-

Posts

5,518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

I hope you left yourself enough room to belay on those pins. Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

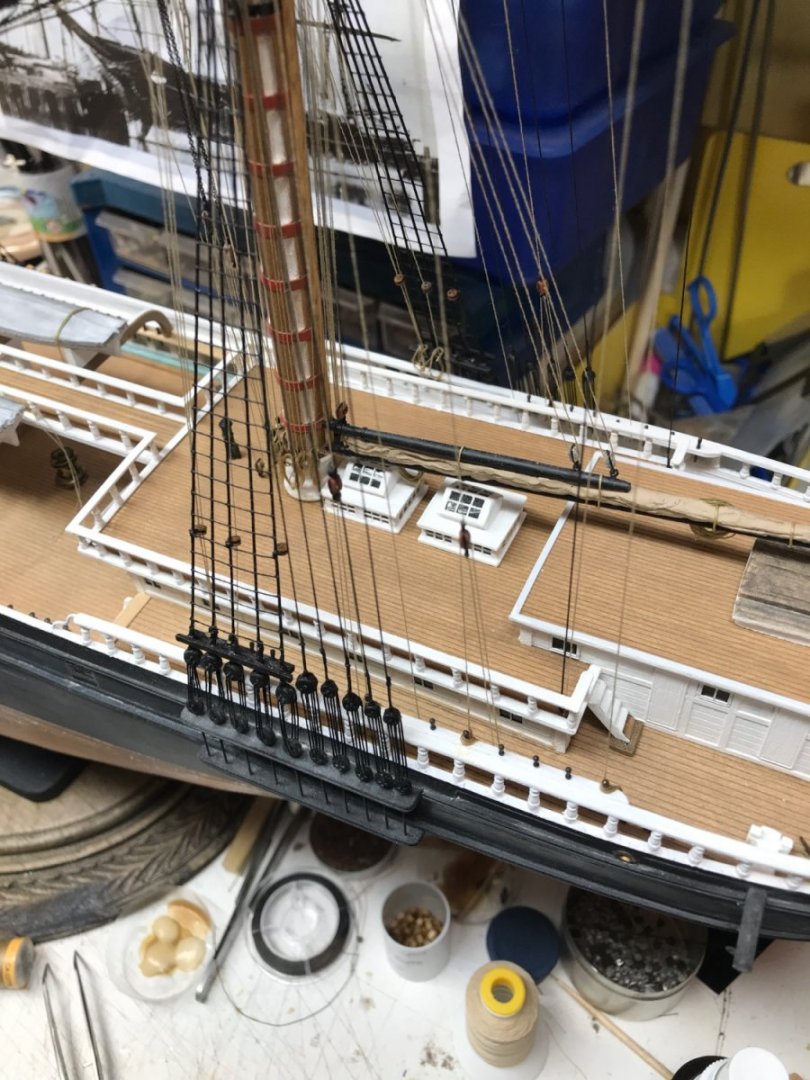

Now I’m ready to begin the starboard backstays. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

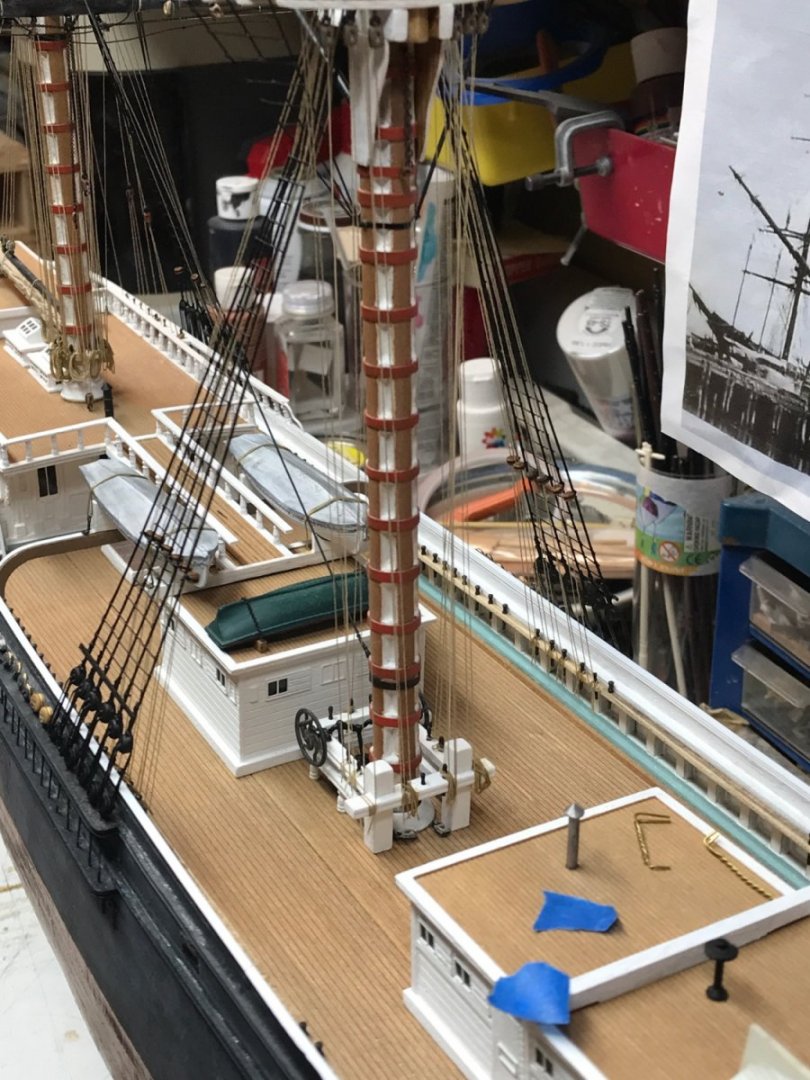

Thanks everyone for the fine compliments. I spent time running the rest of the main mast haul yards as well as the starboard mizzenmast braces. All these internal lines must be rigged before the back stays. I opted to work this side as much before I flip her around…….since that is becoming a real task. While I was thinking, chose to drill out the hull fairleads for the main upper and lower topsail yard braces. Here is a few pics of what I have done thus far. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I build and add the rigging to each mast off model. I rig every aspect for yard control and sail control. Then set the mast and then begin the complex running and belaying the lines to their appropriate pin. you need the shrouds mounted first. before you can rig up the fairleads for the bunt lines and then belay them as well. Currently I am finishing up the haulyards for the main mast yards. The trick is deciding when to include the braces for the mizzen yards....BEFORE I rig the backstays. It is a *layering* maze for sure. Good luck. I'll help in any way I can. Ro

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I love polystyrene formed strips...they come in every imaginable form/shape.....love-em. Great job....... Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

This is so true...One must also take into consideration the type of line you are using...cotton or nylon, coupled with the direction you are reeving the lanyards in the deadeyes. I've been able to control twisting by these simple tricks. Rob

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

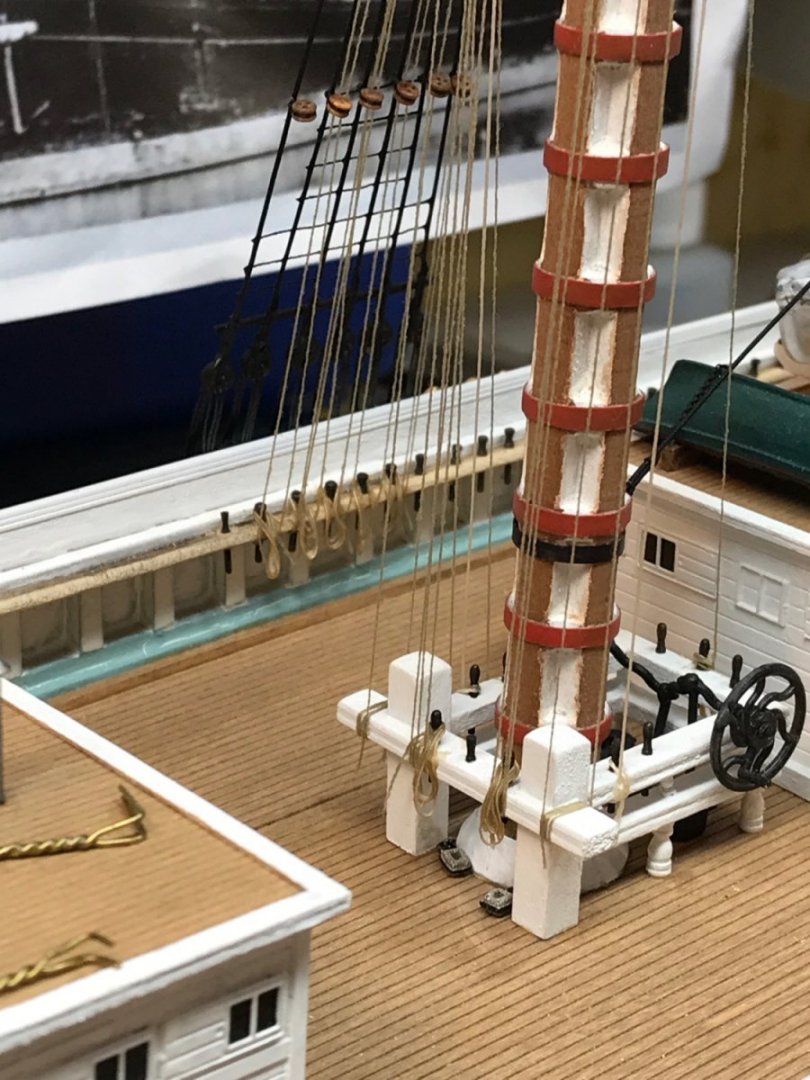

These little guys(No more then a 1/4" long) are problematic in their installation. But they have to go in pretty much as the line gets belayed....because of space restrictions. I can spend an hour just planning out the next series of installs. Do I run the mizzen yard pennants and their braces down to their main mast blocks and then down to their belay pins......or do I do the same for the main mast yard pennants and their braces down to the mizzen mast blocks and down to their belay pins.........or lastly...do I run all the haulyards and their purchases for the main mast yards first? This mental process takes time....but really what is happening, is I'm trying to devise the easiest systematic process for install of all these elements, in the easiest sequence. For my mental stability's sake. I chose to run the main mast haulyards first....because, I had to reach deep within the build to add the deck eye bolts for the haulyard origin and the return blocks on the opposite side, mounted on the pin rail cap. 8 holes drilled for 4 eyebolts and 4 blocks-n-eyebolts. Thank the Lord I have small 90deg drill heads for my dental hand pieces......Or I would never have been able to successfully drill the holes for all those eyebolts. Foot long sharp tip tweezers are essential. One final note. I'm not sure if I will be adding the stay sail rigging....most of the time, these sails and their rigging where un bent and brought down while the vessel was in port. I'm still thinking about it. All of this before I install the backstays Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

The 70’s I think, it has the plastic sails. The hull isn’t painted copper, like my 50’s versions. Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Good job, very clean. I was out yesterday and I found a CS kit at a local steam tractor museum for sale(believe it or not), and it is still in its original plastic wrap. I’m gonna use it for parts. Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

That’s a quick and easy solution. Make sure the eye is on the bottom that you have on the top. Proper deadeye position. Good move. Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Yeah……those fair leads are smaller then a 1/16” and with 3 leads through them that thread like needles. Tiny stuff. I had to add two more belay pins at the rail to accommodate all the additional lines coming in from the mizzenmast yards. Calculating the sequence of line install takes as much thought at actually installing the lines……so I have no mishaps with tangling and crisscrossing. Thank for the confidence. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Indeed, that is why I use foot long tweezers and good agility. Still it takes a steady hand. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Yes… the GR was much smaller in scale, 1/128…….but because of her size she is still longer then Glory is at 1/96. Man GR was. Handful to rig. I left off no detail. I’m hoping to do the same or near the same with Glory. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Worked on finishing the port bunt line fairleads and belaying of the lines. Sweewww. What a web. Rope coils will follow. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Indeed, the miniature nature of our models makes tanglement of lines more difficult, do to the difficulty of viewing the issue from the deck up. Sometimes my vision goes wonky and I see weird depth phenomenon. Thanks as always. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Spent some time finishing up the rat lines and belaying bunt lines and adding rope coils. Lots of little details. Soo soo much more to do. Rob IMG_2863.MOV

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

No...no specifics. I opted to use dead reckoning.........and visuals. Those items are so *iffy*, but if you use your head and determine from other ships...you can make a pretty close proximation. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Yes...you can easily fare out the inner edge to reduce the *flaring* of the lanyard. Still it is no real problem....remember not all of these bullseye's lanyards have to be the same length...they are indeed meant for tightening. But to keep things shipshape and Bristal clean...do your best. I'm currently reading the book *before the mast in the clippers*....to compilation of diary entries of a young man....and on several occasions he notes hours of painting the rigging and his hands were black as coal. Even historical accounts demonstrate the practice. So if the most accurate and detailed model is your aim...why not continue to be correct and rig properly too. Great job on your CS. Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Just paint the ones you already did black..... Rob

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.