-

Posts

1,933 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hamilton

-

Work area pictures only

hamilton replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

@Nirvana - Yes that's my scratch Bluenose (the last model I completed) in an early stage of development - you'll also recognise Syren perched between the frames of another project I've been slowly working up in secret - a 1:48 scratch of HMS Scarborough based on the Anatomy of the Ship Blandford - which I'm building using a hybrid P.o.B. (from the gun deck downwards) P.o.F. (gundeck and above) approach - it's another version of the 1:100 scale Corel Greyhound I built as Blandford over a decade ago.....work at the bench is slow, but time still flies!!! Aspects of Einstein's relativity theory can be experienced in this way! hamilton -

Work area pictures only

hamilton replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

Hi Tim - nice looking space - I'm guessing you use that two-hander saw on the wall for particularly large modelling projects. Here's my little corner of the world - though honestly it has not seen much use lately, sad to say - been too busy with work and home projects and other things for the last few months.....a couple of before shots of the dilapidated garage it used to be for comparison....the "after" photos were taken when it was more or less brand new (2021) - it is a bit messier now with more tools and more storage space....but it's a nice spot to be in on a sunny Saturday morning with a hot cup of coffee. hamilton -

It is hard to believe that a model manufacturer can long sustain the cost of absorbing the tariffs - though I also acknowledge my ignorance of the business side of model manufacturing...I just can't imagine that there is the kind of critical mass, given competition among manufacturers, for this to be a long-term solution. Fortunately for us Canadians, we can still import from Europe under CETA without these concerns and we (like US customers) are exempt from the UK's VAT as I understand, but our market is (like in everything else) tiny taters compared to the US....will be interesting to see what the future holds...regardless of how expensive it gets, hull planking still drives me crazy!! hamilton

-

Actually, in response to US tariffs on China, China imposed tariffs on Canada (I personally don't get that logic, but).....so them shipping through us is not a viable solution for the import tariff situation south of the 49th.....one thing seems clear - that things are just going to be more expensive unless you can source domestically - regardless of what country you live in....time to tighten your belts! hamilton

-

Cool idea - as an occasional puzzler (1 at Christmas, completed furiously; 2 in the summer, nibbled away at in my leisure) I've noticed that there are a diminishing number of good subjects and manufacturers seem mostly to be going for either branded images (disney, star wars, etc.) or really crazy-making and repetitive ones (near identical red and white striped candies in a bowl, or a bunch of watches in a pile, etc.). There is the Ravensburger 9000-piece Battle of Algiers (which I hope to get as a retirement gift - though my pension statement tells me that I won't really be able to afford to retire until my mid-70s), but right now that is not a realistic possibility, attractive as it is. I usually try to find historical images, cityscapes or landscapes - but these are increasingly not on offer by the main manufacturers, and I just can't bring myself to do a puzzle featuring kittens playing with yarn or an assortment of Disney princesses (no judgement against those who go for that sort of thing). These images immediately attract the eye and are actually interesting subjects even for people who aren't into ship modelling. hamilton

-

Well it's been a while since I posted here - been in and out of town a lot, but mostly the issue is that I am completely stymied by the main deck framing.....I've got the beams cut and I made what I thought would be a useful framing jig, but now I really have no idea how to proceed....notching out the beams for the beam arms and carlings seems relatively straightforward, but fabricating the lodging knees and beam arms to account for the deck camber has my head spinning and every time I've sat at the bench, I find myself just looking at things, trying to decipher from the practicum exactly how to go forward....so at the moment I'm stuck and with work starting up again next week (!!!) I'm not sure when I will be able to just knuckle down and start in.... If anyone has any tips or pointers for this part of a fully framed model, I would deeply appreciate it....but this log may be silent for a bit until I can get my head around things and get back to work once again...... hamilton

-

Ahh the quartergalleries!!! This brings back memories! I think you absolutely made the right decision going your own way with these! the metal parts are both brutalistic (as a single cast piece) and also really finicky (if you wanted to paint them in anything approaching an aesthetically pleasing way). yours look good! A nice improvement on a flawed (but ultimately not too bad) kit. hamilton

- 220 replies

-

USS Constitution by mtbediz - 1:76

hamilton replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

What an incredible place...Reminds me of a more extreme version of Montserrat in Catalonia....been to Turkey but not to that spot - wish I'd known about it when I was there! hamilton -

In BC we only pay GST and PST....12%. HST is in place in some provinces (Ontario, e.g.) as a slightly lower combination of these two other sales taxes....These costs are not my problem, though - for the cost of this particular kit, which is on the cheap side at $127 USD, I'll shoulder them. The issue is I can't even choose to this since I can't even make an order to Canada at all....Model Expo has taken my choice away....which I don't appreciate.... I do get why a US business would take this route in the current environment - in fact, I imagine it's tricky for many businesses to look too far into the future right now if they rely to some degree on foreign markets - but I think it should be left to the consumer to decide whether they are willing to shoulder the extra costs, rather than cut out a whole national market for a product that is already relatively low-demand....I'm certain that there are Canadian modellers (like myself) who would be willing to absorb the extra costs at least on lower-cost or medium-cost models (the current sale at M-E would still, even with duties and taxes, bring the cost lower or maybe about even with the non-sale price of the kit), rather than turn to what is undoubtedly an even more expensive source - British and European sellers and manufacturers.... Anyways, a high-barrier hobby just got a little less accessible - at least above the 49th parallel.....can't say I'm very happy about it.....good thing I have a decent back log of unstarted kits....at my current construction speed it'll probably be more than enough to ride out the current period of trade uncertainty! hamilton

-

Hi all: I had decided to purchase the 1:48 Phantom pilot boat from Model Shipways but discovered that Model Expo is no longer shipping to Canada because of tariffs.....this decision makes no sense since there is, as I understand, a de minimis exemption for shipments of under 800$....happy not to give ME my money if they're not willing to recognise these exemptions or make exceptions for those of us who may be willing to pay more regardless of the tariffs.....ship modelling is hard enough without politics getting in the way..... hamilton

-

I can see how the coppering might have slowed you down a bit....not the most exciting, but still an exacting part of the build...before my 1:98 phantom got destroyed, the copper plates had begun to age quite nicely. I like the way this part of a model interacts with the climate over time - reminds you that the work is a living thing! hamilton

-

Thanks Druxey - I will make a couple of sanding jigs (concave and convex, using the deck beams as blanks to get the correct round-up. I have some 1/2" maple ply that I think I'll use for this purpose as it's mostly scrap anyway and will be firm enough to withstand some sustained kinetic action. Was thinking I'd sandwich a few pieces of this together to make a nice broad surface for the sanding of the beam arms. With the upper deck beams more or less completed and dry-fitting snugly, I think I can also proceed to a part of the build I'm looking forward to - making the bitt pins for the sheet and jeer bitts - the first bit of superstructural detail since I made the well... In any event, at this point I probably won't be able to get back to Echo until mid-July, and then we're out of town again at the beginning of August....sheeesh - this summer is vanishing rapidly.....and it's not even summer! hamilton

-

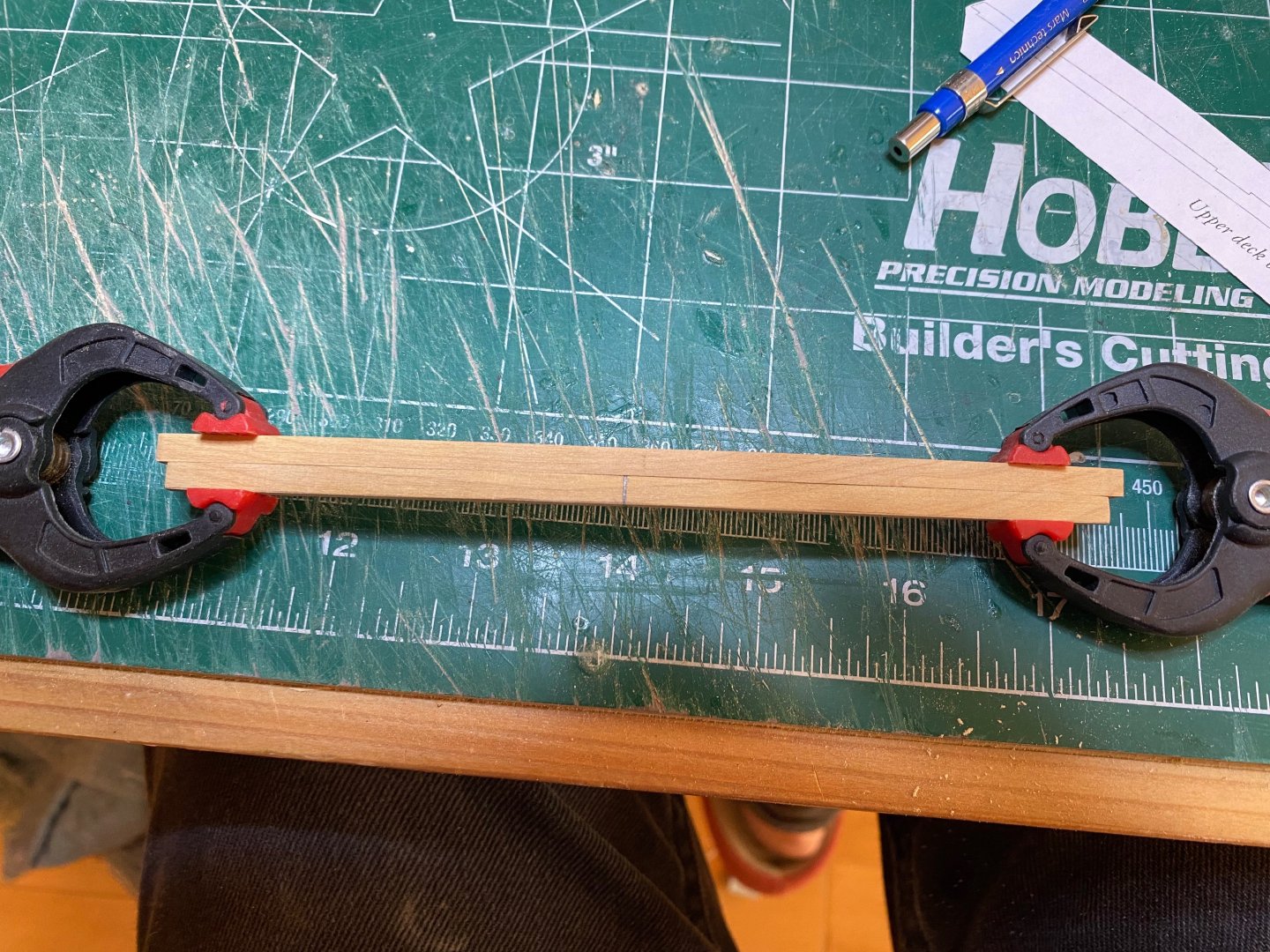

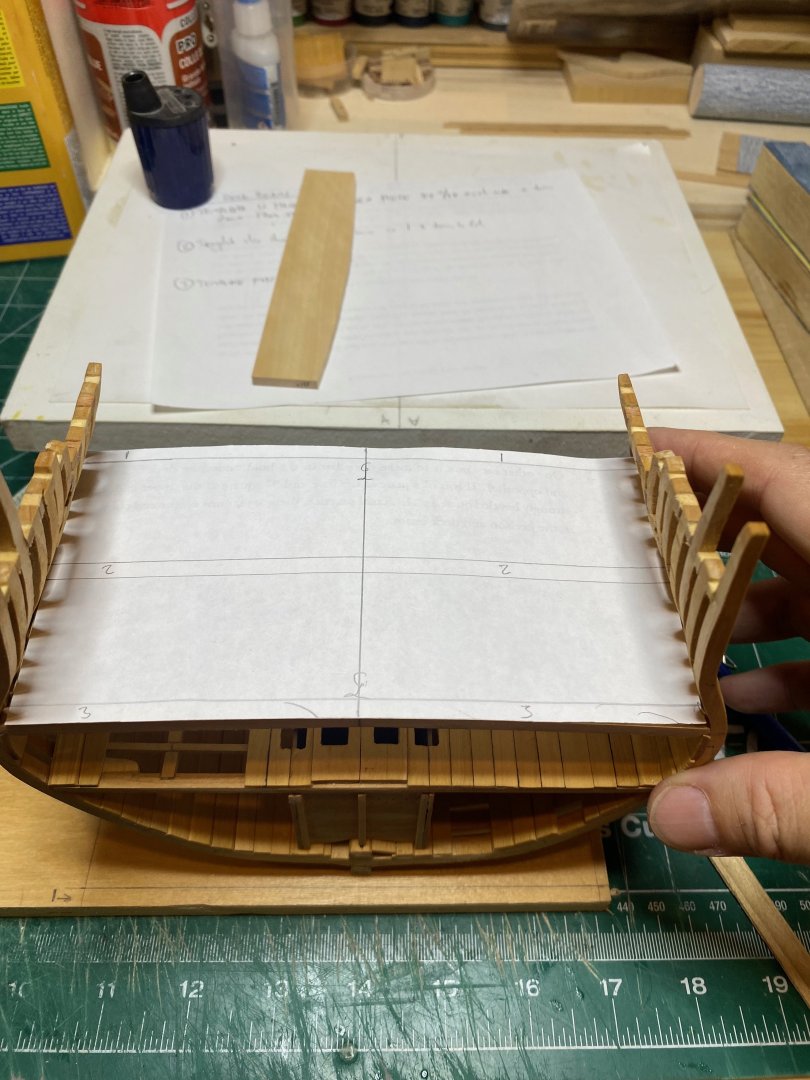

A bit more work on the upper deck framing. I've made all three of the deck beams and started to refine them (they're not quite finished but I'm not aiming for perfection, so....). My main task now is to make a framing jig so I can assemble at least the major components (beams, beam arms & carlings) off the model as I did with the lower deck. As of now I've gotten as far as making a template of the deck with the beams marked on. My model deviates slightly from the layout given in the practicum (modeller error is the blame here) so I'll use the drawings as reference for finishing the template. I had thought of making a simple jig - fitting a couple of 1" (scale) thick battens along the port and starboard side to simulate the deck clamps (into which beams are let down 1") and then a 5-1/2" batten down the centre line (the deck rounds up by 5-1/2"). We'll see how this goes and whether I need to expand on this basic concept..... I am a little concerned about the beam arms - these seem to be a little finicky to get right considering the round up needs to be sanded into them as well....I'm going to be away for a couple of weeks as of Friday and this week's a busy one getting ready to go, so it's hit or miss whether there'll be any time in the shop...but...in the meantime enjoy the photos and happy modelling. hamilton

-

After another relatively long break, I've managed to find a bit of time to work on Echo this afternoon. No great strides forward, though I did manage to make a test of one of the upper deck beams. I made a template out of card paper using the drawing in the practicum against some carbon paper, and then rubber cemented this to some 9" boxwood that came with the original framing package. I think that next time I will simply use copies of the drawing itself, printed onto card. I think this will likely lead to a more accurate template and a better result. Fortunately I have enough of the 9" box to do a bit of testing before committing to anything. I had imagined that the test beam would be fit forward, but it ended up being a fraction to short for that purpose. But it fits perfectly athwartships in the aft beam position at frame 5. So even though right now the piece still looks very rough (as seen in the photos below) I hope I can tidy it up and perhaps use it since it does fit so nicely....I also made a strake of deck planking to fit in line with the port side lower deck waterway - not too difficult or exciting. The upper deck framing is going to be quite tricky I think - I'm not looking forward to making and fitting the beam arms and am a bit concerned about the beams being at the correct height.....but we'll see in the next little while how it comes together. Enjoy the photos and bye for now hamilton

-

At this scale the rigging gets very crowded indeed - I followed Lees for the entire rig of my version of this kit - it was a challenge to get everything just so, but Lees facilitates things through his period-based breakdown of rigging practice by period and rate. From what I've read here, Lees is a very good standard to work to. I also have no idea what the logic was behind the reversal of the preventer and stay in this case - but as we see all the time, questioning people who've spent their lifetimes learning about specific things is a good way to get things wrong, while following them is a good way of learning how to do things right. hamilton

-

Managed to install a single ceiling plank this morning and to mill the remaining strips for the lower deck planking. I will have to fudge the planking a little bit, as the space to be filled is not exactly equal to the number of 10" wide planks that will fit there - there is a roughly 2" space remaining, so I'm going to mill a couple of 11" strakes to compensate for this - hopefully the difference won't be too noticeable at this scale. I'll also need to figure out the spirketing plank on the port side - this will require some spiling to fit against the curved waterway. I won't be fitting ceiling planks on the port side, in line with the overall concept of alternating the planking decks and hull) port and startboard. Externally, I'll plank the port side but not starboard below the wales, but I won't leave the frames exposed at all above the wales. hamilton

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.