-

Posts

3,046 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

A collection of nice ship kits has about 23 hours to run on ebay UK. Golden Hind by Scientific, Bounty by Constructo,Seeadler and Toulonaise by Billing Boats. Gotta be worth a look, use Ebay search for item number 363033792880 Mods, please move if needed but there is limited time. Also, the sale is nothing to do with me.

-

Keel taper question

bruce d replied to bruce d's topic in Building, Framing, Planking and plating a ships hull and deck

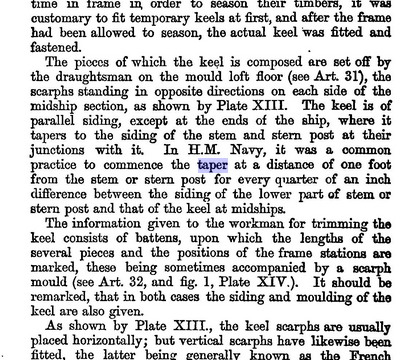

This looks like a pretty clear statement on the subject: ... from page 179 of Naval Architecture: A Treatise on Laying Off and Building Wood, Iron, and Composite Ships (1876) by Samuel James Pope Thearle Naval Architecture- A Treatise on Laying Off and Building Wood, Iron, and Composite Ships 1876.pdf Writing in 1876 his wording indicates he is describing an outdated practice but does not nail down when it was in use. -

Keel taper question

bruce d replied to bruce d's topic in Building, Framing, Planking and plating a ships hull and deck

Well, I should have known that trick but DOHH! it makes a difference. Thanks. The subject clearly has demanded the best forensic approaches by some very experienced members. For example, from about post#197 in this thread... ... some clear light is cast on the subject and I have looked at the source documents cited. Yet, the source is describing practice in English shipyards and is biased on larger ships. The rule(s) related there are difficult for me to imagine were appropriate for a schooner, but I am not able to point to an alternative rule. However, the guidelines for keel taper explained by Mark in post#2 in this thread make sense and seem to be reflected in a drawing I have seen of a late 19th century Bermuda built yacht. Thanks for the input, I appreciate the help. -

Welcome to MSW Gerry, wonderful work on the mandolin.

-

Matthias from Berlin, Germany says Hello

bruce d replied to victory78's topic in New member Introductions

Welcome Matthias, I look forward to seeing your fishing boat. -

Keel taper question

bruce d replied to bruce d's topic in Building, Framing, Planking and plating a ships hull and deck

Apropos to nothing at all, the keels of Bermuda built craft at that time were usually Honduran mahogany. -

Keel taper question

bruce d replied to bruce d's topic in Building, Framing, Planking and plating a ships hull and deck

Me neither! I know it exists because I scribbled in a margin on a drawing 'taper: see discussion'. The explanation you gave tallies with my recollection, many thanks. Since this much too early for such sport I expect there was another practical reason for a tapered keel. The only guess I am willing to put forward is the belief that maximum strength was needed in the middle of the hull structure and the taper was seen as part of the process of fairing in all underwater lines. Stem and sternposts did not need to be as wide as the widest part of the keel but the keel needed to be one continuous piece (thanks to scarphs) so they were used as the reference points for the fairing. Maybe one day one of us will find 'the discussion'. but for the moment I believe I have seen enough to carry on. Don't want to shock anyone but I may be starting a build log soon .... Thank you both, Bruce -

Hello, I am looking for some help. It concerns the keel of a Bermuda built schooner circa 1800. The keel is 10 inches breadth tapering to seven inches at each end. The question is: where does the taper commence? The options seem to be … (1) There is a section in the middle of the keel where the sides are parallel and then the taper begins at a point approaching each end. If so, where does the taper begin? (2) The keel has little or no parallel section with the tapers starting from (presumably?) the width extreme point. It would be very easy reading various scantlings to believe this was the intention. This option seems pointless but what do I know? Thanks in advance, Bruce

-

Christian, I understand your feelings, and I have also had a difference when posting pictures. Something is different but I am not a 'techie' so can only say that I made it work recently by uploading the pictures and placing the cursor where I wanted the picture before hitting ' + '. This may be a bad explanation but it possible. Read what your friends say above! Please continue to post!

-

Excellent work, Richard, I will join the audience if you don't mind.

- 30 replies

-

- armed launch

- panart

-

(and 1 more)

Tagged with:

-

Looks that way. I can't think of any other use, will watch for comments.

-

Totally by chance, another current thread may have come to the rescue. The thread 'Deck Layout Mermaid Cutter 1817' by Cabbie ... ... has images from the drawings of Phillip Parker King between 1817 and 1822. The second image in that thread I have pasted below: The block and line (whatever it is called) is present and better illustrated. It goes loosely under the boom and sail. Perhaps one of the more salty members knows the function of such a line, but I don't. HTH Bruce

-

Hi from15 nm west of Hamburg / Northern Germany

bruce d replied to Oboship's topic in New member Introductions

Hello Uwe and welcome to MSW. -

I see what you mean. It clearly goes either side of the sail yet the port side line seems to have no termination point. It can't be secured to the gaff boom because we can see that the lowest edge of the sail is behind the boom. ? Well, my comment doesn't get you closer to an answer but I will follow along to see what happens.

-

Those sails look fantastic. I appreciate this advice, doing experiments to find the 'right stuff' is not my favorite use of time.

-

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Ah, good, that is what I thought. -

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Here is a more contemporary scene: ... in the NMM collection, "British and American Gunboats in Action on Lake Borgne, 14 December 1814" Date made: Early to mid 19th century by Hornbrook, Thomas Lyde This painting shows how I imagine a schooner the size of Pickle would have rigged boarding nets (I suppose technically anti-boarding nets), but I have nothing to verify that. The nets illustrated are bulky and, if the ship faced a threat of boarding, would have been useless if not available quickly. Would it make sense for a modest craft like Pickle to stow them below decks? I don't want to speculate, so will keep an open mind. Perhaps the answer is in Gilkerson's books. -

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

This is the way Dodd portrayed Pickle under the guidance of Lapenotiere, her captain: The naked woman rescued from the water at Trafalgar by Pickle's boats was from the burning French Achille. Her name was Jeanette: close enough? Bruce -

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Eyewitness account of a midshipman in Euralus (later retired as Rear Admiral) Hercule Robinson. Also, although I do not have access at the moment, there is a mention in Pickle's logs of 'nets' without further details. Pickle was active as a fighting ship as well as a messenger. She was involved in blockade duties and her boats were part of cutting out operations and raids, plus she had close encounters with gunboats and other small craft. I am open minded but am having trouble visualising the sailplan of Pickle supporting the nets shown in your illustration. I had imagined nets along the sides ready to foul the efforts of hostile small boats, but perhaps you are right. I suppose the basic question is if the nets were stored on deck what might this have looked like. I do not intend to model Pickle with her nets out. -

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

These books are news to me, many thanks. I have looked for reviews and citations and they seem to be the go-to source for the subject. I have put them on that 'wish list' I keep in the drawer with my lottery tickets. In the meantime, I am hoping for a bit of guidance to finalise the deck layout of the plans I am drawing. I don't want to speculate too much but if the nets were stored on the deck it would not be a surprise. -

Boarding nets

bruce d replied to bruce d's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Morning Mark, Thanks, but it seems not. What started me down this path is finding that HMS Pickle had her boarding nets up at Trafalgar. I wasn't expecting that. Regards, Bruce -

Mods: please move if this is not the right forum. I wonder if someone has some answers about boarding rigging, Nelson era. All info welcome but my interest is focussed on one of HM schooners. 1 - Was boarding netting stowed on deck? If so, what did it look like? 2 - Were there standard sizes and materials? Concerning 1 above, in my case there were only four of the potential 14 guns mounted so there would have been more room for storage around the deck, if such a thing was permissable. Thanks, Bruce

-

Byrnes machinery dust collection

bruce d replied to Bill Hill's topic in Modeling tools and Workshop Equipment

I have a 'Henry' vac set up as a dust collector. The noise factor was originally bothersome but that changed when I finally got around to making a proper spot for it under a bench. It was absurdely simple: I sat it on a piece of styrene foam and it became quiet! Presumably the hard plastic wheels resting on the wooden shelf had been the source of the racket. Now it stays running for long periods and I can listen to the radio. BTW, I made an impromptu hose adapter by cutting the bottom off of an empty plastic pill bottle. The bottle's lid-end fits the sander and the Proxxon saw, the other fat end fits the Henry hose. -

Need CAD type program

bruce d replied to Sambini's topic in CAD and 3D Modelling/Drafting Plans with Software

My brain hurts. I have now, thanks to the help received from Ab, Rene' and Terry, imported the background image I wanted into the Delftship workpiece and adjusted it to the correct size. This absolutely basic step is now complete and I can plug away to get a good result. The learning process also illuminated a number of the features within the software and I can see how some of the other stages will be more straightforward now. Delftship is no doubt a marvellous tool for modellers with the patience to learn the techniques peculiar to this software and I can only hope that one day there will be a 'DELFTSHIP LITE' version without the sophistication of the professional ship-designers requirements. It sounds odd but I believe the complications I encountered could be eliminated if the advanced features were stripped away. It would be of more use to modellers with only the basic tools to produce detailed drawings, not the 'real' shipbuilders' calculations and options. I would pay for a version tailored to that narrow specification. Also, a tutorial for a 'draw only' edition could be much more focussed and I believe could make the product commercially viable. Perhaps I am a dinosaur and more nimble minds would have danced through the steps that defeated me, but we shall see what happens now that I am up and running (well, not running but moving along anyway). Many thanks to all concerned, especially Terry who stepped in to shine further light on the subject. Regards, Bruce

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.