-

Posts

2,005 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Thanks all, JJ - it’s a fine line with how much planking to add as I still have not decided if I’m going to rig the ship and how many cannons I want if any to display. Will need to make my mind up pretty soon after I finish the Bulwark though.

- 889 replies

-

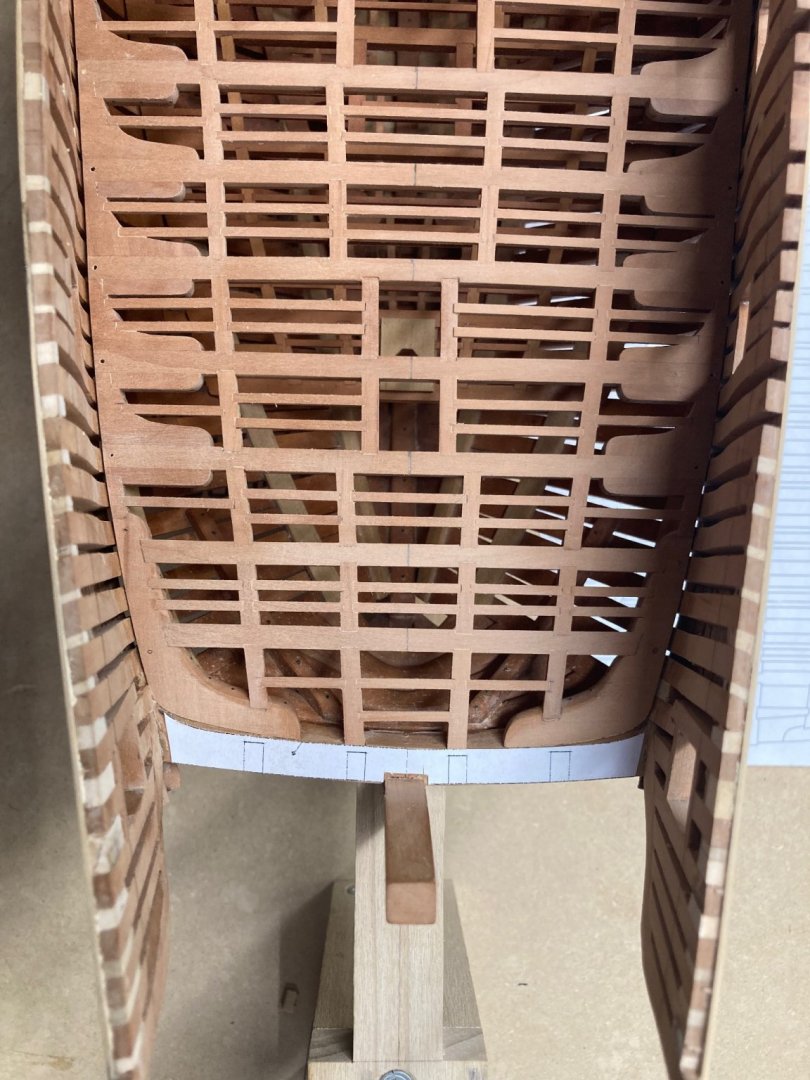

Thanks for the likes and nice comments. Upper deck framing is now completed. Next steps will be the waterways, port stops, bulwark planking up to the next deck clamps and then the stern framing. I also have to start thinking/designing how much of the upper deck will be planked and how much I will leave open so the framing and lower deck can be seen. ben

- 889 replies

-

- 889 replies

-

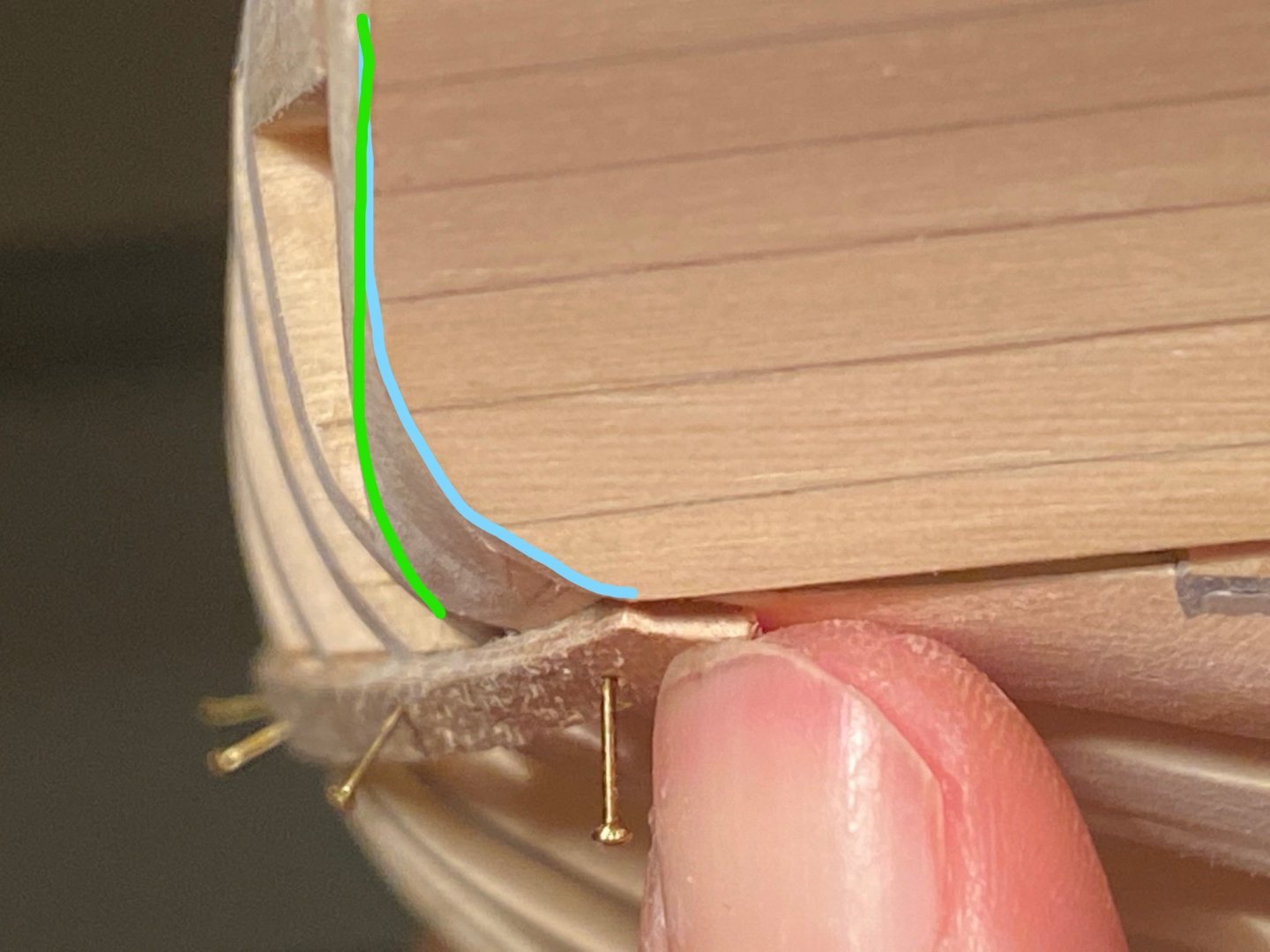

Work on the bulwark planking underway - then I have to decide if I’m going to paint it and add the fancy laser cut panels for the main cabins or not. I’m not a great painter but I’m leaning towards it for this model and trying to improve that skill set too. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 889 replies

-

Looking great, just DONT forget that you need to sand the outside of the outermost frames thinner, back to the dotted line on the plan/template after you add the QG support framing.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

NAIAD 1797 by Bitao - 1:60

Trussben replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Superb! -

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It appears to me that you have sanded the bottom of the lower counter too much, it’s easy to check - look at the plans at the stern section or print out the frieze for that area and hold it to the counter to see if you need to make adjustments, better now than when you come to plank and find it’s wrong.

-

- 889 replies

-

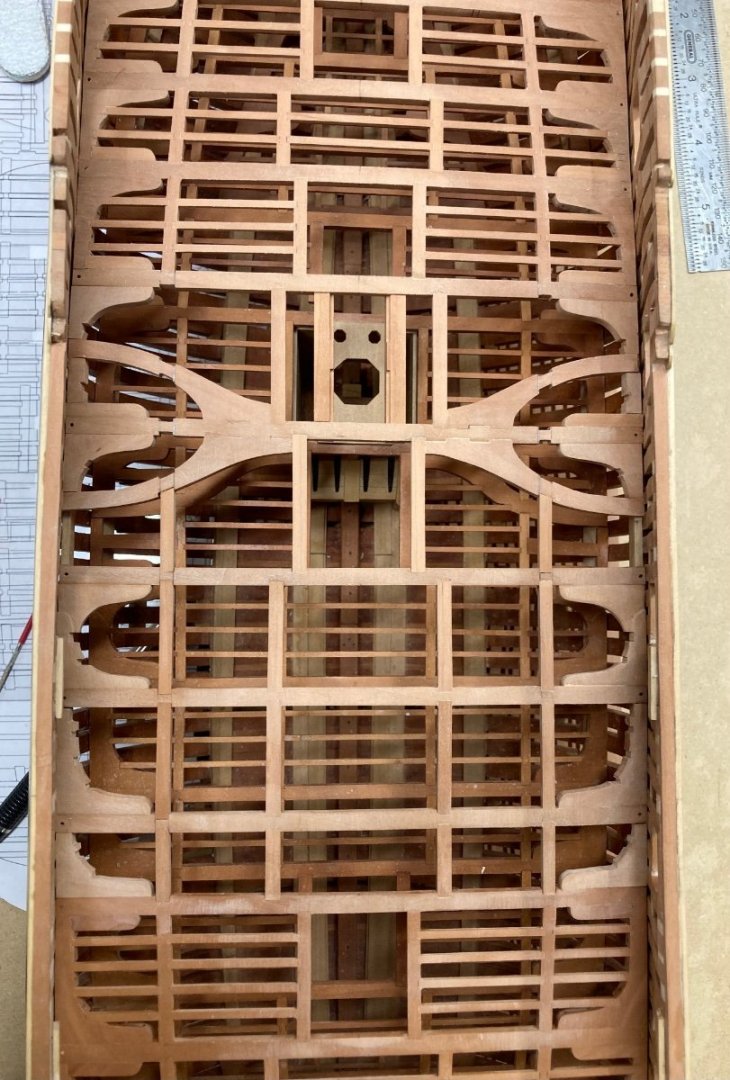

Chapter 4 work has begun. The 6 false deck parts have been installed, then the filler pieces for the hawse holes were put in.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.