-

Posts

3,039 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Vintage unfinished speedboat model, any ideas?

bruce d replied to LMDAVE's topic in Wood ship model kits

Found this, It dates from the 1960's. https://aerofred.com/details.php?image_id=93530 -

Vintage unfinished speedboat model, any ideas?

bruce d replied to LMDAVE's topic in Wood ship model kits

There is a step in the hull of your boat that I don't see on the Italian hotrod. IIRC Model Boats magazine (and maybe Marine Modelling? ) published some hydro types back then as plans, maybe worth a look? -

Hello Halfdan and a warm welcome to MSW. Both models look good and it is interesting to see what can be done with the MiniMamoli kit when it is treated seriously. Looking forward to your build log. Regards, Bruce

-

WW2 ship drawings anyone know what this is?

bruce d replied to Dean77's topic in Nautical/Naval History

https://www.klueser.de/kit.php?index=5137&language=en Sadly, it appears no logs of Mousa survived, nor is she mentioned in damage reports. Small craft logbooks are rare in The National Archives UK because most were destroyed (without proper consultation from Records Branch) to free up shelf space in the 1950's. If she is mentioned in records it will probably be as a participant in events rather than as the main subject herself. Dean, perhaps you have already applied for your grandfather's service record? It will include not only the ships on which he served but under what command, flotilla etc. This may prove worthwhile because it can reveal involvement in historic events. HTH Bruce -

Welcome from the UK, looking forward to seeing the Drakkar. Bruce

-

Which Glue

bruce d replied to Old Fart's topic in Building, Framing, Planking and plating a ships hull and deck

It is interesting to see what these guys... https://www.talkbass.com/threads/confused-about-glue.1329881/ ... have to say. The Luthiers Mercantile Yellow product first appears in post#9. I found their observations about the differences in sanding LMY and Titebond a real eye-opener. Also, I was unaware of just how much difference there is between Titebond products until reading this. -

WW2 ship drawings anyone know what this is?

bruce d replied to Dean77's topic in Nautical/Naval History

Dean, The blood chit is in good condition compared to many I have seen, They came in many forms depending on where they were needed. Here is one: https://www.iwm.org.uk/collections/item/object/30081074 ... and judging from the number of languages on yours the user was expecteing to travel a lot! -

WW2 ship drawings anyone know what this is?

bruce d replied to Dean77's topic in Nautical/Naval History

What good pieces of history, you must be happy to know they are in safe hands. It is possible the 'GENOVA' in the text of the plans refers to the city of that name, but I don't speak Italian so someone else will have to comment on that. There was a ship named GENOVA but at a glance the dates don't line up: "Empire Swan Empire Swan was a 7,965 GRT cargo ship which was built by Merchant Shipbuilding Corp, Chester, Pennsylvania. Completed in June 1925 as Missourian for American Hawaiian Steamship Co. To MoWT in 1940 and renamed Empire Swan. Allocated in 1942 to the Belgian Government and renamed Belgian Freighter. Sold in 1946 to Compagnie Maritime Belge and renamed Capitaine Potie. Sold in 1948 to Compagnia Genovese di Navigazione a Vapore SA, Genoa and renamed Genova. Sold in 1955 to Compagnia Genovese di Armamento and renamed Flaminia. Now 8,791 GRT. Sold in 1963 to Compra Vendita Covena, Genoa. Sold in 1965 to Bakhashab Mohammed Abubakur, Saudi Arabia and renamed King Abdelaziz. Arrived on 23 April 1970 at Kaohsiung, Taiwan for scrapping. " HTH, Bruce -

OK, I will tell you what I thought when I first saw the picture: it looks like one of the publications put out by museums to describe the exhibits. The second booklet in the picture has the same style. So, no, I do not know the book but ... look for museum publications about SS Great Britain to get you started. Have you tried a Google Image Search? HTH Bruce

- 3 replies

-

- drawingsplans

- steam ships

-

(and 2 more)

Tagged with:

-

Update: the replies above suggested that it was not common practice to clean the copper on a ship. I thought differently but had to admit I could not point to anything that confirmed the practice. Today I stumbled on an entry in the description of a document held at The National Archives UK which clears up the matter. Document ID: ADM 359/47C/72, dated August 13 1827 'Copy letter from the Sheerness Officers stating that it has been the general practice for the scrubbing of ships' bottoms to clean the copper to be carried out by the crews of the ships. Mr Abethell states that while he was a Foreman in Plymouth for 7-8 years, it was the invariable rule to have the copper cleaned by the ship's company. This was the case with the Prince Regent, the flagship of the Port Admiral when he docked here last August. Captain Horton said that when the Gloucester docked here in July 1825, no such requisition was made by Mr Lang, the then Master Shipwright.' The original is held by the National Maritime Museum and is included in the catalogue of The National Archives. Perhaps other navies had different views on the subject but this shows that the practice in England was to clean the copper. HTH Bruce

-

I know it rambled a bit but the answer is in post#22. Also, since then I have had confirmation of the practice. The turning point from tapered to straight planks being the norm is the introduction of (and gradual access to) advances in sawmills. A plank cut by hand using a sawpit does not have to be straight and may as well use the natural taper of the log, whereas a log run through a sawmill will have straight edges as the norm and be much quicker (= cheaper) to produce. So, after a shipyard installs an adequate sawmill, the bulk of the planking will be straight. Some yards mixed the two, perhaps under terms of a contract since change takes time. Of course joggling was still needed and generally followed traditional practice.

-

It has been an entertaining show and I am sure others have enjoyed it as much as I have. Add to the topic? I would never assume anything I stumble across is 'news' to you so … tell us what you are still looking for. Thanks, Bruce

-

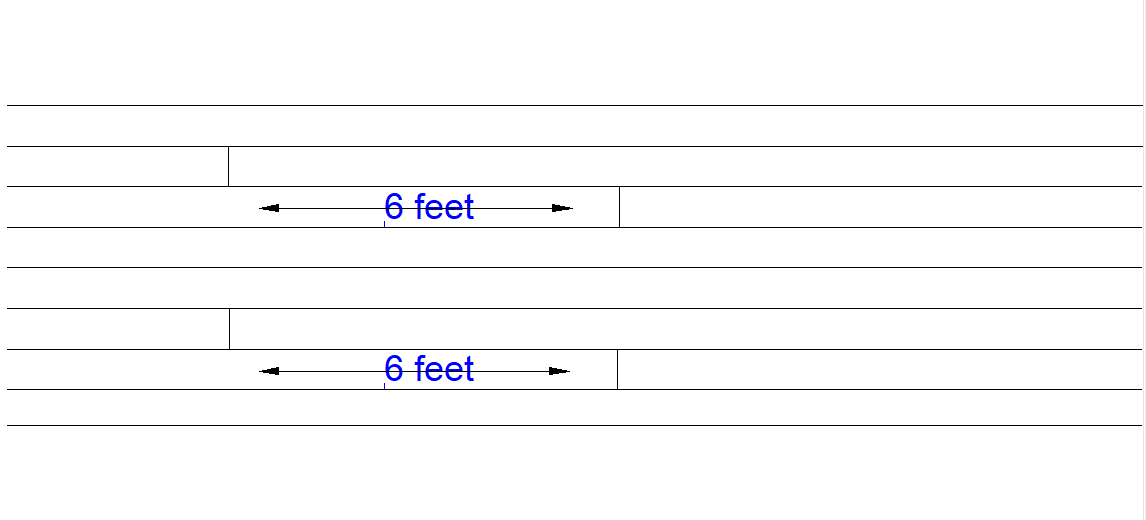

It is very possible that we have been mixing our apples and oranges. I certainly have, because the English practice did not reflect the American rule quoted. The original question concerned an 1855 ship, HMCSS Victoria. Jaager's answer quoted text from an American rule of building from around that time. However, the illustration which first appeared in post#2 is from Goodwin's The Construction And Fitting Of English Men Of War 1650-1850, clearly a work on English ships. According to Langridge, Anatomy of Nelson's Ships, and David White Traditional Wooden Shipbuilding (pt 9), the illustration in post#2 from Goodwin's The Construction And Fitting Of English Men Of War 1650-1850 is correct. It is worth pointing out that all three of these works mentioned are based on original sources and not rehashhes of the work of others. I do not have access to their original sources but accept their findings. To quote White (Traditional Wooden Shipbuilding (pt 9) Model Shipwright 63, page 56): '...(the planks) should be worked to a three plank shift, which meant that there should be three whole planks between any two butts on the same beam. Second, the butts had to overlaunch or be shifted at least 6ft. That is to say the butts in any two adjacent planks should not be closer together than 6ft.' He illustrates his description with a drawing which I have recreated below. It shows two butts on adjacent rows of planks and they are 6 feet apart, hence they conform to the requirements. The '6ft overlaunch or shift’ is the rule that he cites, not the number of beams. He does not quote any rule at any point that I have yet found which requires a minimum number of beams between butts; to the contrary, he describes what to do when butts are on adjacent planks. He also tells in detail how to work around hatches, deck fittings etc but that is beyond the original question. So, if the ship is being built to English rules and the layout of the deck and the shift pattern calls for it , keep six or more scale feet between butts when on adjacent planks and you are ‘legit’, whether it is a three, four or five butt shift. It seems that the clarity of the American rule is admirable but does not reflect English practice. HTH Bruce

-

That is the part. I have now looked at a few examples and wonder (as mentioned in post#12 above) if it was (A) an American rule and (B) ... … is not something I have used but does the '1870' indicate a different date and practice? I don't know the answer but someone does. If there is an error in Longridge's Anatomy of Nelson's Ships we should nail it down.

-

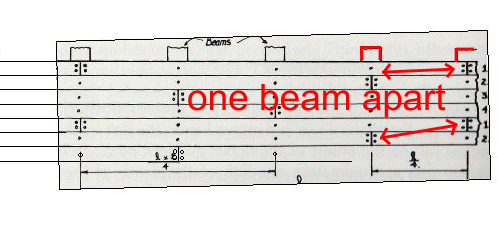

Sketch 2, row 1 and 2, from the top: Right hand side, the butts are one beam apart. I have looked at the original in Anatomy of Nelson's Ships countless times and didn't see it even when I was writing my 'program notes' for the deck I am laying out. Whether I would or would not have picked it up when cutting holly, who knows? All I can say is 'better late than never'. Thanks Jaager.

-

Welcome to MSW and let me add my compliments. That is a good looking ship.

-

Kevin, well done. Untill I watched I didn't 'get' the decision to use a master with grooves cut in, or for that matter how to make the grooves. Now I get it and clearly it is a good way to produce identical boats. A couple of questions, if you don't mind. (They will not make sense to anyone who hasn't watched the video) Once the ribs/frames were in place, you sanded them down. I get that and of course this was possible because the ribs were supported in the grooves in which they were sitting, but still I wonder how you went about the sanding without overstressing the already small pieces. Hand held sanding block? Rotary tool? The PVA release agent looks like a good find, well done English (see the video to decipher that message). If I am hearing your dialogue correctly you say that it left a residue: is that correct? Does the residue peel off or does it perhaps soak in to the wood which may affect later finishes? Thanks for taking the time to produce the videos. Bruce

-

Found this; La Belle.pdf LA BELLE: RIGGING IN THE DAYS OF THE SPRITSAIL TOPMAST, A RECONSTRUCTION OF A SEVENTEENTH-CENTURY SHIP’S RIG A Thesis by CATHARINE LEIGH INBODY CORDER - La Belle was a late 17c French vessel that was described as a barque or 'small figate'. Many artifacts illustrated and direct comparisons with the practices of other countries. Should be useful if considering a subject from 17th-18th centuries. HTH Bruce

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.