-

Posts

6,684 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Nice work, Ferrus. Great visual interest, now all it needs is a cane pole.

- 56 replies

-

- Lindberg

- sternwheeler

-

(and 1 more)

Tagged with:

-

She's really taking shape, Glen. I'm glad that you found the MWP plywood beneficial. For small scale structures and bits it's the cat's meow. Too funny.

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

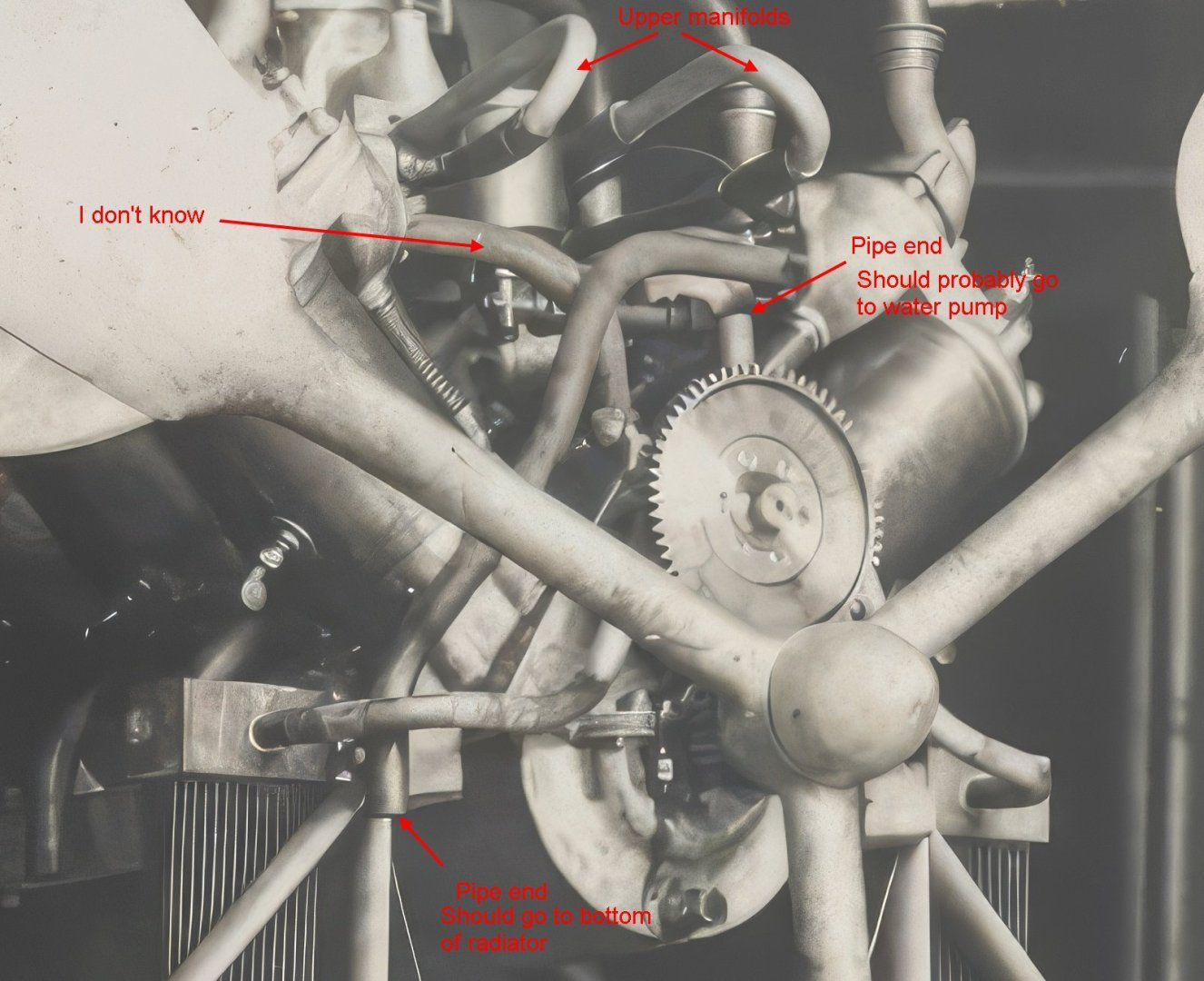

This is why I'm having trouble with a water pump being thrown into the mix, early water pumps were sketchy at best. I know those 16 cylinders are going to produce heat but the designer is adding a sketchy pump for a ten minute ride? As long as there was enough external water and room for expansion ten minutes is nothing. It's a whole other kettle of fish if we're talking hours but ten minutes? I just can't see trying to invent the wheel for ten minutes. I've seen guys run V-8's without any water (testing after a rebuild not wanting to add coolant in case they had to pull the heads etc etc) for almost ten minutes. You guys say water pump, okay, but I gotta tell ya I'm a bit skeptical.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Greg, please correct me if I'm wrong but I think I remember you saying that the engine was run for a very short duration of time when at trials hence the small fuel tank? What would have been the actual run time between start up and shut down after the run?

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Craig, without doubt the prop is driven off the crankshaft. If the engine was thermosiphon cooled the need for a water pump is eliminated and the two pumps at the rear can be oil and fuel. When I was restoring cars I restored a 1919 Model T (a for real fairground racer out of Wisconsin) and the engine was thermosiphon cooled. I rebuilt a couple of Chevrolet 216 engines and they didn't even have oil pumps! I think every early designed engine was unique and far far different than today's engines to say the least.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Below is from Google AI... In a 16-cylinder, two-stroke engine, the crankshaft gear will turn four times for every one rotation of the camshaft gear. This is because a two-stroke engine completes its cycle in a single crankshaft rotation, while a four-stroke engine requires two crankshaft rotations. Therefore, the camshaft, which is typically geared to the crankshaft, would rotate at the same speed as the crankshaft in a two-stroke engine, meaning it would turn four times for every four crankshaft rotations, as opposed to the normal 1:2 ratio in a four-stroke engine. Gear size relationship for 2:1 ratio.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

I'm amazed they got away with no oil on those gears unless there was runout oil from/off the crankshaft/prop shaft. Or is there a cover I've somehow missed?

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

I assume this beast had a camshaft, is the large gear driven off the prop shat the timing gear driving the camshaft?

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

You guys are way ahead of me on the engines technical details but have either of you considered a simple thermosiphon cooling system? The elongated radiators on either side appear to be ideal for such a system.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Simple and clean, Jacques. Very very nice.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

The building jig looks great, Jacques. Nice job.

- 139 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

Eric, I thought the same thing. Ferrus started his build log fire not realizing how many ole moths would be drawn to the flame which is a testament to those in the modeling community who's interest run deep in sternwheelers and working boats.

- 56 replies

-

- Lindberg

- sternwheeler

-

(and 1 more)

Tagged with:

-

\ Ferrus, the flue gasses travel in a u-shape going from front to back and back to the fore to exit. Theory of design being the longer the flue gasses remained in the boiler the greater the heating capacity. IMHO the Southern Belle kit is a rudimentary example of a 19th century sternwheeler begging no forgiveness for details not accurately betrayed. It is what it is, made for the enjoyment of building the kit.

- 56 replies

-

- Lindberg

- sternwheeler

-

(and 1 more)

Tagged with:

-

Those davits turned out great, Glen.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.