lraymo

Members-

Posts

297 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by lraymo

-

Finally finished the "Step", using several different blades, needle file, sandpaper, and wood filler to help smooth out the edges. It's not perfect, but it looks ok to me, so I'm moving on. Thanks for all the suggestions and the encouragement! This was slow going, and I'll probably do a bit more filing, but it's essentially done. Next up is the sternpost, stem, and keel (made it to page 4! Whee-ha!) Fixed the stern The bow looks better now too!

-

Thanks again for the suggestions. I had my first carving mishap with the knife. Went completely through the bulwark. Glued and clamped to fix, and I'm hoping I'll still be able to carve, file, and sand through the glue, as there's still more excess wood to remove from the area! For now, going to let it dry and try again tomorrow! It will be interesting to see if I can make this all look good, but I am hopeful!

-

Thanks Keith! I was encouraged because the file you suggested is the exact one I picked to use when the package arrived! I haven't made any discernable progress yet, but I'm working on it. Can't believe the "step" part is so hard for me, as I know there are much more difficult areas ahead. Ah, but then I remember it's all a learning experience! Now, off to experiment with getting a smooth surface!

-

My new needle files arrived. I am not really sure how to use them, and carving the step is very rough... not sure how to get the smooth, finished surfaces I see in other posts. But this is just the first pass. I'll try to use the files to smooth it out... and may try some wood filler to create a smoother finish!

-

Starting to carve the step. Realizing I'm not very good at carving, but feeling ok about it, since I've never done this! Just finished the initial pass on one side. I can see there will be LOTS of sanding and touch-up to make this look ok, but at least I've started. Much more work to do on the step, but for now, I'm off to play pickleball!

-

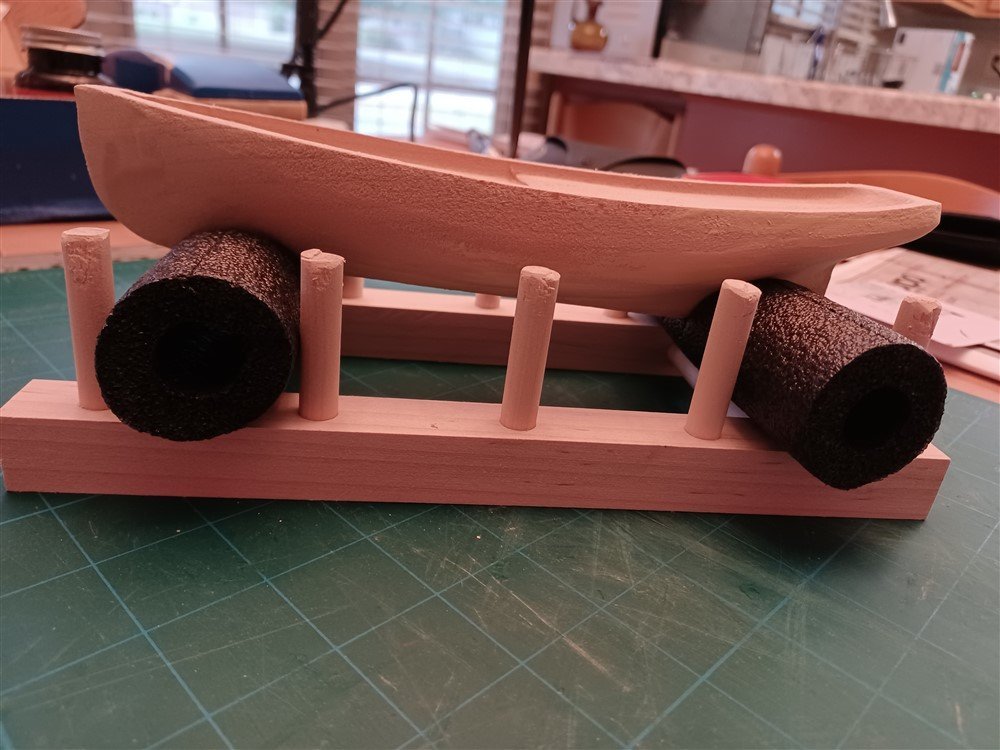

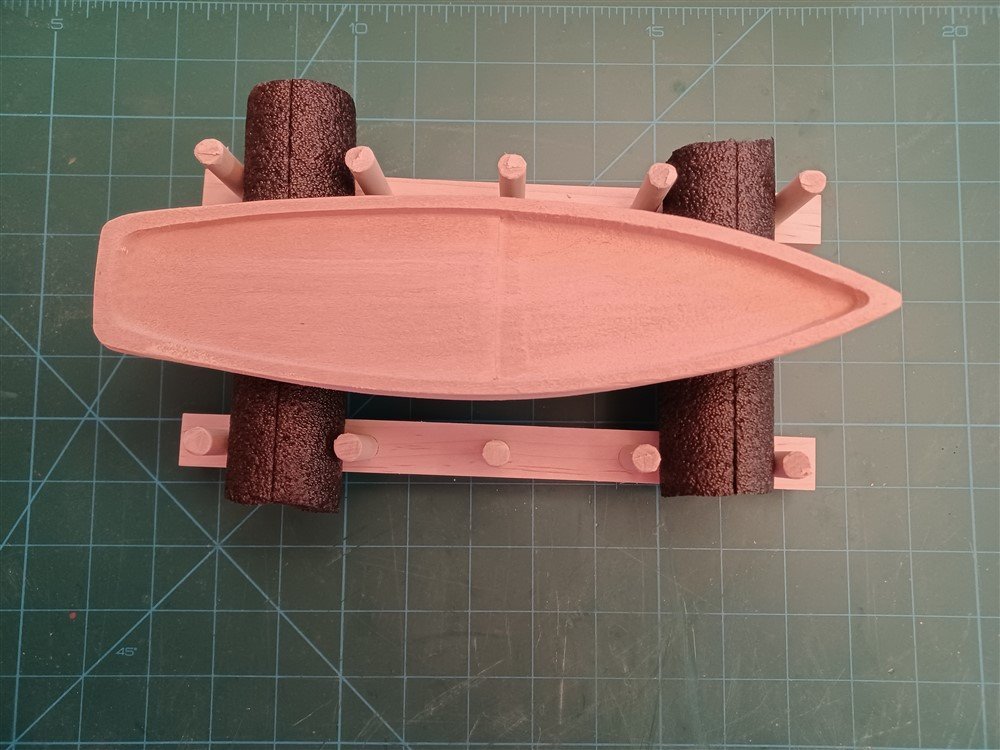

Very slow going, as I have too many other commitments going on! but I am making some tiny progress. Created a ship holder out of a trimmed down dish holder and some pipe insulation. Also tried out my new dremel tool to shape some of the hull, sanded off too much and made some gouges, and filled in alot with wood putty. Waiting for everything to dry so that I can sand it smooth, and probably will call it "good" since the overall shape looks ok to me. Then I'll carve in the "step" mentioned on page 3. (Can't believe I've only made it to page 3, but clearly this will keep me busy for weeks & months to come, so that's a good thing!)

-

@crjmjh Thanks for the kind words. Your Dory looks terrific!

- 85 replies

-

- Lowell Grand Banks Dory

- First Build

-

(and 2 more)

Tagged with:

-

Thanks everyone, for all the information. I see that I had completely forgotten terms I learned in the first two builds! Of course, the instructions make much more sense, now that I know what they are talking about! My bad... I'm going to go back and relearn the terms before proceeding. (Thanks for your patience with me!) And Cathead, I totally agree with Keith, its an excellent diagram!

-

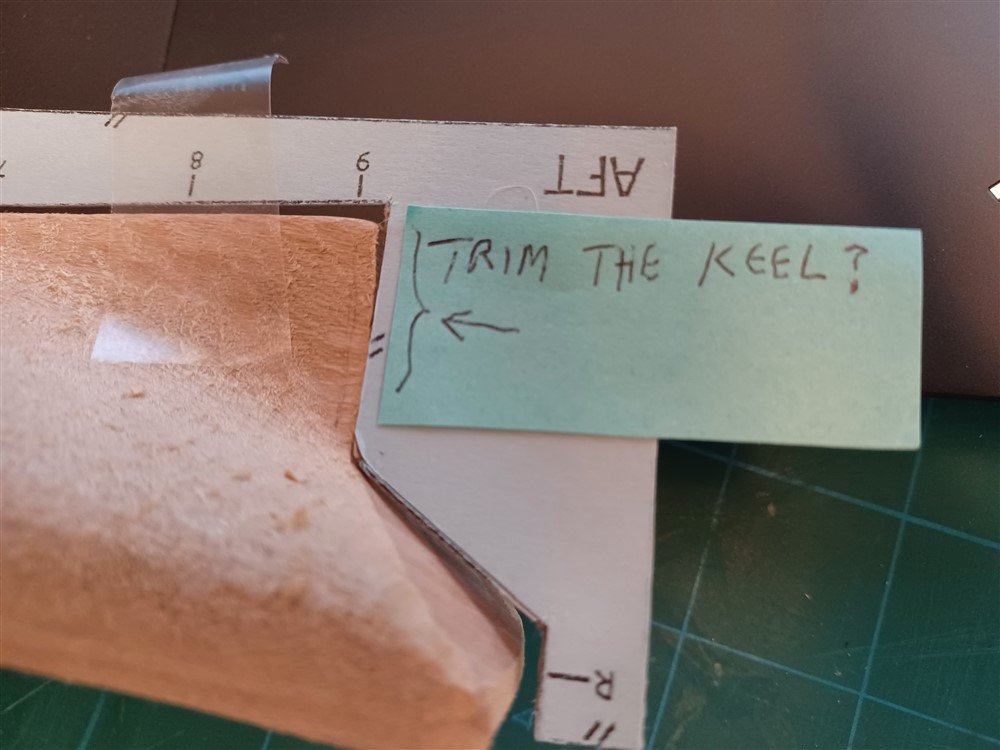

I knew I'd have questions right away! So the hull measures about 1/8" too long (as noted in the instructions). But the instructions tell me to remove this extra 1/8" from the stern? When I put it up against the templates, it looks like I should remove this extra wood from the KEEL, not the stern. Is this correct? Should i remove the excess from the KEEL, instead of the stern? It seems reasonable to trim the KEEL to match the template. But want to ask you all if this is correct?

-

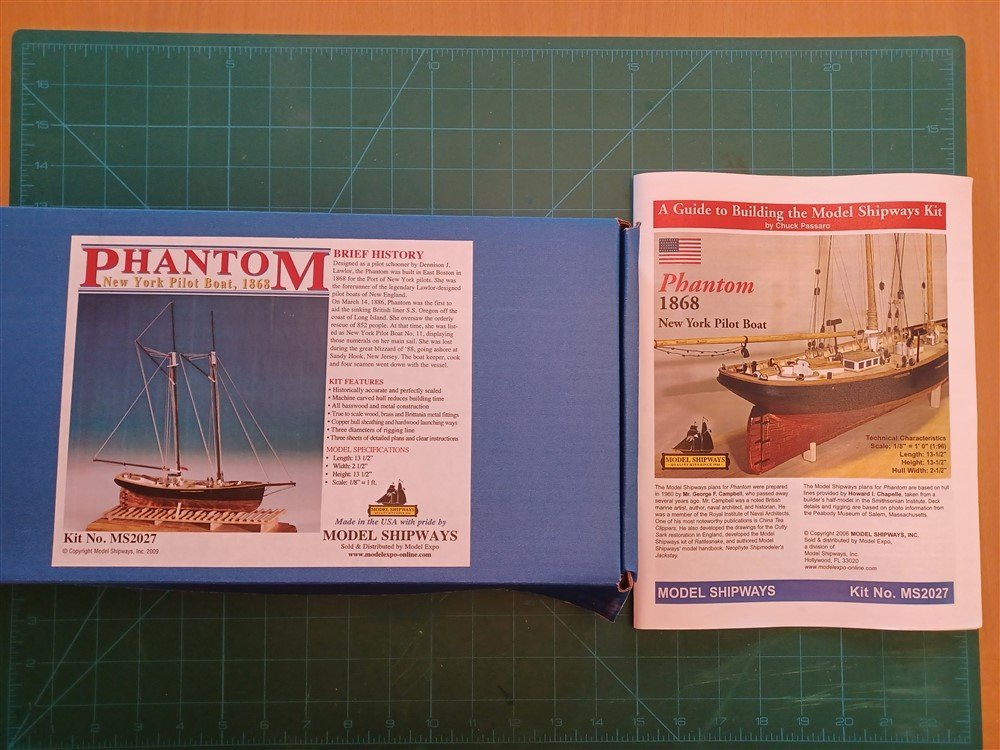

I started the Phantom! Check out the new build log:

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

I started reading the instructions for the Phantom. Looks like I'll be doing a lot of rounding, shaping, etc, so the drill will come in handy (I need to start practicing!) Speaking of practice, my golf game needs a lot of it! But I enjoy it, and every game there's that "one amazing shot" that keeps me coming back to it!

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Ha! Thanks for the advice!

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Keith, thanks for explaining the procedure! I understand what you're saying now. And, as part of my household tools, I actually do have a drill. It goes forward and backward, and the speed is regulated by the pressure I put on the trigger, so I'm assuming it can be called a variable speed drill. I will begin practicing with it! (Mostly, I use it to drill holes for picture hanging, or other little home repair jobs around the house, although I'm not very "handy" when it comes to house maintenance!) Thanks again for all the encouragement. My new Phantom model kit arrived today. I'll probably take some time off before starting it, as the Kansas heat & humidity has finally abated somewhat, and the plan is to play a lot of golf in the nice weather!

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Ok, NOW I get it! So in your photo above, you held a jewelers file against the round dowel to shape it. That seems hard to do, freehand. I'm assuming you held the file in your hand, maybe supporting it somehow. OR did you hold the ndrill in your hand, and move it against some sandpaper or a file? Or was it a two-handed operation - where you had the drill in one hand, and used the file in the other hand? I thought I had it, but now I'm confused again! (By the way, the gun looks great!)

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

I confess, I'm not quite sure how to use a drill to shape masts and spars. How is it used? (Clearly, I will need lots of practice, since I can't even visualize how to use one yet!).

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Hi Steve. Just noticed you were building the Dory. She looks beautiful! So clean, crisp, and the paint looks great! Wow!

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

I bought a dremel rotary tool (with a flexible shaft extension), but I haven't used it yet. Would it serve a similar purpose as the cordless drill?

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.