-

Posts

6,061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Keith Black

-

-

That's some super nice work, Paul. 👍

-

3 hours ago, kurtvd19 said:

Here is a link to where you can get your HO scale ruler, fast, easy & FREE. Make sure to set your printer to 100%.

Thank you, Kurt!

2 hours ago, sheepsail said:It is so easy to not get a feel of scale from the photographs of the Hard coal stern wheeler. This just means that I am in awe of the modeling skills here and look forward to the next installment of this build. Great work.

Thank you very much, Julie. And thank you for the entire post, very interesting.

- Paul Le Wol, Canute and sheepsail

-

2

2

-

1

1

-

As my ole carpenter foreman used to "file to fit, paint to match" Nice solution, Chris.

- Ian_Grant, Glen McGuire, Coyote_6 and 2 others

-

5

5

-

-

1 hour ago, kurtvd19 said:

WOW! I marvel at your small works of art. I have started building at large scales so I can add the details.

Thank you very much, Kurt.

At some point my fingertips aren't going to be able to continue working at this scale and I'll have to go to a larger scale. I'm seriously looking to move up to HO scale on my next build.

1 hour ago, Knocklouder said:Great work my freind, I know the feeling of making a beautiful little part of a ship to just cover it up, and you got to look sideways up close to see it.

Does this mean your finished this, and may be working on that ship I noticed in the background several times lol.

Fantastic work,

Thank you very much, Bob.

I'm a couple of months away from finishing this boat but I want to build an accompanying barge under the same build log which should take another couple of months, so we're looking at being done with this log about Christmas time. I then need to get back to the Tennessee and finish her while I'm still able.

- clearway, Knocklouder, Glen McGuire and 5 others

-

8

8

-

Roel, I love the way you've kept everything to the same scale. It keeps everything realistic and believable. Always a pleasure seeing each new post.

- Javelin, Glen McGuire, Paul Le Wol and 1 other

-

3

3

-

1

1

-

-

20 minutes ago, JacquesCousteau said:

Very nice work!

11 minutes ago, John Ruy said:Wow!😮 I am a FAN!

Excellent!!!

Thank you very much, Jacques and John. I hit the post button before adding my text (danged old people!) so you may want to go back and view again.

- Glen McGuire, Canute, Paul Le Wol and 1 other

-

4

4

-

Thank you to each of you for the comments and the likes.

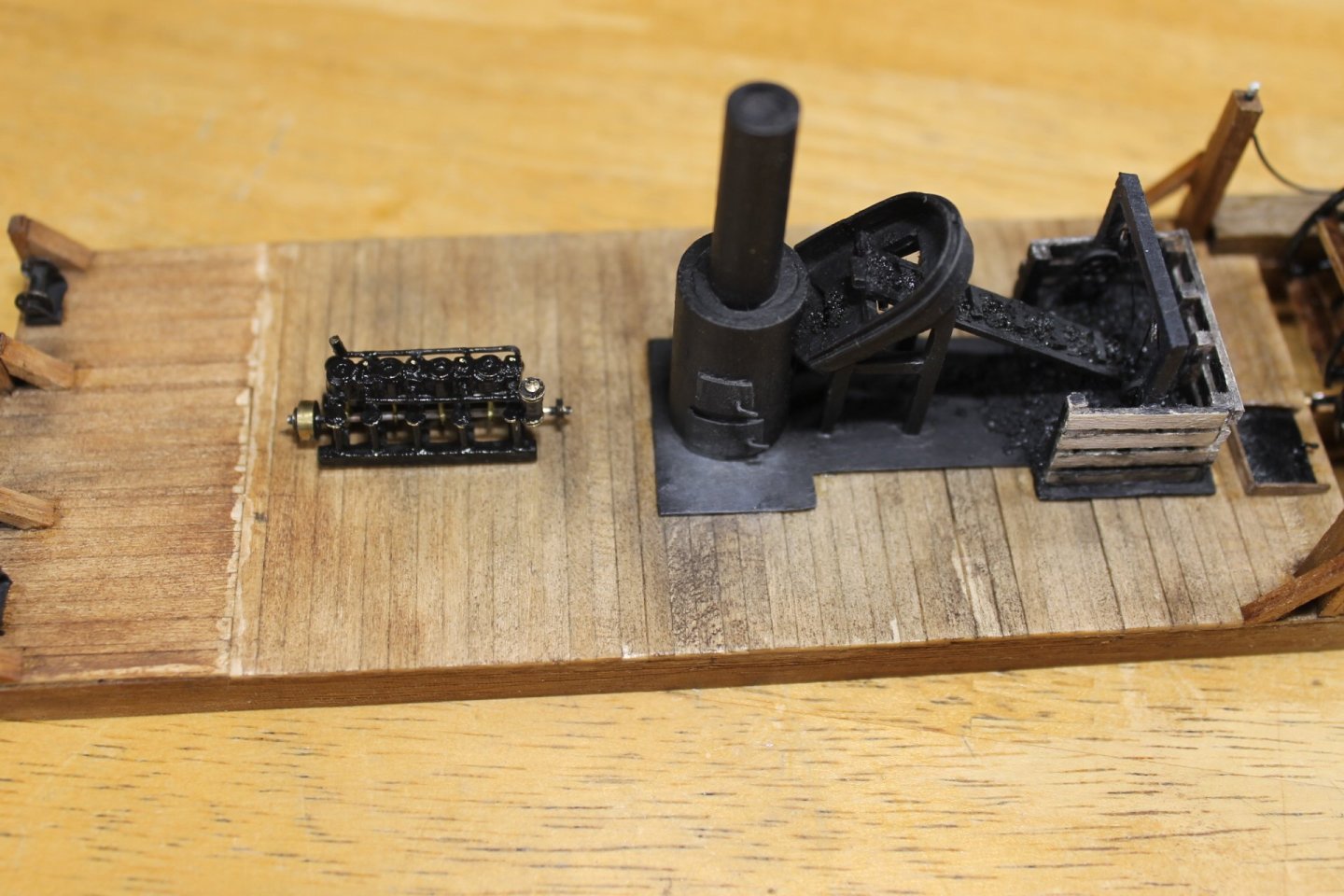

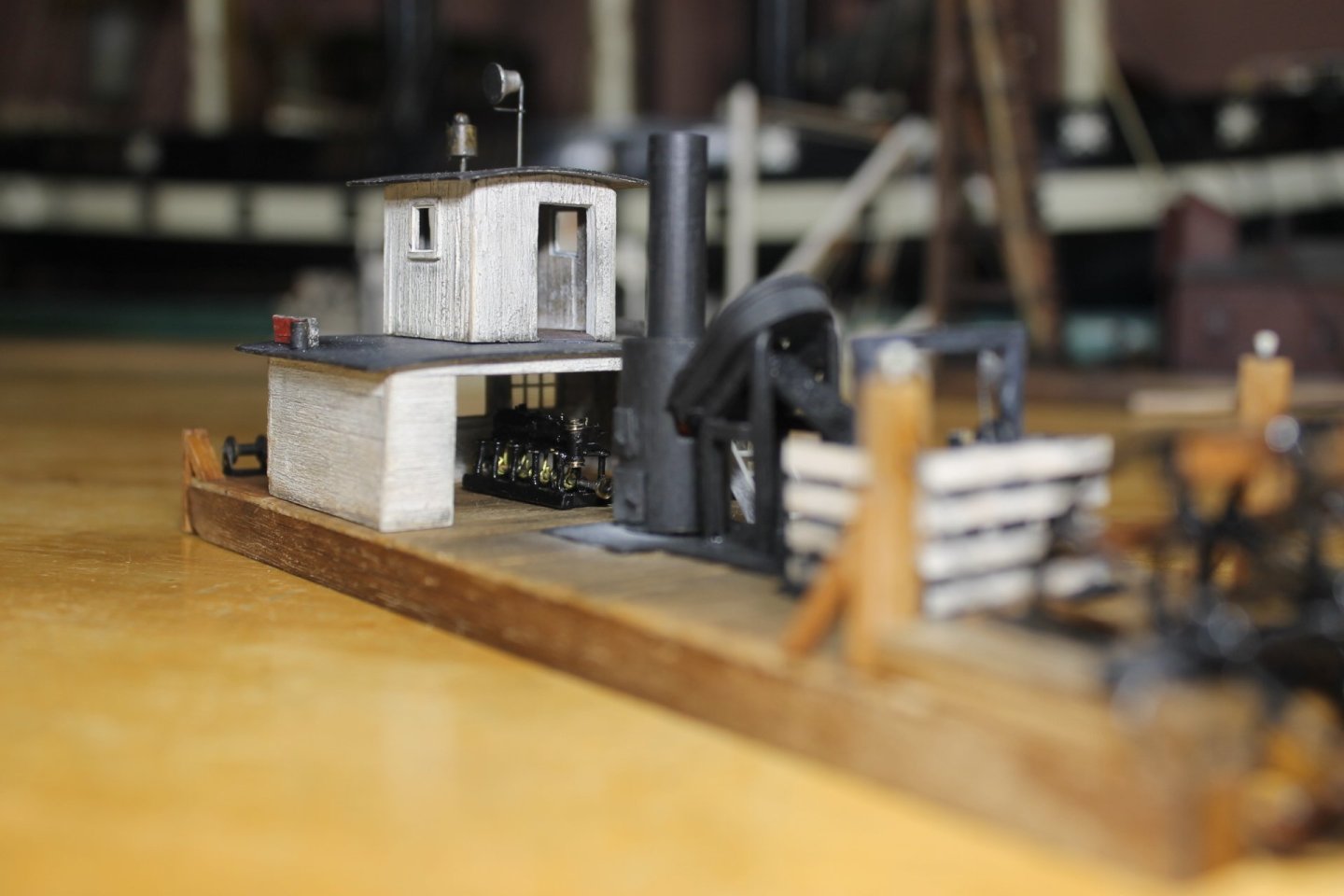

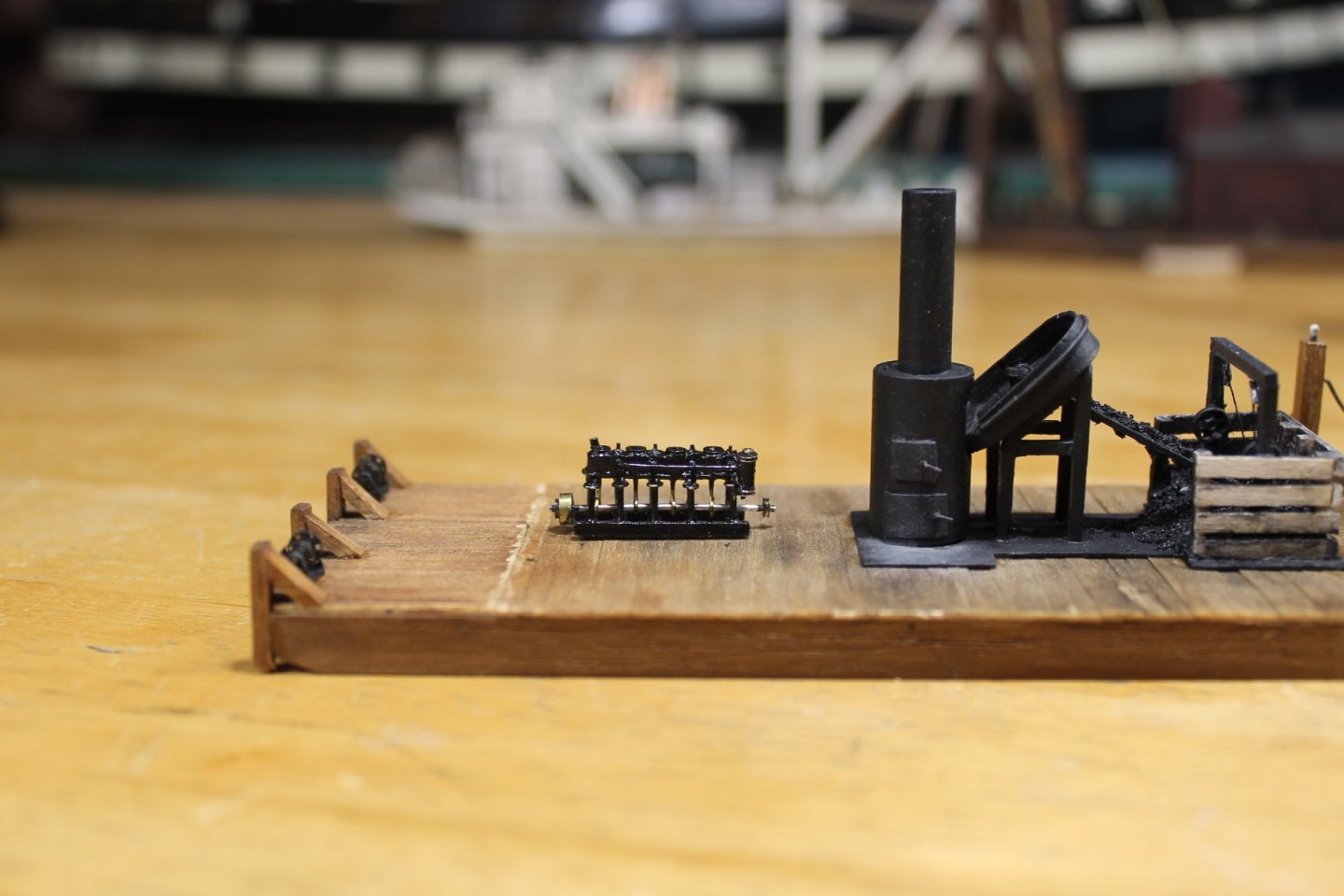

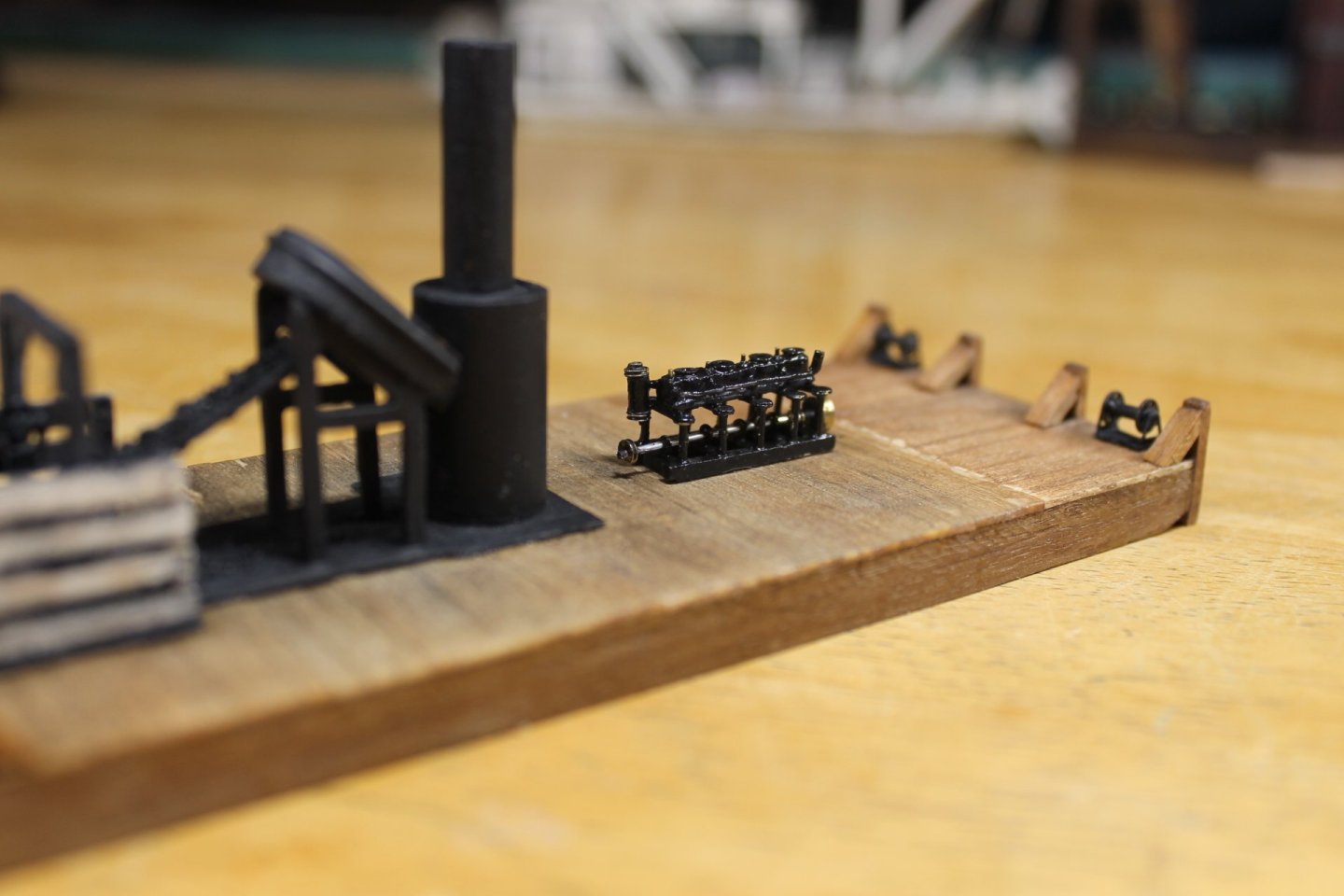

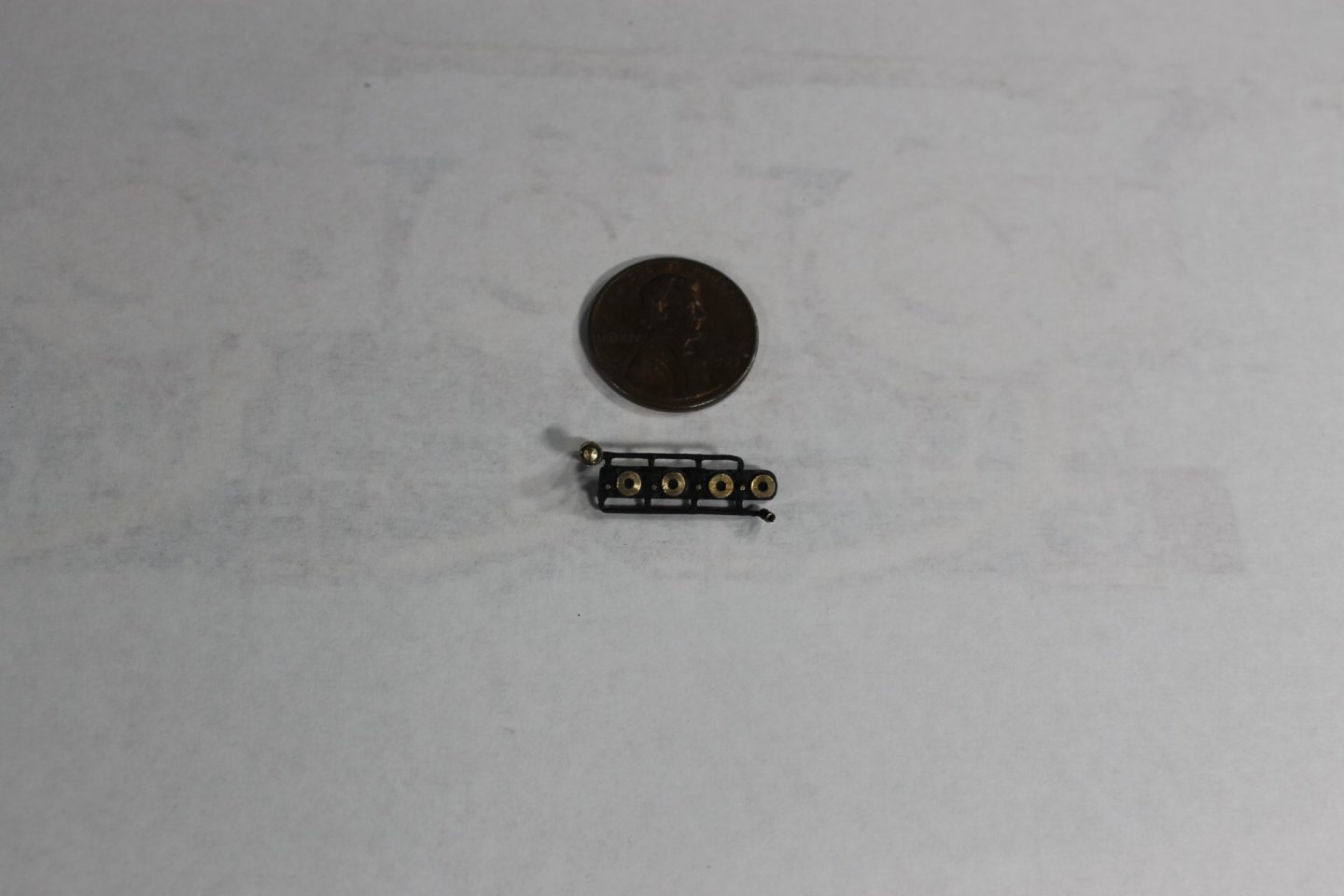

I'm calling the steam engine is done. I could add the reversing leavers but they would be on the starboard side and wouldn't be visible with the engine room attached. The engine can only be really viewed from the port side and with the reversing levers on the starboard, it's work that to me is somewhat pointless.

The crank is straight, there was no way I could make journals and get the nine eye pins (rods and bearings) to align. That task was tough enough with the crank being straight!

I get a real kick taking my boxes of bits and making something mechanical. The engine's final dimensions are engine body, 0.90 L x 0.41 H X 0.31 W inches. Flywheel to tail shaft is 1.15 inches. It took 64 individual pieces to make the engine.

There's no mistaking it's an engine even though little can be see when surrounded by the engine room.

It seems it's like this is becoming my signature, build an engine and bury it.

Thank you for your support and for being part of the journey.

Keith

-

-

SH, welcome to MSW. Glad to have you aboard.

-

-

Beautiful work, Jacques.

-

1 hour ago, clearway said:

even if condensers fitted there is a pipe for the boiler safety valve normally behind the funnel- your workbench looks soooo tidy compared to mine Keith🤪

If so that's incredible, Keith. If I get more than two deep I pretty much come to full stop.

- Glen McGuire, Canute, MAGIC's Craig and 1 other

-

2

2

-

2

2

-

- GrandpaPhil, Glen McGuire and Canute

-

3

3

-

10 hours ago, wefalck said:

Sound awfully familiar 😬

And yes, it's better to take pictures on a medium grey surface. I tend to use a medium green surface, as most of our parts are usually not green and that gives a good colour contrast.

Good progress so far. Looking forward to the rest of the engine !

Thank you, Eberhard.

12 hours ago, Dr PR said:Could the steam in the photo in post #222 be a whistle instead of engine exhaust?

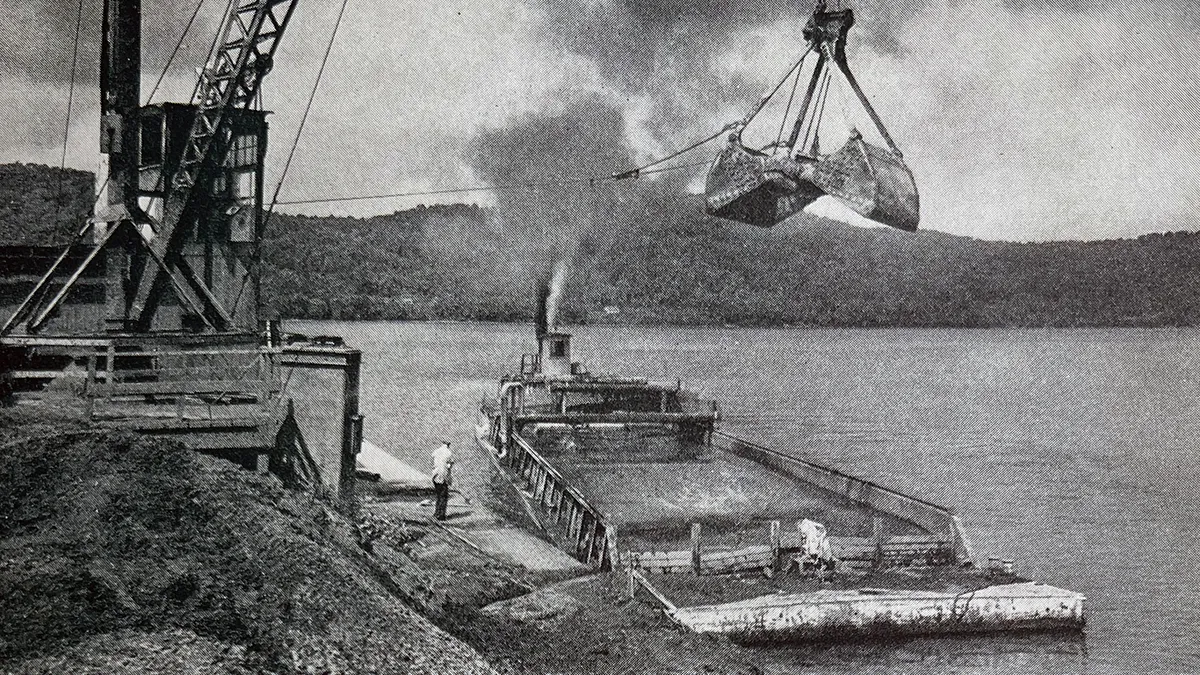

I don't think so, Phil. If it the engine had been a condensing/compound engine there wouldn't have been the need for an exhaust stack at all, just a pipe over the side. Note the exhaust pipe coming off the engine as seen through the engine room bow window.

- GrandpaPhil, Glen McGuire and Canute

-

3

3

-

Beautiful micro work, Ilhan.

- Ilhan Gokcay and Paul Le Wol

-

2

2

-

BB, welcome to MSW. Hoping your Bluenose goes well. Glad to have you aboard.

-

1 hour ago, Paul Le Wol said:

Keith, that is a fine bit of micro-fitting!

Thank you, Paul.

2 minutes ago, Coyote_6 said:So small. So cool. Love seeing the fleet together!!

Thank you, Steve.

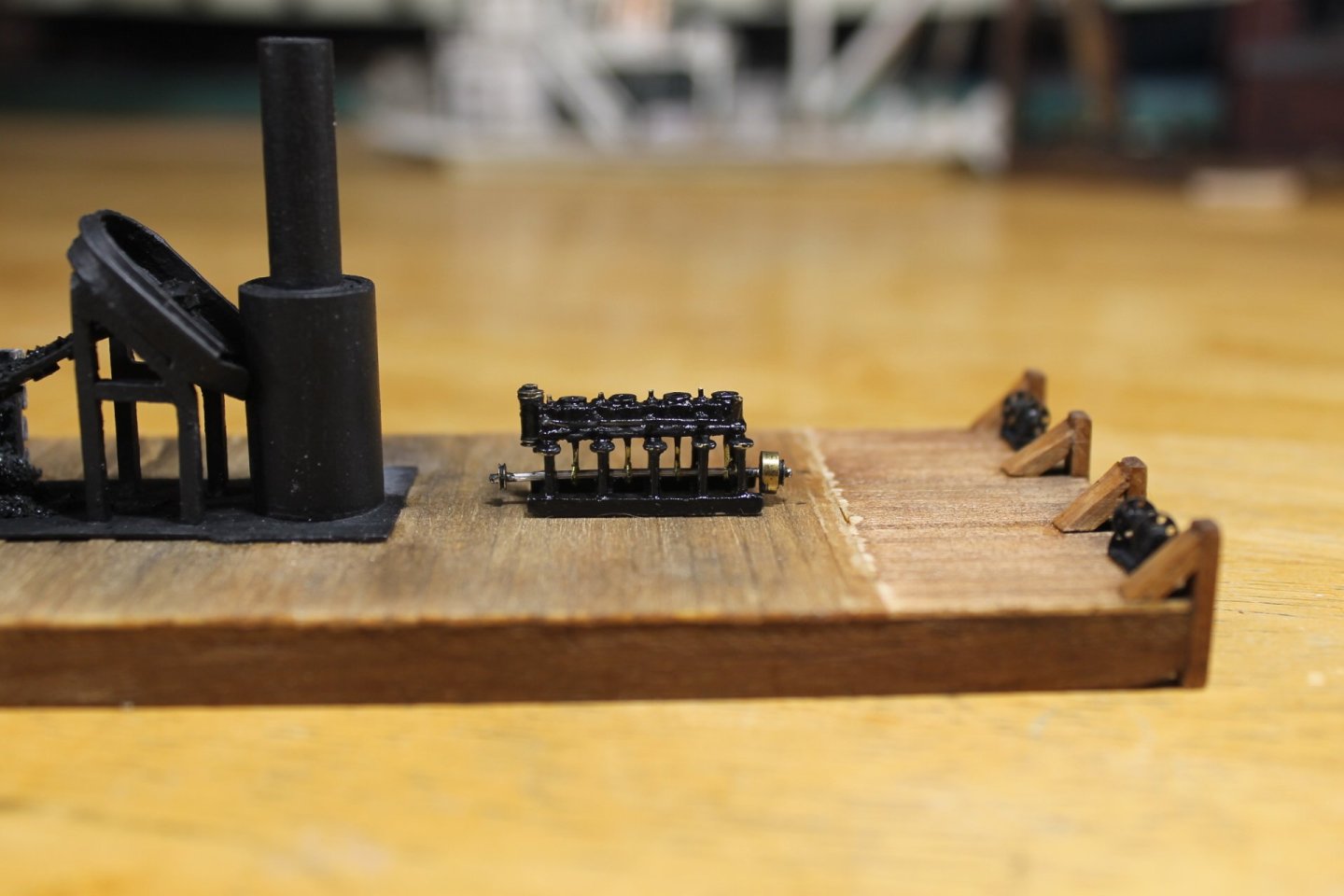

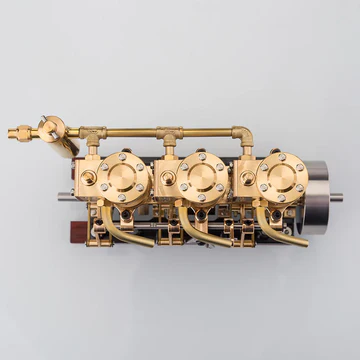

Those photos in my last post were bugging me so I took what look a little better. I had also wanted to include a top down photo of the three cylinder model.

When the engine is completed I'm going to ploy coat it due to machinery paint gloss, oil, and moisture. I think it will look more natural with poly coat than flat black.

-

Thank you to everyone for the comments and likes.

There should be a steam engine in there somewhere.

In the heat of battle. All that mess working on a piece less that an inch long.

Cylinder heads and steam chest glued to plywood backing. I have a large work surface but invariably I work at the bottom edge of the table, that's why I have so many escapees.

The top end is done. Horrible photo, no more taking photos on a white background.

I'm pleased with the top end, hopefully I can get the bottom end to match. It took 31 pieces to make the top end. I was trying to hold the top end length to 0.70 inches but it came out to be 0.90 inches. This means the completed engine will be about 1.1 inches, to scale that makes the engine 11 feet in length. What a monster!

Thank you for your support and for following along.

Keith

-

Great recovery, Vaddoc. Hercules is coming along nicely.

-

Dan, I assume you have an X-Acto knife. If you don't, get one because they are great tools. Using an X-Acto knife with a #11 blade practice on scraping away material by practicing on the spure. Those four outside legs would be perfect practice pieces.

-

2 hours ago, Javelin said:

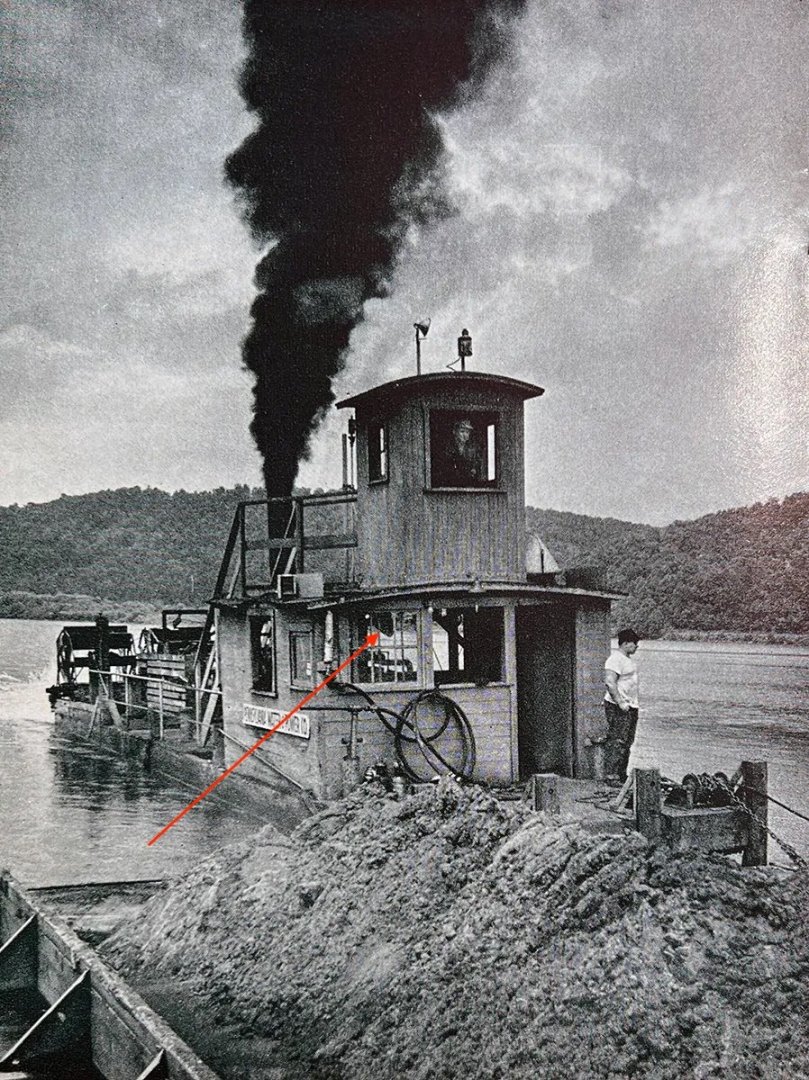

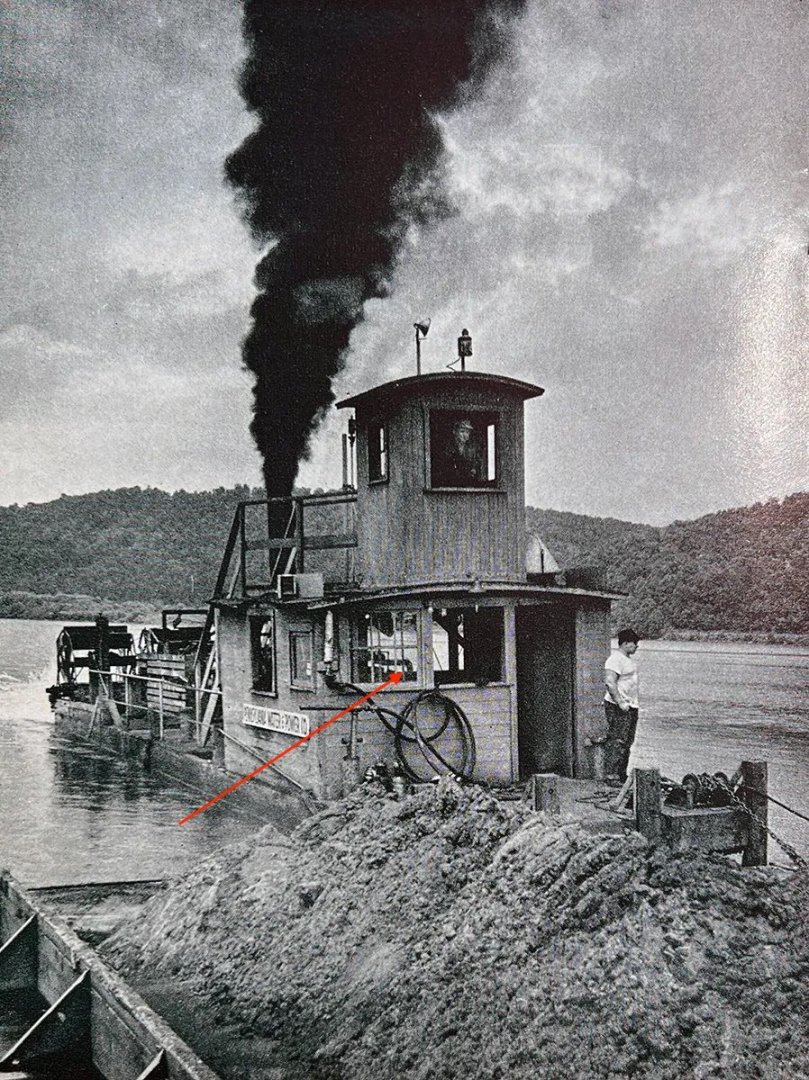

I may have missed something, but in the pictures, I only see black smoke being emitted from the main funnel. That would be the exhaust of coal being burned in the boiler. I do not see any white steam being emitted except from that small pipe in some pictures.

That said, with such small space, placing a condenser etc. wouldn't be very practical. On the other side it would require a lot of fresh water stored in tanks...

All in all, a very fine build! Love that subtle weathering, a difficult task at such scale.

Thank you, Roel

The below photo is the best for showing the exhaust. As much as I tried talking myself into the engine being a triple expansion I couldn't because of this photo.

On 8/24/2025 at 1:03 AM, Dr PR said:

On 8/24/2025 at 1:03 AM, Dr PR said:I would search the US Patent Office for vertical non-condensing steam engines. I would expect to find quite a few - with drawings. Just pick one dated from about the time the tug was built.

Thank you, Phil.

I have enough engine photos to move forward as they all look close to being the same. Finding mention of a special four cylinder marine non condensing engine allowed me to consider and make that engine. Good news, the engine build is going well. Hopefully I'll be able to post photos this evening.

- Coyote_6, clearway, GrandpaPhil and 7 others

-

10

10

-

4 minutes ago, JacquesCousteau said:

and run some battens to help determine how to place the cant frames

To me that sounds the easiest and most accurate way to do it, Jacques.

- Paul Le Wol and JacquesCousteau

-

1

1

-

1

1

Motivated Newbie

in New member Introductions

Posted

Rich, welcome to MSW. Glad to have you aboard.