-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ioannis

-

Im surpised when i saw your first steps it looked like a turtle shell ,but on your next photoes ,soon after sanding it looks beautiful Im impressed about your building method . Im pulling a chair closer you Look forward to your next update

- 102 replies

-

Thanks Niels. By the way i have just red about the dramatic end the ship had and how.... Rather than let the enemy capture they ordered the ship to be scuttled using dynamite..

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

ioannis replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Pits propeller??

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

very nice jesse. You did well with planking ,I could say stern and bow beautifully as the wives rear

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

ioannis replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Im still learning from you nice tips .well done Nenad Живели- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

I will check it again.but two of the fotoes are jpg format. Thank you.

- 17 replies

-

- abythistos

- cutter

-

(and 2 more)

Tagged with:

-

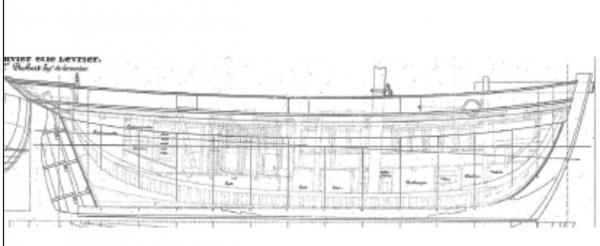

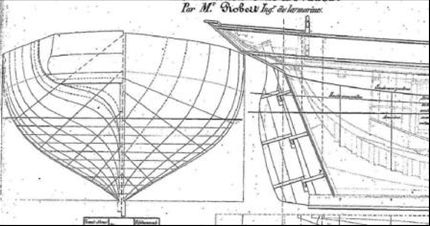

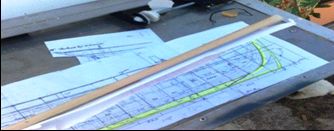

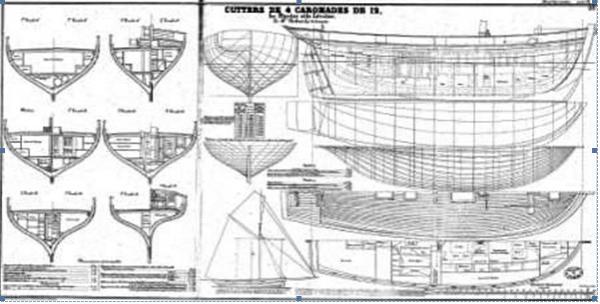

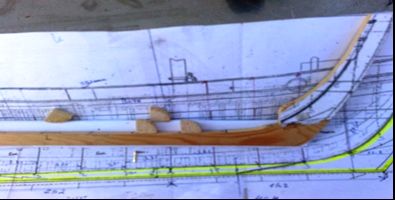

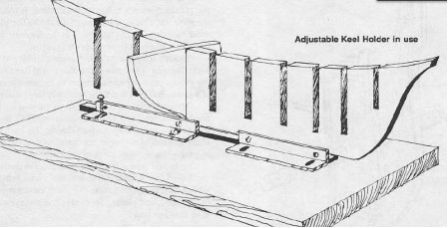

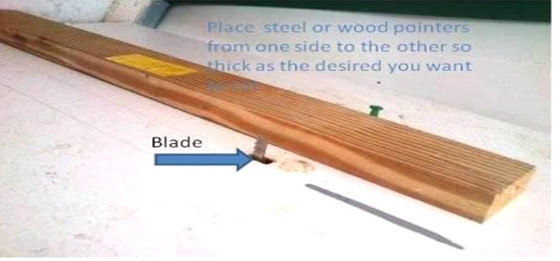

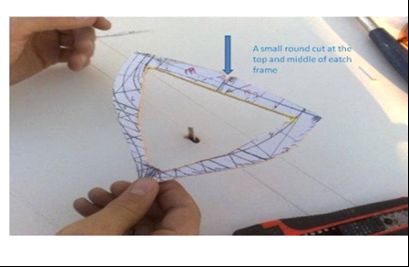

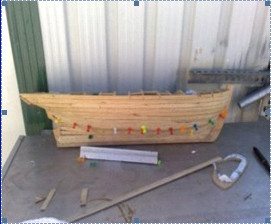

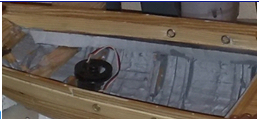

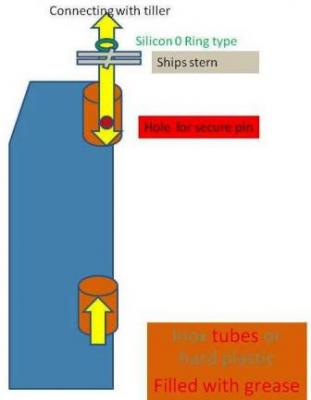

Dear forum and modelers Scratch build ABYTHISTOS –French 1784- was really a dream for me. The building Idea has come 3 years ago while me and my son were watching photos and video from R/c models, and old time ships. Yea I used to have a 2 mast wooden ship but I was not the builder ,I knew how to sail her how paint her and repair any engine easy damage but build one? how do we start? …sure from keel but then?… Thanks to all people on this forum that keep on writing giving ideas tips solutions, and answers I have spend almost a month reading and watching your articles and tips before I decide to build my project I have found scanned on the internet a collection of plans Easy to imagine .Difficult to build ? What wood or other material to use for a certain part on the ship on the other hand. from where do we start? A plan to begin and a thought how is going to be at the end? manual skills required patents and ingenuity but most of all, patience A cutter, nice curves with single deck one mast and less construction details comparison with a warship CUTTERS de 4 CARONADE de 12 [1784] I have acquired a set of plans body, sheer ,half breadth to start plus a general plan for riggings I choose enlarge photo method you can alter plans to any size you desire, then copy to a memory stick and, you have as much copies as you need for photo copying But important point ,the lines on the original drawing must be very fine MODEL SPECIFICATIONS NAME -ABYTHISTOS- LOA:0.73 cm bowsprit included LBP:0.44 cm MAX,BREADTH :0.17,5cm MAST HEIGHT measured from deck roof :0.65 cm Bowsprit length:0.21 cm DRAFT Keel to white waterline :0.15 cm , Water line to upper deck top rail :0.10cm Watertight compartments 3 1 electric motor 6v , 1 gig LOA 0.10cm 4 Sails./ 2 anchors continental type18th century/ 1 French gun x18pounder First day I bought various strait pieces of wood and finally After watching a lot of dif ships plans I decided the cutter The build method I used I call it COPY-PASTE Choosing the keel, a strait piece of wood [beam]0.80 mm thick Lots of calculations with Microsoft world program till I reduce the plan dimensions from the original minimize to the desired plan and also couple of photocopies I will need them to cut and glue on wood pieces so I have exactly similarity according to original ships plans More building details I took also from other similar cutter ships KEEL assemblage The backbone of the whole ship. It also includes the rudder post and the stem mounted together with glue and a dowel Small angle pieces of wood vertical installed on keel as floor will secure in place the ribs-frames. Keel assemblage procedure finished next step I made an adjustable keel holder using a baseboard and 2 aluminum angle to snug the keel as picture below Tips I made my own carpenters wood saw machine simply and cheap way without limits I used an electrical hand saw with RPM adjustment And screw it at the 4 hole edges of its base as photo below Mine has open holes at the metal basein case there are not in yours just remove the base [allen screw usually used]and make the necessary holes with your drill Tightly fasten with screw or chuck the two ends of an angle iron or wood ,parallel to blade and set your cutting mm distance according to desired There are 2 types of blade Choose long blades. And For hard wood try iron blade and not the blade type for wood REMEMBER start slowly with low RPM don’t rush and .in case of hard wood also lubricate the blade with oil drops.[i use a wet with transparent -no cooking- oil piece of cloth] You may destroy the first wood piece till you find the better way but when you do you will be rewarded …sand paper will do the rest and don’t forget to remove wood dust close to blade after, use I have not used plank from storehouse Timber balsa wood is soft and fragile for planking unknown behavior to sea water Seawater ? Yes me and my son wanted to sail with So I need harder and good quality wood Dry furnished Pitch pine medium hard long fibred tough doesn’t break easily with the tip I mention before I manage to cut several 2mm thick planking good white glue quality 2 types express and waterproof FRAMES Making frames copy paste method with cheap plywood… A keyhole saw is good for accurate plywood cutting A triangle piece of plywood has been removed from the interior of each frame so I can freely move my fingers between George my son came forward as volunteer to help me cut out frames –piece of cake- he said. Well he did well but I had to cut 4 pieces twice due to his badly cut The above picture 7 shows how does the frame look like after I have cut them to right size With some careful sanding the resulting pieces are nice and accurate On the same picture 7 you can see the frame on top and middle of witch I drilled a hole [blue arrow] CENTER LINE I have discovered a new method to connect frame with keel Picture below –a long machine screw will connect at middle all frames top Assembling the stern with frames most difficult for me Due to the curvature stern has been cutted for propeller use even my wife’s clothespin in use Plank on frame Plank bending has been made with the simply way of ,wetting them first And place them later bowing and buckling on the wooden board with rustproof nails Holding the plank in position on the model while the glue dries is a test for my nerve by the way thats my roof garden next to my small workshop Some who favored the old ships Thats from today ,during my trip i met this yacht waiting outside Hydra island Greece a little further away and meeting her you can see the sailors up in masts well thats enough for today i have lots of things to do more .I must work my solar oven also. Im back uffff..... in every step i must think about leaving space for servos motor shaft how to set up steering.Never did it again.The whole building is in my mind ,but next steps have been made longer After placing frames things are getting better with hull planking. When job finish plywood frames will be removed and replaced by real wood pieces Planking, clean work pleasant time lots of pinball holes A small sandpaper machine will give a fine surface Looks a bit ugly but timber is 2 mm thick,this ship is going to meet poseidon at see water so must avoid any bending Picture below showing Extra strength Small plywood supports have been set vertical between frames [as guides and stoppers] to avoid movements Patience and ..planking finished Before I remove plywood frames I replaced them with new 2mm thick ribs made of curved solid wood [blue arrows picture above] I did glue them tight to inner hull planking Hull has completely covered by planking I m starting to remove Plywood frames.Τhe inner part must be clear. Now I have free space enough for motor shaft servos steering I have painted the internal with first a coat of white waterproof glue and the next day a second coat of fat oil primer Before the electric equipment installation The interior has been sealed’ I could also use polyester. Gives you hardness but also weight. Once I made a small boat i used liquid polyester it smells awful and also its hazardous Patience Now sitting on a chair I’m holding the ship on one hand On the other hand a special bosh electric tool a handy multi sander and rolling it slowly with low rpm in all around the sides don’t forget wood planking is tough for this timber last sanding and my hands replaced the tool by a very thin sand paper 180 grit so at the end of the day I had the desired smooth shape Now I have got strength to continue I will need to putty the body but that’s not urgent I kept some wood dust I will need it later. to make my own colored putty Hmm ,,midnight again and everybody on this house went to sleep all ? no ..except..my partnerships 2westy dogs watch carefully every step i do Quiet.. time… to consider my next steps… Deck construction I forgot to mention that deck beam supports of wood have been added at all around last upper planking Beams will guide me and support the roof deck later A plywood piece of 1.3mm thick took place as deck flat base on top of which I did glue with fine barbeque round wooden meat sticks --wonderful result ideal for decks you may try it-- The special bosh multi sander with 100 grit first 180 later sand paper gave me the desired flat deck surface ready to varnish Deck divided in 2 pieces for reasons of installation servo..moteur,,battery Forward deck piece is 1/3 of the whole length glued to beams Aft deck piece 2/3 of the total length can be easily remove With 4 inox screw of 6mm Time for putty and ballast keel as ballast a weight of 1.2 kg 0.8mm thick long lead[yellow line under ship] glued with epoxy and 3 inox screw under wooden keel and under the lead a thin false keel 2mm has been added to protect the lead RUDDER CONTRUCTION DETAILS this plan showing how connected the steering wheel [red letters -hole fore secure pin -] [orange letters- inox tubes or hard plastic filled with grease-] I know i post pure and sort details but i always hurry to do something else and my hands are still covered with glue. CHEERS.

- 17 replies

-

- abythistos

- cutter

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.