-

Posts

333 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Derek C

-

Luckily I got the first few planks on without incident. But the boat was very fragile to handle, I thought for sure I was going to snap a bulkhead or two I would recommend leaving the inside bracing on and just cut enough off to install the transom .I see why Steve asked his question and realize my mistake as soon as I removed them,a noob mistake for sure . And I'm sure more of those to come lol ,

-

I started planking today and found out teak don't like to bend the way I wanted it to . I Even soaked the pieces over night . But it did not phase the wood planks. So I went to the kitchen and boiled them, I started with six planks but found once they cooled even slightly they were not as playable is I wanted .so I boiled two and formed them let them cool and dry and then set them on the hull . Then repeated process.

-

I have glued in the bulkheads and fillers at the bow ,I also glued a couple pieces of basswood strips on the inside of the hull to help sturdy it up a bit while fairing the outside of the bulkheads. I glued them close to top of the bulkheads to make removing the basswood and cleaning off the glue easier .

-

Hello from Perth, Western Australia

Derek C replied to Peter Bloemendaal's topic in New member Introductions

Welcome to MSW Peter I am new to this forum as well, and have used many parts of it to get help on many different subjects from tools to wood ,and the knowledge you get from the members and there posts are overwhelming I can read them for hours until my brain can't hold any more lol Have fun can't wait to see your Syren get started in a log Derek -

I started on my bulkheads, Using the traced bulkheads from the plans and proceeded to "hack " out a rough shape around the paper templates. I say hacked because as u can see from the photos I wouldn't say I "cut " them out lol . Then I used files and sanding blocks to get the shape to match my template , then I got smart and got rid of the files and sanding blocks and broke out my dremel with the rotary shaft and sanding drum and life was good . I did use the files and sanding blocks to get the final shape of the bulkheads . I really enjoyed building the kit of this longboat , but must say the joy of creating these pieces from scratch is great and very relaxing. this is the first time doing a scratch build and I think I'm doing it ok . I hope to have the bulkheads done, glued and the hull faired so I can start planking this weekend . Also I posted earlier that I was cutting my planks at 1/32x3/32 but that was incorrect . The planks are cut 1/32x 1/8 . I cut them a bit larger so I can sand the edges to get my final measurements and keep them all true .... well that's the plan anyway. I will let y'all know how that works out for me .

-

-

Welcome to MSW , there is so much info and knowledge here at MSW , I'm sure you will find all the help you need here to point you in the right direction. Best of luck Derek

-

After I had the rough cut out , I used a few drops of glue to adhere the paper template I had traced earlier to it. Then I broke ot my files and sand paper and slowly worked the rough cut teak to match my template. I then removed the paper, and sanded of the glue and shaped the aft of the fakse keel. I also shaped the bottom edge of the false keel bringing them down from 3/32 to 1/32 to allow the planking a nice place to sit.

-

Today I actually got to start fabrication , I wanted to get the false keel done first , as it looked like it was going to be the most complicated peice to make. So I traced the plan for the false keel onto a piecs of paper and then transferred that onto a piece of 3/32 teak that I had ripped earlier in the week . Then I used my Dremel with a multi purpose cutting bit #561 , and the cutting guide attachment. To get a rough cut around my marked pattern.

-

Welcome to MSW , There are many forums and members here with tons of great info and experience. I am new to this hobbie as well , and love being a member of MSW its helped me alot. Derek

-

Looking real good just read through your build log , and like the fact you work through the problems with ease. Shes going to be a good looking ship

- 181 replies

-

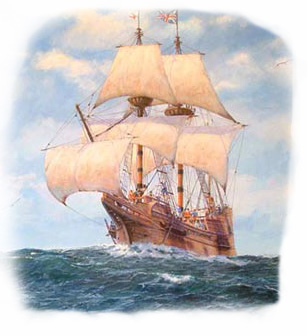

- santa maria

- mamoli

-

(and 1 more)

Tagged with:

-

Ok so I finished my longboat kit build from model shipways and found it was fun and challenging,so I started looking at other kits to build my second model . Then yesterday by chance I got a bunch of teakwood from a friend and thought to myself what am I going to do with this . Then I figured why not cut it up and build another longboat but this time from scratch using all teakwood. I have never done anything like this before and never worked with teakwood before . But what the heck I figure I'll give it a shot. I will build it using Model Shipway plans and instructions .

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.