles are very hard and the pieces will shoot off like projectiles when you try to snip them off. At the very least, use safety goggles. Per

-

Ships name lettering

Per replied to Ian B's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I have used Scale Link's etched alphabets and number. They look really good. Per -

I am looking for an old roll top desk or two for the same purpose. That would make the workshop look very shipshape and Bristol fashion. Per

-

Ilhan, I found a couple of good photos here: http://www.flickr.com/photos/withloveforjin/7008102377/in/photostream/ and one photo here: http://zuluboat.blogspot.se/2009_02_01_archive.html Hopefully a member close to San Diego could do better. Interesting. It is the first steam windlass i have seen with upright steam engines. Perhaps because of tight space on the forecastle? Per

-

Mine are called Dovo, a German make. Got them from an embroidery shop and they were not cheap. What I like is that they, like me, are left-handed so I actually see what I am cutting. And the cutting edges are micro-serrated, keeping the thread from sliding when you cut. Per

-

Just saw this video and thought it might be of interest: http://www.stewmac.com/epa/0631?utm_source=EPA&utm_medium=email&utm_content=hero_img&utm_campaign=EPA_0631_C_20140309&tab=Video I have no connection to Stewart-MacDonald other than having spent a lot of money on them. I'm just a sucker for both tools and musical instruments... Per

-

Using chisels for turning brass

Per replied to tkay11's topic in Modeling tools and Workshop Equipment

Forming the end of the graver (about 60 degrees) with a bench grinder gives it a sort of hollow shape. All you have to do is hone it so the tip and edges are flat, leaving the hollow in the middle. Bill Smith: I like your Tanzania story. Amazing what a skilled workman can do with just hand tools. In the early seventies, my Nikon camera died on me one time in Laos. The town watchmaker spent the night filing up a new gearwheel from brass sheet and fitted it to the camera motor drive. Per -

Using chisels for turning brass

Per replied to tkay11's topic in Modeling tools and Workshop Equipment

I use a diamond lap (Eze-Lap?) and finish off with a hard arkansas stone. If you use a bench grinder like Bill Smith suggests in the Sherline article, there is really very little steel to remove afterwards to get the right shape. You can also search for "Scary sharp", there are many MSW members here that recommend that method for getting a sharp edge. A bit off topic, but a great many years ago I watched a jobbing brass turner in Clerkenwell turn up a large telescope lens mount from a brass casting, completely by hand. The handle on his turning tool must have been two foot long. He jammed it into the armpit and leaned on it to get the depth of cut he wanted and the brass chips were flying. Next thing, he turned the inside threads with a chasing tool, finishing off the job by heating the machined casting, still rotating, with a spirit lamp and wiped on shellac. The whole thing can't have taken more than two minutes. But please don't try that at home! Per -

Using chisels for turning brass

Per replied to tkay11's topic in Modeling tools and Workshop Equipment

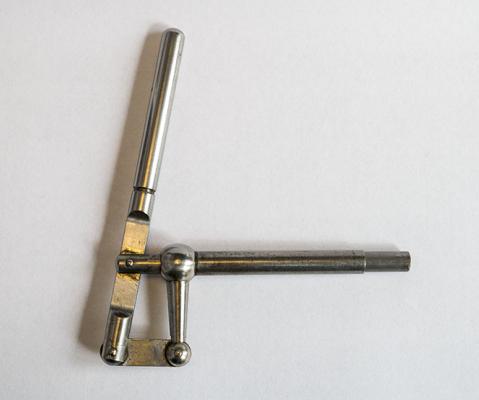

Here is one of the gravers i use on my Unimat 3 and my Boley watchmakers lathe. I pressed a bushing into the handle to hold a 1/8” HSS square toolbit. I use handles bushed for 1/8” and 1/4” round and square toolbits on the Unimat, on the Boley mostly 1/16”. The handle is about 80 mm long, enough to hold comfortably in the hand. The long handles you see on turning chisels are to make it easier to apply leverage for a heavier cut, something you don’t want to do when turning with gravers on a small lathe, a dead sharp graver using fine cuts is the way to go. Start using a speed of around 200rpm, you’ll soon get the feel for the best speed for what you are doing. Oh, and never plunge the graver tip into a cut, that is a surefire way of losing both the graver tip and whatever you’re turning. Angle the graver up (or down) and cut with one of the front edges. Per -

Paul, As davyboy says, it can't hurt to contact Aberdeen Maritime Museum as they do have the builder's model. I don't know how accurate it is, since it was made for the owners' approval before building the real ship. Possibly changes were made before building: http://www.aberdeenships.com/related.asp?searchFor=thermopylae&index=13563&shipid=99403 Per

-

I was to one of these parties when the firm I worked for celebrated a jubilee fifteen years ago and rented the museum for the evening. They had a lot of 17th century food on the menu, oodles of different herrings and salted meat. The beer went down easily after that. But my best memory of the ship is as a kid when my school class were actually allowed on board to tread the decks. Definitely not allowed anymore, unless you are a visiting head of state (Obama was the latest last summer). Only wish I had better sense and a better camera as a kid. Just a few bleached-out instamatics remain of that visit of a lifetime in the 1960s... Per

-

PRIMING WIRES: "Two and a half the diameter of the bore of the piece in length from the back of the eye to the point and two tenths of an inch in diameter. To be made of drawn wires. The end which forms the eye to be welded to the others The point with four squares [The last statements make little sense as written ...] I suppose what they mean is that the point was square in section, like an old-fashioned ice pick. Makes sense if they use it to pierce the cartridge. Per

-

Aluminium cut straight from a can is very hard. Annealing the sheet, heating it until a piece of wood leaves a brown streak when drawn across it, leaves aluminium that is soft and pliable and can be easily formed.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.