KirbysLunchBox

Members-

Posts

221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KirbysLunchBox

-

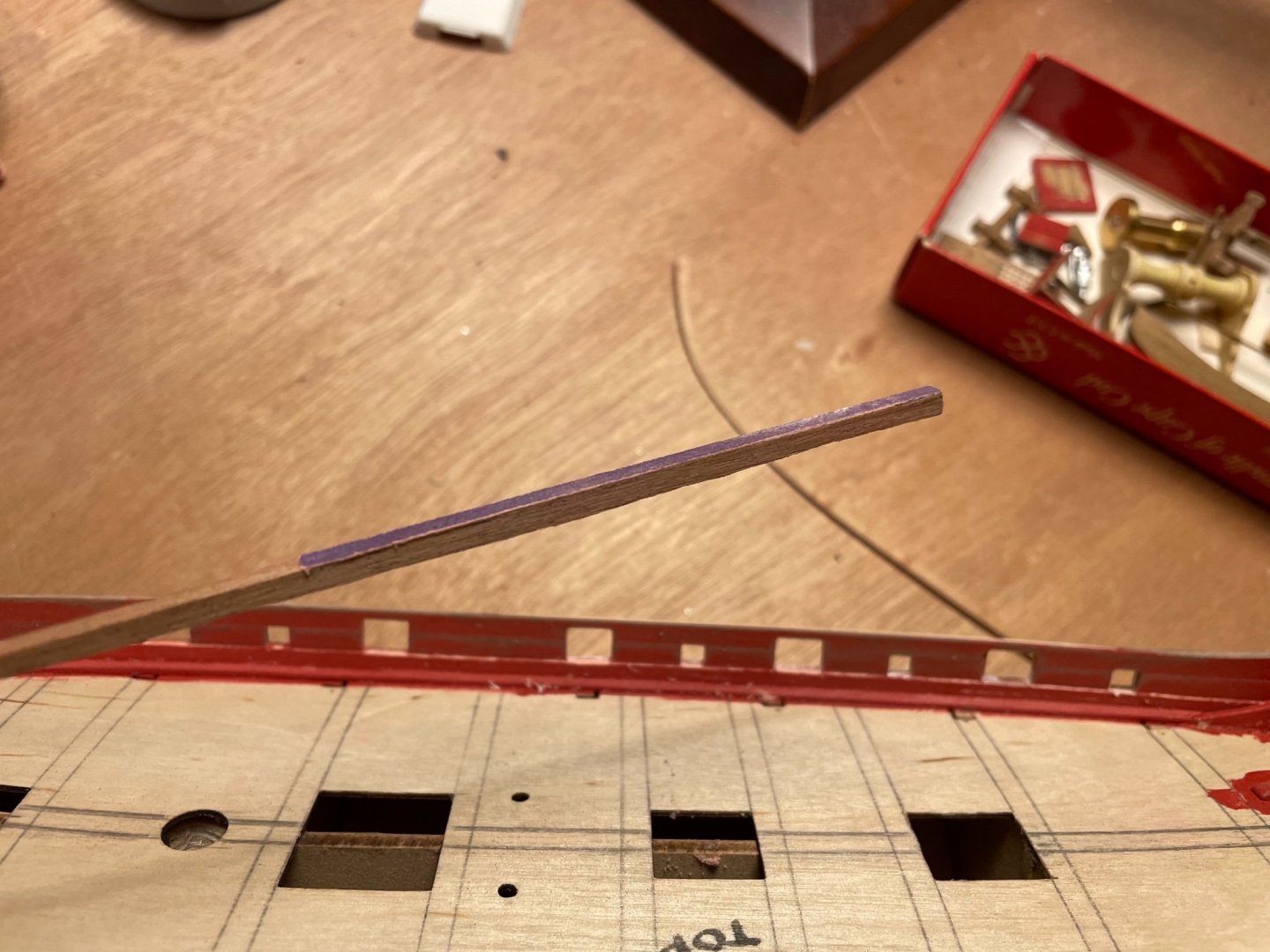

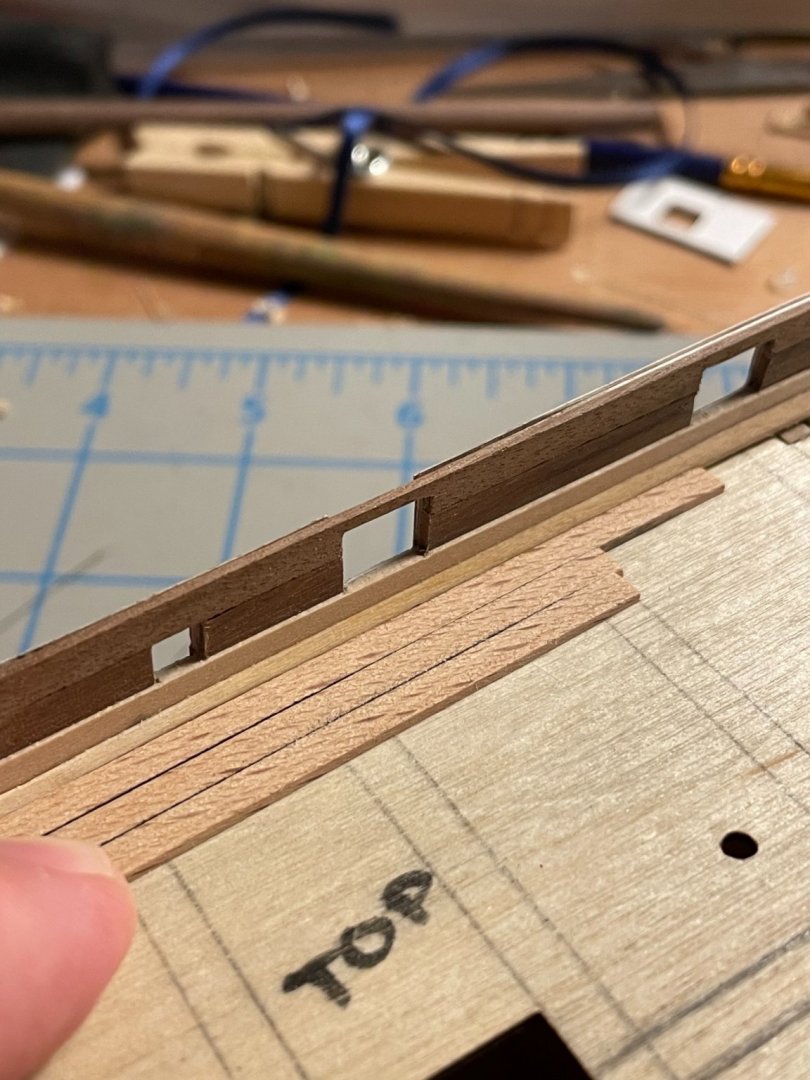

It’s been a bit since I had time to work on the LN, but here comes a tiny update. Since I previously decided to adjust the port openings to follow the deck line instead of the plans, I had some holes to fill. The bottom spots were taken care of with filler, but the top required making a custom piece. The end result came out pretty clean I think. I struggled a bit at first when I was trying to sand the ports from the filling process. I kept sanding the edges over square. I came up with a simple little sanding stick with sand paper on one edge that bridges across the deck to the opposite port. This way as I sand, I keep the edges nice and square. It even worked on the bridle port! I am getting really close to second planking now I think.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

I will be following along on this one too!

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

I somehow find comfort in a pro like yourself also dreading this task. i love the modifications you are making. Got to take some creative license when you can. It’s what makes this hobby so much fun!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That is really fascinating! I tried googling sailcloth flooring and just got adds for modern flooring. Lol. Thank you for the lesson!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I am not up to speed on my history here… they made that floor pattern using sail cloth? I always assumed it was just painted wood or some form of tile. Much googling I need to do now! Love your build though! Look forward to watching it all come together.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

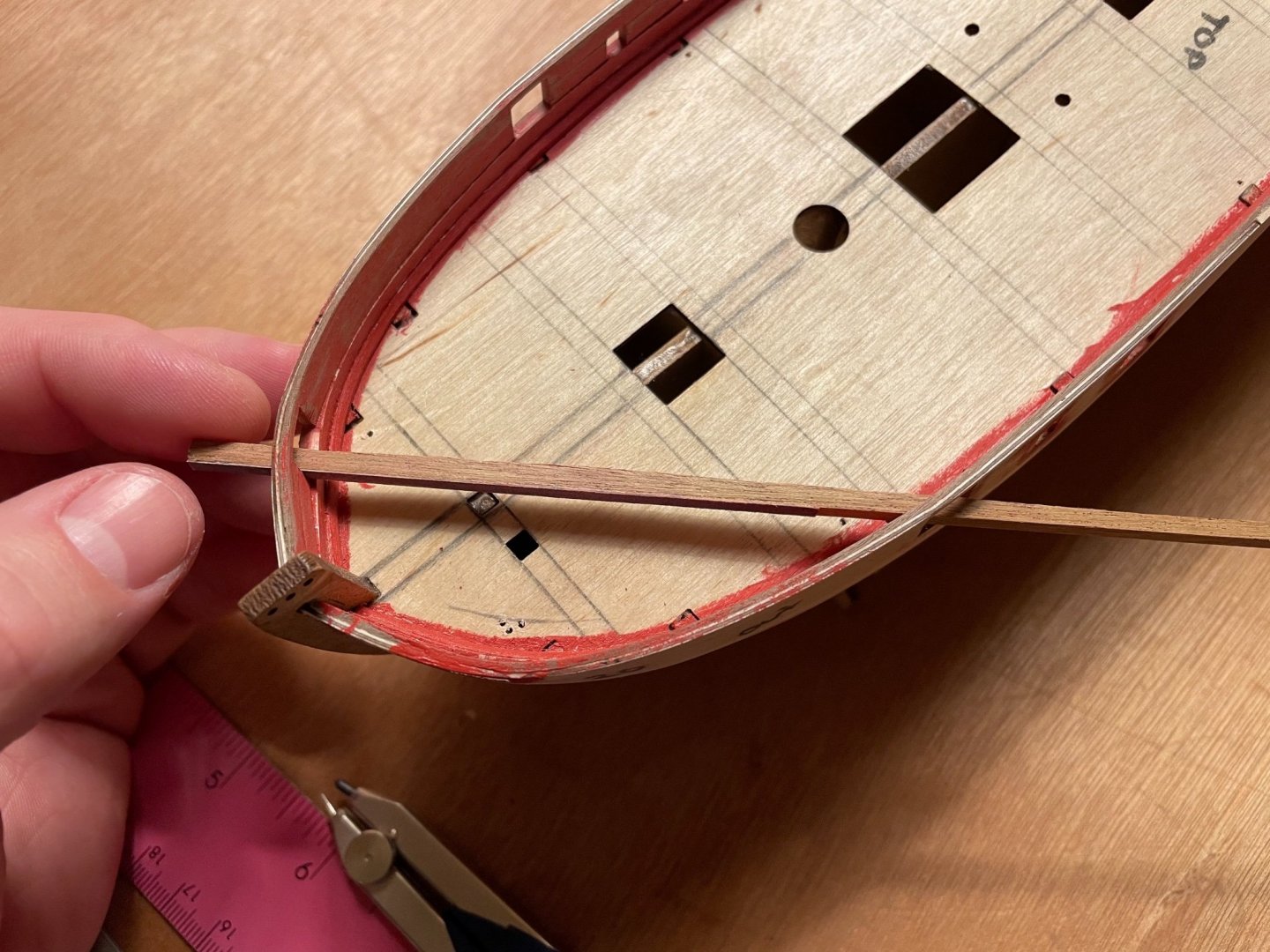

Decided to put some paint on the inner bulwarks. I went with a more rusty color than a bright red. I don’t really know what it’s supposed to be, but I like the look. It did expose more than a few places that need some filling. I probably should have applied some sanding sealer before the paint, but I was planning on two coats with some sanding in between. After sanding, it is funny how it gives it a warm and weathered look. It won’t be staying like that though.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

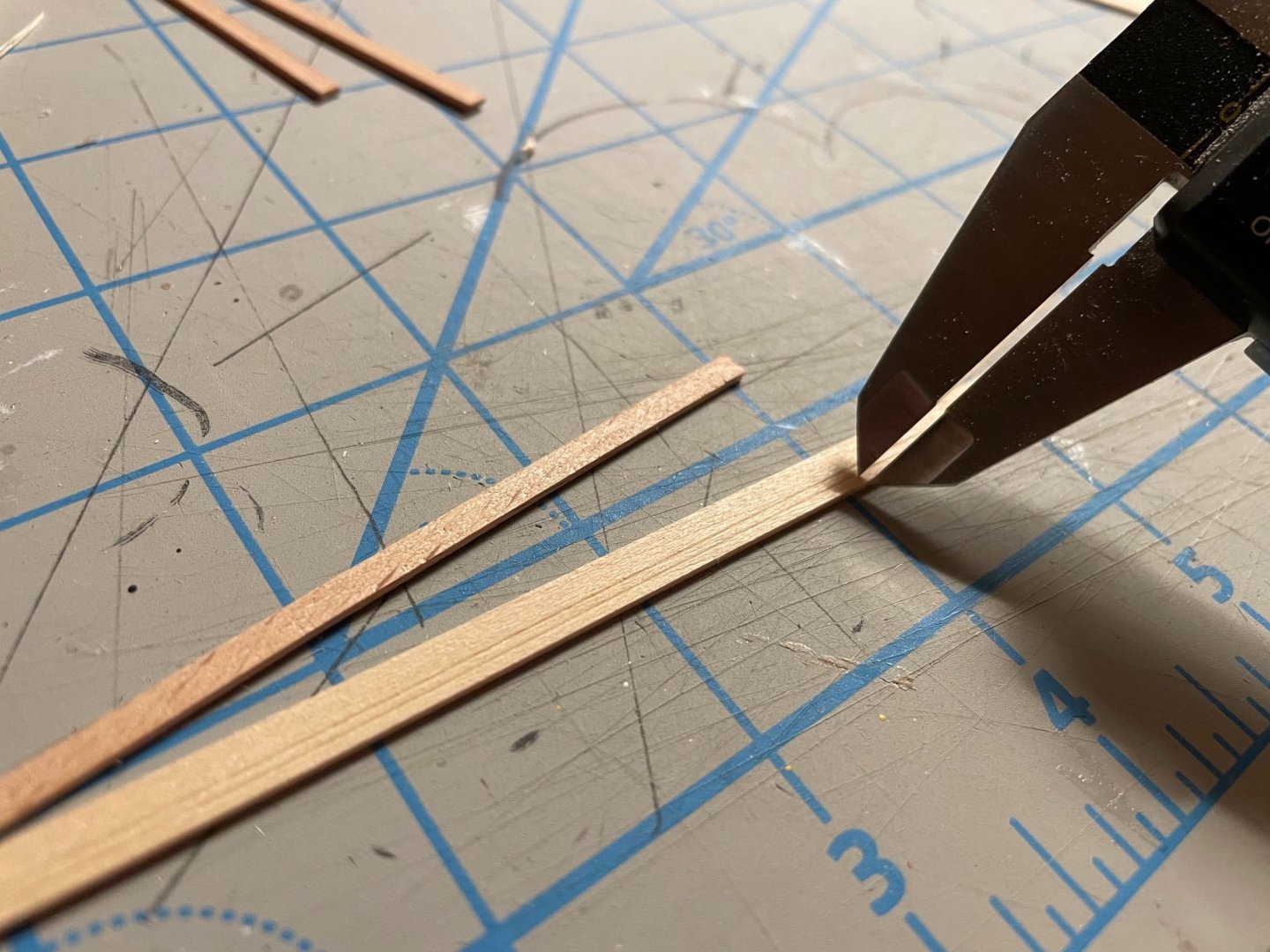

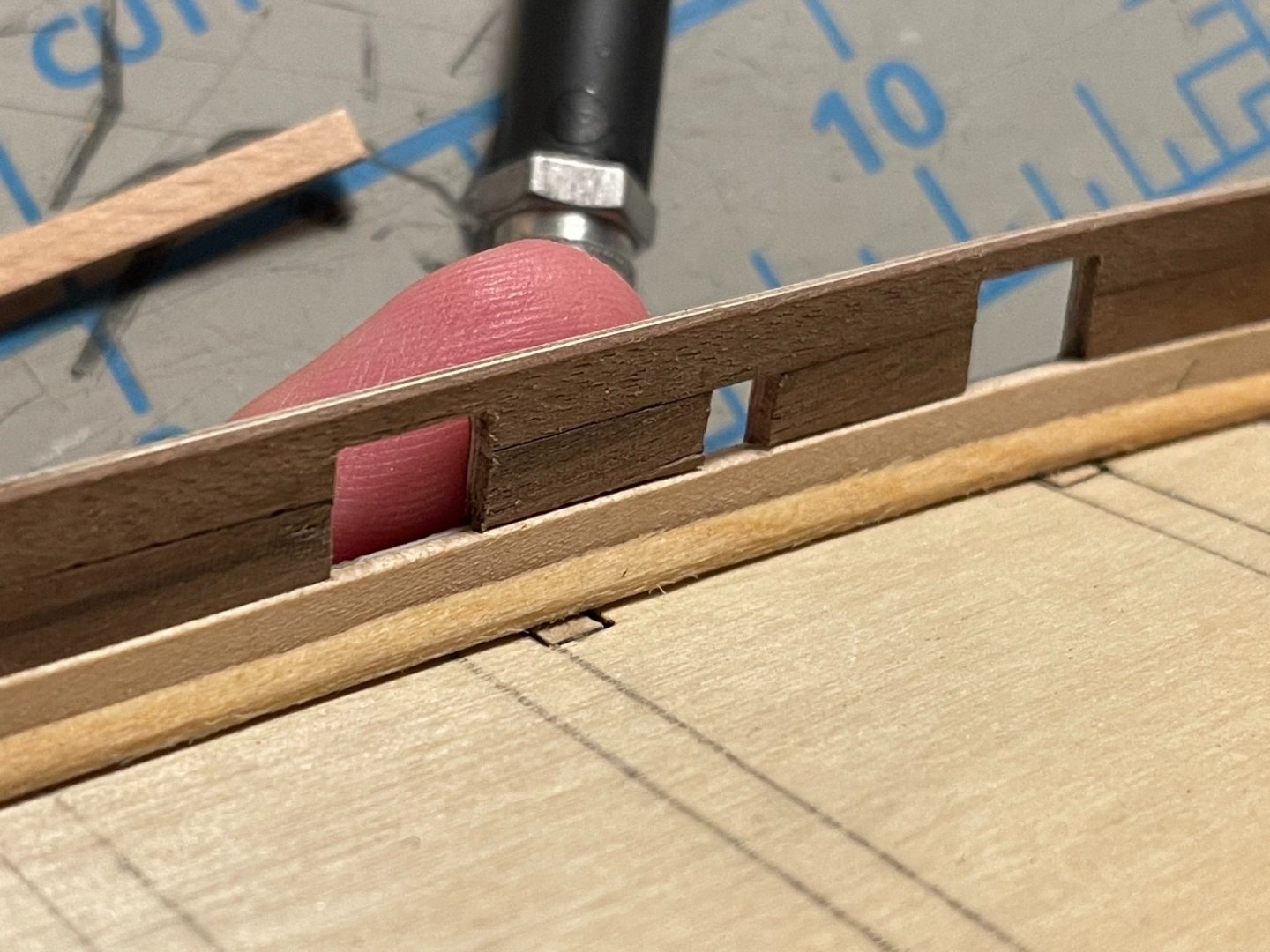

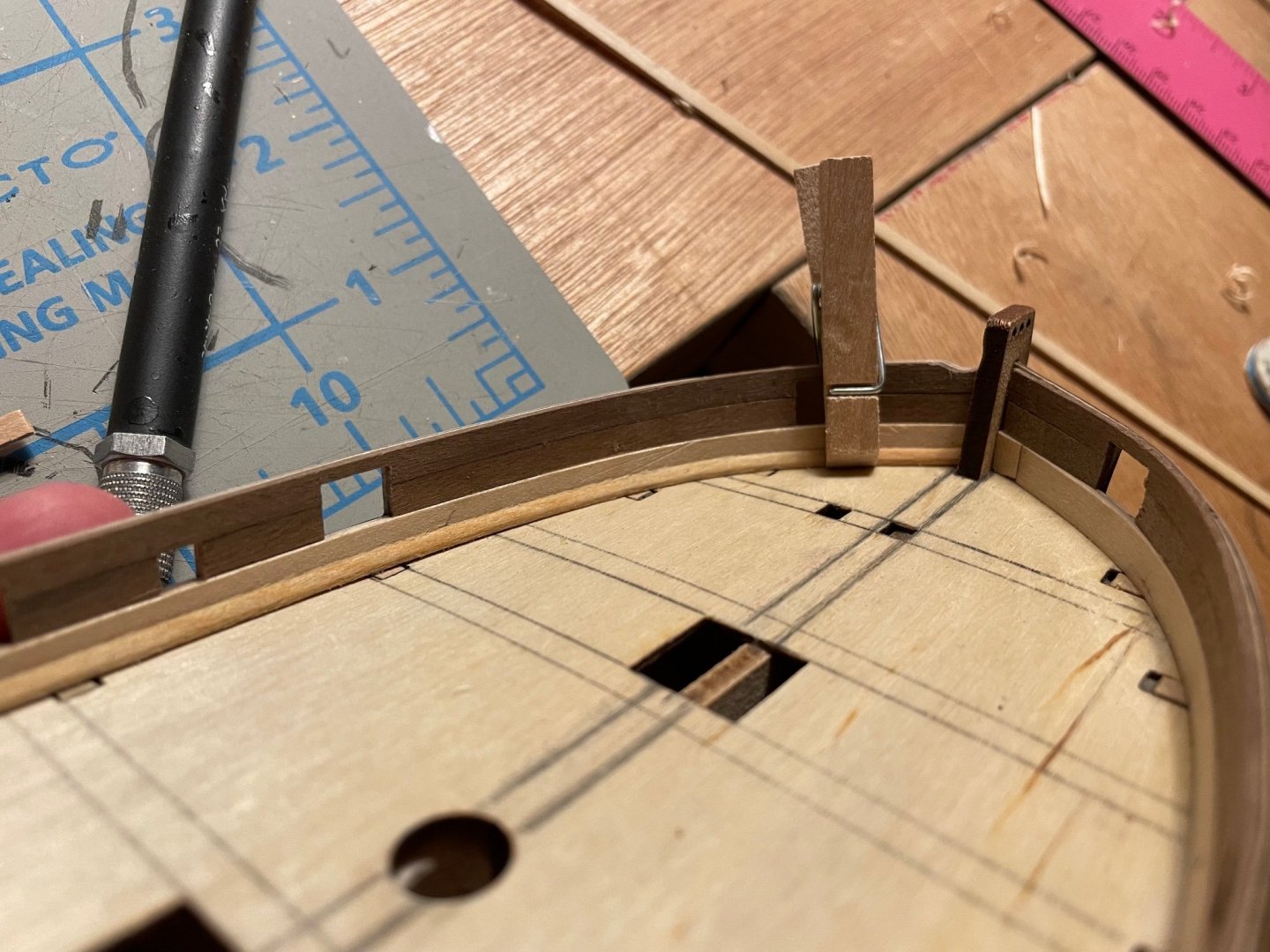

I finished the other waterway. I thought I would document my process. I probably spent an hour trying to make the first one and made at least two scraps for the bin. The second one barely took 15 minutes. I made them out of left over lime wood from the first planking. I took my calipers and measured the thickness of the deck planking (~1mm) and locked the calipers and scored a line along the lime wood plank. Then I opened up the calipers to 2mm and scored another line. I carefully cut along the 2mm line and the even more carefully carved a 45 degree chamfer down to the 1mm line. Some light sanding and the waterway was ready for trimming to fit. I won’t glue these in until I have the margin planks ready so to make sure the chamfer lines up with the top of the planks correctly.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

Ladder time! I thought I had a picture of my setup to drill the pockets for the rungs, but apparently not. The side rails are pine 2x4’s and the rungs are 2” hardwood dowels. I used my drill press and a 2” forsner bit to drill down a pocket 3/4”. I had to use a mallet to tap the dowels into the pockets. It was very satisfying! The top of the rails are matched the side of the ship. I won’t trim the bottoms until it’s in it’s final place.

-

It took three tries to figure out a technique to carve a waterway without having access to a miniature table saw, but I am happy with the result. I also started forming a test margin plank. Nothing is glued yet. Will want to test fit some more to make sure I am happy with it.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

Actually there will be a carving for the stern! I found a neat looking scroll piece at Home Depot that fits nicely! Next up will be the ladder (where the water bottle is in Jasseji’s post) and a few finishing touches before stain and paint. No figure head planned at the moment. My son wants one though. I might try to 3D print something?

-

Transom planking! Pretty straightforward, only tricky part was making the holes for the assembly bolts. I was able to use an appropriately sized forsner bit and a paper towel tube to make a little tunnel to the bolt. This was a very fun process. Going back and forth from my saw to the boat to size, mark, cut, nail and repeat! The main part of the transom comes off in one piece. I attached some guide planks to the outer pieces and the finished them with the main piece removed.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.