-

Posts

3,050 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Jorge, For what it is worth, here is my opinion: do not attempt to use the saw (or judge it) until you have bolted it down solidly to a worktop. Do not use 'vibration dampening' rubber feet, just tighten it down directly to the bench. Get some good blades. Then, set it up from scratch following the makers' instructions. Once that is done you will be able to figure out if the saw is adequate for your needs. Bear in mind that if you replace the saw on the basis of current performance, you will have to follow the process above to set up your new one properly anyway. HTH, Bruce

-

ancre La Jacinthe 1823 by guraus - Scale 1:48

bruce d replied to guraus's topic in - Build logs for subjects built 1801 - 1850

Alexandru, Fantastic. Well done. I especially like your deck work and boat. Regards. Bruce -

Wait! Did it say the boat was collapsible, or the soldiers?

-

Newcomer looking for help with Cutty Sark rigging

bruce d replied to Ann's topic in Masting, rigging and sails

Hello Ann and welcome to MSW. Your story is proof, if any was needed, that this is a hobby with a purpose. I am sure you will get pleasure from completing a task with such deep personal connections and hopefully the forum will be useful: it usually is. Regards, Bruce -

Now that is a pretty good trick: 17ft long, 100 soldiers with kit and drawing three inches of water! Reminds me of a modern cruise ship.

-

So let's see: he was a fake bone model seller working for Bonaparte. Does that make him a Boney phoney? Or a model spy? I know, shuddup and go back to sleep ....

-

Yes it does. When I saw it, that is exactly what I thought but wondered how often is it applied to a model? Now that the subject is itching me, I will see what is hidden in my shelves or digital stash that tells the story. Thanks, Bruce

-

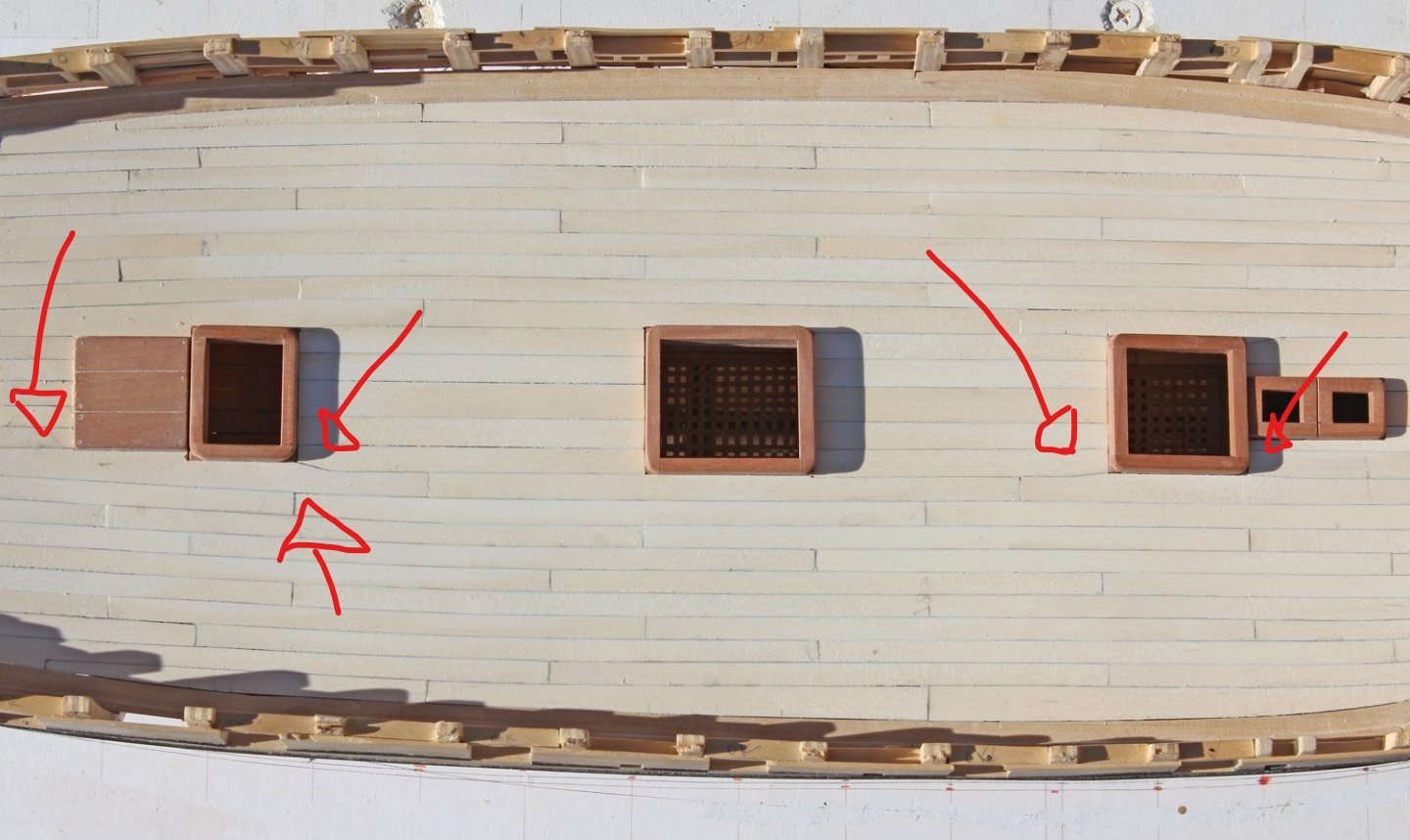

Thanks Druxey. And the next question: where is that rule written down? This isn't meant to sound picky. I looked at the planking on Toni's Swallow and saw a wide plank and a narrowed plank side-by-side to make good a section where the curve is subtle. I refer to the planking around the aft hatchway, better shown in the photo below.

-

Toni, many thanks for the first class descriptions and images. There is something in the picture in post#44 that has made me think. This hurts so I hope you can cast a bit of light on the subject. I have indicated (with bad skill) the shaped planks around the deck fixtures. I have seen something like this before but do not know the rules. Are there rules? Are they dependant on the era? Lovely job on Swallow, I am learning every day. Bruce

-

What is a jewel iron and what does it look like?

bruce d replied to Roger Fyre's topic in Masting, rigging and sails

From The New Shorter Oxford English Dictionary: jewel-block (nautical). either of two small blocks suspended at the ends of main and fore-topsail yards, through which the halyards or studding-sails are passed. There is no mention of 'jewel iron'. Hope this helps. -

Moxis, what a tidy workshop!

-

Hello Candice, I don't want to guess how the rules are applied in your area but gunsmiths use chemical blackening solutions as well. If anyone who is still trading overlaps that industry perhaps they can help? It is a sad surprise to hear hardware shops are shut. Here in the UK they are deemed essential because of the cleaning materials they sell. Good luck, Bruce

-

Hegner. Built to last, good customer service.

-

I just upgraded my Scheppach bandsaw to a METABO BAS261. I love it! Big enough to do some real work and still a benchtop machine. I used FFX Tools and they bent over backwards to get delivery sorted despite the current conditions.

-

Alan, I just want to speak up and say how much I enjoy your 'press releases'. Many thanks, Bruce

-

Mini Table Saw recommendations

bruce d replied to captainscott's topic in Modeling tools and Workshop Equipment

Tony, can I ask have you found a good UK/EU source for blades? -

MODEL LOT#8 MPM Models - Fairey Albacore 1/72 Ardpol Models - Curtiss O-IE floatplane Heller Curtiss - SBC-4 Helldiver 1/72 Phoenix Models - Kirby Cadet 1 vacform (British primary training glider: this is the simplest vacform ever) Models are free, just pay for HERMES delivery. Please let me know if you want one or more of the lots and we will use PMs for exchanging payment information. These have gotta go so don’t be shy. On hold, see post#14

-

MODEL LOT#7 Fujimi Ju-87 G-1 Stika Tnkbuster 1/72 Supermodel Macchi C.202 Folgore 1/72 Zveda LI-2 (Soviet clone of C-47/Dakota) 1/200 Models are free, just pay for HERMES delivery. Please let me know if you want one or more of the lots and we will use PMs for exchanging payment information. These have gotta go so don’t be shy. On hold, see post#14

-

MODEL LOT#6 Toko Models 1/72 Nieuport IV Toko Models 1/72 Nieuport 11 Rising Decals -‘Japanese Early Birds’ 1/72 decals for Nieuports Revell 1/72 Albatros D.III Naval Aviation Factory (Esoteric Models) F7C-1 Seahawk 1/72 vacform with decals Models are free, just pay for HERMES delivery. Please let me know if you want one or more of the lots and we will use PMs for exchanging payment information. These have gotta go so don’t be shy. On hold, see post#14

-

MODEL LOT#5 = Mixed bag aircraft & auto Glencoe Models- Indy Racer/LeSabre concept car double kit. Tamiya- Aichi Val AMT Winnie Mae Lockheed Vega Airfix Gosling (bagged) 1/72nd vacforms: Airmodel He178, VacWings Tachikawa Ki-36/55 Ida, VacWings Kyushu Q1W Lorna ---- Models are free, just pay for HERMES delivery. Please let me know if you want one or more of the lots and we will use PMs for exchanging payment information. These have gotta go so don’t be shy. On hold, see post#14

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.