-

Posts

3,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

Hi Bill - last week, I was referencing the St. Philippe monograph plan in 1:96, to begin figuring out what line diameters I needed, and the deadeye dimensions, and so forth. Then, I realized that because I want my masting to proportionally resemble that of the SP monograph. I could simply figure out what the relative proportion of the main topmast (from topmast heel to just beneath topmast cap) was to the lower main mast (from main deck level to just beneath mast cap), and then apply those proportions to my topmast. For the t’gallant, I could apply the same process, relative to the topmast length. Now, I don’t have this in front of me, right now, but my recollection is that my main mast rose 10” above the main deck to just below the mast cap. For a sense of proportion, that is about 5/8” more than what is shown on the 1:96 SP plans. That is okay, as far as I’m concerned. I raised my main mast height early in the process, back when I thought I would copy the kit topmast lengths. This idea for a proportional rig only just occurred to me. Again, it isn’t in front of me, but the SP topmasts work out to something like .825 of the main mast height above deck level. Applying that proportion to what will be my scratch made topmasts, I come up with something like an 8 1/4” topmast. Applying the same logic, the t’gallant height is something more than half the height of the topmast below. I don’t remember the exact figure. Overall, my rig will probably seem a little taller than it should, but I have also extended the overall length of the hull by 1/2”, so maybe it won’t be too noticeable. It is more important, given this compromise, that the mast sections at least be proportional to each other because that is what makes them functionally able to be lowered and removed.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

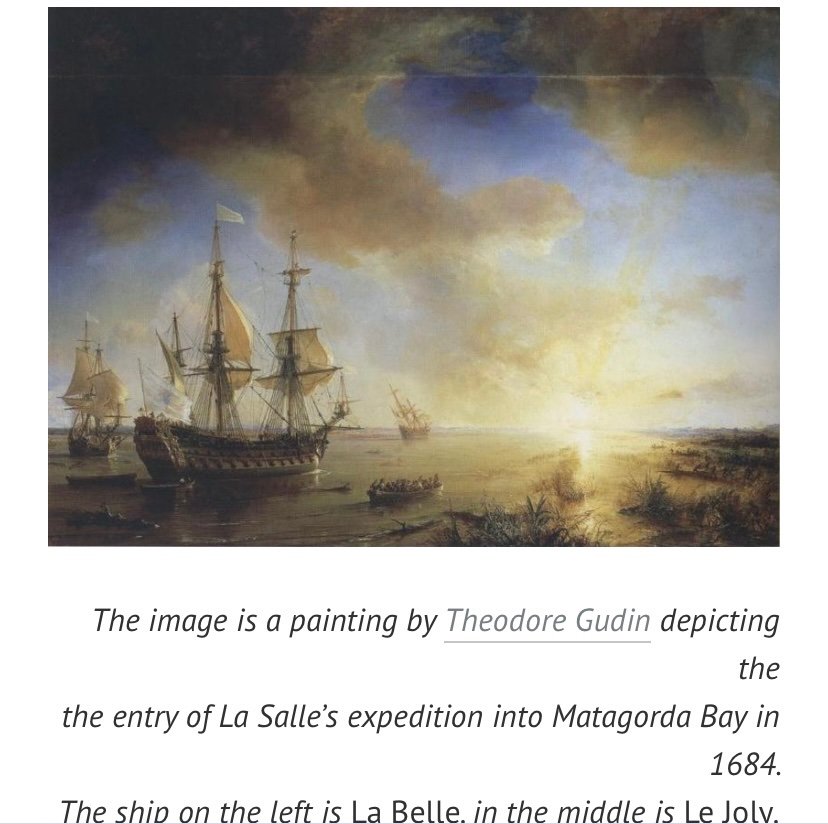

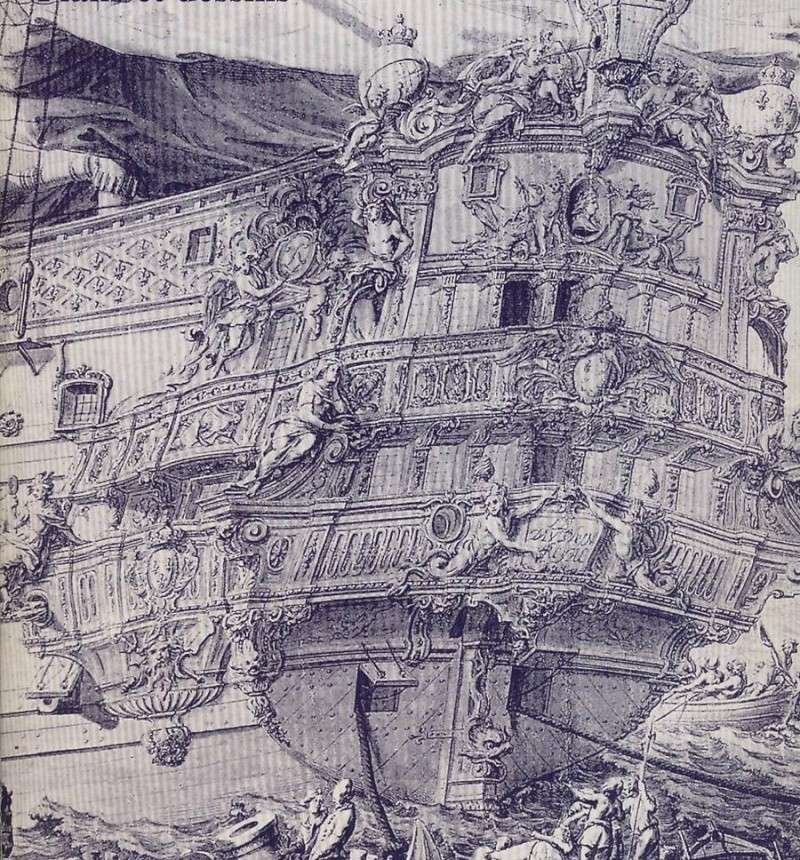

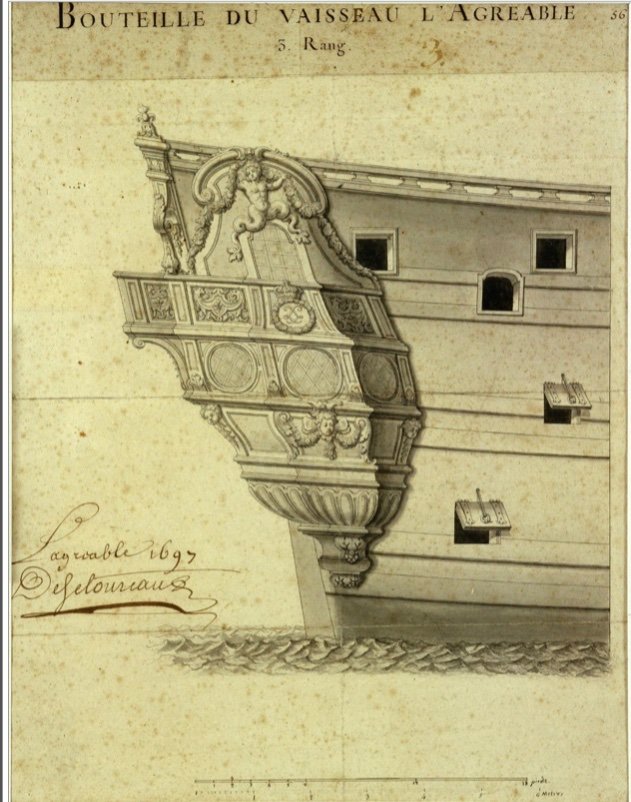

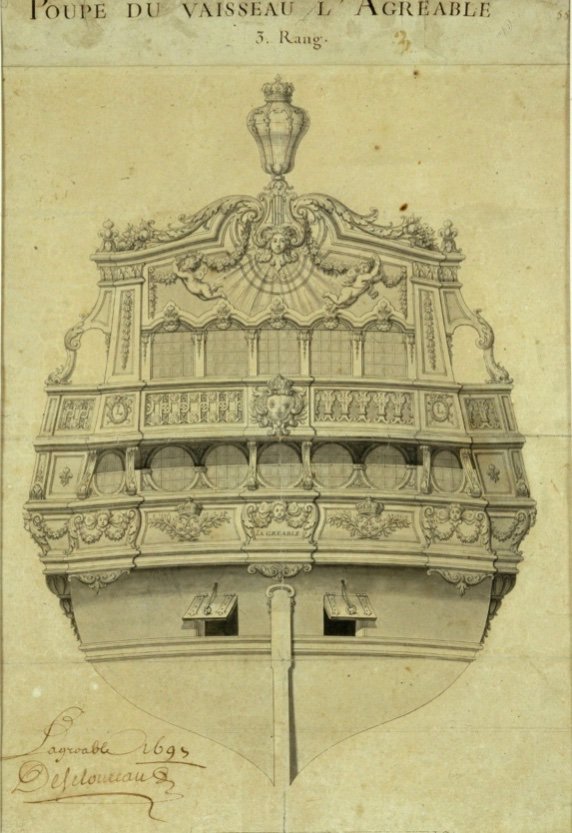

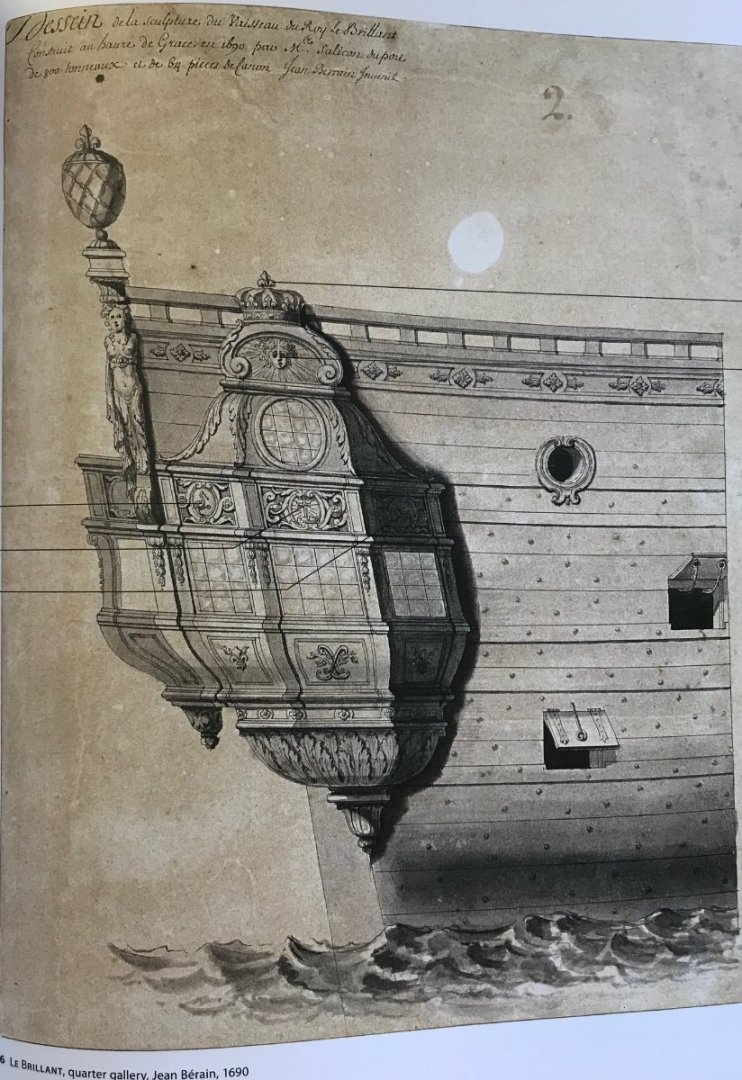

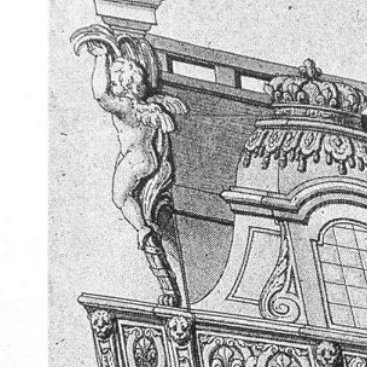

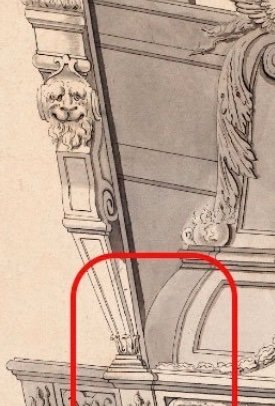

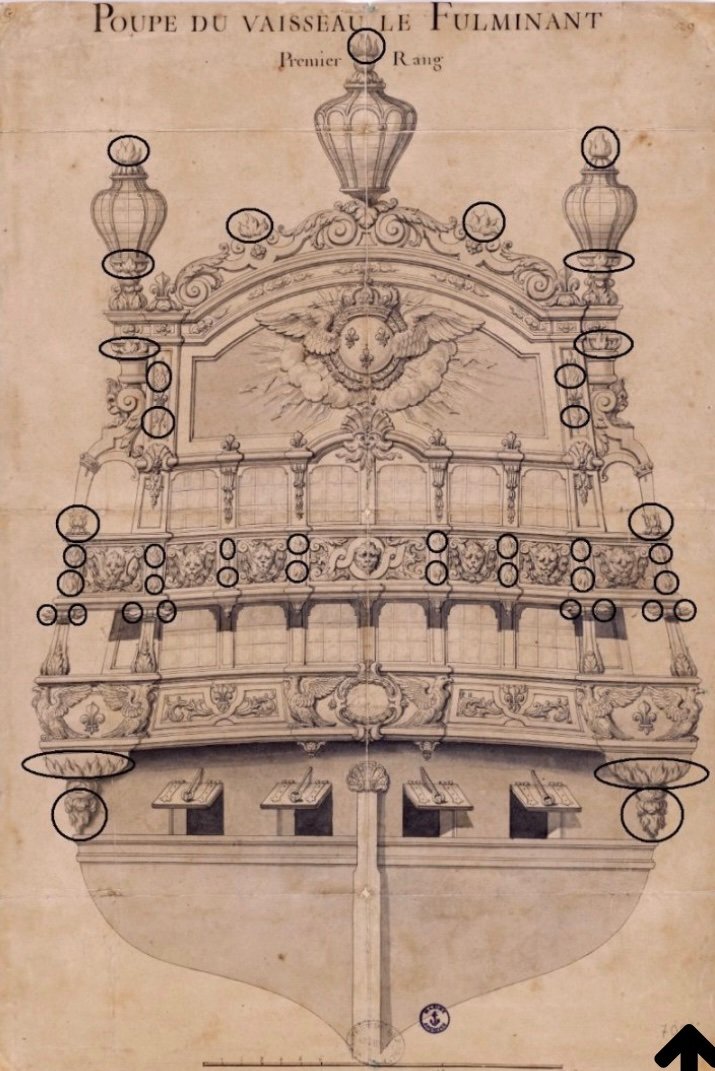

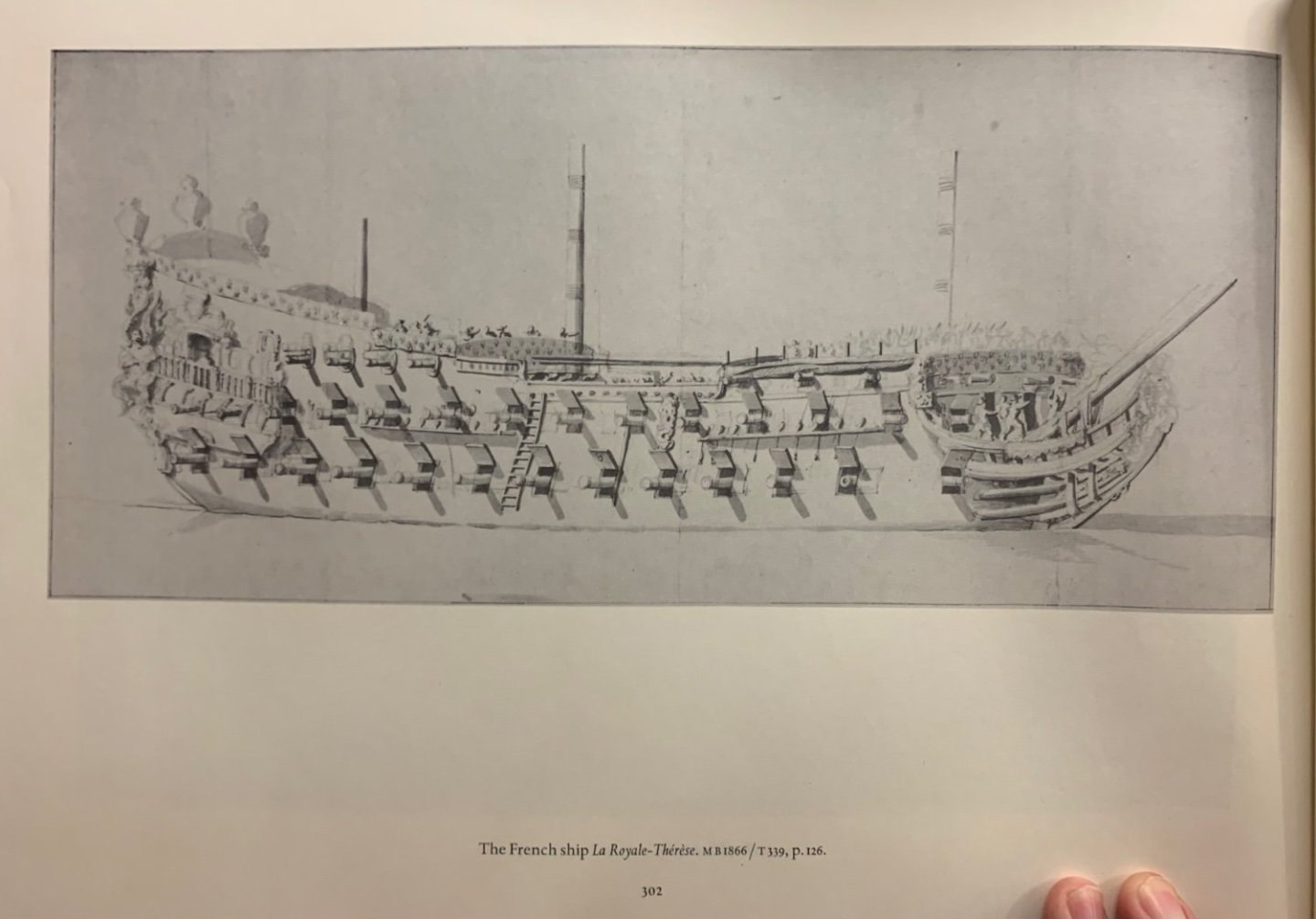

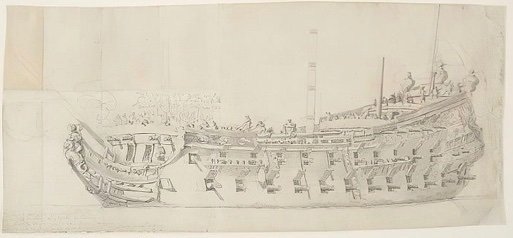

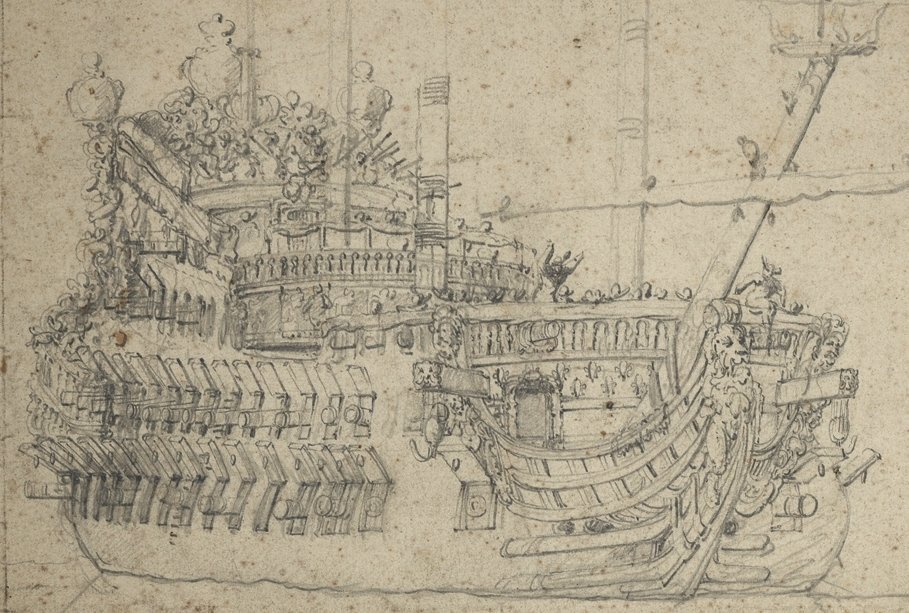

This is always, IMO, the difficulty of interpreting Berain drawings - even among known sets of drawings that are signed and dated by the arsenal intendant of the time, e.g. Desclouszeaux circa 1690s, there are often weird incongruities between the stern and quarter view; the stern or quarter drawing may not always support the logic of the one or the other. More on that in a minute. I agree that your observations of the shading along the forward edge of the upper quarter gallery, as well as the oddly broken plane of the quarter deck window, would seem to indicate a fully closed quarter gallery. However, I will do my best to articulate why I think the quarter gallery upper finishing is actually a shallow trompe l’oeil amortisement. When it comes to Berain drawings, one conceit of his style appears to be that when he draws the stern view - whatever details of the quarters that may still be visible from the stern, in real life, are simply not included. Let’s begin by looking at your work-up of Le Fulminant’s stern: Focus first on the lower tier of lights. At the corners, where the stern wraps around to the quarters, this is shown as completely open. In reality, though, this lower corner is the functional seat of ease; there would certainly be a false window panel, integral to the quarter gallery and visible from the stern. This whole lower level of the quarter galleries would be enclosed with false lights. Now, look at the upper tier of lights, where the stern wraps to the corners. There is what appears to be an open, pass-through archway. Whether the design intent be a trompe l’oeil amortisement - which, in reality, would still be visible through this stern archway - or a fully rounded upper finishing, Berain has not drawn any representation of either. Consider, now the stern and quarter view for Le Brillant of 1690: Here, it is a somewhat different story. On the lower wrapping corner, there is an oval frame for a shaded blank panel, concealing the functional toilet. On the upper wrapping corner - rather than a pass-through archway, there is a scrolled buttressing bracket that clearly delineates the boundaries of the upper stern balcony as being within the five lights of the stern, as opposed to wrapping to the quarter galleries. The quarter view confirms this interpretation. Interestingly, though, Berain’s quarter view of Le Brillant appears to show an open and walkable stern balcony at the counter level. This simply would not have been the case, at this later stage in the development of stern architecture. By the 1680s, these fragile structures, which were vulnerable to following seas, were done away with completely. The stern counter facade, on the other hand, continued to be decorated with pilasters and reliefs that were consistent with the balcony decor on the levels above; it became, in other words, a kind of shallow “false” balcony to support only carved figures or brackets. I believe that Tanneron’s model of Le Brillant interprets this architecture correctly: Although, it must be noted that Tanneron makes interesting departures from the drawing, with his interpretation of the big carving below the tafferal. Next, consider the drawing set for L’Agreable: Again, we see the open archway at the top corner. Interestingly, the balcony overhang shadows do not continue to the quarters, which would seem to indicate that the balcony only extends to the ship sides, as opposed to wrapping around to the corners. The quarter view seems to confirm this as the side of the upper balcony is noticeably shaded, as though set-in from the sides of the quarters. If the upper finishing of this quarter gallery is fully rounded, it seems to me like an awkward transition, beginning at the balcony level caprail and diminishing at the sheer rail. Perhaps Tanneron thought the same and preferred to represent the upper finishing as a Tromp L’oeil amortisement: The model is damaged, but Tanneron’s intent of a wrapping and walkable balcony through the now missing pass-through arch is clear. This interpretation is consistent with that of Tanneron’s contemporary, the Court Marine painter (1830’s), Theodore Gudin. Here is a famous painting of the LaSalle expedition of 1684, featuring a consort warship, Le Joli, of the same class as Le Brillant and L’Agreable: The structure of the quarters and stern is very close to that of Tanneron’s L’Agreable. It is impossible to know exactly what sources were available to these two artists, who were recording structures from 145, or so, years prior, but their agreement on the matter must carry some weight, IMO. One last example comes from a slightly earlier time, and from a rigorously detailed artist. Puget painted, below, not a proposal for decor, but the actual refit appearance of Le Dauphin Royal in the early 1680s: Here, the pass-through archway and wrapping upper balcony to a shallow amortisement upper finishing are plainly decipherable. Interestingly, the lower level of the quarter gallery is open on it’s sides - an artifact of the early First Marine (1670s) stern architecture, but closed-off from the stern view with buttressing brackets. I maintain that by the late 1680s, this level would have been completely closed up with false/removable lights. Another possible artifact of this earlier time may be a small “Juliet” balcony at the center of the stern counter. It is hard to know whether that is actually a place where someone can stand. Personally, I doubt it. With all that said, and considering the Fulminant drawings, in particular, I will draw your attention to two small details. Going back to the stern view: The upper balcony casts a shadow beneath that extends fully to the ship sides - a point beyond the shadow that would be cast if the balcony ends were actually located between the second and third lion mascaroons. This suggests that the balcony extends to the end of the quarters. Now, take a closer look at the archway for L’Ambiteaux: Notice the shading just visible beneath the pass-through archway. The same is present for Le Fulminant: Given the way that a fully-rounded upper finishing would scallop back towards the ship’s upper bulwarks, in the characteristically concave French Style, this would be a really weird and awkward transition, if one were to walk to the ends of that upper balcony and look through that open archway. It’s not impossible, but it would not be very coherent. The tromp l’oeil amortisement just makes more sense here. I think that Boudriot’s monograph interprets this correctly.

-

After seeing your Victory, Ian, I will be very excited to see what you do with this kit.

- 106 replies

-

- Soleil Royal

- Ship-of-the-line

-

(and 2 more)

Tagged with:

-

Awesome historical recap, John. The two best books in my library are both Rif Winfield books: French Warships, as you reference, and First Rate. I do think it is probable that the ship was repaired after Beveziers and her ornamental program completed (I have repair estimates from the archives, after the fleet’s return to port), before Barfleur in 1692. However, like most other things related to SR, there are no concrete records detailing the specifics of this. The screen shots I have of these repair estimates are barely legible. I will have to remember “Harbor Queen,” as I design my conjectural 1670 SR. It’s hard for me not to imagine the members of ABBA as Admiral and supporting officers 😀

- 106 replies

-

- Soleil Royal

- Ship-of-the-line

-

(and 2 more)

Tagged with:

-

Where did you source 3.5 MM from? I’ve been referencing the St. Philippe monograph because, included among the plates is a sail and rig plan in 1:96. According to that schematic, 5MM (3/16”) is appropriate for the lower main and fore deadeyes. The trick is finding a good balance of scale graduation for everything else. On the monograph plans, the spritsail and mizzen top deadeyes are impossibly small - as you noted earlier in your log. 2.5 MM is the smallest size I can find. Forget about the t’gallant crosstree deadeyes, which look practically non-existant! I was thinking about 2.5 for the sprit, fore and main t’gallants, and the mizzen top. I could probably get away with 3 MM on the fore and main tops, as well as the backstays. Then maybe 3.5 on the mizzen shrouds. My annoyance is that the Amati deadeyes are not nearly as nice as the Dockyard Models version, but Dockyard doesn’t offer half sizes. Maybe I can do a little dressing of the Amatti product to make them look more like Dockyard.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

Bill, your lower deadeyes are 5 MM, correct? And 3 MM for the fore and main tops?

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

Marc, it is great to see you back on the forum! Your L’Ambiteaux is looking CAPITAL in her fresh paint. Thank you for the kind words and for checking-in!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

The paint work is exquisite. That is more like what the ventre-de-biche color is supposed to look like. It looks as though the flood caused black mold to grow along the baseboards. Did you cut away and replace the bottom foot of sheetrock? Be very careful of black mold - a serious danger to your respiratory health.

-

Yeah, there are a number of really good block suppliers out there, but the shaping of the Dockyard blocks is really superb, and they offer the smallest sizes. Their violin blocks look particularly good to me. Thank you guys for all the kind words!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

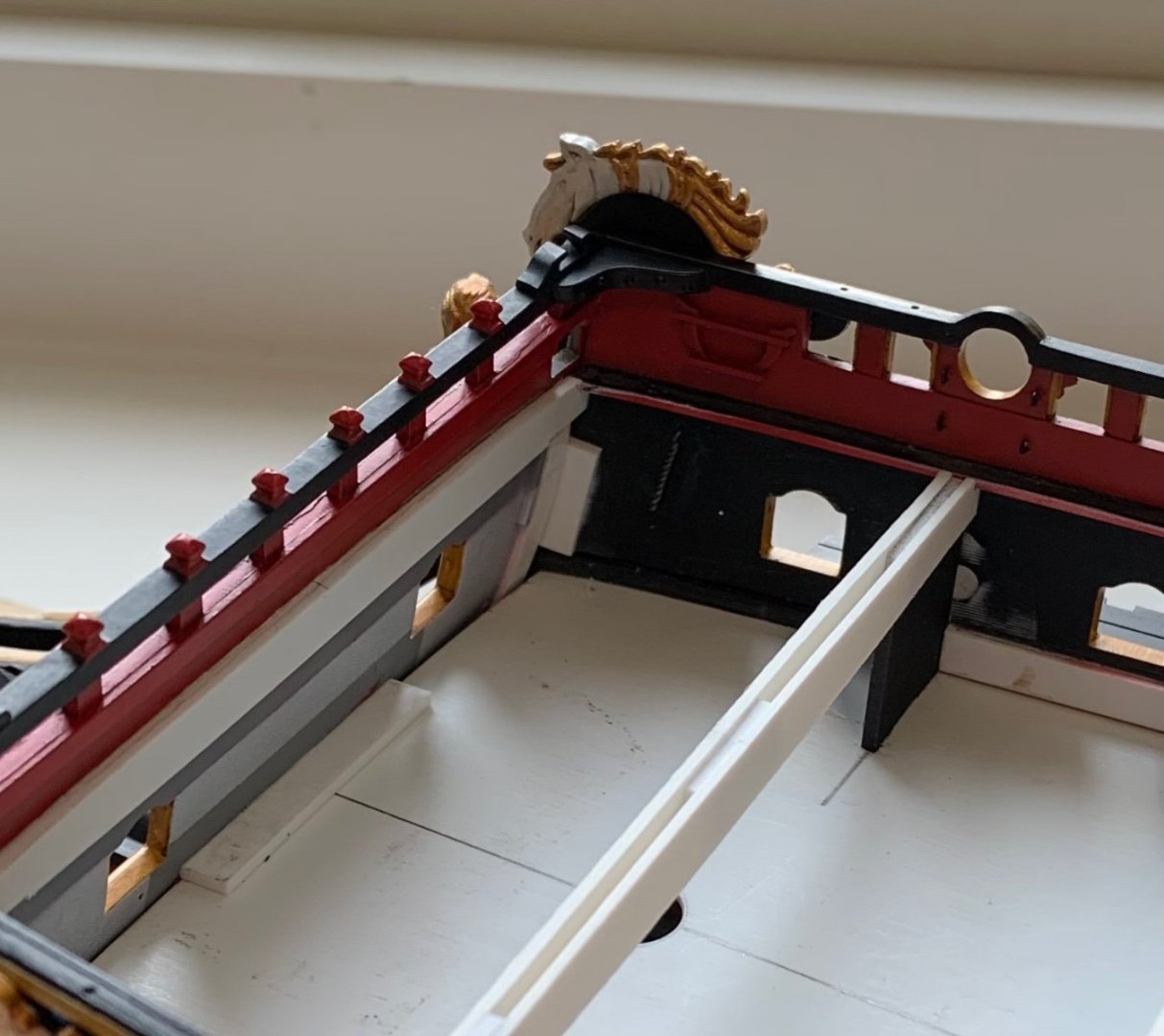

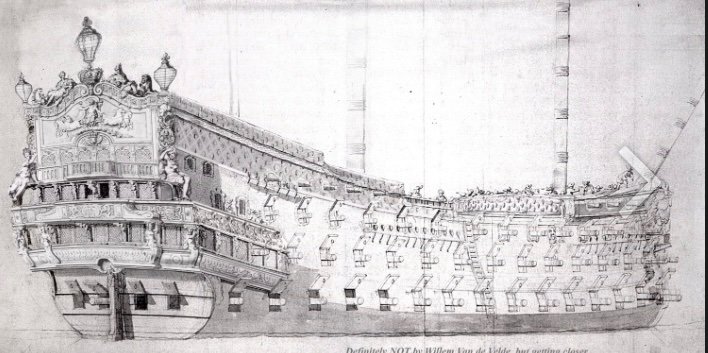

Yesterday witnessed the arrival of our first adult dining table and chairs which, sadly, ushers out the butcher block trestle table that was my work station and the backdrop of this project for the past six years. It was a bitter-sweet day because I love that old workhorse of a table. I bought it second-hand for $50 and refinished the top three times. On the other hand, it is very nice to walk into our place and immediately see a touch of sophistication. There will be no painting or gluing on that marble-top table, though! Fortunately, IKEA makes a very nice birch gate-leg table with built-in drawer storage, which will soon become my new designated work station. In the meantime, though, I wanted to get the model to a stage of crispness and clarity before I had no place for paint re-touching. Please forgive me my self-indulgence. Here is where we are at, presently: I am very satisfied with the head-grating, and the way that all of the head elements integrated together: One thing that was niggling on my conscience, though, was the fact that the aft headrail rosettes were glued under tension. I have a solid welded bond, and I did wick CA into the joins, where I could, but I wanted a little extra insurance. My solution was to drill two small holes a side, through the third headrail and upper bulwarks, to feed a length of annealed wire. You can see where I painted over the exposed wire with red: And inside, you can see how I twisted the wire ends taught, and then fixed the whole thing in-place with liquid CA. This is all minimally detectable and will quickly fade out of view with everything else that will be going on around it. I feel better now 🙂 I made a start at roughing out the figure of Africa. I had quite a lot of the same wood (linden, maybe) that I used for the lower quarter galleries. Unfortunately, this material really isn’t suitable for carving fine detail. I will have to get my hands on a little boxwood, or some fruit wood like apple or pear. A little fun with pictures. Here, the juxtaposition with John Ott’s near-Van de Velde: As I’ve said before, Heller really does manage to capture the early sheer of these ships very well. Despite it’s many imperfections, my hypothetical recreation does, I think, capture something of the essence of what may have been. Moving forward, I have been figuring out where I will source line and blocks and pins and cleats. I really like the blocks from Dockyard Models, and the polyester rope from Ropes of Scale. I can get most accessories I need from Dockyard, but anything else I will obtain from HisModel. For the time being, and until the new worktable arrives, Soleil Royal Redux will shelter in her dry-dock: I will occupy myself, until then, taking measurements of the materials I need, and developing an understanding of what needs to be done with the rigging. Along those literal “lines,” John Ott has been a tremendous help in sharing his sources, and the rig and belay plan that he has developed for his model. My belay plan will likely look a little different, but only because I do not intend to make the same use of pinrails. If anyone is not yet aware, John has begun a build log for his magnificent Soleil Royal of 1693, which can be found here: Many thanks to you John, for your help and generosity, and to all of you for sticking with this project for such an absurdly long time. It is greatly appreciated!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

To compensate for the long topmasts, I raised my lower main mast by 3/8”, if I remember correctly, and the fore and mizzen lower masts were raised, accordingly. In order to improve the spread of the topmast shrouds, I made wider tops from scratch. The mast sections which are really overlong are the t’gallants. Those I will make from scratch and shorten.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

“Delicious” dichotomy, indeed, John! That precisely expresses my own fascination with ships of this epoch. I am so glad that you are finally bringing your unique expression and perspective to light in a build-log for your ship. I am absolutely certain that many others, previously unaware, will be absolutely gob-smacked by your talents. Not a fine-scale modeler? I stridently disagree!🤩 So, one thing that has always bothered me a little is that so many vocal types on the various message boards love to complain vociferously about the kit’s numerous flaws and inaccuracies - essentially calling it a pile of junk - yet, they hold Tanneron’s model in the highest regard. Well, what you have so perfectly illustrated is the fact that the Heller kit is really a very direct copy of the Tanneron model; many of the Heller flaws originate in the Tanneron model. The thing I find so remarkable about the origination of the Prestige Series is that Heller made it possible, for a moderate sum, to bring faithful copies of world-class museum models into the average person’s home. They are flawed, yes, but aren’t we all to some degree or other? When I first spied the very pressing I am building from, in my next door neighbor’s hobby room shelves, back in 1981 (he was building the 1:200 Heller Royal Louis, at the time), I was instantly hooked, and thereafter obsessed with this magnificent puzzle of a ship. Unfortunately, Mark Hansen did not live long enough to build the ship in retirement, as he had planned to. All of this informs my view that there aren’t any “perfect” ship models. All models are constrained by the quantity and coherence of their service records and portraiture. In my opinion, an effective scale model is one that strives for fidelity to the period, while stimulating debate about its various details, and INSPIRING others to see what else may be possible. John’s Soleil Royal is all that and more!

- 106 replies

-

- Soleil Royal

- Ship-of-the-line

-

(and 2 more)

Tagged with:

-

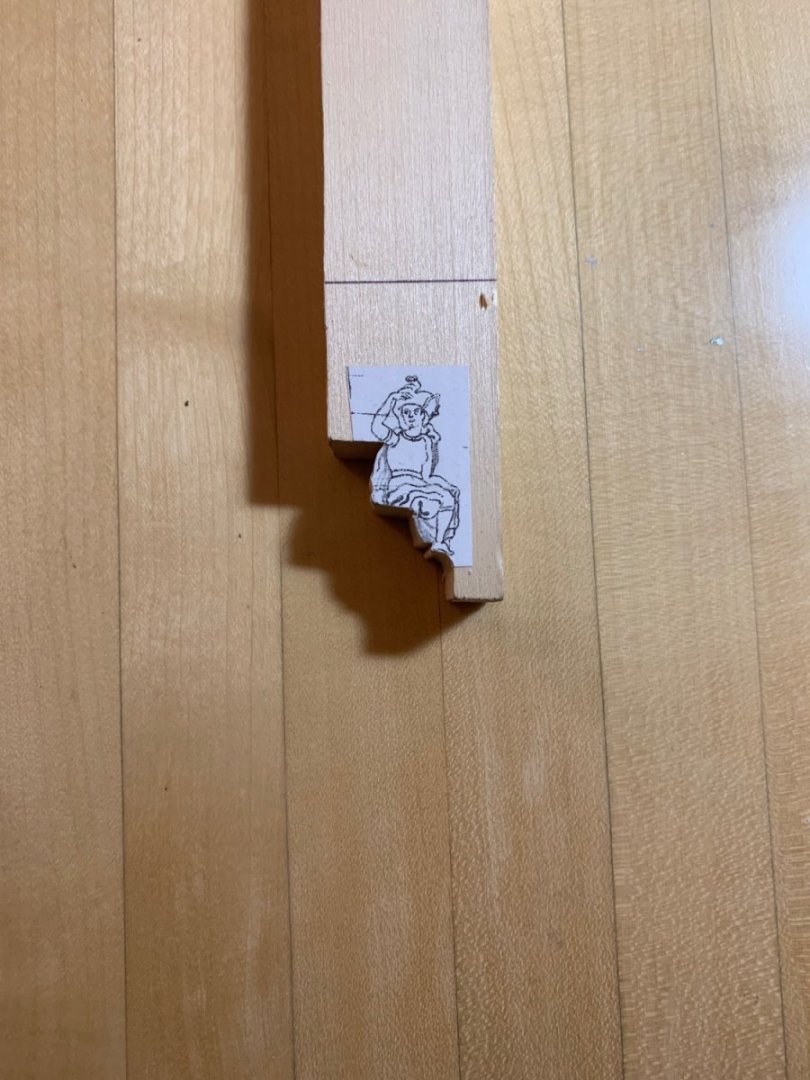

Your point about the hierarchy of ornament is well-taken and correct. If there is a place for human forms, where they are otherwise absent, it would certainly be at the figurehead. Frolich’s version of L’Ambiteaux carries a lion as it’s figurehead, while the builder below employs this human figure: I’m not sure whom this figure from Greek mythology represents, exactly, but my guess would be Apollo, as that is the character most closely associated with Louis XIV. He is carrying a victory laurel and Fame’s trumpet proclaiming his dominance and superiority to all comers. I do not think there is anything inherently wrong with an effigy of Zeus as your figurehead, even if you don’t employ and other human figures, elsewhere in the decor.

-

Although, one idea that occurs to me straight away concerns the lower finishing of the quarter gallery. L’Ambiteaux employs these twist-tail dolphins for the lower finishing: It seems to me that a stylized eagle with it’s outstretched wing, extending into the stern counter, could also carry a clutch of lightning bolts in its clenched talons, below.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.