-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

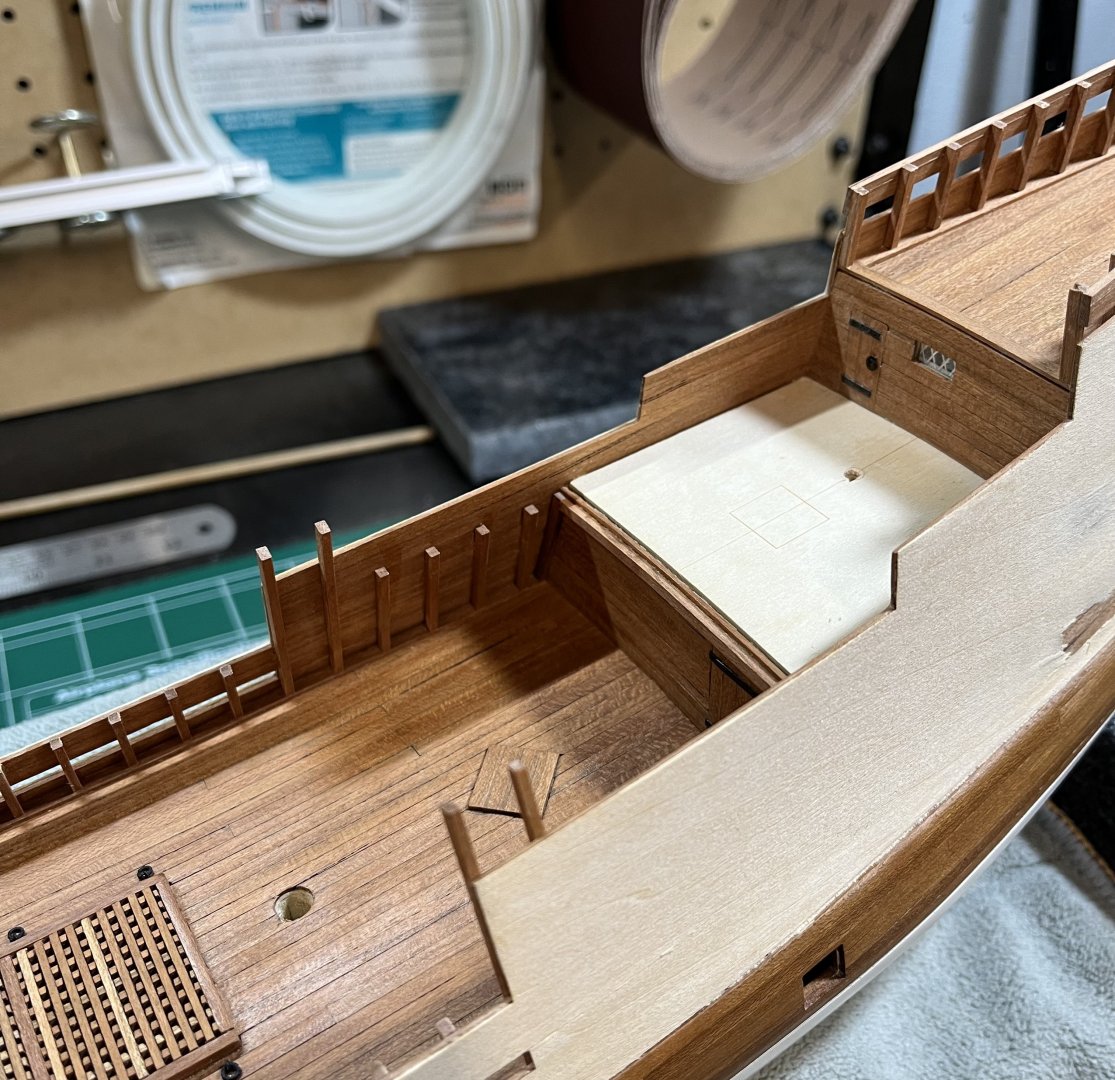

Construction under the half deck is complete minus the capstan. Beams are installed between the planked “j” templates. The decorative knees and columns are also added. You’ll notice a 1/32”x1/32” strip installed over the beam. This will sit flush with the deck when it’s added to create a smooth transition with the cherry deck planking. More sanding of the bulwarks and capstan construction is next. For those of you following- thank you for all the likes! Steve

-

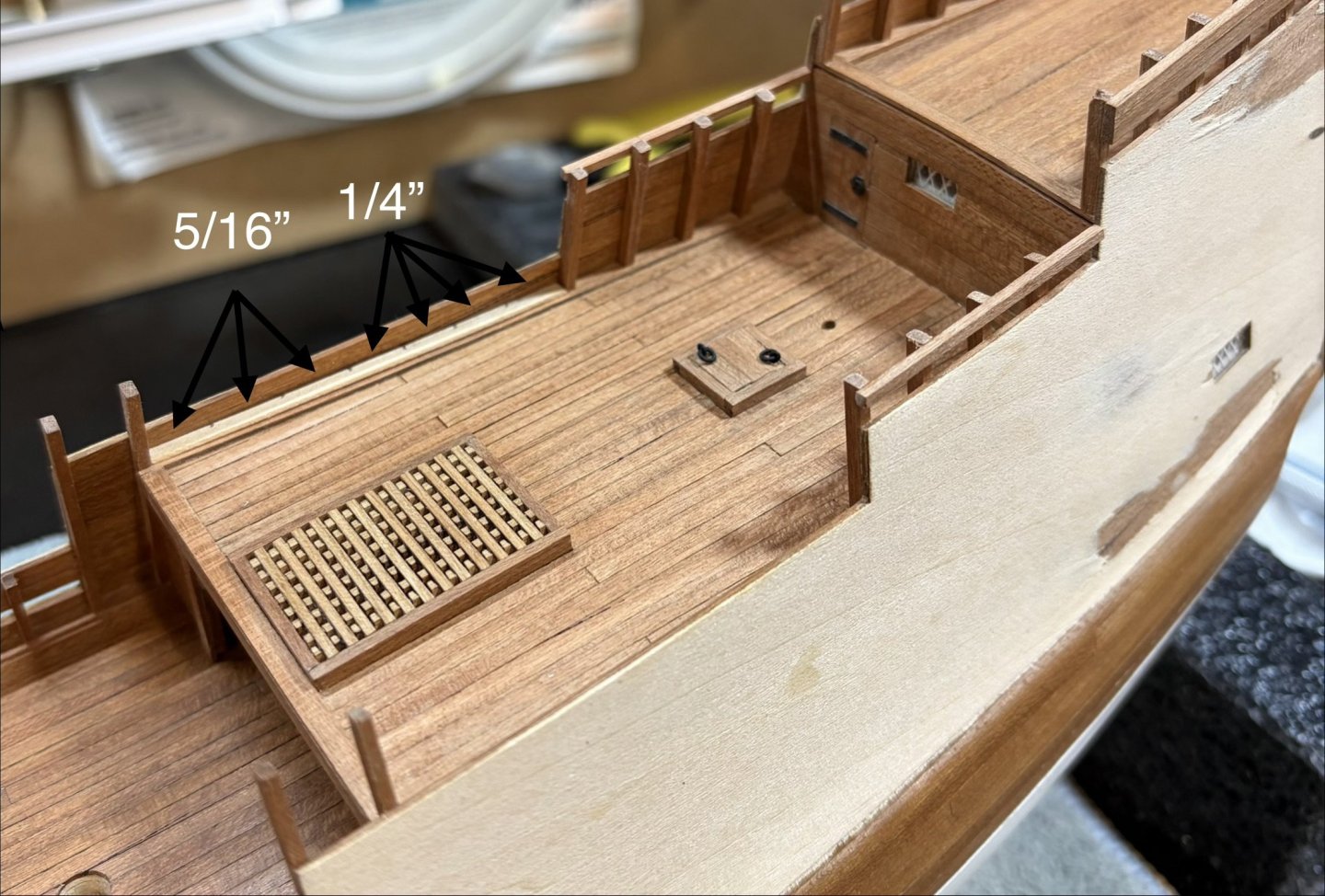

Below quarter deck stanchions complete. These were spaced with a 5/16” strip. I also installed the first beam across the great cabin bulkhead. I am constructing the stanchions in two parts, above and below the quarter deck, to avoid having to notch the waterways. (Yes, another “hack” from Stuntflyer!) Steve

-

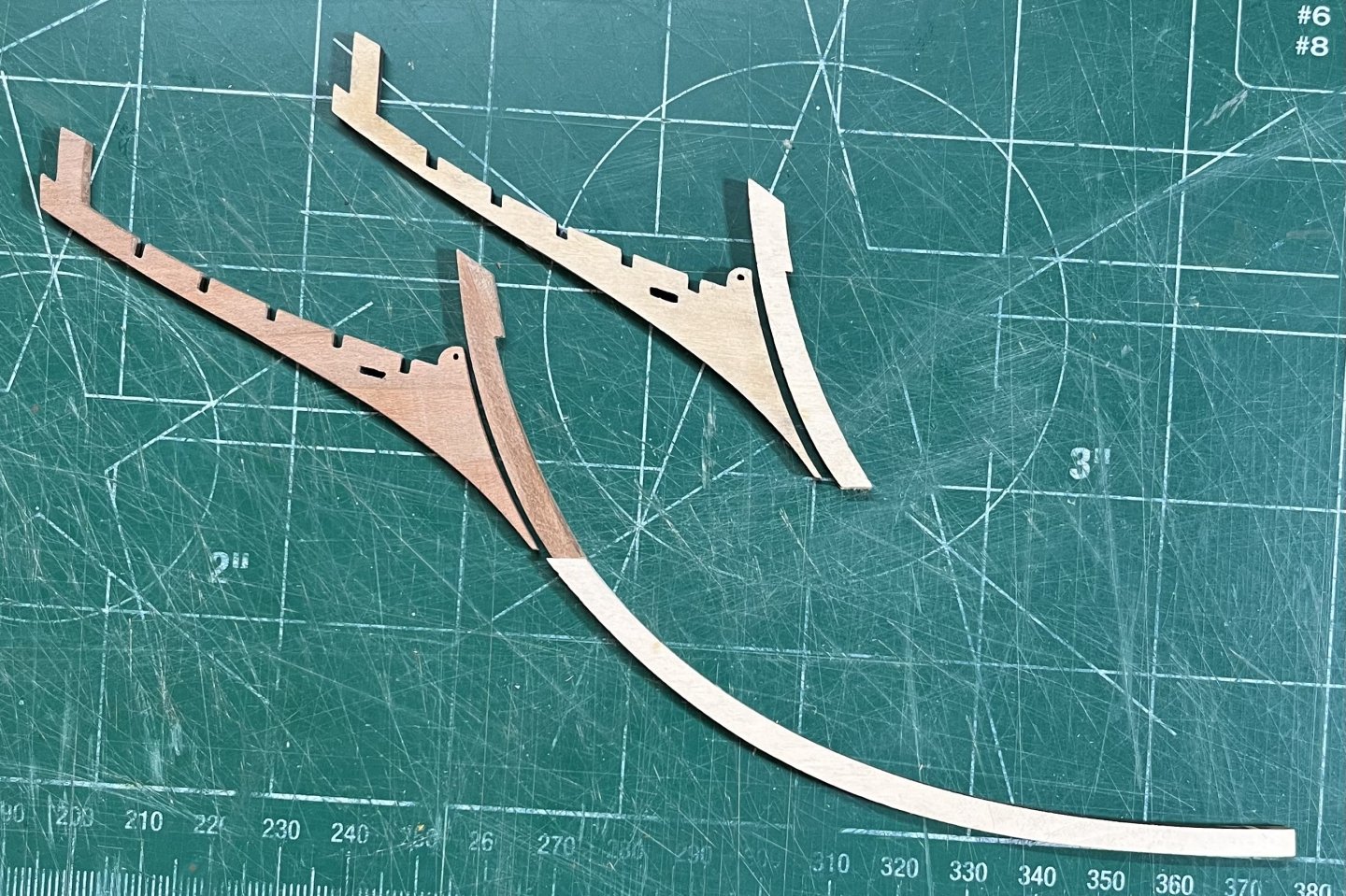

Poop deck stanchions complete. Same procedure as with the forecastle. The transom did need to be raised about 1/16” to accommodate the pre-planking. I noticed in Mike’s log that he had to do the same. More sanding was done on the bulwark templates to get them to 1/32” thick. One photo shows how I measured the thickness. The smaller pre-planking pieces were custom shaped. 1/8” x 1/16” strips did not fit the space proper. One photo points to this area. Just like with the forecastle, there were many redos on this part. Forward progress still outweighs the setbacks. Steve

-

Completing the forecastle stanchions and pre-planking was tedious and required planning and concentration. I’ll outline what I did to assist those few building this kit. I started by sanding and applying Wipe On Poly to the 1/16” x 3/32” strips. I measured 1” sections and cut them using the mini chop saw that I used earlier in this project. The corner stanchions were installed first so I could plan the spacing of the rest of the stanchions. I created tick-strips out of scrap basswood to mark even spacing for the appropriate number of stanchions as shown on the plans. Make sure you check the plans carefully here. Pin rails will be mounted later to specific stanchions. I taped the tick-strips to the deck so I had visible reference points while installing. This was absolutely necessary to line up the stanchions. Using spacers did not work for me here so I adjusted them by eye. I remounted several along the way. It took several days to figure out this method. The pre-planking was prepared and sanded before cutting to length. These were not treated with WOP as they will be painted later on. I installed the fore and aft pieces first. This helped when mounting the side pieces. See photos for this and the method I used to bend these pieces. Hot water then bending as shown. Excess lengths were cut using a sprue cutter. I tried a rotary tool first, but this was a mistake. Sanding sticks were used to polish the rest. I will round the stanchions after the rest are installed on the poop and upper deck. I hope these methods provide useful to others. Steve

-

The stem, keel, and stern post have been installed. Some wood filler was added after these were installed to seal any gaps. Before working on the bulwark stanchions, I added the waterways along the sides of the forecastle, poop deck, and upper deck. I will photograph the waterways after I compete the stanchions. Steve

-

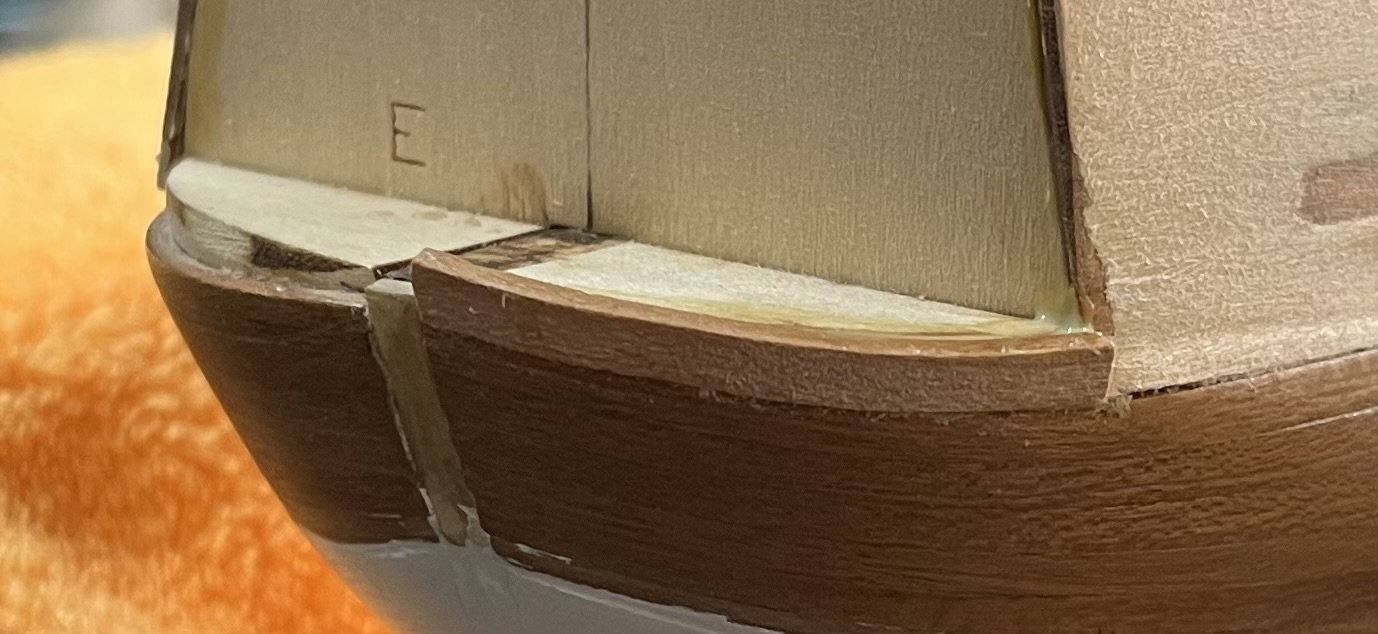

Behold the stern completed. When creating the windows, I did not cut the 1/16” framing tape down to 1/32”. At the time I did not think it would make much of a difference, but at this scale it does! After the windows were mounted on the ship I added 1/32” x 1/16” wood strips on the top and bottom to create a thinner reveal of the white tape around the windows. This helped. The knees were created in cherry as shown in the photo. As with many parts of the project, I figured the stern would be easy. I was proved wrong, as I had to make many adjustments to accomplish acceptable results. I am learning not to linger too long on a particular part of the project, only redoing things that look out of place or inconsistent with the rest of the ship. Steve

-

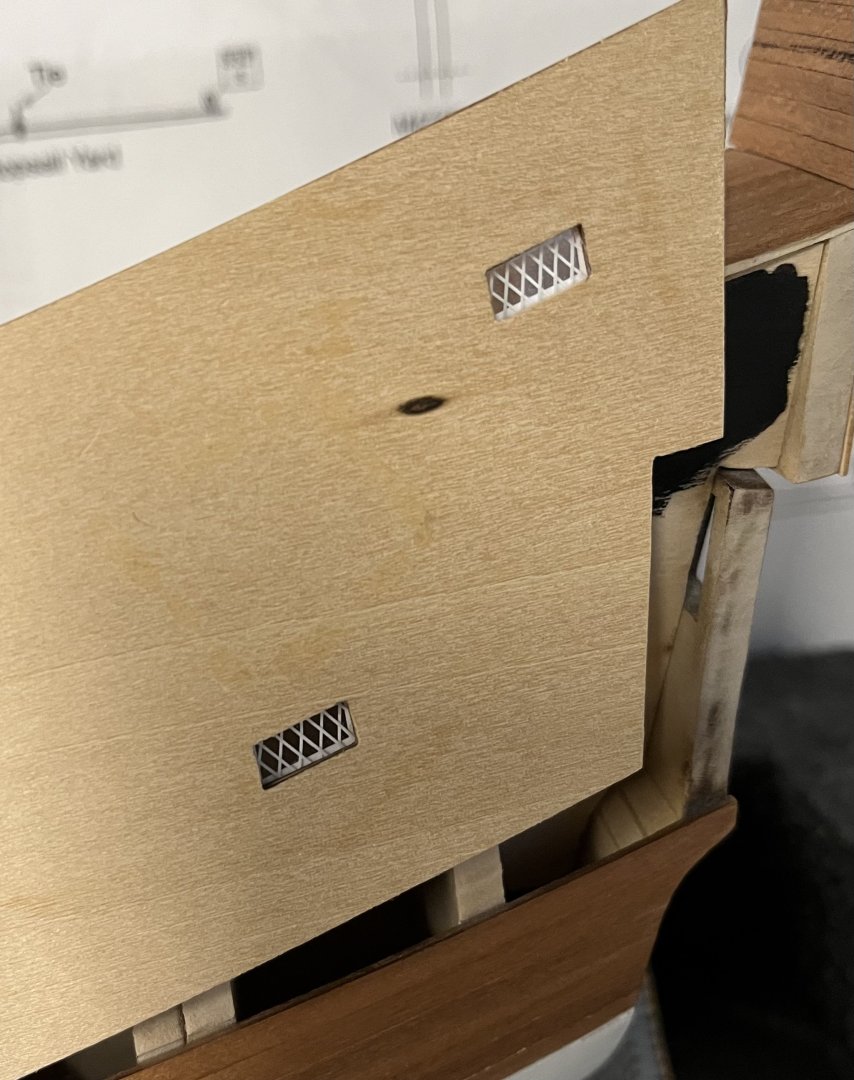

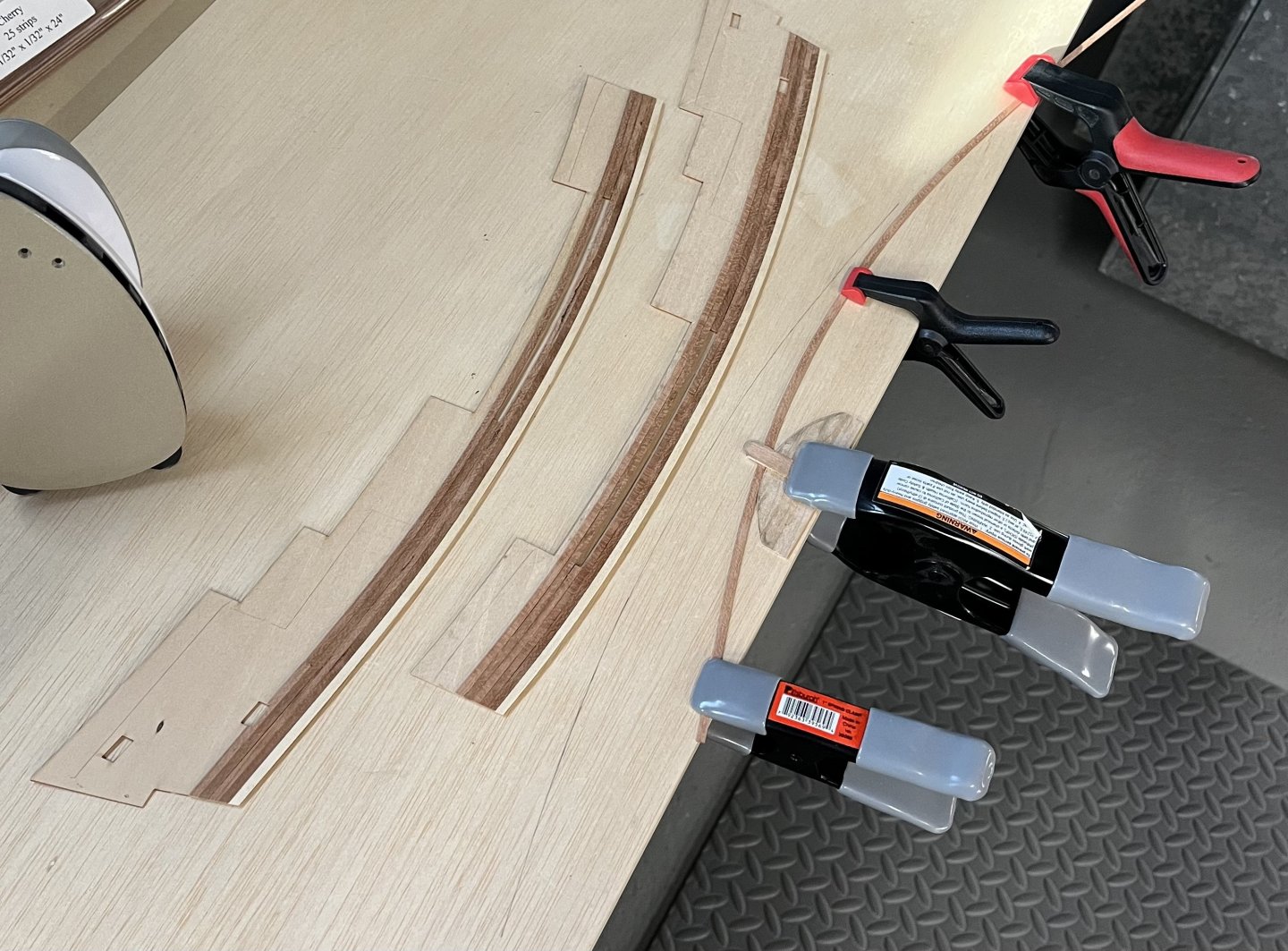

I redid the metal rings around the gratings because they were loose and drilled the mast holes. Finally, the bulwark template install is in progress. It’s not as easy as I thought. It took a couple of glue sessions to secure the first template. I’m making some supports so I can clamp down the next template properly. Steve

-

Here’s a couple sites to check out. Have not used them myself. The ones I used don’t seem to offer what you need https://www.ttplasticland.com/products/acrylic-display-case?srsltid=AfmBOoo9eoBuQwHC1ql7_2kjnMWaUFpLD4PyAp2VcHKFNevTj9VJBK4M https://pleximart.com/?srsltid=AfmBOoo1hSpvoTvGuE9w1rog3mQ-DbKJMelmkxB6WJ_Zw-s-bOhM9XdD

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.