Jeff T

Members-

Posts

247 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

San Diego, CA, USA

-

Interests

Plastic sailing ship models,16th-19th centuries.

Recent Profile Visitors

-

Jeff T reacted to a post in a topic:

SOLEIL ROYAL by Robert Taylor - Heller - 1/100 scale - PLASTIC - side project

Jeff T reacted to a post in a topic:

SOLEIL ROYAL by Robert Taylor - Heller - 1/100 scale - PLASTIC - side project

-

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Bill Morrison reacted to a post in a topic:

Mayflower by Bill97 - FINISHED - Trumpeter - 1/60 Scale - PLASTIC

Bill Morrison reacted to a post in a topic:

Mayflower by Bill97 - FINISHED - Trumpeter - 1/60 Scale - PLASTIC

-

Jeff T reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

Jeff T reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Jeff T reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Jeff T reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Jeff T reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Jeff T reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

Jeff T reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Jeff T reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Jeff T reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Trumper07 reacted to a post in a topic:

Spanish Galleon by Jeff T - Revell - 1:96 - PLASTIC - with modifications

Trumper07 reacted to a post in a topic:

Spanish Galleon by Jeff T - Revell - 1:96 - PLASTIC - with modifications

-

JeffT reacted to a post in a topic:

Spanish Galleon by Jeff T - Revell - 1:96 - PLASTIC - with modifications

JeffT reacted to a post in a topic:

Spanish Galleon by Jeff T - Revell - 1:96 - PLASTIC - with modifications

-

I am finally back at work on my galleon after a hiatus of several months while I worked on a different project. There is not much new to show yet, though. I just started to apply a matt varnish to the glossy upper surfaces of the ship. I am brushing it by hand, because I have not had good luck with matt spray varnishes in the past, and I do not want to deal with an airbrush. Brushing a matt varnish can be tricky. It may at times be difficult to achieve an even, consistent appearance.

- 133 replies

-

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Old Collingwood reacted to a post in a topic:

Black Pearl by P.Raveneau - Zvezda - 1:72 Scale - PLASTIC

Old Collingwood reacted to a post in a topic:

Black Pearl by P.Raveneau - Zvezda - 1:72 Scale - PLASTIC

-

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Old Collingwood reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

Twokidsnosleep reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

Bill, here is a link to a place that sells 2-wheeled carriages: https://www.mantuamodel.co.uk/products/ship-fittings/guns-and-cannons/964/gun-with-carriage-kit-1-detail The wheels are rather proportionately small, though. I ended up modifying 4-wheeled carriages to make 2-wheeled carriages for my Spanish Galleon.

-

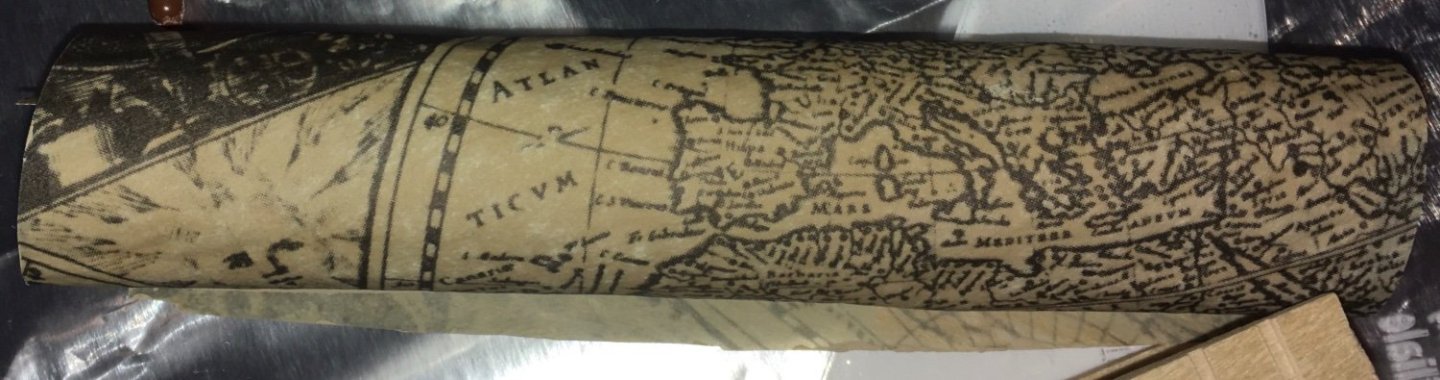

Correction: Actually, I recall that I had to cut the area down before I painted it, because the water in the acrylic paint makes the paper buckle and warp, and I needed to tape it down to try to prevent that. It ended up buckling anyway, so I rolled it a bit to smooth out many of the buckles: This rolling technique may be helpful if acrylic paint is needed on paper sails or flags. Once the paint is completely dry, the paper can be unrolled and then rolled again in the opposite direction, repeating the process until the paper is flat.

- 133 replies

-

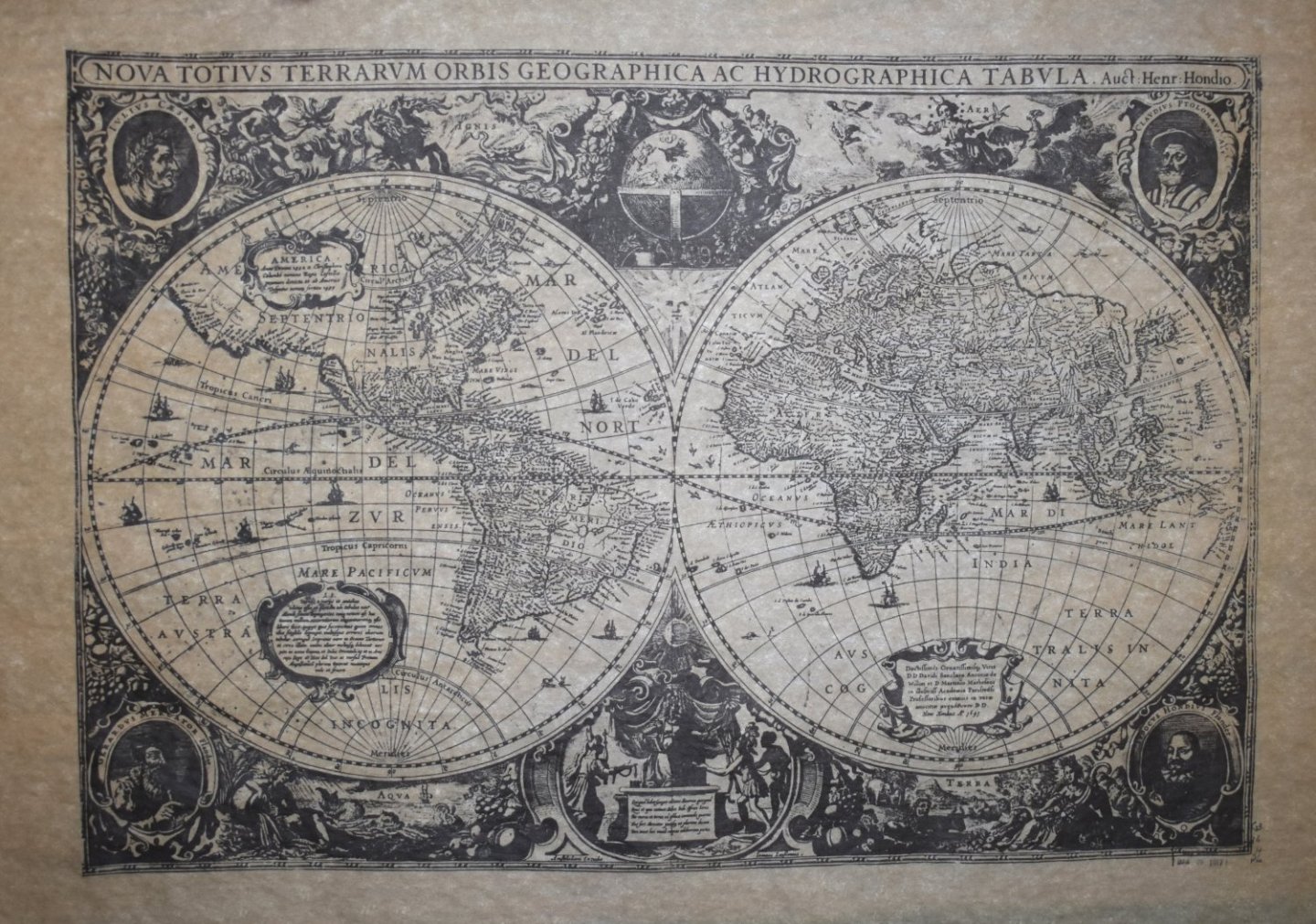

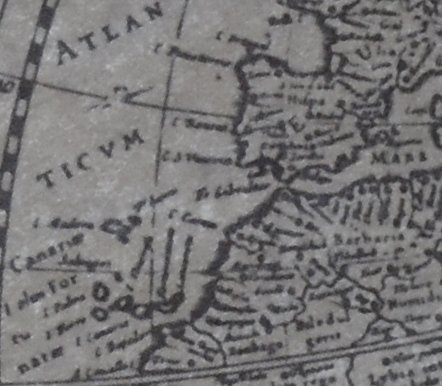

Here's a little update. I wanted to add some maps to the cabin furnishings, so I ended up using a copy of a famous 17th century map of the world from 1630 by the cartographer Henricus Hondius. He was Dutch, but the place names on the map are in Latin, so I think that that would still be OK for a Spanish galleon. The copy is on a faux parchment paper: The parchment effect gives it a more antique look, and some maps from that time period may have been printed on parchment anyway. This map is pretty large, so I honed in on a small area of it for the model: I thought that by including a contemporary map of the Iberian peninsula and its surrounding water and also a map of the Canary Islands would be a nice way to link the ship to its nationality and to the 17th century. I also wanted the maps to avoid emphasizing Spain's political aspirations and conflicts during that time period. Therefore, the maps do not specifically focus on countries which were historical enemies of Spain (but are now its allies). True, the map is very much out of scale for my ship, but I wanted to show recognizable detail, and by using a couple of very small portions of the big map, I could make a "large" wall map and a sizeable "desk map" for the captain's cabin. The faux parchment paper is somewhat translucent, so in order to prevent the glue (used to affix the wall map) from soaking through it, I needed to paint the back side with tan acrylic paint. I cut the area down to size after painting the back: So a piece of this was trimmed down to fit on the inside wall of the fore bulkhead of the captain's cabin. Below is what the bulkhead looks like from the "outside". It will be eventually be situated just aft of the helm. The back side of it (inside the cabin) is where I glued the wall map: Note that the inside surface of the bulkhead is not flat. Initially, it was flat, but it did not have any usable detail at all, because the windows were not open and nobody would be able to see inside the cabin if I built it "out of the box". The window on the right is raised because it is where I glued a piece of clear polycarbonate to serve as "glass" to cover the window, which I had created by cutting out the center and gluing wire mesh over it, then painting it gold. I purposely painted the inside walls of the cabin a dark color (Testor's Model Master Italian Dark Brown enamel) so that they would not be very visible and hopefully absorb much of the light, allowing the emphasis to be on lighter objects such as the maps, windows, beds, tables, chairs, figures, sea chests / treasure chests, and lanterns. On the larger table, in the captain's cabin, I will place a map that I trimmed down to show the Canary Islands. It will be laid out before the captain, who will be seated next to it. In the pilot's house, I will place a rolled-up piece of the faux parchment on the smaller table (the "scroll" map idea is one that I have seen elsewhere on the forum). So that concludes the cabin furnishings. My next project will be to apply matte varnish to the glossy areas of the ship so that it will then be ready for me to glue down the gun carriages.

- 133 replies

-

Jeff T started following Sovereign of the Seas by 72Nova - Airfix - PLASTIC

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.