-

Posts

1,995 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Are you going to add stump masts Chuck?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Gary the only place that I know that sells really good quality “ WHITE” Holly is Domex, but it’s not cheap! Expect to pay $100 for a piece 1x6x20”. http://www.domexhardwoods.com/catalog/holly-lumber

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hey Gary, Go for it! I like the look, but to purchase really nice Holly that has no grey striations is quite expensive, some of my planking shows a little bit of it even though it was good quality! But when you see it in natural light it really looks great IMO.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

ancre Le Gros Ventre by ChrisLBren - 1/36

Trussben replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Nice progress Chris! -

- 889 replies

-

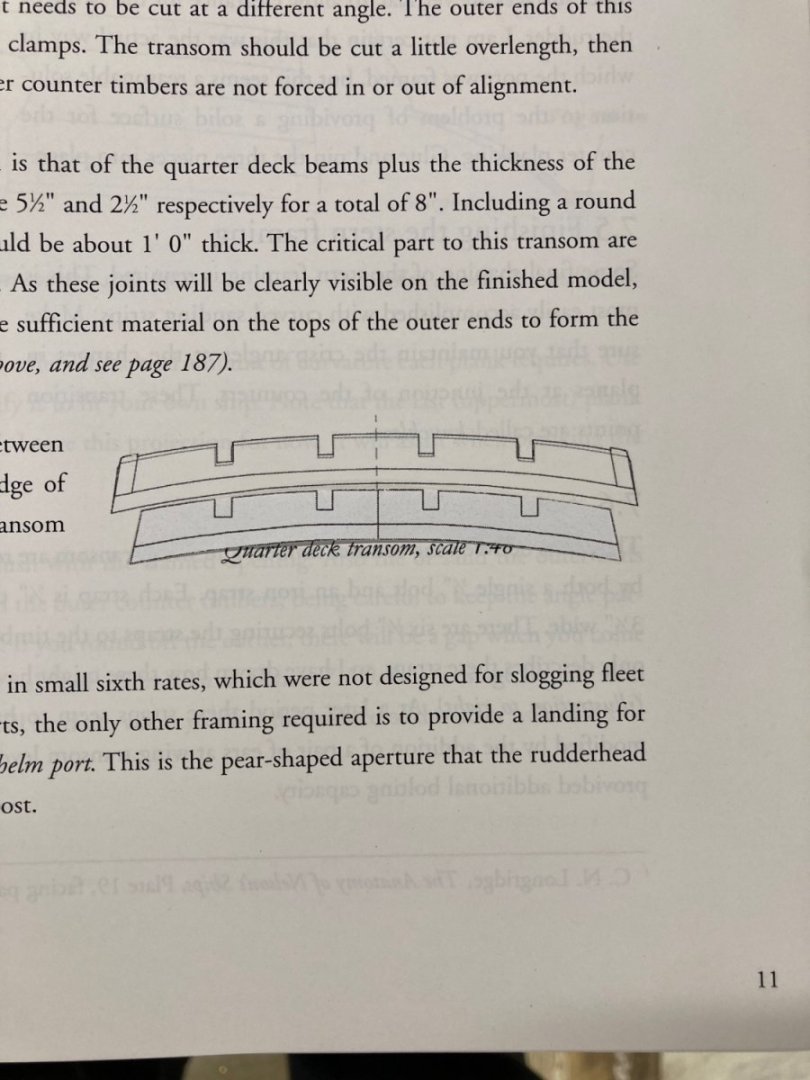

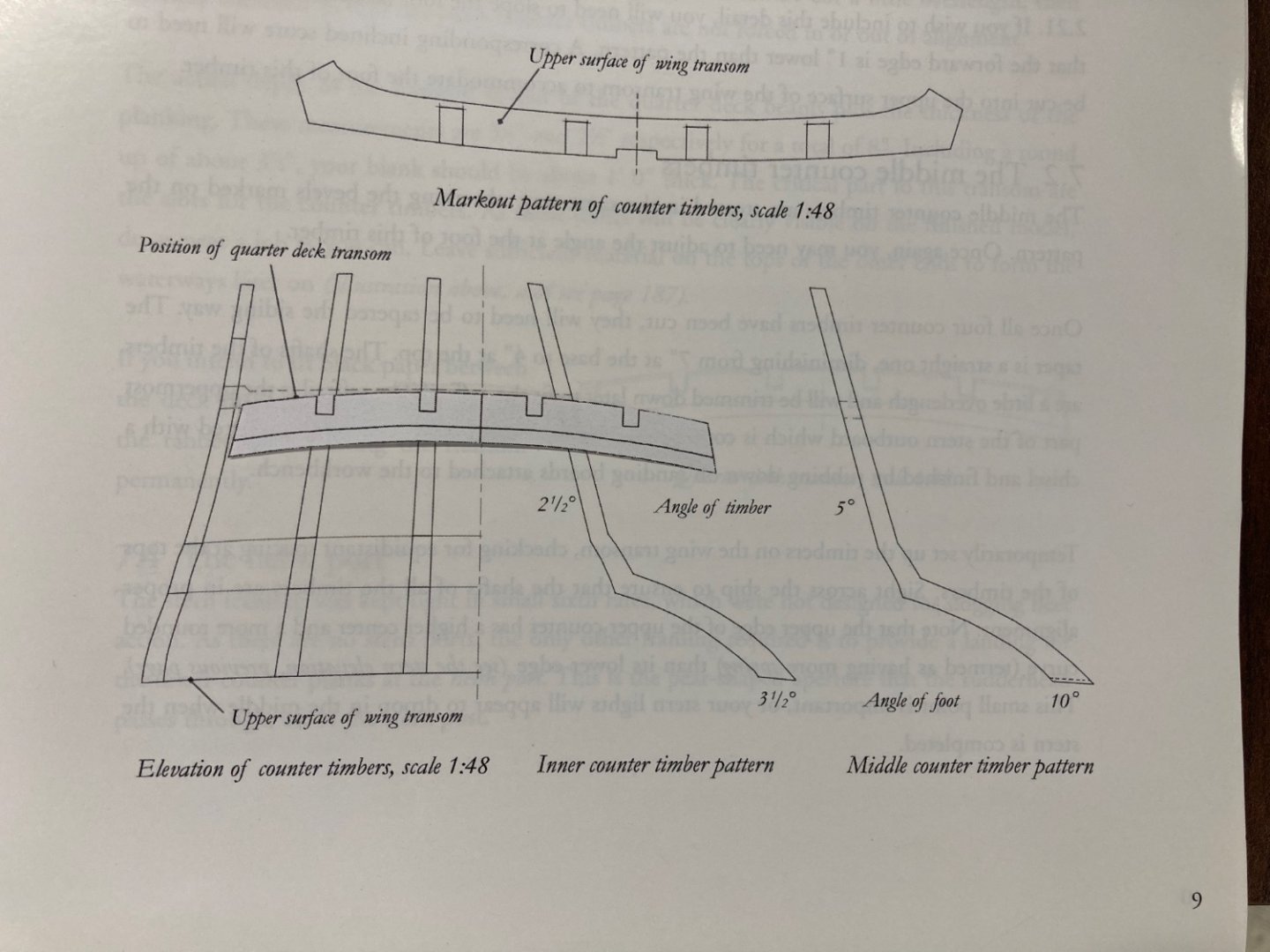

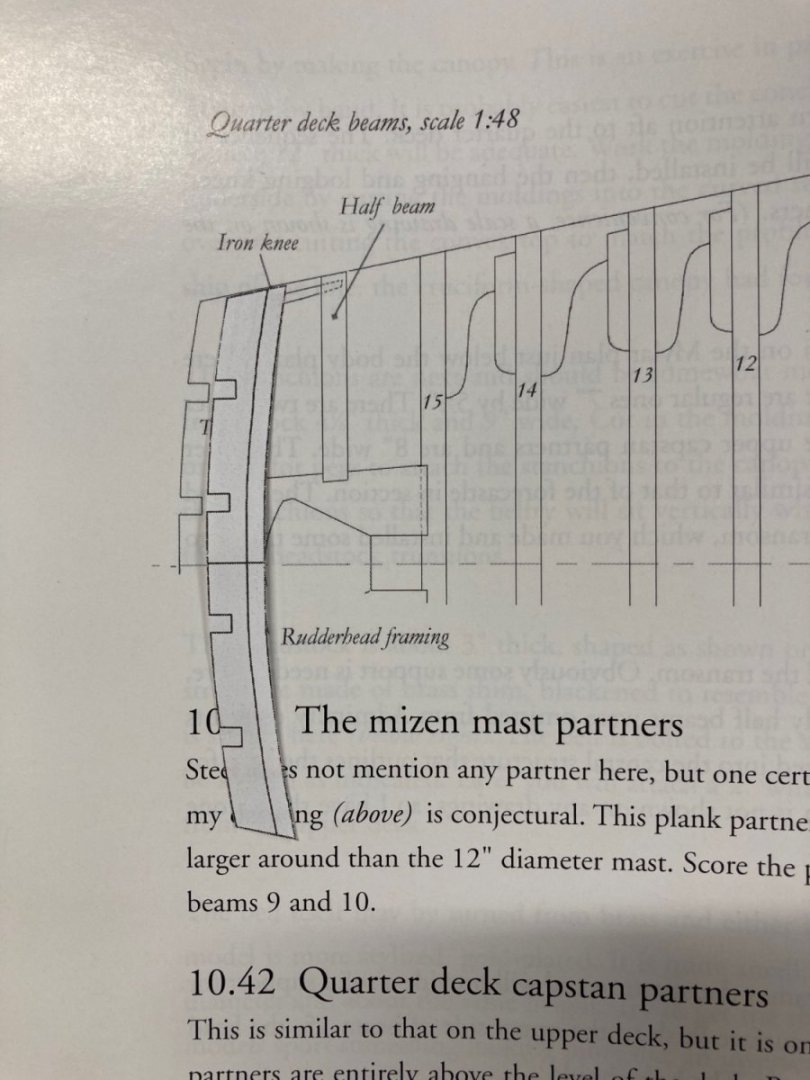

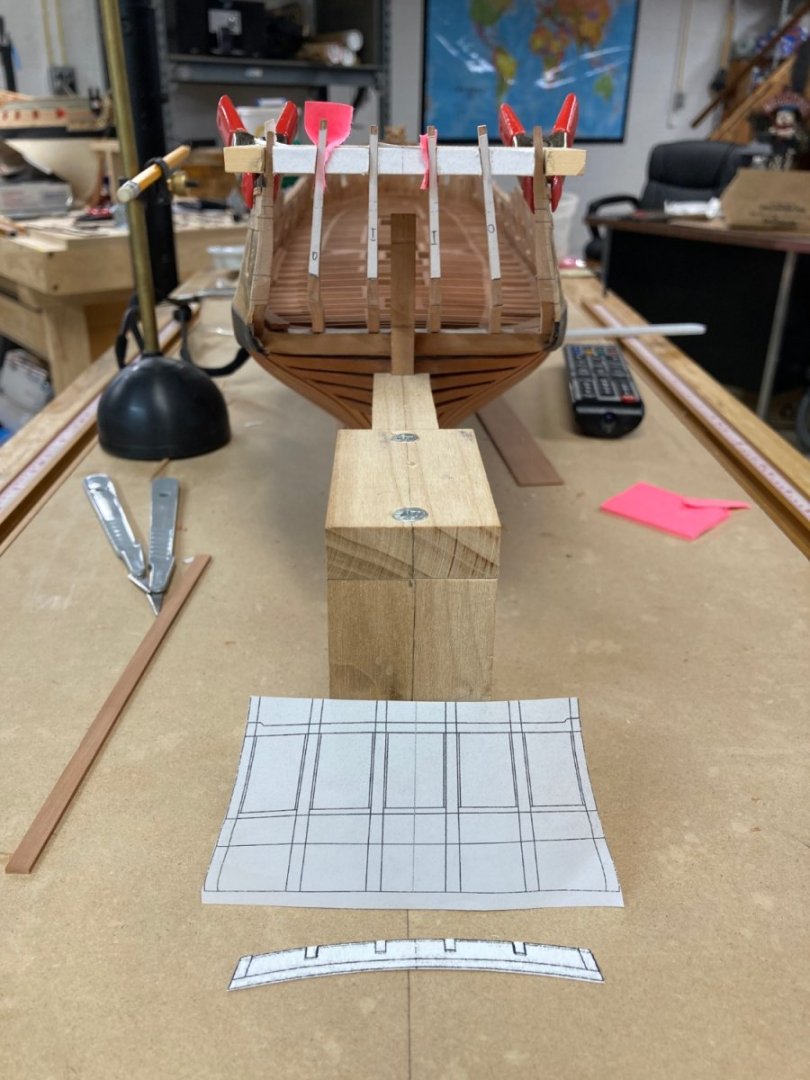

Hi All, I was having a lot of issues revolving around the QD Transom piece that I have now figured out and thought I would share with other SWAN-TFFM builders, not knowing if this has been recognized before. On page 11 of TFFM-Vol #2, there is a pattern supplied in 1:48 scale for you to use to cut out your blank with, however it appears it is not the correct size!! Let me explain that I tried using this pattern and kept finding it far to wide compared to my own Pegasus aft framing and I was starting to worry until I decided to check the pattern's width as compared to other drawings in TFFM. If you compare it VS the "elevation of counter timbers" drawing on Page #9 TFFM-Vol #2 you will find the pattern is approx 3 11/32" at its widest point but the drawing is just about 3 3/32" I decided to test it against another drawing on page #182 of TFFM-Vol #2, this shows the Quarter deck beam layouts but it also shows the QD transom on it, and this as well makes the Transom 3 3/32" wide. SO - I copied and made a template using the page #182 transom and this fit almost perfectly to my model. See some pictures below showing the difference in size and what my new one using page #182 looks like.

- 889 replies

-

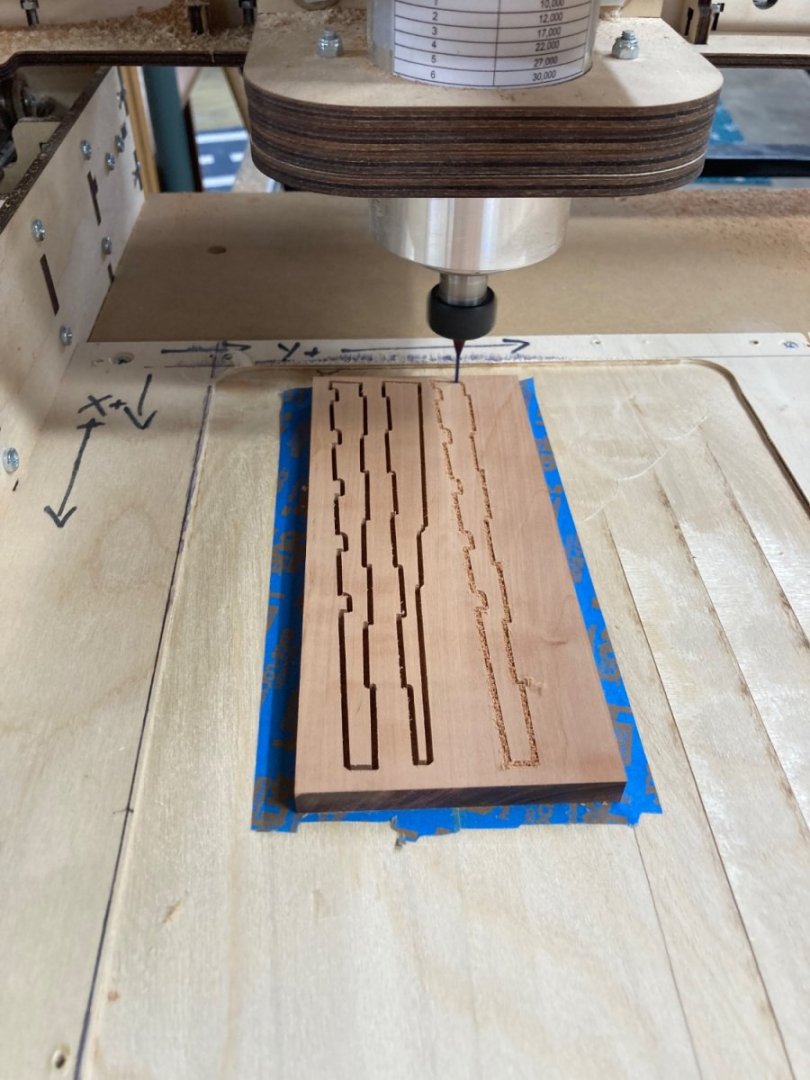

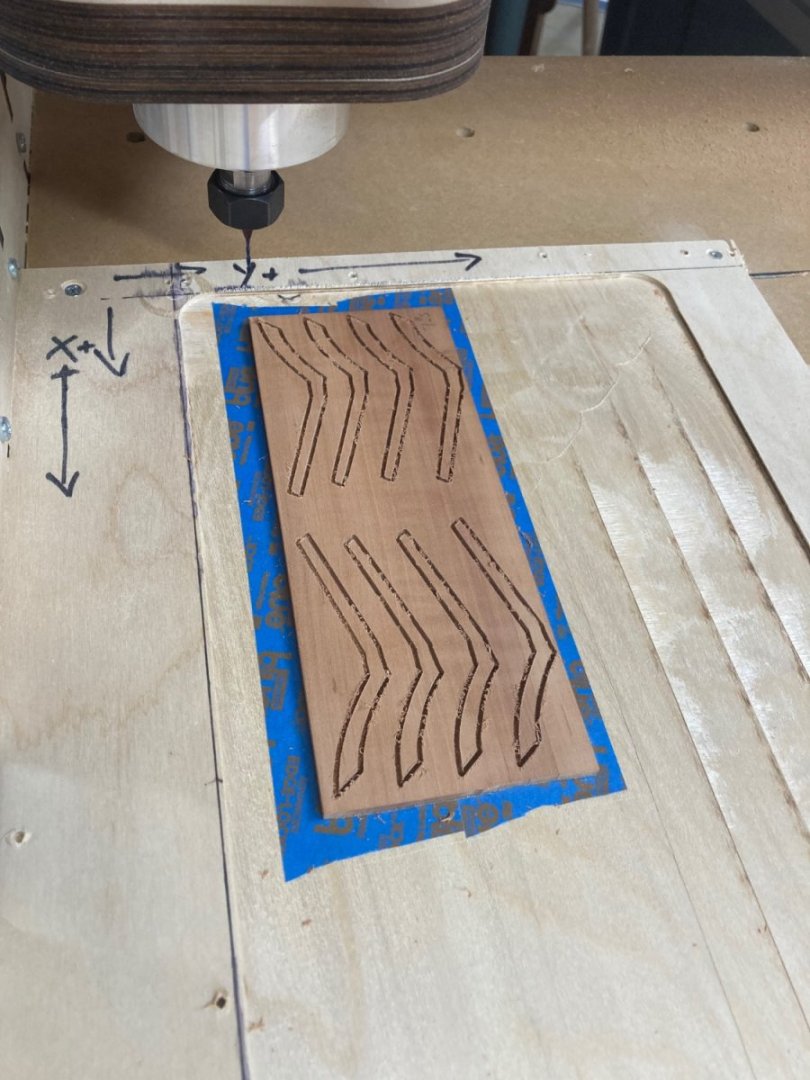

Hey Greg, Using a 1/16" router bit just leaves a slight round that just needs a quick swipe with a square file to remove. I would of used a 1/32" bit, but its cutting depth capabilities were not long enough to cut deep enough into 16" stock ( 15" + 1" for onion-skinning ). Ben

- 889 replies

-

- 889 replies

-

ancre Le Gros Ventre by ChrisLBren - 1/36

Trussben replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Nice to see you back building Chris! Looks like you have a good head of steam up now. I think we all know about trying to get free time for modelling. -

Very Very nice clean work there Steve.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Now I’m trying to figure out the layout for the stern, I see that I do need to do a bit of fairing to the outer counter Timbers to make them and the inner framing a little thinner.

- 889 replies

-

- 889 replies

-

Looking really good, I enjoyed this part of the build.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No Greg, The frieze prints are in two parts, but I believe I can do a much better job second time around trying to make it as seamless as possible, and I still have the portside to start.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Headworks on the starboard side almost complete, I think i will remove the hair bracket friezes and replace them to try to better match it all together so the seams are less visible.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’m sure your model will be as excellent as your scratch work is. Yes - Holly lower planking.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Rusty! Glenn - no secret, just many hours sanding it off using 120/220 sanding sticks and a few small diamond files.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.