GrandpaPhil

NRG Member-

Posts

4,907 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

Lettering

GrandpaPhil replied to bobc622's topic in Painting, finishing and weathering products and techniques

I like to generate lettering using word art in Microsoft Word. I make up what I want in Word, then I print, cut out the lettering and glue it down with PVA. I finish up by sealing the lettering. -

Welcome!

-

HMS SUSSEX by KarenM - FINISHED - 1:48

GrandpaPhil replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Incredible work! -

The second set of wales are on and the first ones are painted: I suppose I should start laying down some second planking. This planking won’t need “tar” between the planks, because the entire hull will be painted IAW the Matthew Baker drawing. The only bare “wood” will be the deck planking. That will look better in my personal opinion and provide some contrast. The planks will be approximately 9/32” wide by 4 1/2” long to simulate 18” wide by 24’ long planks.

-

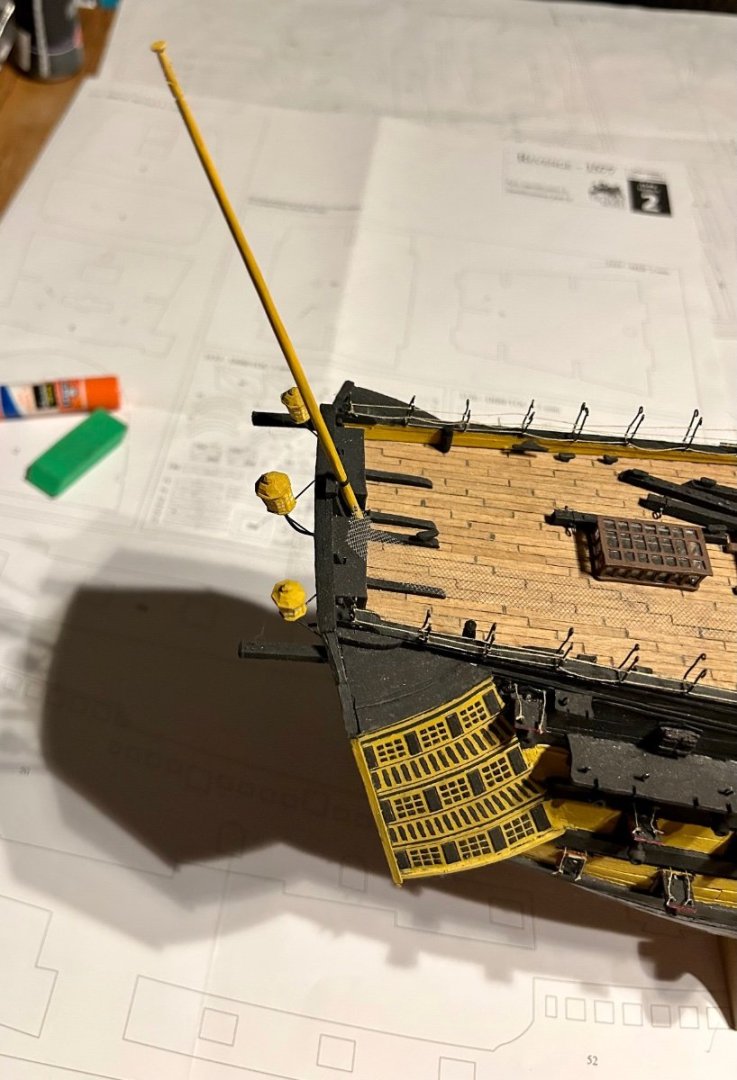

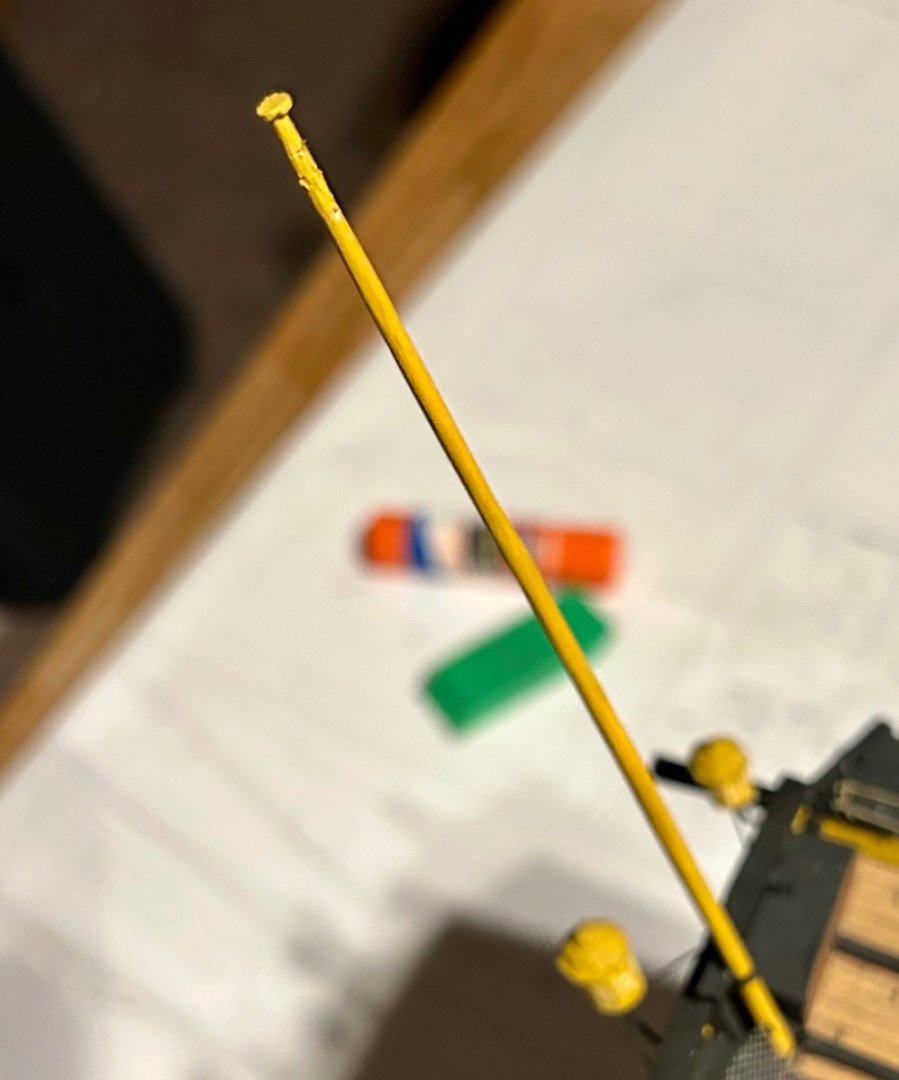

I ordered another model off my bucket list. I have been wanting a Wasa for a while. I thought about using the Sergal plans or the Corel plans. However, the Wasa museum says that their hull shapes are wrong. Orel’s research has been pretty good so far, plus the kit is published in the red color scheme. So, I ordered the Orel card kit. I will use it as a guide and basically rescale everything to 1/64 like my Revenge (I’m enjoying this model). Then I’ll use the parts as patterns to make my own pieces and build from there.

-

For myself, my primary kit consists of a scalpel, a razor saw, a good pin vise with a swivel head, various tweezers, various sandpapers, a couple machinist scales (metric and imperial), a steel ruler, diagonal cutters, pliers, steel pins, clamps, a self healing mat, a good pair of scissors and a couple of coping saws. I do not typically use power tools with the exception of a regular electric drill that I use for larger holes, like masts. Power tools can save time, but if they slip, they can do a lot of damage very quickly. For glues, I primarily use a max-cure CA and Mont Marte PVA glue that I bought off Amazon.

-

Steven, Your Cerberus came out quite nicely. I’m not at all surprised that it sold very quickly. You did a nice job of it.

-

Very cool! Thank you very much for the information!

-

-

LOL! Indeed my friend! Here’s that pile of parts: That was a lot. Here is the transom piece: It is nearly ready to install on the Revenge. I copied the pattern that came with the plan set. The lower wales are painted now and the hull is ready to take the transom once it dries for a bit and I trim the upper edges and the gunport. I am going to step out of sequence again and install the middle wales prior to planking above the lower wales. I like having my actual wales in place before second planking because it serves as a nice guide. I have already made the middle wales themselves and just need to install them. This model is supremely well designed. I am glad that I bought this plan set.

-

Based off what I’ve seen of your work, I second the opinion that you would not have any difficulty with making shrouds or ratlines. Your galleon is looking great!

- 279 replies

-

- Spanish Galleon

- Imai

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.