-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

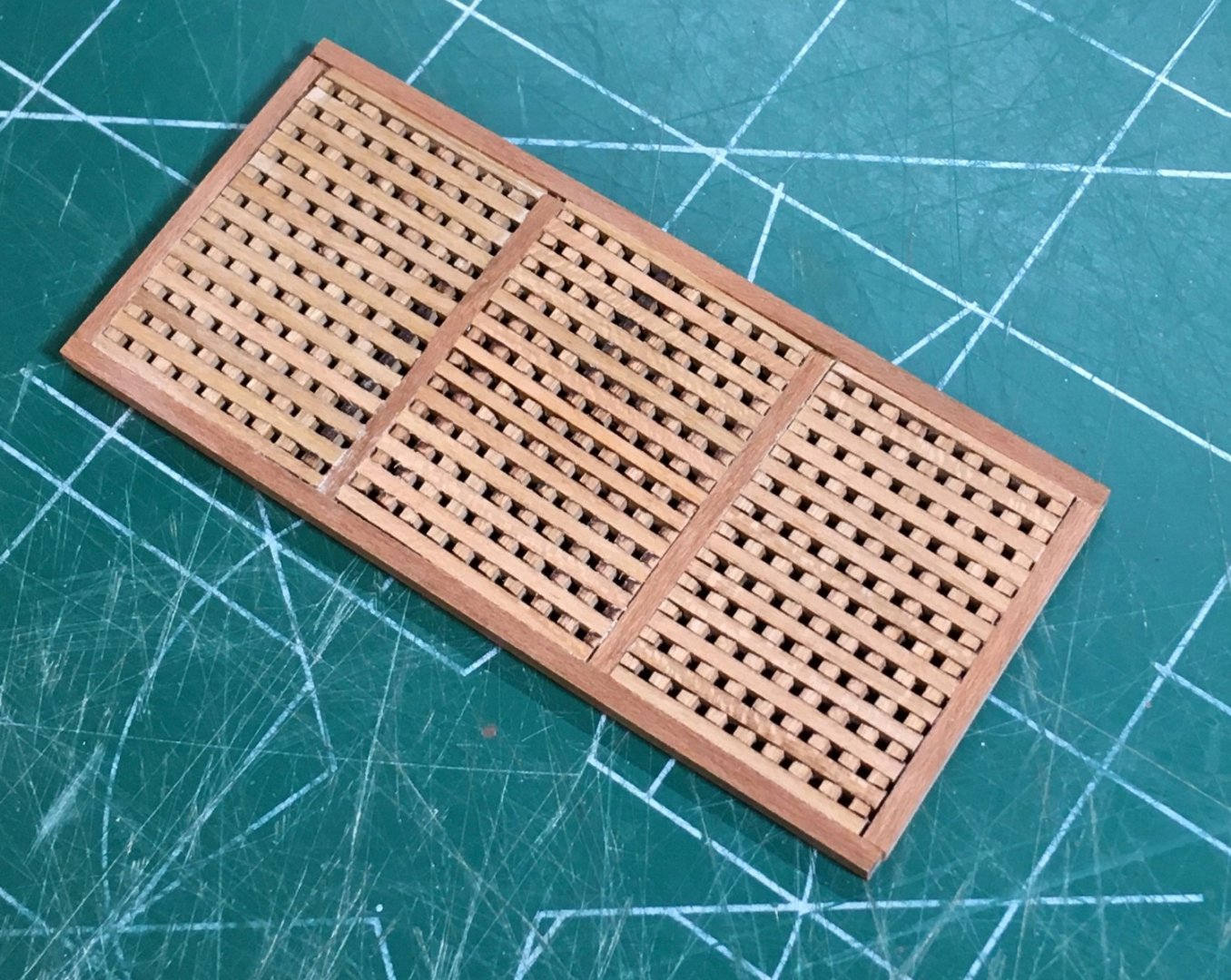

Gratings for the upper deck were completed using 3/16” cherry grating strips from Model Expo. The coamings were created first using a jig I created from previous projects. The quality of the grating strips were good. It was a tedious and frustrating process. The center gratings are slightly askew. This being my second assembly of this portion, I opted to not redo them. They will be obscured by the ships boat anyway. Steve

-

Another superb and inspiring build! Steve

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

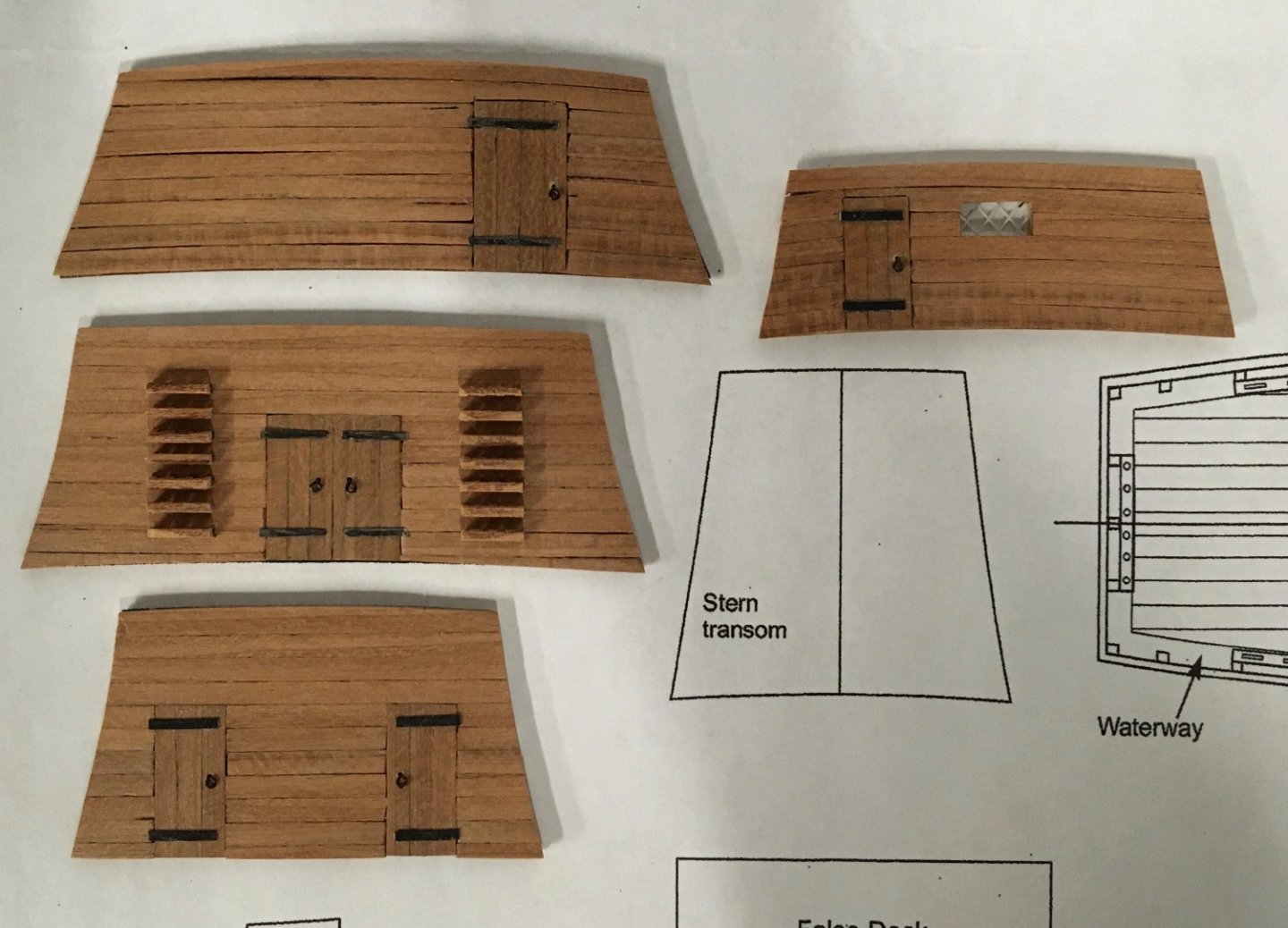

Quick update on the completed door handles. After drilling the holes deeper I was able to place the eyebolts through before bending and using marker to blacken them. The paint I have wouldn’t adhere. I am not completely happy with this result but it is tidy enough for this scale and I believe it will blend in when other details are added. The main hatches and upper deck planking is next. Steve

-

Nice work! Look forward to your updates. Steve

- 60 replies

-

- Confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you so much for the kind words! It was a fun project. Steve

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

Looks great! Good luck on the boats! Steve

- 126 replies

-

- Finished

- confederacy

-

(and 1 more)

Tagged with:

-

That is pretty outrageous. Sorry to hear that. I noticed someone picking up my model to view it at one point. I thought that was a bit out of line as well. Unless you give permission that is not okay. Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you guys for the nice comments. Mike, back to building the Mayflower. Steve

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

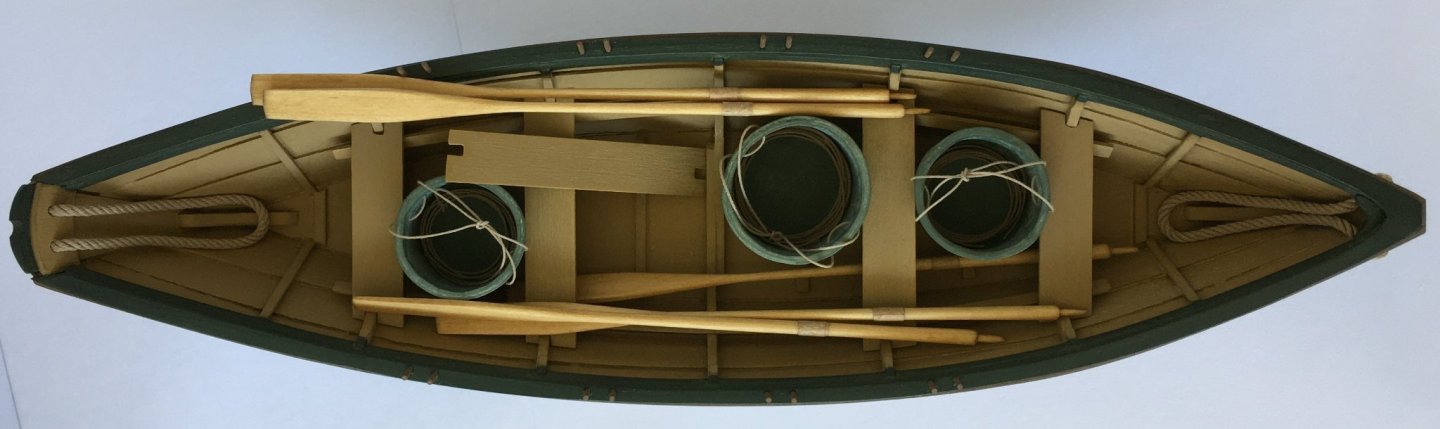

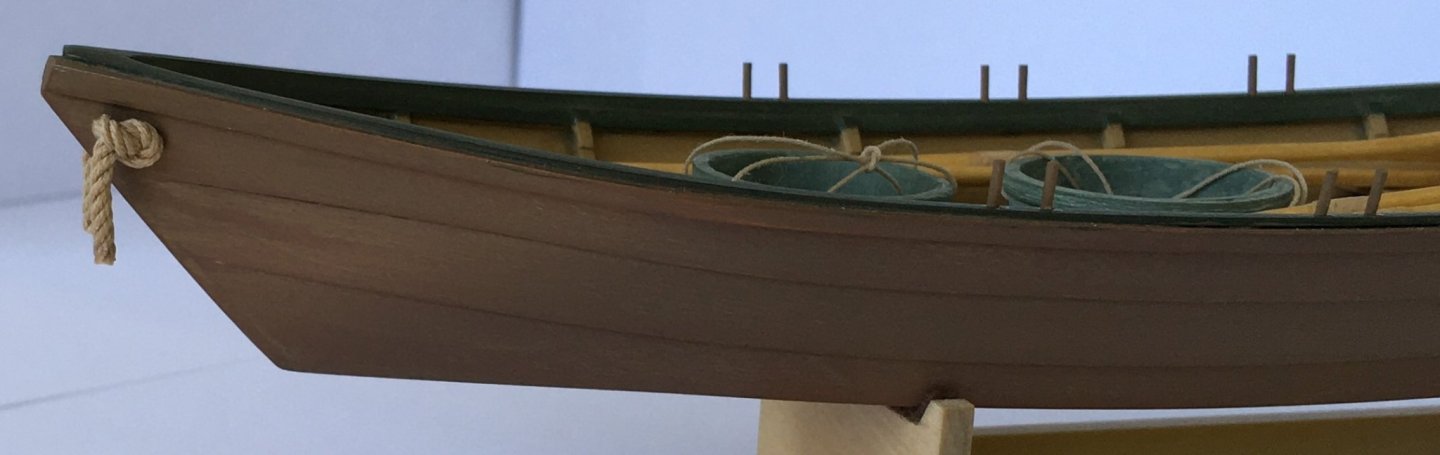

Prior to installing the boat on the display base, strips of brown felt were glued for a custom fit. Three days of rigging the buckets with handles and rope coils using Syren ULTRA scale rope completed the model. I did my best to tie sheet bend knots, although that detail is difficult to notice at this scale. This was an enjoyable project and I learned a lot. Thank you David for designing this kit and keeping an eye on the build. Ryland Craze and Mike Stuntflyer, our exchanges on paint strategies and finishes was invaluable. I hope the rest of you will continue to follow as I get back to the Mayflower- Model Shipways. Steve

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

Yes, agreed. A drill will be necessary, but I don’t think she will need it for quite some time into her next project.

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.