-

Posts

1,079 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

All the stays are now up. Some run close to the mast and shrouds so you have to look for them. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

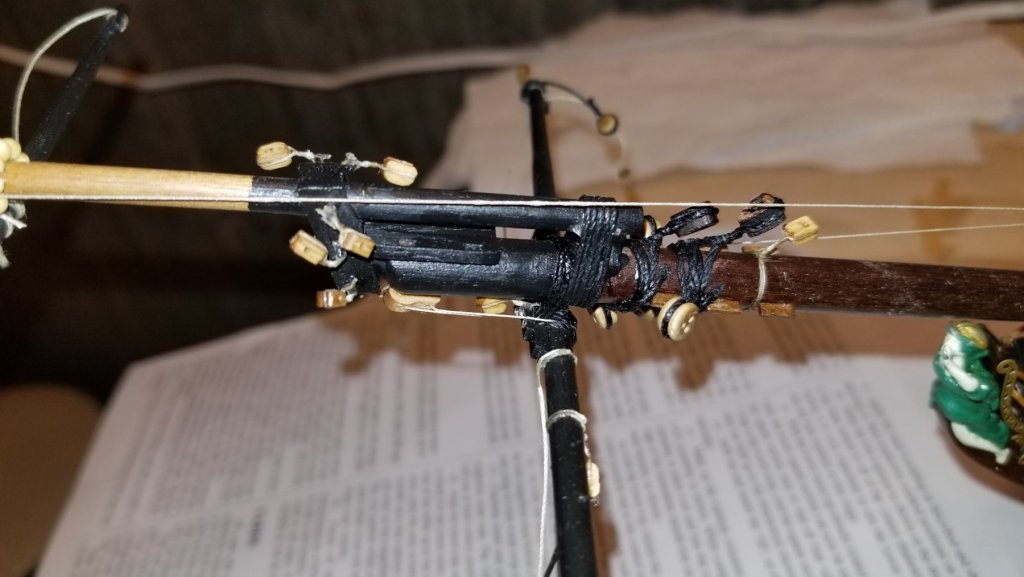

Foremast crow's foot rigging is up. As I was snipping the last loose piece of crow's foot, I managed to commit the ultimate rigging sin and snip the crow's foot too. 😫 All of the "feet" are one long continuous line. So I spliced the last lead and saved it. You can see the splice if you zoom in on the second picture and look at the leftmost "foot". But it's hard to see with the naked eye, so all's well that ends well. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

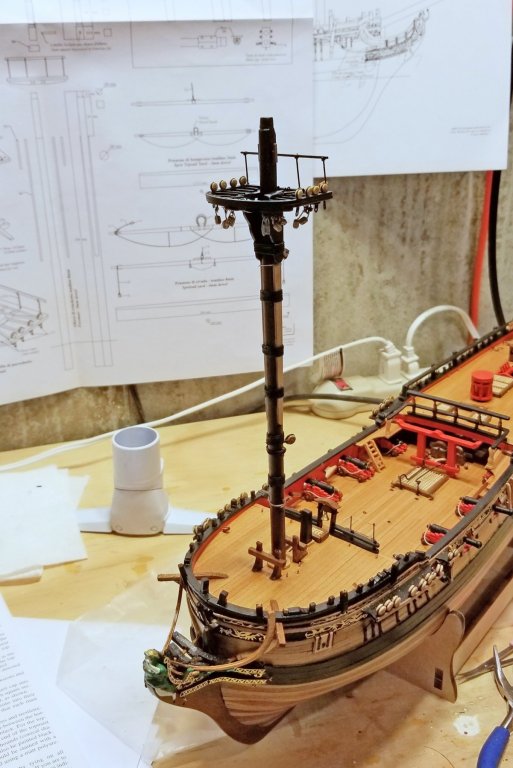

All shrouds are now up. 😂 I think I've been seeing ratlines in my sleep. Now on to other rigging, in between some business trips coming up this week and next. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

I haven't posted in a while, because I have been traveling and also busy with some business. But this week I was able to do the mizzen lower shrouds and finish off the lower shrouds, futtock shrouds and ratlines, so here's a picture of that. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

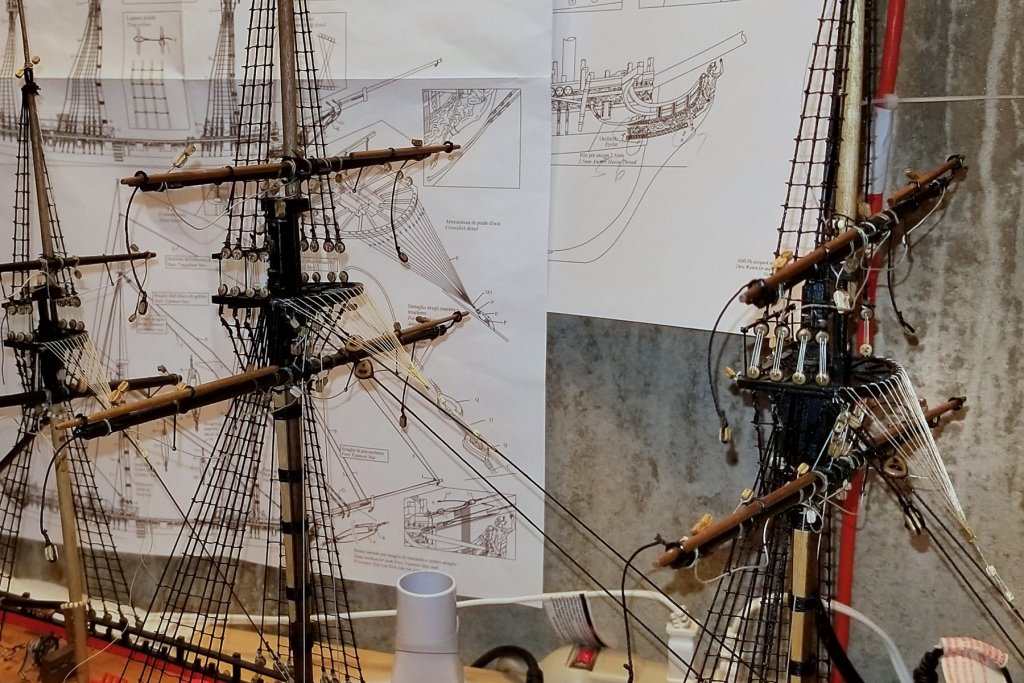

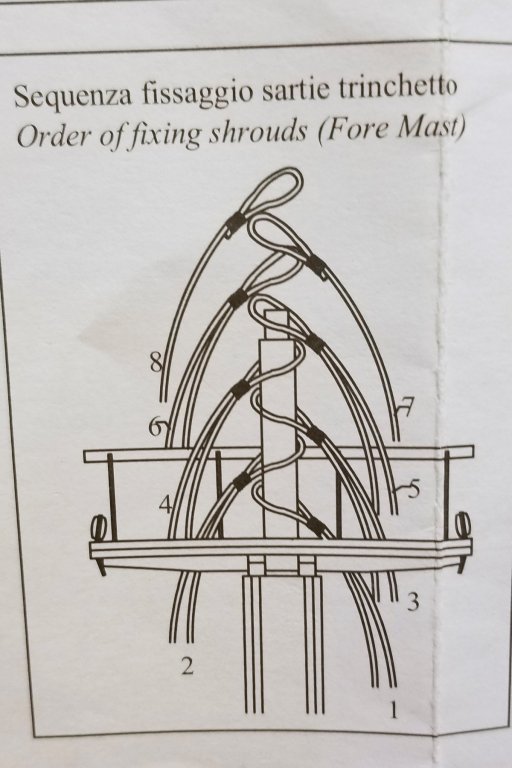

Continuing to work on shrouds. When I did the foremast shrouds, I followed the approach noted in the drawings (see below), which is certainly structurally sound and is probably how shrouds were "hung" off the mast on the real ship. The issue I had was twofold: alignment of the deadeyes when fixing the second deadeye in the loop, and more important, creating the proper alignment and spacing at the top. I really had to struggle to get separation and not have the shrouds cross approaching the top of the lower foremast, and the alignment I had on the foremast was marginally OK, but not what I really wanted. So for the main mast I went back to the approach I used on the Revenge, which is to rig the shrouds one at a time, fixing the alignment and tensioning at the top with CA gel. I'm much happier with the results. See below, including two pics with white paper behind the shrouds so the alignment up to the mast is easier to see. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

It's been a bit since my last post, partly because I was away last week, but also because I have hit the shrouds and ratlines -- and you all know what that's like. Never ends. Here's my first stage of those -- the lower foremast shrouds and futtock shrouds. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

The shrouds will be the traditional black. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

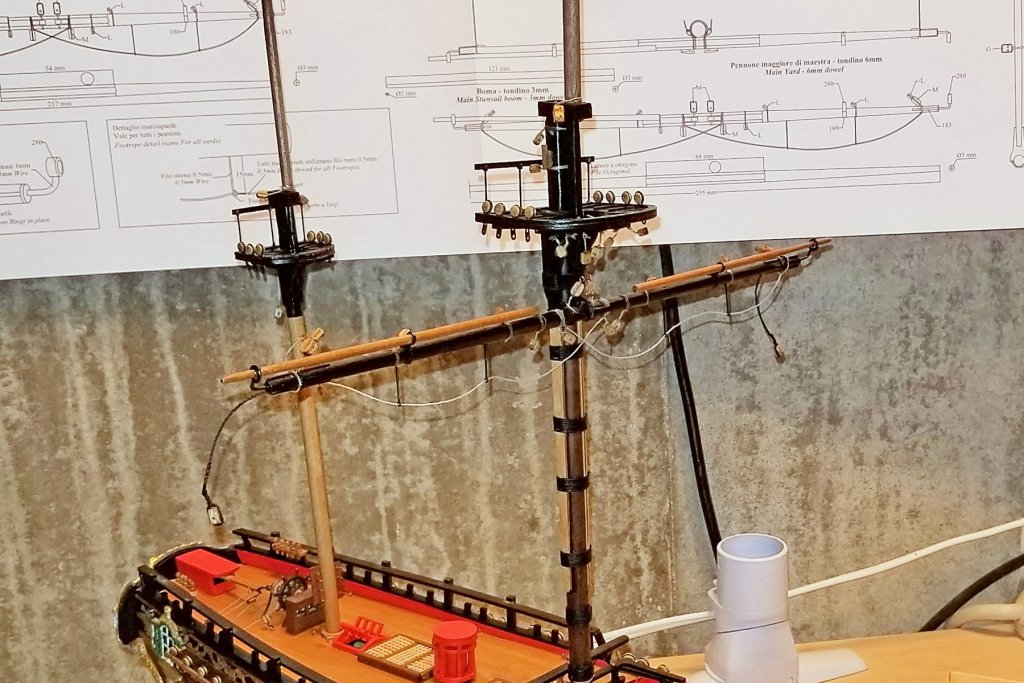

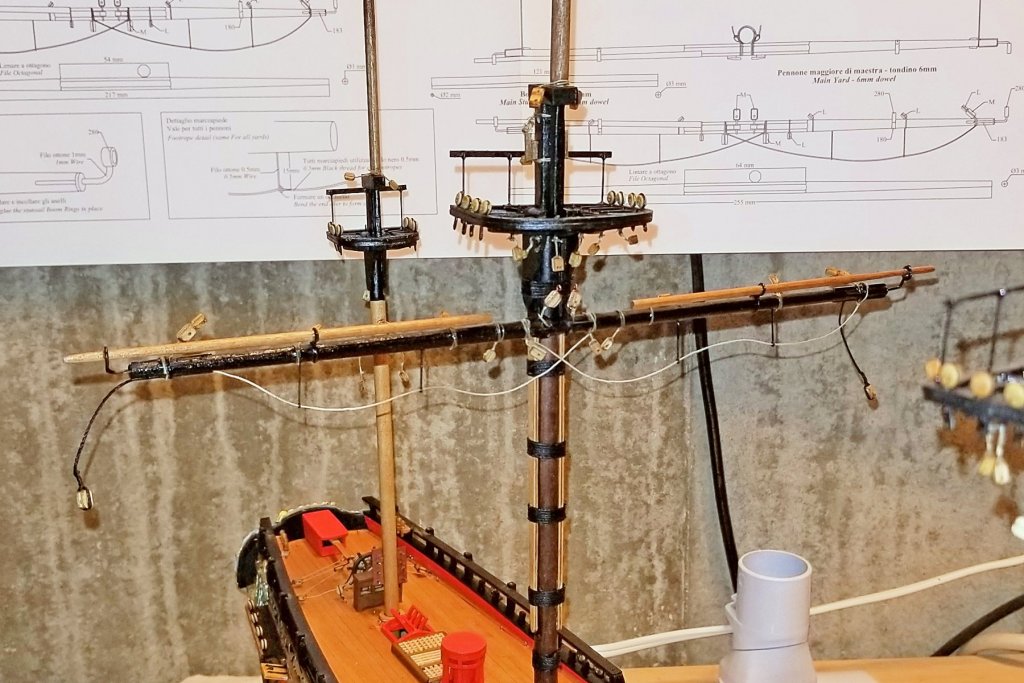

All the yards are now up. I also mounted the driver boom and driver gaff, even though they don't have rigging support, because I think it would be much more difficult with the shrouds up. A kit note: not enough parrell beads supplied. Fortunately, I had some left over from the Revenge. Now on to shrouds -- which I'll be at for a while. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

I have finished the 3 main mast yards and mounted them on the main mast, then stepped the mast to the boat. Picture below. When I started this kit, I wondered if the upgrade kit would prove worth it (other than the lifeboat kit it contains). But there are three brass fittings in it that have proven to be really valuable: The deadeye fittings are upgraded and are more secure. The footrope stanchions replace having to fabricate them out of thin wire, and are better looking than anything I could have created myself in the non-upgraded kit The fittings for the stunsail booms again avoid having to fabricate two fittings per yard end (4 per yard) out of separate parts. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

I guess maybe 2-3 hours per day when I don't have a lot of my professional work to get to. I spent more time yesterday on the main yard -- maybe 4 hours in all. Each part is an engineering challenge for me. I look at the drawings and think about how I'll build it, and part of that is the "what is the most efficient way?" Here's the catch: if you zoom way in on my woodworking, you'll see that it doesn't stand up to some of the really outstanding detail work I've seen here -- such as by Zappto, Vossy and AntonyUK. I think it's fine, and looks good on the model for normal viewing -- but I just don't have the patience that I've seen some others apply -- and their results show it. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

First yard done and mounted -- lower main yard. I hadn't run into stunsail booms before, but really like the interest they add to the yards. I know that some modelers pin the yards to the mast, but I'm always concerned that I will "prang" them during rigging with a random elbow or hand strike (and have done so many times), so I installed a pin on the back of the mast and "hung" the yard to that, which supports it but still allows for play in the yard. This one is lashed to the mast, but the next one above it will be installed with parrel beads and ribs. One yard down -- 9 more to go. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

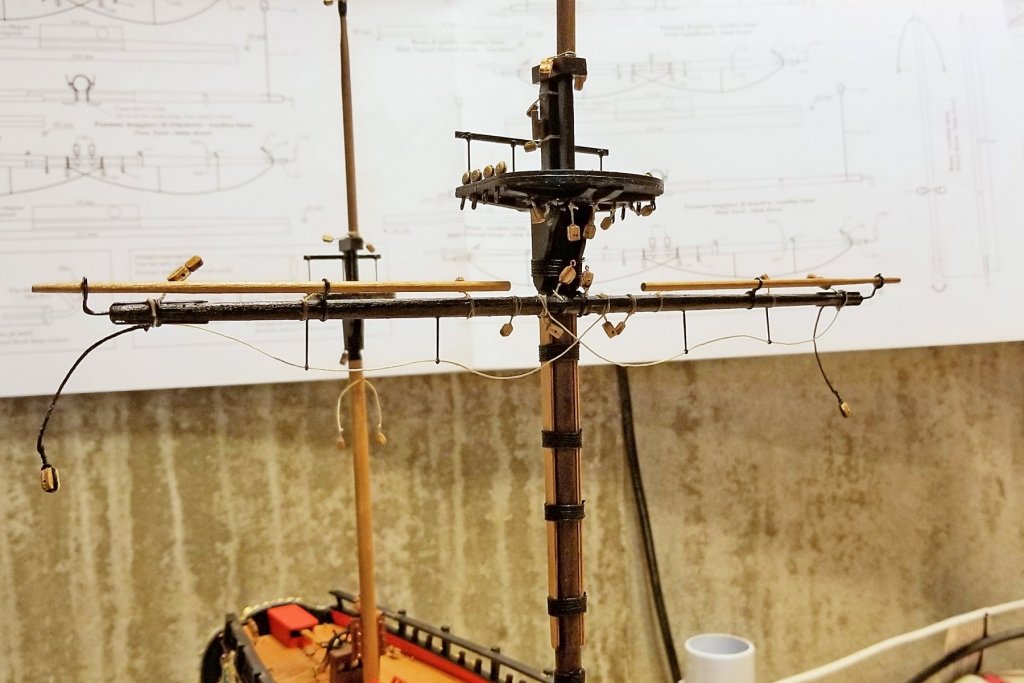

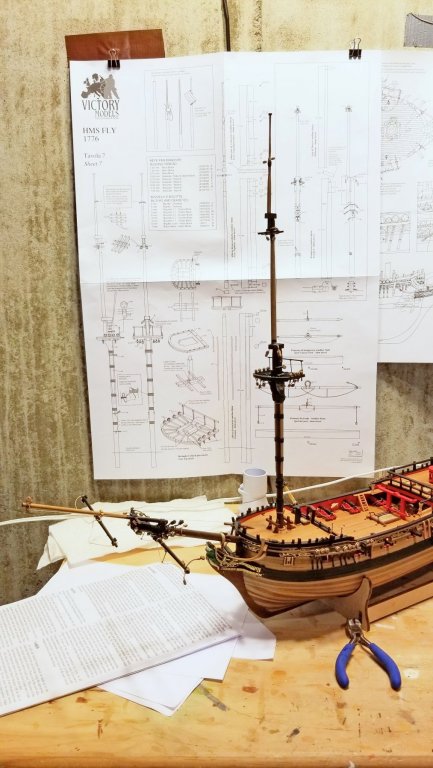

Finished the bowsprit and went ahead and did the bowsprit yards and mounted them. The only rigging on the bowsprit so far is the yard lifts. I thought the bowsprit was the most complicated block/deadeye assembly I have encountered so far in modeling. I also included a shot of the full foremast, which I completed since my last post. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Thanks, Martin. I think I go fast and then slow, depending on what else is going on. I'm working on the bowsprit now, and there are a LOT of blocks to tie on. I think I'll do the bowsprit yards and attach them, and then shoot out another picture. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Antony: I am in astonished admiration at the beautiful quality and precision you have achieved in a scratch build. This is a masterpiece. Regards, David

-

Finished the lower fore mast. It's just dry-fitted in the picture. Lots of detail and blocks to attach. I really like this kit, but one thing I don't much like is the instruction to dye natural thread black when a small diameter thread is needed. The reason given in the manual is that black thread gets brittle when glued, but there was plenty of it in the Revenge kit, which is a later Amati Victory series kit. So I'm using the leftover thread from that kit when I need thin black. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Chris: Yes, I do plan to rig them -- but I forgot and might have kept forgetting, so thanks for the reminder! Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

All deck fittings and gunport doors now done. Next step is masts, yards, and rigging. Regards, David

- 126 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.