-

Posts

186 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by cotrecerf

-

-

Danke für die Grüße! I definitely will enjoy it and I'm sure to realy learn a lot and I can make use in my model(s) to come.

In 1946 my father was transferred due to unbearable humanitarian conditions from a French POW camp in Marseille out of French custody into US hands to Camp Holabird in Baltimore. He told me once that this hand-over really saved him from severe illness, starvation and death in the Marseille camp. I still own his German-American English dictionary stamped by the camp's library. So I have some personal relations to Chesapeake Bay and Baltimore in particular.

Greetings

Joachim

-

Many thanks to USS frolick of course for the link and to Mark for the confirmation of the book's value.

Joachim

-

Just ordered the book, many thanks Mark for that link.

Greetings

Joachim

- SaltyScot and thibaultron

-

2

2

-

Giampiero,

tante grazie! Thank you ever so much! The idea to seal the underlying wood with shellac prior to burnishing the metal completely excaped my mind (shame on me)

Have a nice day

Joachim

-

Buon giorno Giampiero,

she is a real beauty! I see, that the blackened metal parts such as chain plates etc show no scratches or uncovered spots at all.

How do you proceed with the mounting of these parts:

1. Dry fit the un-blackened on the model first?

2. Take these parts all off again and dismantle the wooden components such as the deadeyes etc.?

3. Blacken (what is the agent?) all metal (brass?) first and then reinstall the wooden components again.? (great risk of hurting the metal and the blackening)

4. Finally fastening of the completed and blackened part on the ship ?

Or alternatively

1. Dry fit the un-blackened on the model first and then

2. Blacken them in situ? Not staining clear wooden parts with the blackening agent (Liver of sulphur?)

I would be very gateful if you enlighten me in these matters.

best regards

Joachim

- rybakov, CiscoH, billocrates and 1 other

-

4

4

-

As usual I'm fascinated by your modelling capabilities and the quality you achieve. Absolutely miraculous to me is the super short time of a little more than a year you spent for such a complexe build with so many details. I eny you for your persistence and concentration.

best regards to you and thumps up for Zaprozhia

Joachim

-

Like so: https://preview.redd.it/whats-the-point-of-bucket-rigs-and-why-does-bucket-rigging-v0-odtwdx3gsi9a1.jpg?width=1080&crop=smart&auto=webp&s=d447a1c12b029eee1b31ae9a39ed0306fef1a42f

-

-

-

Hello Markus,

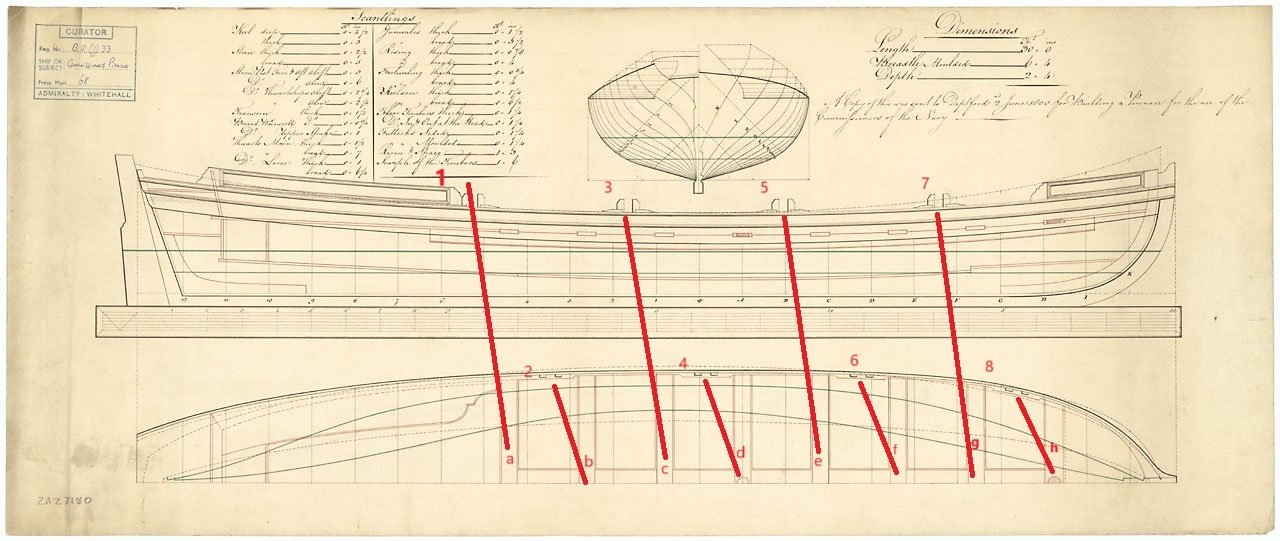

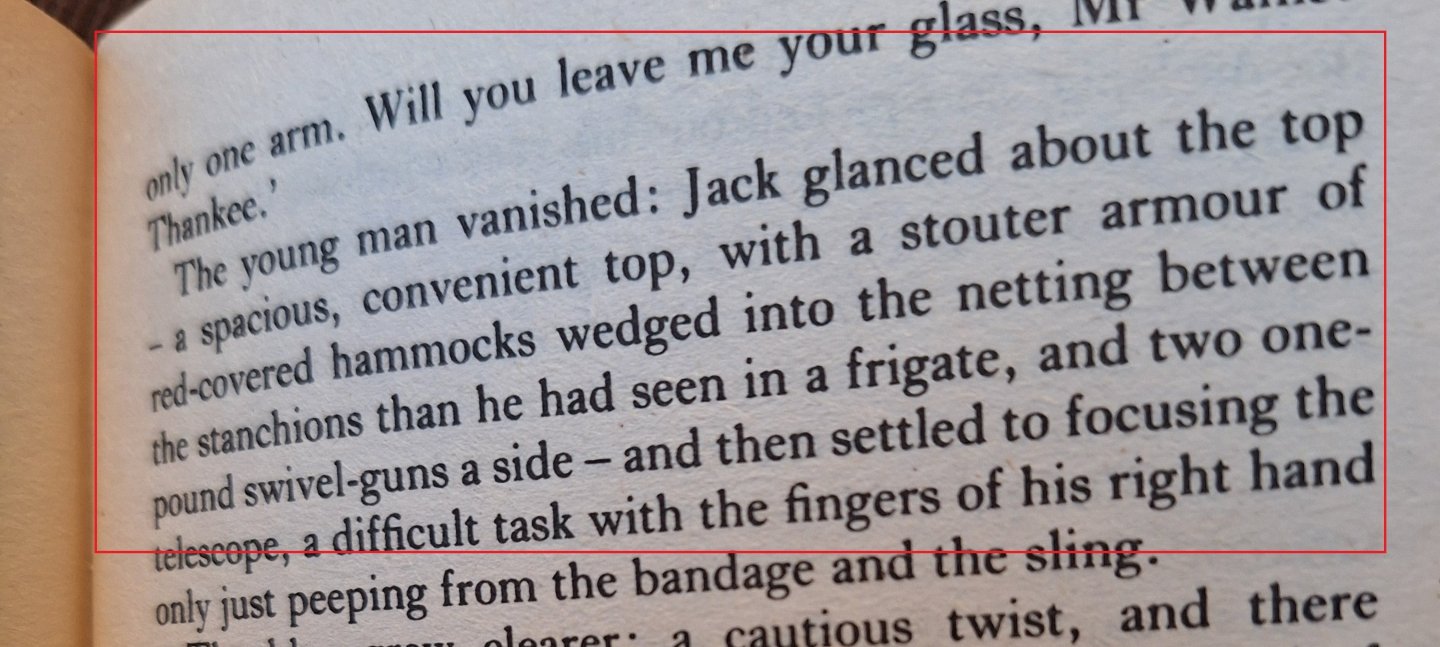

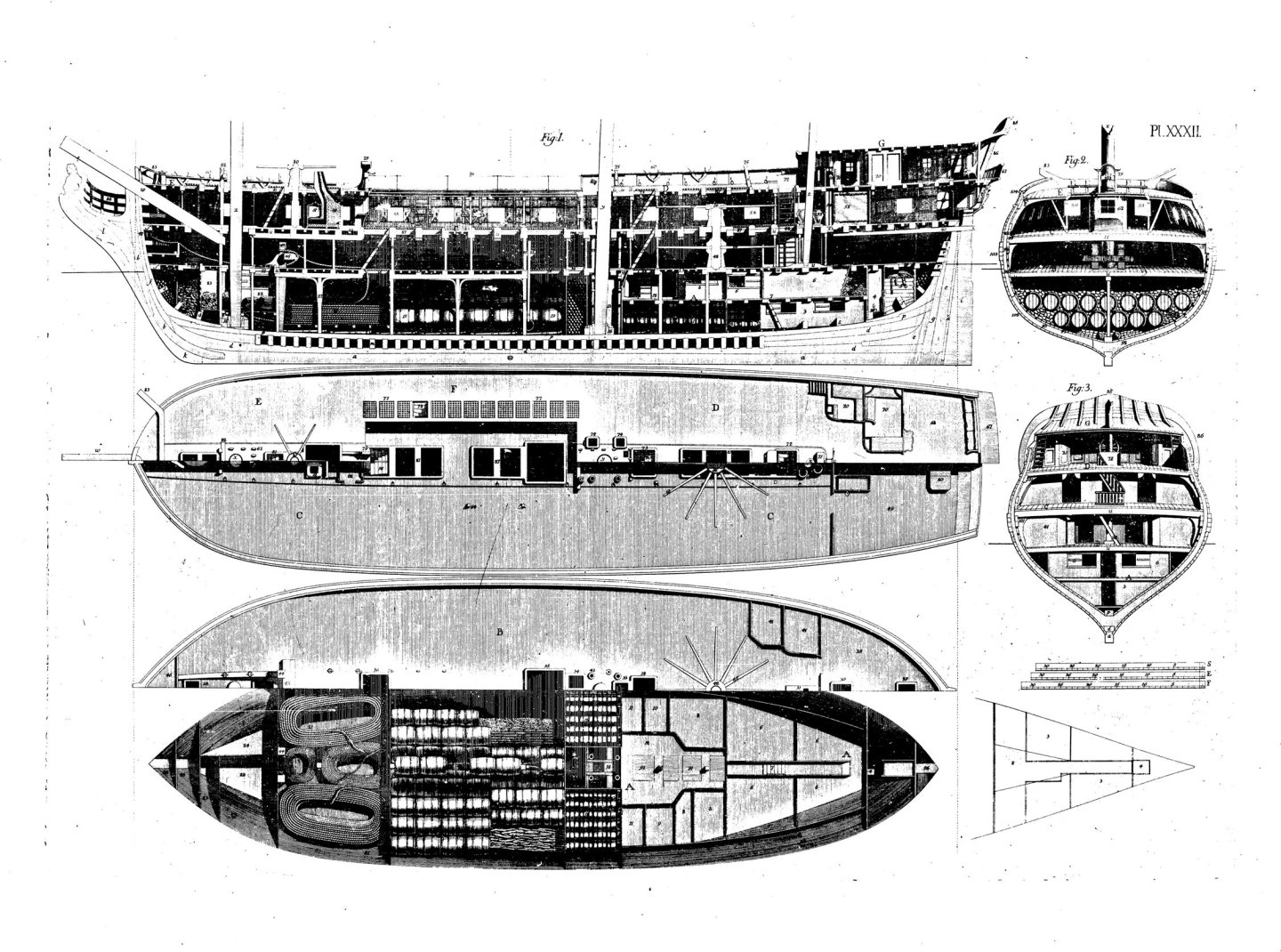

please have a look at the continuing text; you will find the wording "sighting-top" which seems to be a printing error, spoiling the obvious meaning "fighting-top". I have never heard of a "s"ighting-top, where are stowed studding sails and having one-pounder swivel-guns.

Cheers

Joachim

-

Taking Patrik O'Brians novels of the Aubrey/Maturin series a well researched "source" I quote his description of HMS Shannons's mast top during her action vs Chesapeake given at the end of "The fortune of war". It supports Phil's post #21 and I assume hammocks in tops a standard measure of protection long before 1812. It stands to reason that skilled sailors and marksman in the tops were specialists available in limited numbers only.

Joachim

- BANYAN, The Bitter End, mtaylor and 1 other

-

4

4

-

- matiz, Keith Black, mtaylor and 3 others

-

6

6

-

Buon Natale e Felice anno Nuevo, Merry Christmas and a Happy and Prosperous New Year 2025!

- matiz, Keith Black and mtaylor

-

3

3

-

Hello Glenn-UK,

I wonder, why there are these (many) oblong holes provided in the keel and the bow and how they are going to be closed later on? Will you paint the hull, so they will be covered completely, imho with a bare wood hull they disturbe the flow of the wood grain visibly.

cheers

Joachim

-

- GrandpaPhil, Sizzolo, thibaultron and 1 other

-

4

4

-

I just found this: https://www.trinitymarine.co.uk/shop/original-18th-century-ships-salted-beef-barrel/

So there seems to not only having existed the One type of barrels )except for size of course) but various forms and technical executions depending on their contents.

- Sizzolo, thibaultron and mtaylor

-

2

2

-

1

1

-

Pardon, correction: PORT-LOUIS , of course

-

Bonjour François,

si j'aurais su.... if only I had known (or found) your build earlier. Last week I spent two days of holiday in Saint Louis and visited the fantastic Musée des Compagnies des Indes and the Musée de la Marine there. I am very inpressed by the make up and the so apealing presentation of their exhibits. The fortress and the city itself are very impressive and make our hobby even more fascinating giving a perfect idea of naval background in the 18ième centuring.

I congratulate you to your very nice Granado.

Salutations collégiales, greetings and cheers

Joachim

-

-

-

Hello Moonbug,

please can you tell me what a "fire boom" actually is? To me it rather sounds like an item of a fire ship to help setting fire on an enemy ship under attack.

Cheers

Joachim

- Keith Black, mtaylor, thibaultron and 1 other

-

4

4

-

-

Peter,

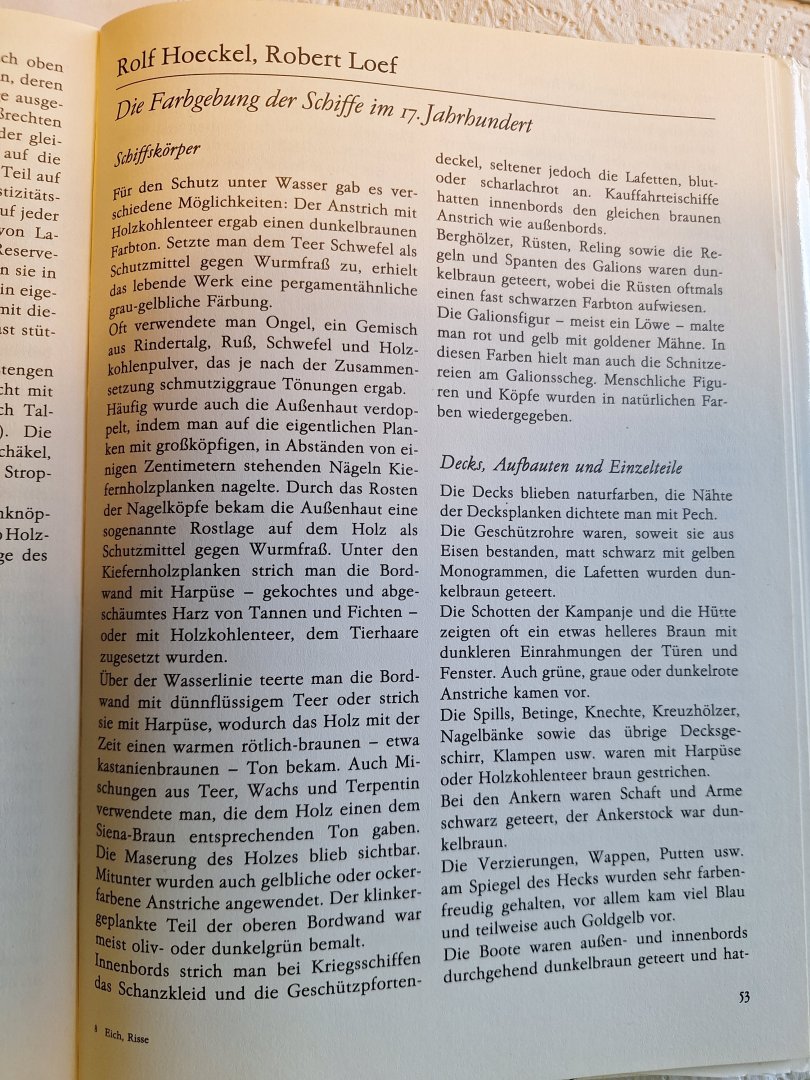

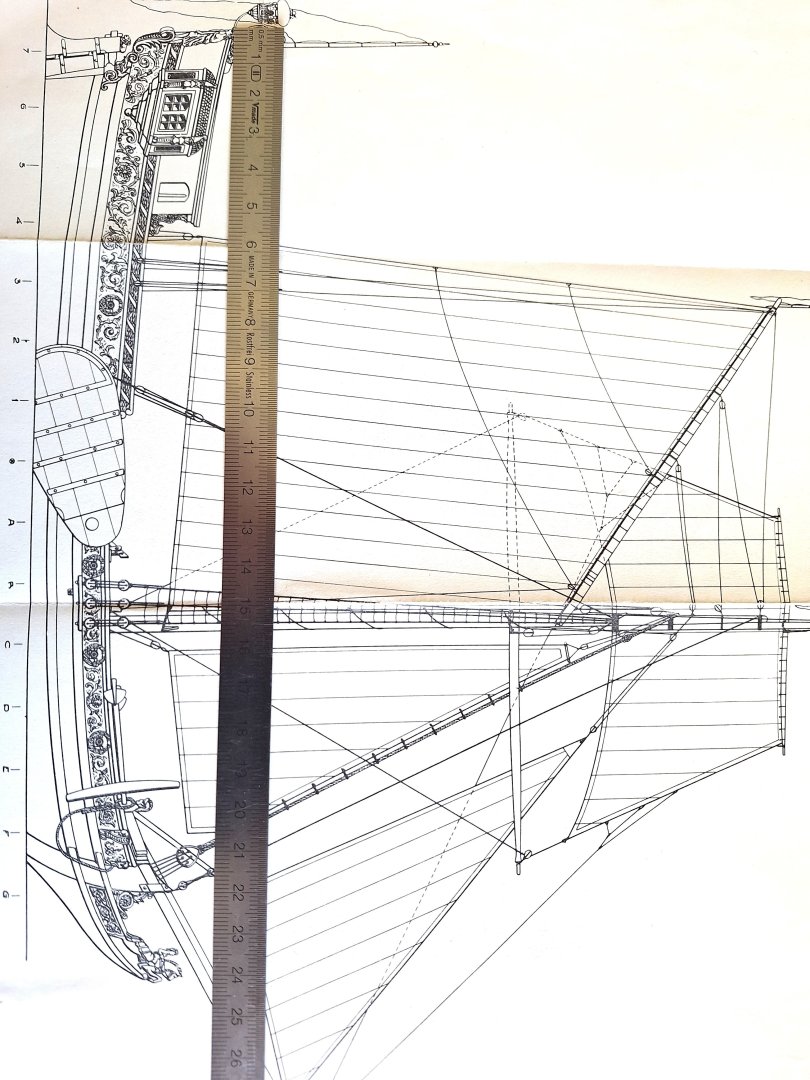

check this link Kurbrandenburgische Marine – Wikipedia. The original yacht belonged to the Elector of Brandenburg at that time and there are oil paintings showing the yacht, the Brandenburg fleet giving you some idea of the colour scheme. I will scan the pages related to era colouring of the Hoeckel book soon. (They are in German language)

Cheers

- Glen McGuire, PvG Aussie and mtaylor

-

2

2

-

1

1

-

- Glen McGuire and mtaylor

-

2

2

.jpg.8105a7d5b9c5bc9b498a0742fe65aa8a.jpg)

The Baltimore Clipper and Topsail Schooner Book Research Thread

in Book, Monograph and Magazine reviews and Downloads. Questions and Discussions for Books and Pubs

Posted

I live a little south-east of Bonn over the Rhine in the Westerwald very near to Hachenburg.

Joachim