-

Posts

1,194 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CPDDET

-

Spent this week painting the hull. Masked off the deck and sprayed the cap rail, frames, waterways and inside of the bulwarks with acrylic sealer. Then masked all painted areas topsides Applied 3-4 coats of primer Painted a wide white stripe in the area were the waterline would eventually be. After marking the waterline, ran a 1/4 inch strip of poly tape along the mark. Also taped over the scuppers and painted the outer bulwarks yellow (photo show tape removed after yellow pain was applied). Extended the masking from the center of the 1/4 inch poly to the top rail. Painted the low part of the hull Then reversed the masking, extending from the center of the 1/4 inch poly to fully cover the painted part of the hull Before painting the top part of the hull black, I ran a 1/16th inch piece of poly tape just above the scuppers. Then painted the top portion black After removing the masking, 1/4 inch poly and 1/16 poly, I gave the entire hull 4 coats of matt finish acrylic sealer Still have a few small touch ups to do on the outboard edge of the top rail and some very minor oversprays

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Judging by your work so far, your rigging will look great.

-

Your a brave soul, taking on such a project for a first build. And a scratch build at that! Looks like beautiful workmanship. Welcome to the group.

-

I will be getting my first airbrush system next week and will be using it to paint the hull of my Bluenose model. On the assumption that I will be doing multiple coats, will I have to clean the airbrush between coats? Or will the paint (acrylic) dry fast enough that following coats can be applied without the fear of the airbrush becoming clogged? I have already researched (through this site and via the acrylic paint manufacturer) the proper method to prepare the paint for airbrush use and will, of course, test things out on scrap wood before painting the model. Dave

-

I now have sets of both Swiss files and Escapement files. While still new to this hobby, I'm finding that, in many instances, files are more appropriate to use than sandpaper. It seems having the correct tools, knowing how and when to use them is key to producing a good result.

-

Swiss made jeweler's files.

-

If anyone is interested Otto Frei is having a closeout on a set of 12 escapement files (various cuts). Regular $190.00 on sale for $155.00 https://www.ottofrei.com/Closeout-Glardon-Vallorbe-Escapement-Files-Set-Of-12-Assorted-Cuts?location=1&quantity=1

-

Poly over acrylic paint????

CPDDET replied to CPDDET's topic in Painting, finishing and weathering products and techniques

My situation is placement of the finished model. I have limited space so the model may very well be placed in a spot that received some amount of sunlight. The sealant will provide UV protection and help reduce fading. Aesthetically it will give more "pop" to the colors. -

Poly over acrylic paint????

CPDDET replied to CPDDET's topic in Painting, finishing and weathering products and techniques

I think I will use this product to seal the paint on my model. Crystal Clear Krylon Acrylic Coating Spray Finish. -

Poly over acrylic paint????

CPDDET replied to CPDDET's topic in Painting, finishing and weathering products and techniques

Per Minwax the only product they recommend over acrylic paint is their Water Based Helmsman® Spar Urethane. -

Here is a close-up of the cap rail after painting. I pretty happy the way it came out. The rail looks smooth, yet some of the gain still shows through so one can tell its wood. I accomplished this by sanding with 400 grit paper, applying a coat of Ceramcoat Sealer, sanding lightly again and painting 3 - 4 coats of Tamiya flat white. I prepared the paint by adding 20 – 25 drops of Tamiya Acrylic Paint Retarder to the 23ML bottle of paint.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

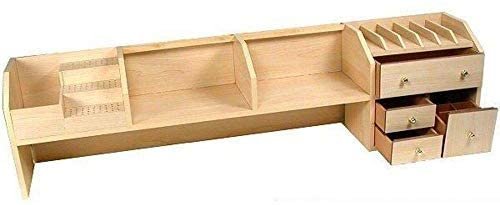

Spent yesterday running around to get necessary supplies and building the jig. Came out pretty decent. Minimum height is 7 inches and maximum is about 10.5 inches. Before moving on to the hull painting I want to touch up a few things topside. But insurance guy will be here in an hour and tomorrow is carpet cleaning day. So dont know how much progress will be made today or tomorrow.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Switched from X-Acto to Excel blades......

CPDDET replied to CPDDET's topic in Modeling tools and Workshop Equipment

I did pick up 2 boxes of disposable scalpels on EBay, very reasonable. The only issue I have with these is the blades are very thin and flexible and, because of this, aren't always the best choice for the job. But they do have their place. -

Cap rails installed and 2 coats of paint, 1 coat to go. Next will be to draw the waterline. I'm going to build the jig shown on page 55 of Frank Mastini's book, "Ship Modeling Simplified" rather than buying one. I'll also follow his instructions for drawing the waterline on page 56 which gives instruction for doing this on fishing schooners, which is a bit different than on other types of ships. Bluenose, a fishing schooner, is deeper aft than forward. Referred to as "keel drag". Looks like I'm off to Home Depot tomorrow to pick up a few boards.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Brush painting hull ??

CPDDET replied to CPDDET's topic in Painting, finishing and weathering products and techniques

Allen, thanks so much for the the clear and precise instructions. This newbie needs all the help he can get. Your instructions clear up many questions and will make my first hull paint job much easier. -

Switched from X-Acto to Excel blades......

CPDDET replied to CPDDET's topic in Modeling tools and Workshop Equipment

Glad to hear you found a reliable, fully stocked place to buy your blades and handles. Makes things much easier. -

Switched from X-Acto to Excel blades......

CPDDET replied to CPDDET's topic in Modeling tools and Workshop Equipment

Yep, half of grandad's old strop was hanging on the kitchen door knob, a reminder to stay in line. 55 years later I'm using one everyday for shaving. -

Brush painting hull ??

CPDDET replied to CPDDET's topic in Painting, finishing and weathering products and techniques

Thanks for the tip Don, I believe I'll try your method when I reach the point of painting the hull. Any further tips you can pass on paint bleed? My Bluenose has a 2 color hull separated by a white stripe waterline. Getting a crisp paint line is important to me and the thinner paint may tend to bleed under tape. Perhaps the coat of wipe on poly id the trick? Dave -

I recently switched from X-Acto to Excel blade. I not only find the Excel blades to be as good or better than X-Acto but I find it much less frustrating obtaining the variety of blades I use. 1. Hobby shops never seem to have the blade types I use. Yes, they always have some of the blade types I need but never all of them in stock. 2. Buying on-line seems to lead to the same problem. Using places like Amazon I have to order from multiple vendors and some of them take far too long to ship. I like the fact I can go to the Excel website, choose the blades I want, choose the quantity I want and get them in a short time. As far I can see, one can't order directly from X-Acto. Just makes my life easier. Dave

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.