-

Posts

596 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by niwotwill

-

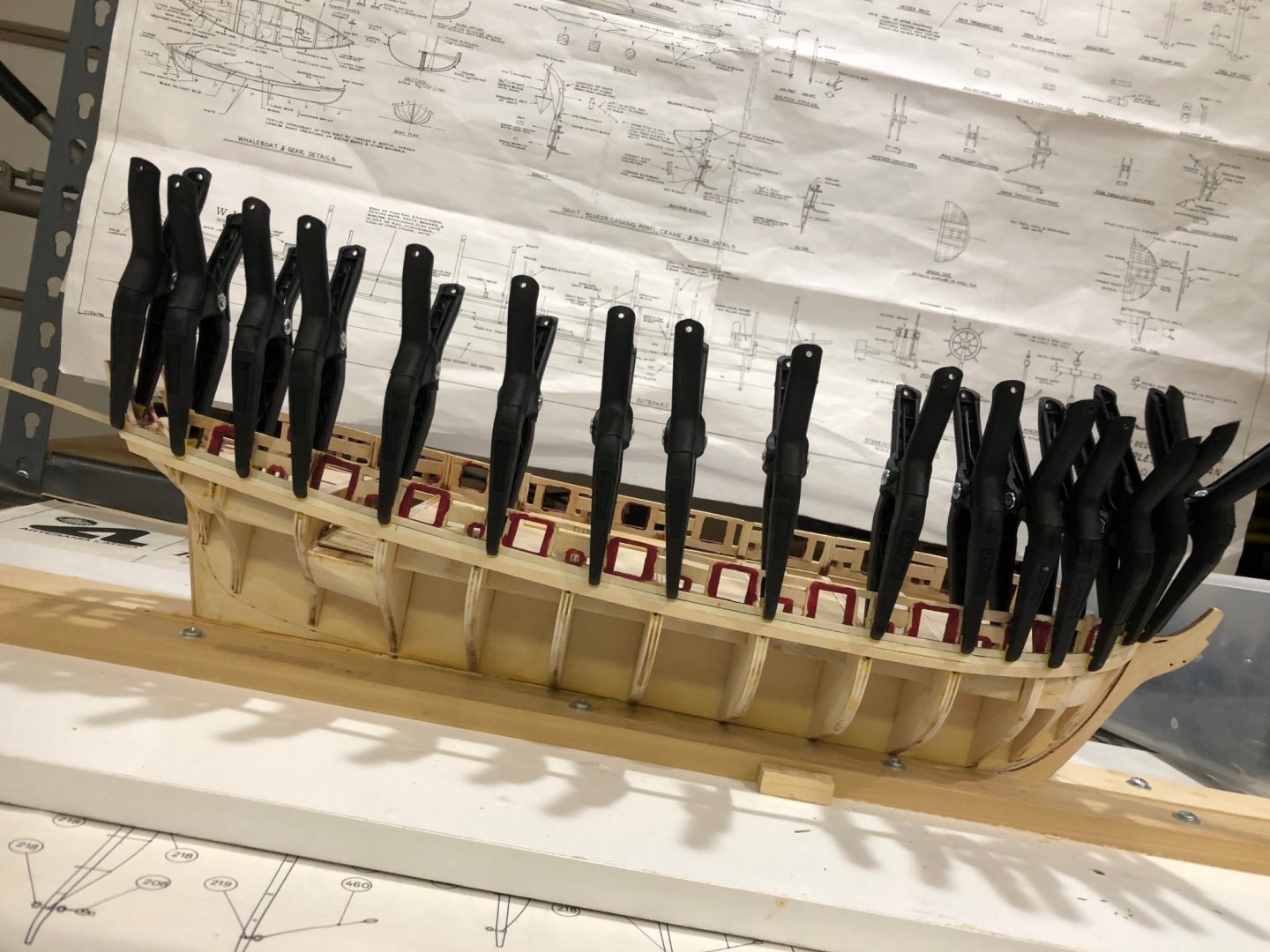

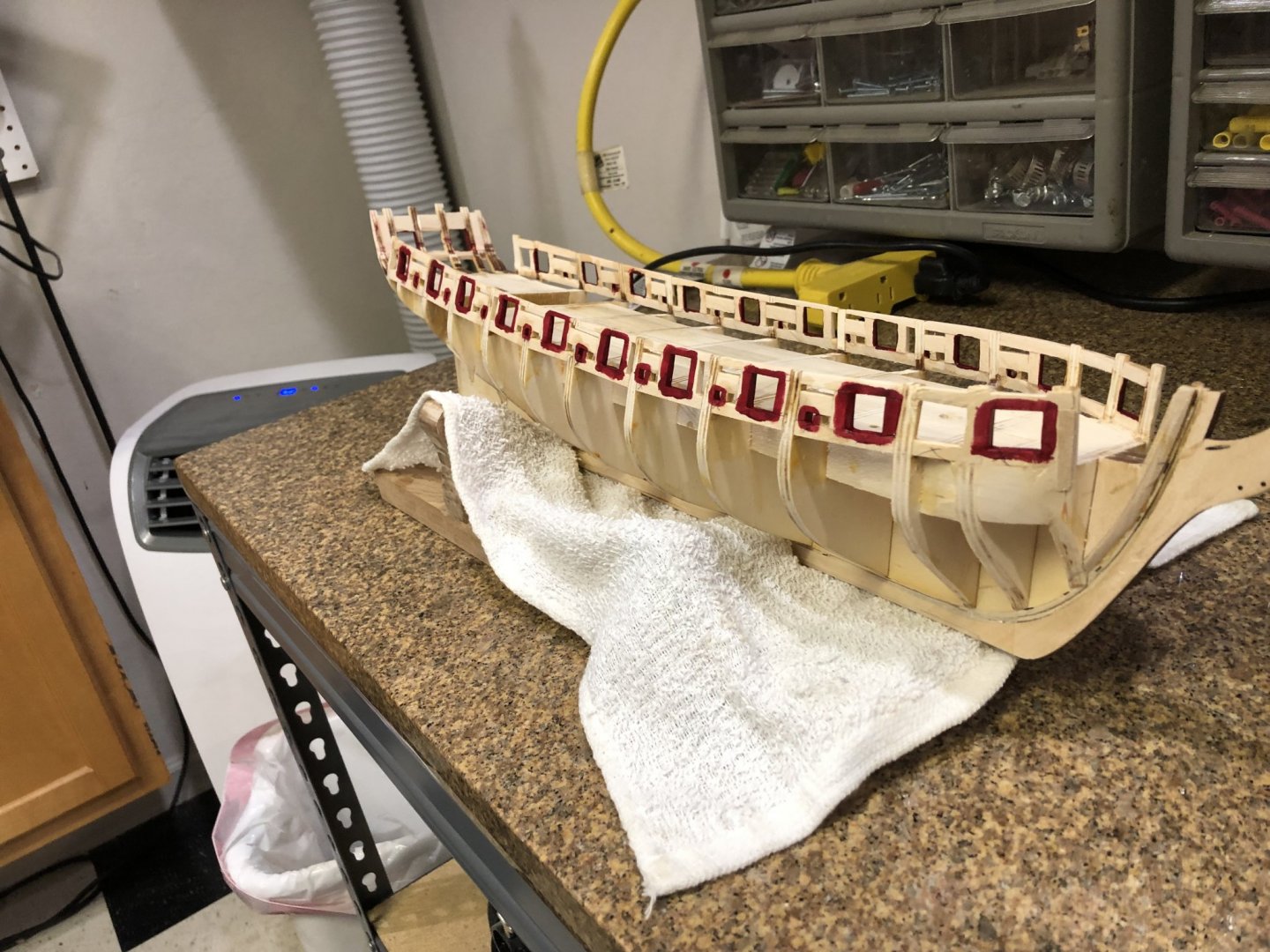

Thanks for the comment Jonathan and everyone else for the likes Well another day spent de-constructing a model. I got all the bulwark strakes and the first wale off with not problems, just time to soak with water. The PVA glue became a rubbery layer of somewhat sticky goo which enabled me to just gently pry up the pieces and the slowly lifted off in one piece. Just took time to soak. I worked on my Morgan rigging while waiting for the soaking still a good day of modeling. I did find one good attribute of basswood during this process and that is it is so soft and porous that it soaks up the water and holds it in place while the PVA softens other than this I don't like the stuff and will never use it again. Now I just need to wait for my Alaskan Yellow Cedar to arrive and I can start ripping and milling to 5/32" x 1/16" and 1/8" x 1/16" strips. Waiting is the hardest part as the song says. Will

-

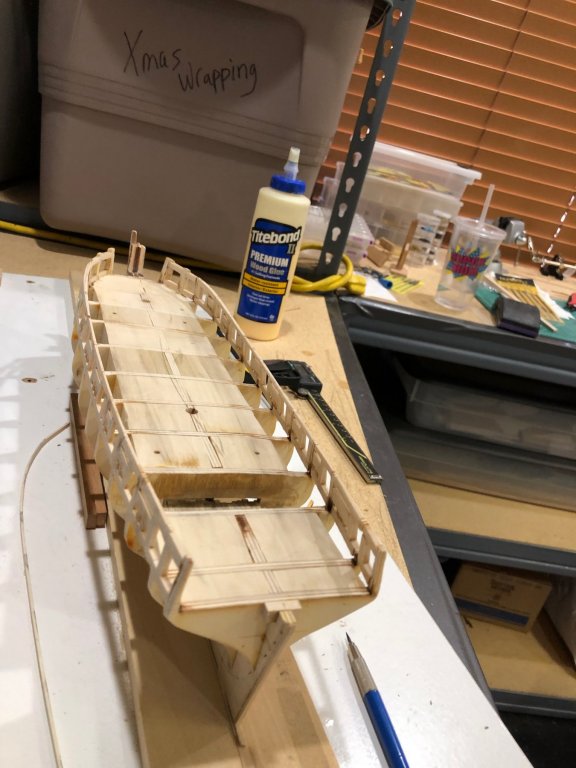

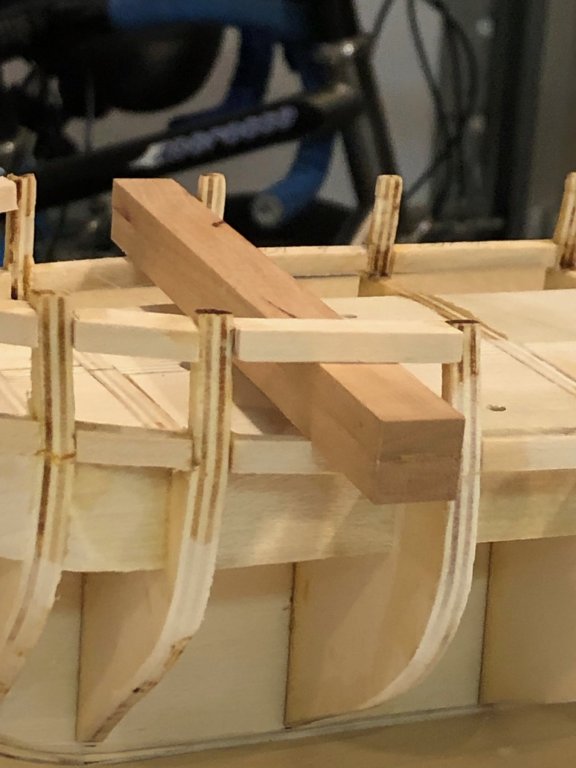

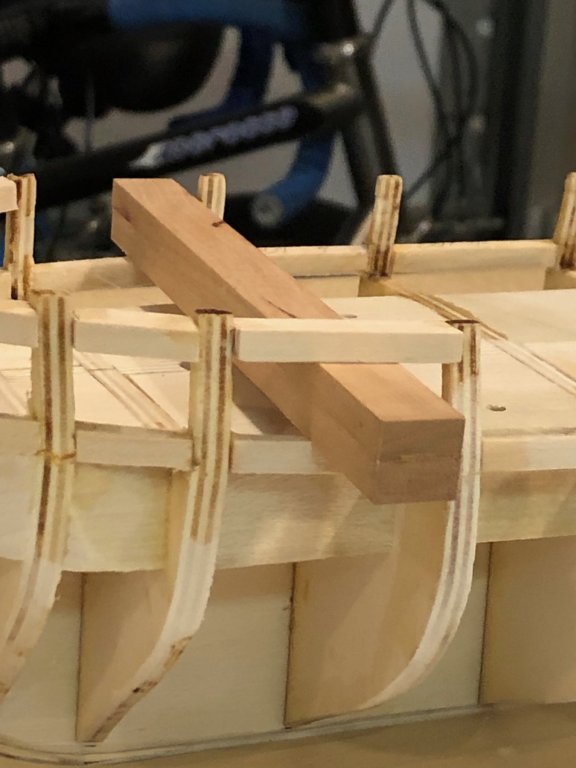

Been awhile since last post but I have been working of the first wale and then starting the bulwark planking. Pictures to follow. When I needed to start cutting the plank around the gunports and sweeps I ran into problems. I have tried and tried to cut the gunport lid sills as described in the manual but can get the cuts as clean and straight as I'd like. No matter what I use if I put too much pressure while cutting the wood starts to crush and not make a clean crisp cut. I use a new #11 blade for each cut and it still is not as I'd like. What I've found is that the basswood does not carve like a hardwood and carving is really what needs to be done on the bottom and top edges so you have a clean crisp straight cut for the sill. The fore and aft edges are much easier since the cut is against the wood grain so the cuts are fine BUT the end grain is problematic since it is so coarse that you can see and and I can't imagine what a stain would do with the open grain. ugh! And then trying to keep the sill less that 1/32" perimeter is very trying. So I took everything off and will start again with harder wood. Chuck has been really talking up yellow alaskan cedar so what the heck I tried some I had around and found it to be much superior to basswood and have ordered enough to plank the bulkheads. I hope it works as well as the little I had to try in my experiment. Let you know when I get my delivery and get it ripped and milled to the correct size next week. Bye for now Will and thanks to everyone for my thanks. PS I forgot to mention the wood in its many shades of yellow, tan, or grey. I realized the I'd have to sort the kit wood for each area that was going to be stained and not painted. Look at the pictures and you'll see the different colors of the basswood.

-

Very nice Maury. I've been following your log and now started to follow with MSB so I get your updates on a regular basis. I'm using TurboCad to develop plans and loft the brigantine Leon from Harold Underhills plans but with so many copies of copies of copies the plans are quite unreliable as the waterline have become blurred. I friend of mine has suggested my starting a pungy she schooner from plans he bought from Mystic Seaport years back. So I'm very interested in your model and the research you've put into getting a very nice model. Great looking model the scale really shows the models construction details. Will

-

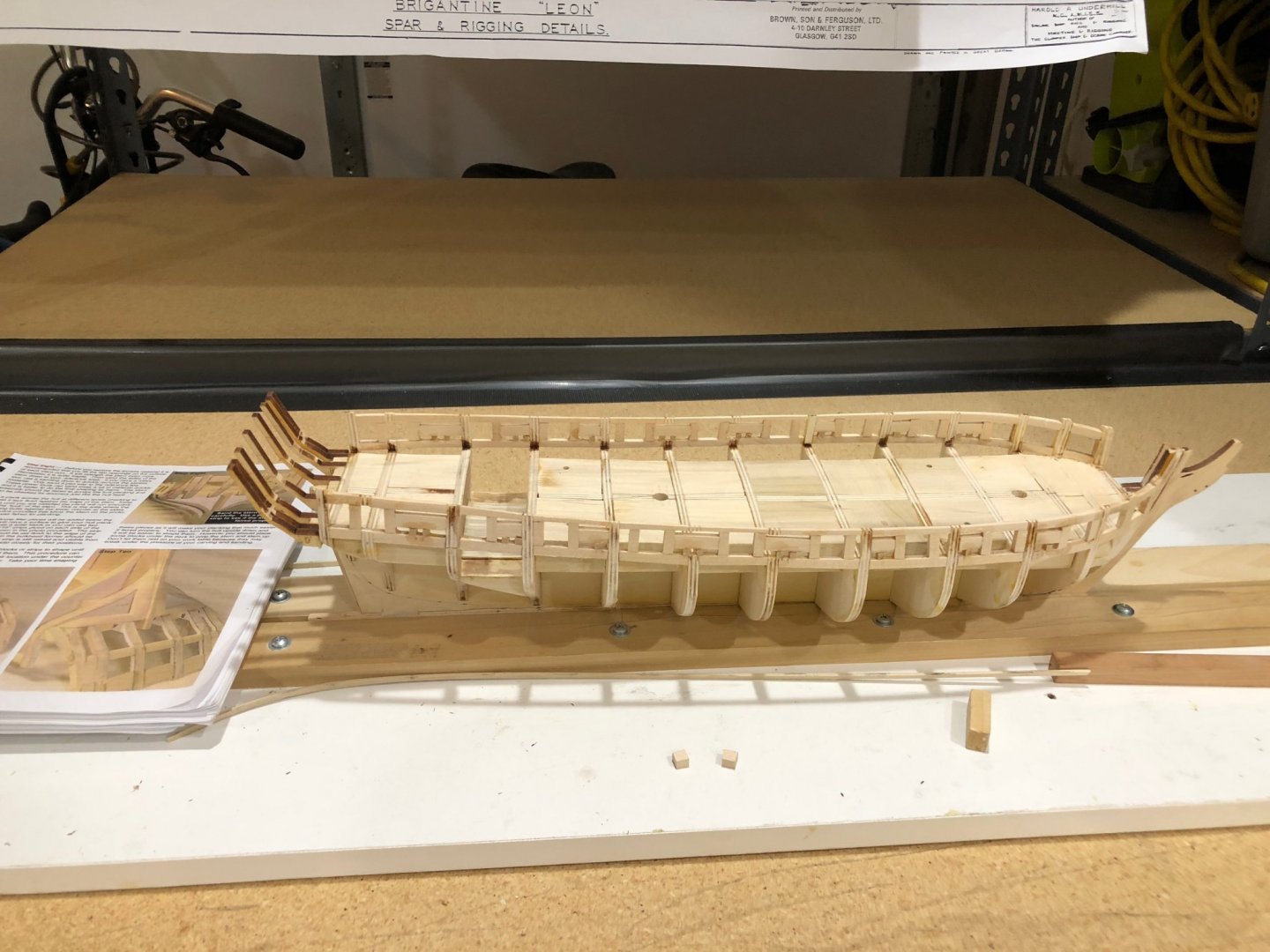

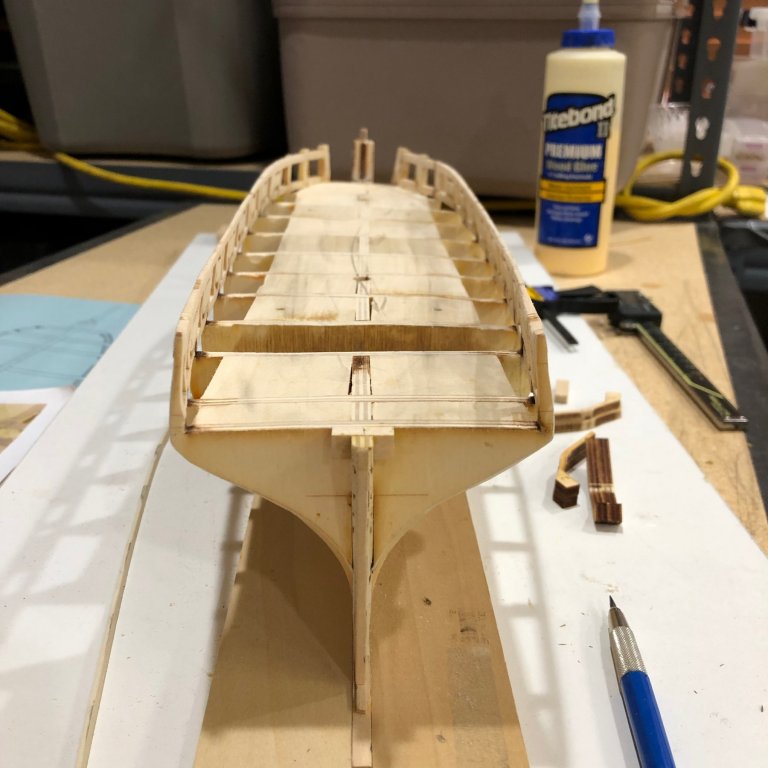

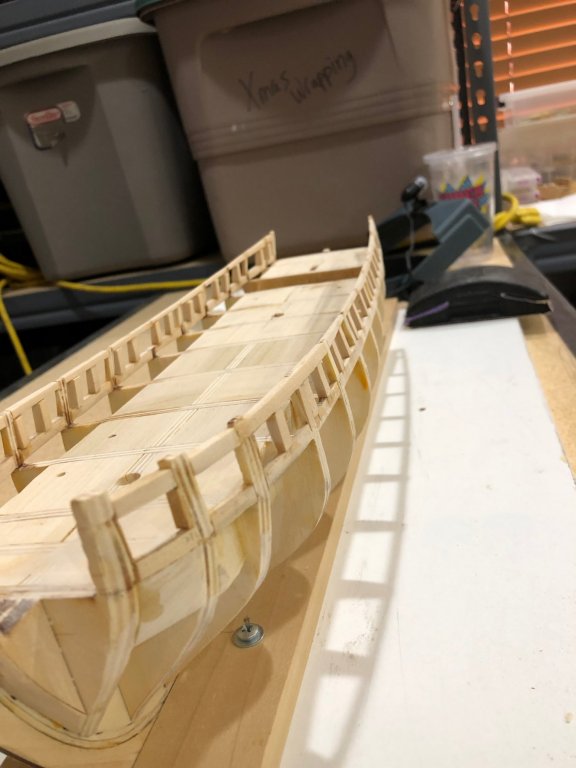

Paints dry and now onto first wale. I used a 1/8" strip that i'd bent to fit the shape of the deck plan to determine if my construction matched up with the laser marks on the frames. With the battens on I looked at the line from all directions, felt it looked good and went to lunch and a swim. Came back in much refreshed and the battens didn't look as good as I first thought, so I took the pins out and moved the middle up until the run looked good from all angles. Checked the the batten to the laser marks and sure enough the marks on frames 6, 7, 8 & 9 were approximately 1/32" lower than my batten top. Question, question, and question where was the difference. I took 7 pieces of 1/8" strip and glued the together like the planking will be, using the jig of strips I started moving down the sides to see if the jig aligns with the top of the wale and the top of the bulwark. It aligned perfectly along the entire length of the batten, so!!!!!! I guess its correct. Went back and checked everything again with the same result. Being a retired engineer (I know an electrical one but still and engineer) as the saying goes "there comes a time to shoot the engineer and go to production". I put the wales on. Wale photos to follow Will

-

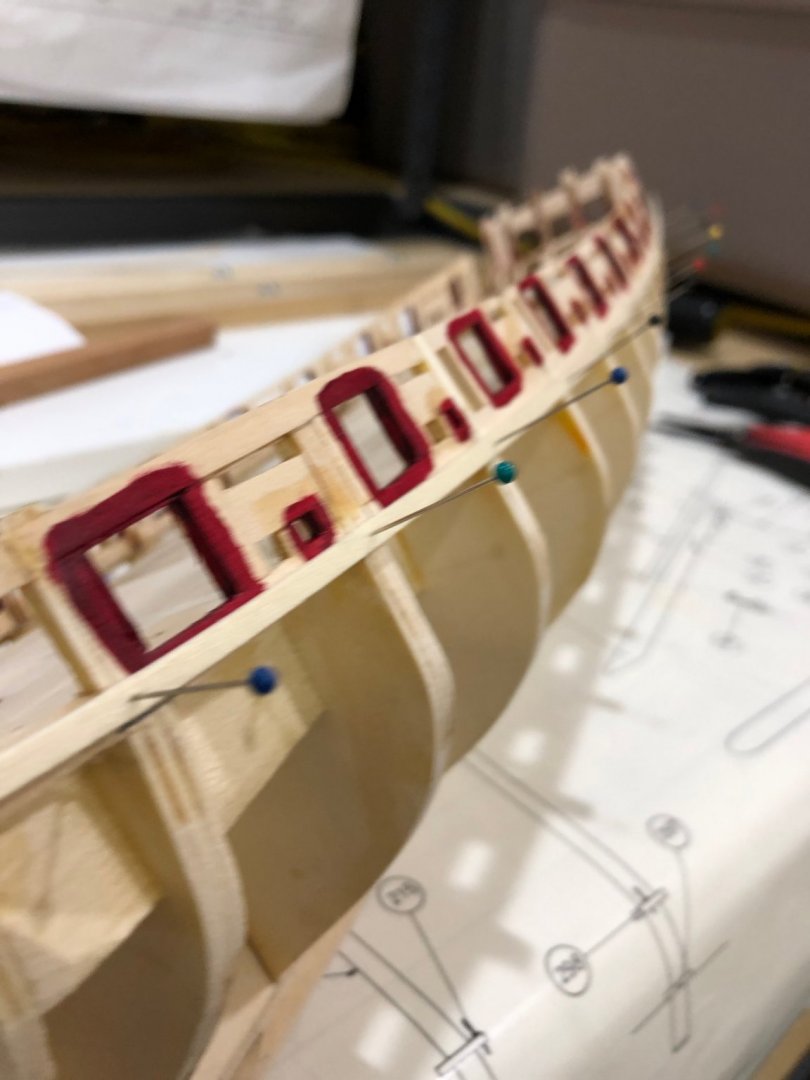

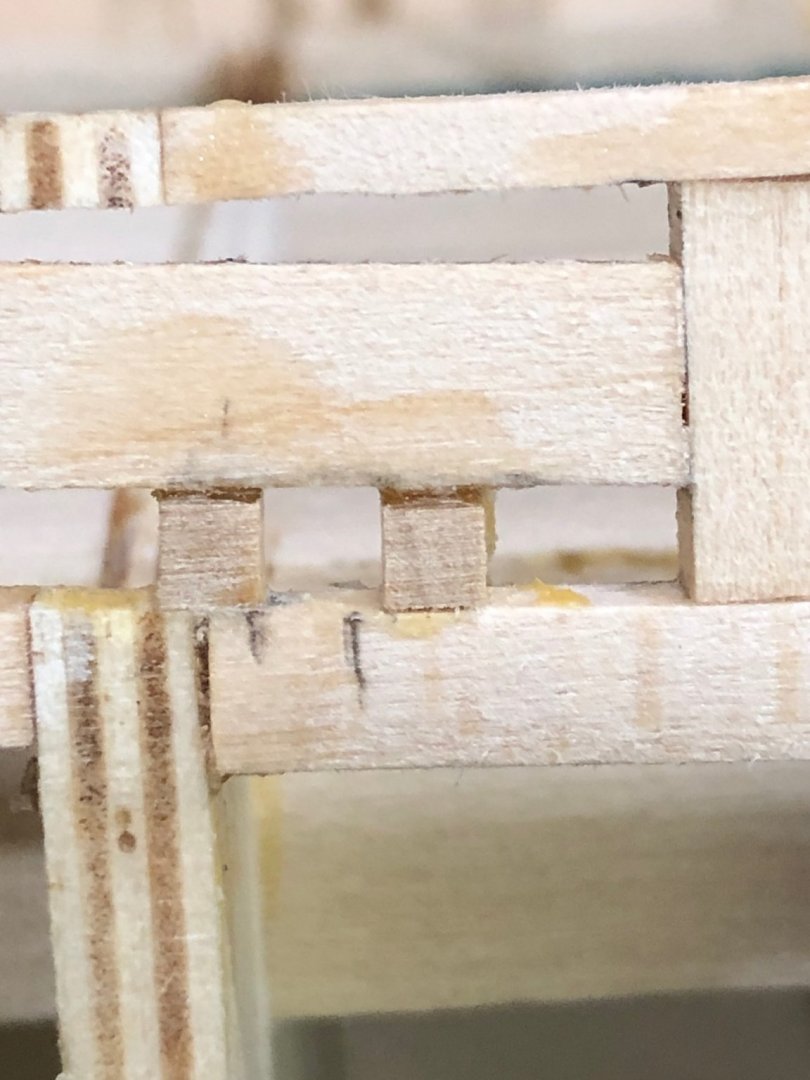

Painted the gunport and sweep ports with sanding sealer and then used 400 girt wet and dry to smooth the insides of the ports prior to painting. Spent a fair amount of time cleaning the surfaces to be painted by vacuuming and then wiping with new tack rags to get all the dust and debris off before painting. I'm painting with acrylic paint and am using Winsor & Newton Professional Acrylic on my models. For the red color I'll use vermillion straight from the tube and thinned very little. I really like the color with the contrast with golden oak stain and black trim, pops nicely but not too bright. I'm going to use english holly on the deck with a diluted golden oak stain to give a golden bleached look. Can't wait to see, but first things first.

-

Getting ready to start hull planking as described in chapter 5. First thing is to paint the gunport and sweep port frame linings vermillion red. Sanding them out to prepare for painting I remembered something I read somewhere "PHOTOGRAPHS SEE AND REVEAL EVERYTHING" so I took closeup photos of gunport and sweep ports and boy what a mess. I then spent the rest of the day filing out each port using small swiss cut files. Take a photo, file more, photo, file more until satisfied. After all completed I'll paint with sanding sealer and check again tomorrow. Thing to remember is PHOTOS REVEAL EVERYTHING. Will

-

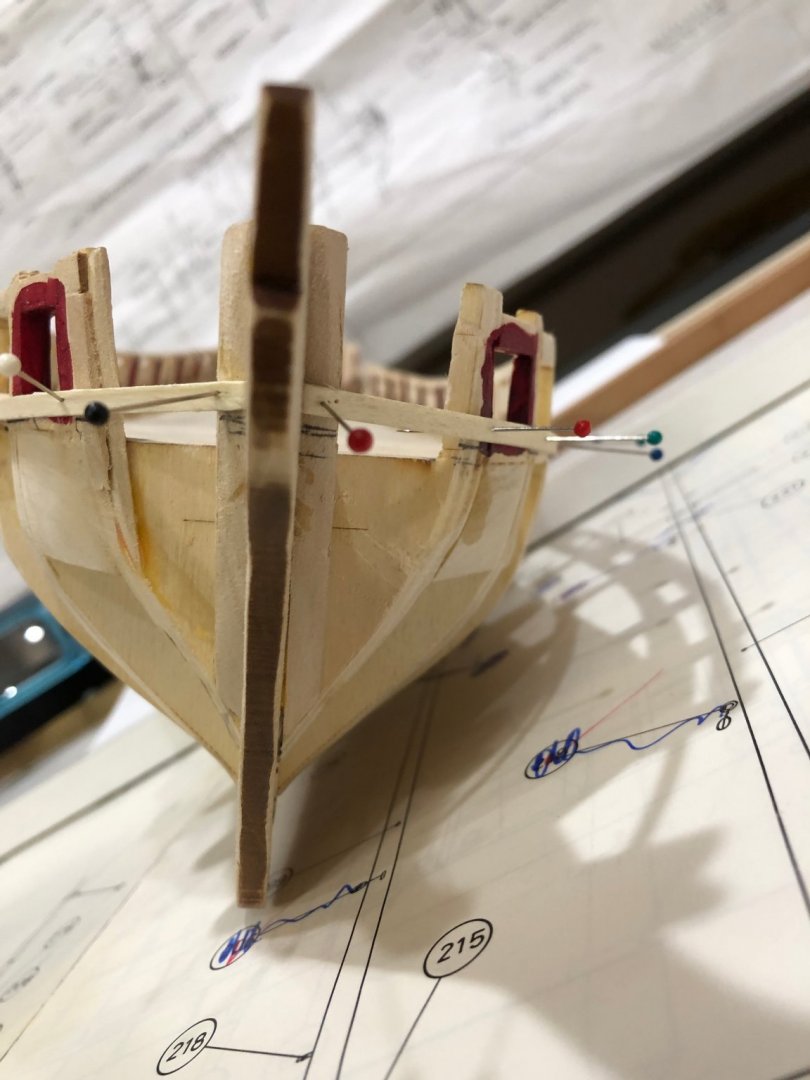

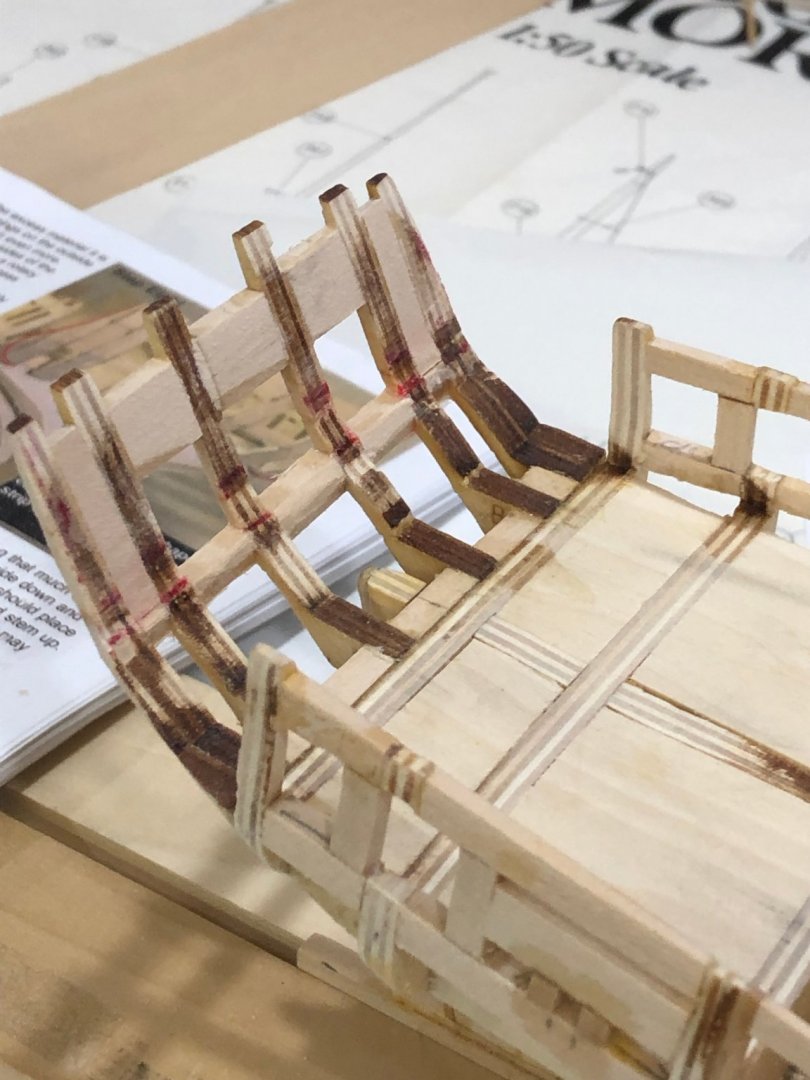

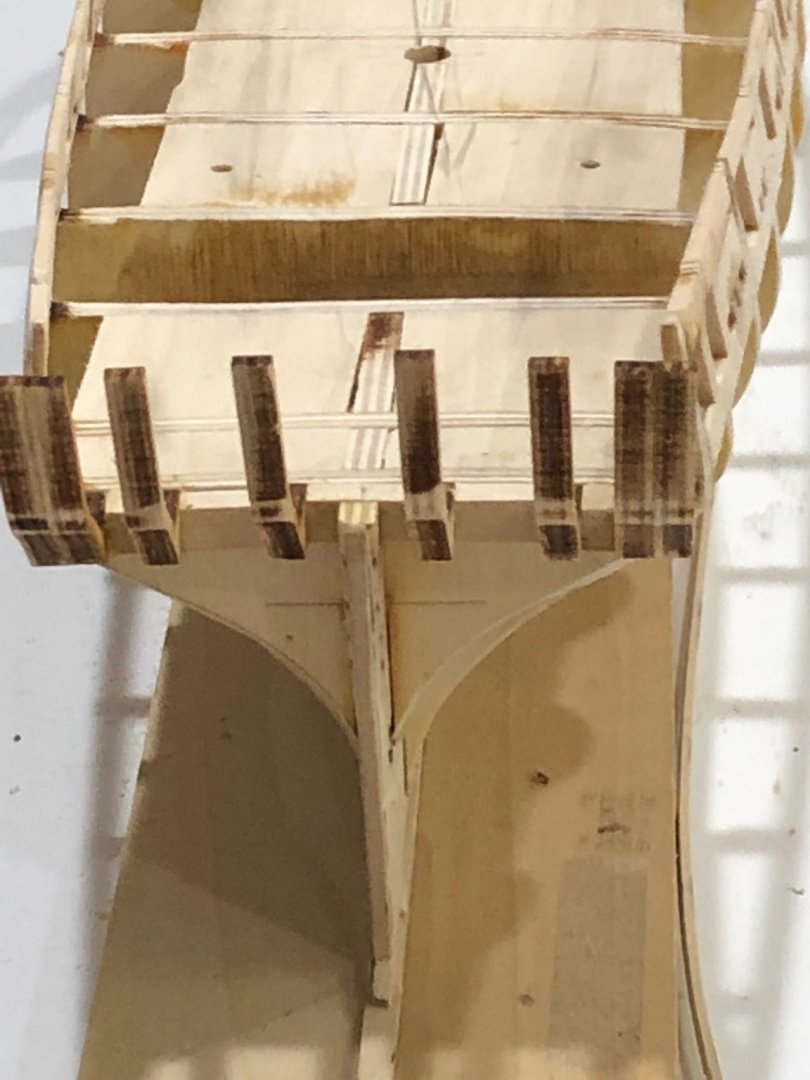

Got stern gunports installed using the same 15/32" square tool used on the port and starboard gunports. Counter filler blocks installed without incident. Marked the bulwark fairing on the outside counter as described in the manual using a wood strip. Faired the counter to the bulkwarks and the counter frames, what was amazing was that I did this without breaking one of the frames. Man are they fragile.

-

Mick did you ever find info on the rigging you asked about? I’m finishing up a project and hope to start my Washington in a month or so. Will

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Mike i read your entire log and now I’m getting ready to start my galley. Still trying to decide on which wood type to use when picked I’ll then rip and mill to size. I think I’ll start my log when I order my timber. i love your work and have one question, oh maybe more but one for now. Did you use silver solder on the stove? Ok another question what silver did you use sheet, wire, or paste? your work is amazing and something to try for Will

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

I’ll check this out tomorrow thanks

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck when I downloaded the drawings I see that they are 1/4" scale but I don't see a scale on the drawing that can be used to verify printing accuracy and such. This is very helpful to those who are scratch building the Winnie. Could you put a scale on the drawing for us to use? Will

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yesterday spent placing sweep ports and fairing the sides. I used the same method to get the sweep ports 1/8" square. Ripped a 1/8" strip from a 1/8" boxwood sheet and placed it across the breadth of the ship to align the sweep ports. Next step is on the section 4 of the plans. I still have to test staining and then stain the lower deck. It'll be a couple weeks before I post again as I'll be traveling. Will

-

More time spent rigging Oh due my finger ache so onto gunport sides. To place the sides I used the plans to mark the location and my jig to insure they'd be 15/32" wide. Fairing the outside and inside took almost a day of carful sanding. I do like this soft wood it's so easy to sand, but also so easy to go to far.

-

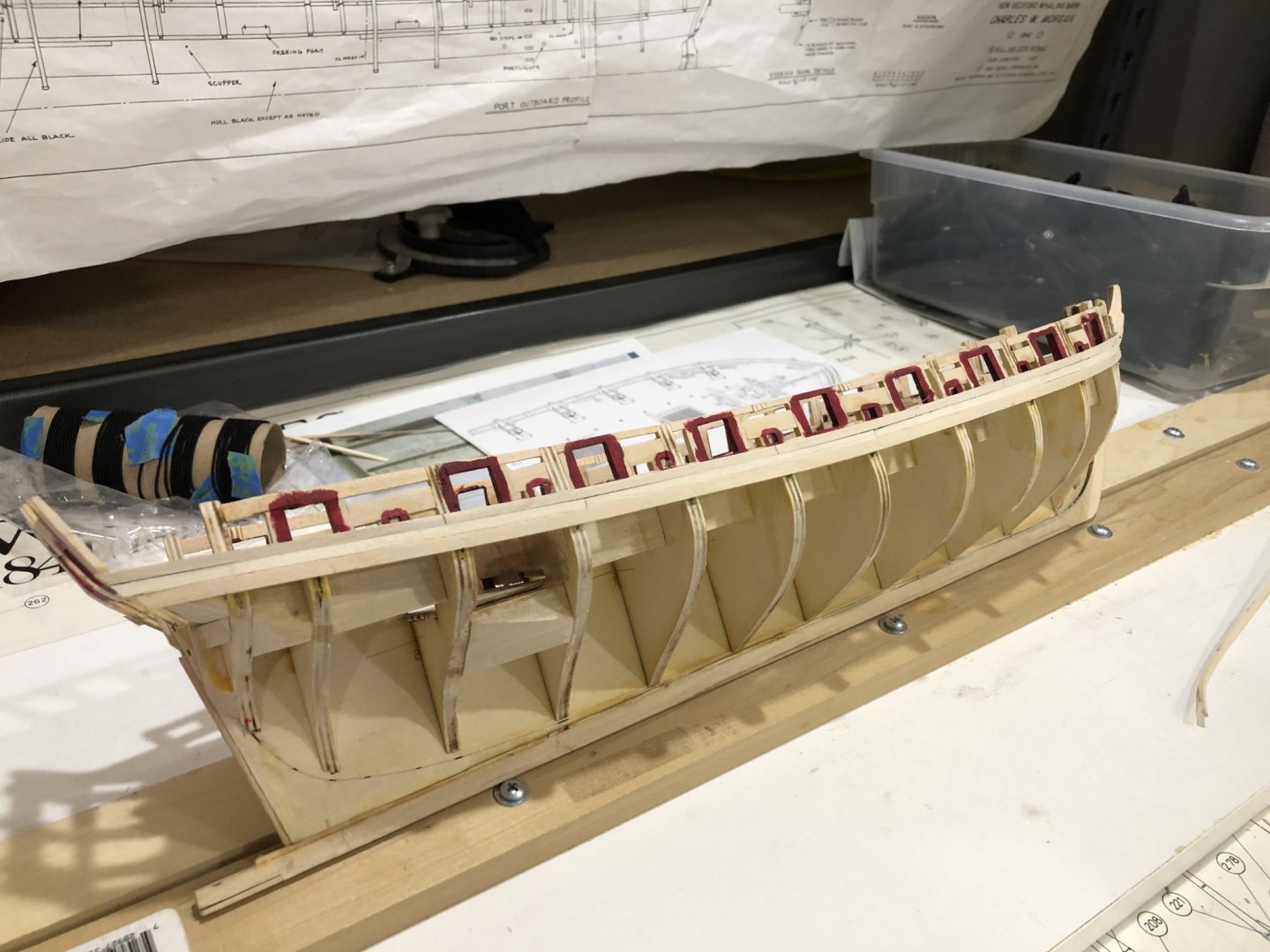

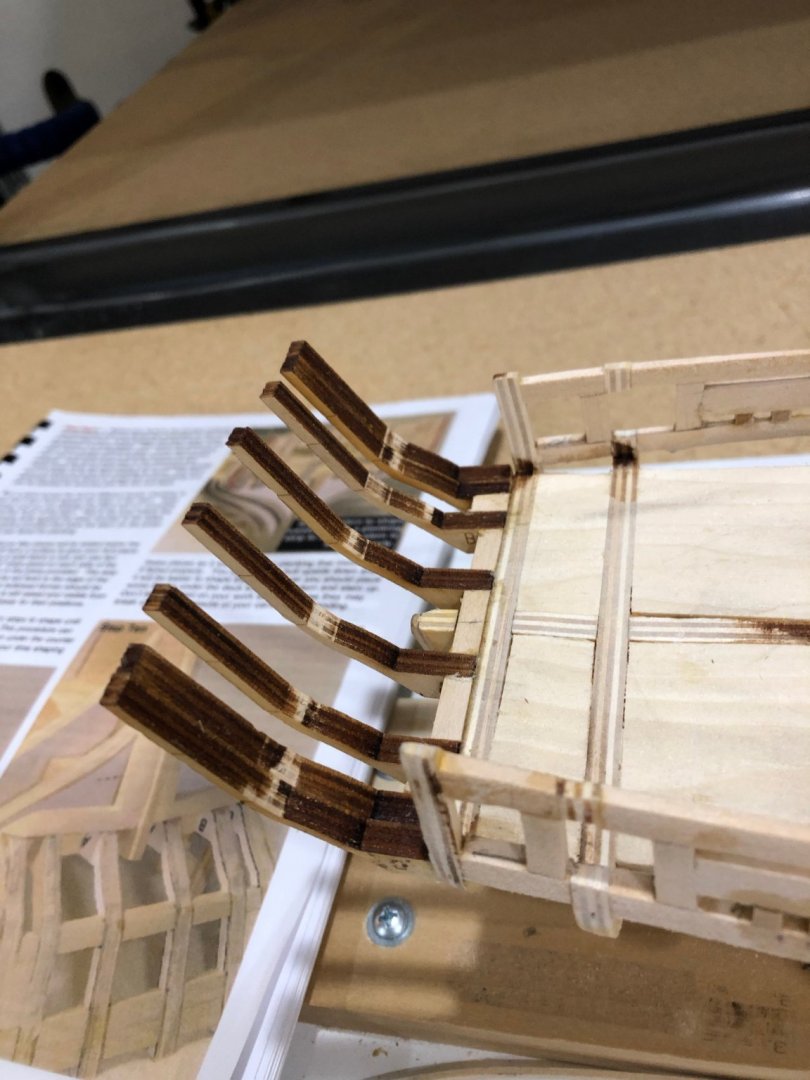

Been to long between posts, as said I'm rigging my Morgan, so I've completed the bulkhead reconstruction. I hate reconstruction almost as much a deconstruction. Spent a day putting the gunport sills in on the starboard side until I realized that I'd read the instructions incorrectly. I'd placed the 1/4" side in the vertical position and the 3/16" side in the horizontal position. Breakout the acetone and soak each glue joint another day spent doing deconstruction. Cleaned up the bulkheads from glue residue and then realized that I might not have enough 3/16 x 1/4 material so I measured and measured and read ahead to see where else I'd need the 3/16 x 1/4. I think I'll have enough. WHEW On to putting the sills in. No more problems. First time a learning lesson. Faired the sills to the bulkheads very carefully, no more broken bulkheads. On to the lintels with no issues. Faired the lintels to the bulkheads with no more breaks. The bulkheads are now quite strong.

-

OMG!!!!! Rich whatever happened. Do you need anything, any kind of help? Will

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

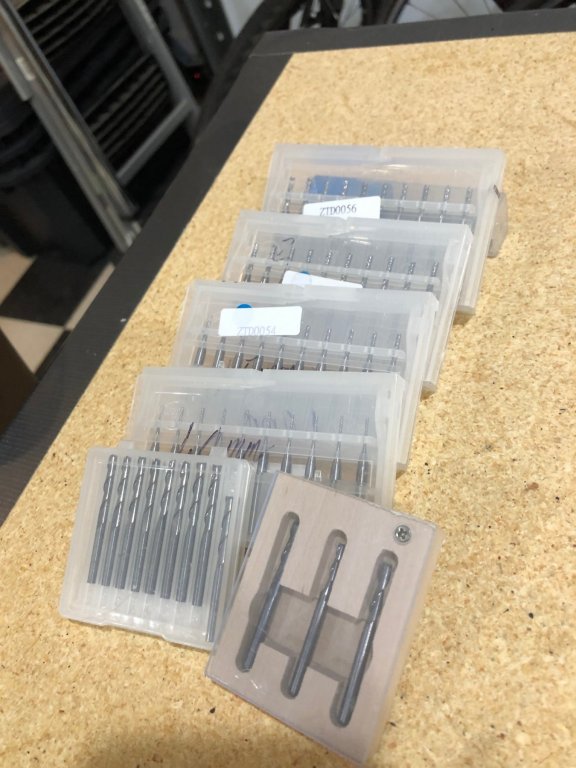

I have a Proxxon MF 70 mill that and I'd like to find it a new home. It's less that a year old, slightly used and in perfect condition. It comes with all the original accessories, a machinist vice and 52 milling bits. The bits are double fluted in sizes 1.5mm, 2.0mm, 2.5mm and 3.0mm. I'll let the whole package go to a new home for $300.00 and shipping. Contact me by PM for addition information Thanks for looking and regards Will

-

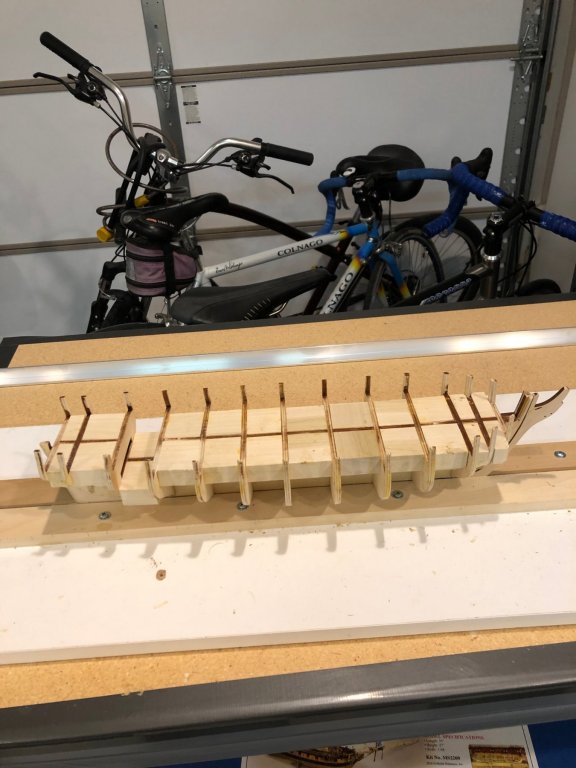

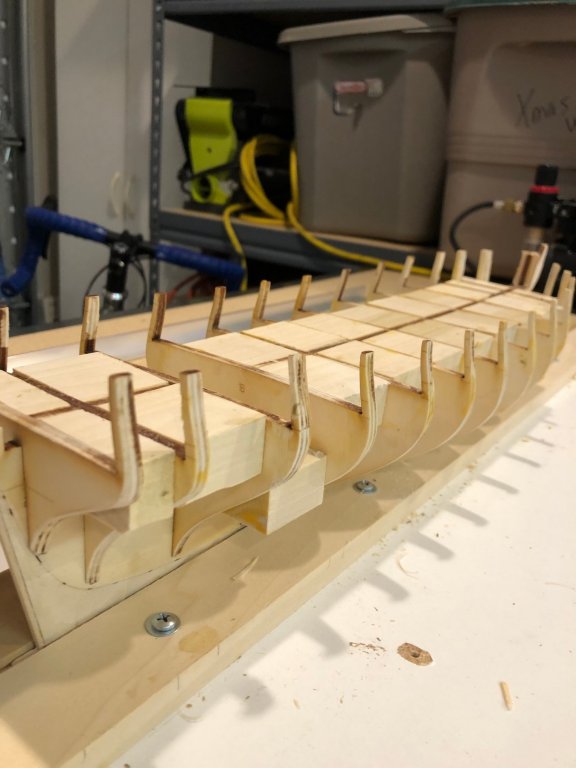

Well with the filler blocks in place and faired along with the deck planking sanded. To get the lower deck planking sanded I made a stick our of boxwood 1/8" by 1/2" and glued sand paper to both sides this allowed me to sand flush up to the bulkheads. Still working on staining. Now its up to fairing the bulkheads outside and inside down to the sizes given in the manual. Oh yeh, only broke three of them. What pain this soft wood is. I thought that with the bulkheads being plywood they'd be stronger, but when sanding the length of the ship the bulkhead do wobble enough to break. So to fix them I felt that just glueing them in place again would not be sufficient so another method was developed. I took some boxwood and planed it down to .02" and glued it on both sides of the fractured bulkhead. I'll make up for the extra thickness by reducing the gunport sides where necessary. To keep the bulkheads in alignment I used the bent strip i used to check alignment seen in a previous post. This kept everything true. Also used another spacer so I could clamp the whole thing together. On to gunport sills Will

-

Hi all, thanks for the likes and comments. It's been a few days and now I faired the filler blocks to create a false deck. I followed the instructions and placed the below deck planking that will be visible through the companionway door. Sanded the deck planking and stained them with wipe on poly golden oak over the bare wood. Boy does the basswood soak up stain in the most blotchy way possible. No other way to describe it but UGLY, UGLY, and more UGLY. Of the reading of how other people has staining success with basswood. In the mean time I made a sanding stick by glueing sandpaper on both sides and started sanding off the UGLY's. All the while I kept singing to myself "a sanding I will go a sanding I will go". Making a sample of planking to test staining methods. Just a sample of my staining experience before sanding.

-

That's fast work Rich. It look great. Will

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Your rats nest is starting to make sense and the coiled ropes on the belaying pins are looking superb, very nice work. I have a small comment on the pump discharge pipes, it appears that they discharge onto the hatch cover and into the hold below. Might be me or photo but I thought I'd mention it. Will

- 367 replies

-

- model shipways

- niagara

-

(and 1 more)

Tagged with:

-

Went to my local big box and bought some 3/4" by 1-1/2" poplar to use for filler blocks. I took 2 days to carefully measure and cut the blocks. The hard part was to make sure the block did not move the frame from true square to the BF. I had to sand them so the side that touches the BF was angled to maintain the deck camber. Doing this will make a strong false deck for the planking. The other thing was to make the blocks so a very slight friction would hold them in place while the glue set. Had to go get more poplar as this lent itself too many pieces being too short or the wrong angle for the camber. Even with camber angle I still had to fair the surface but not by very much. Next I'll plank the lower deck that will be visible through the companionway door.

-

Stay cool as you can I know what heat is, but we've been acclimated to living in the desert. it's going to be 43 degrees today. I read you first page and was so intrigued and that I went to the last page and now I'll go back and read the entire log. It looks great. You're doing a wonderful job. Will

- 550 replies

-

- confederacy

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.