-

Posts

629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Matt D

-

I hear what you're saying. Especially drilling such a nice deck as yours. But the ring bolts and eyes really add a lot and you'll be amazed at how they look when you get them installed.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It looks like you've done a fantastic job on your bulkheads. I agree with you that buying Chuck's laser cut bulkheads would be much easier, but you can't beat the feeling of having done it yourself. Plus, your next model might not have that as an option, so now you know that you can make your own. My own had many errors that I didn't recognize until I was fairing the hull. I had to fill a few voids and file a few humps. From these photos, I think you're in great shape.

-

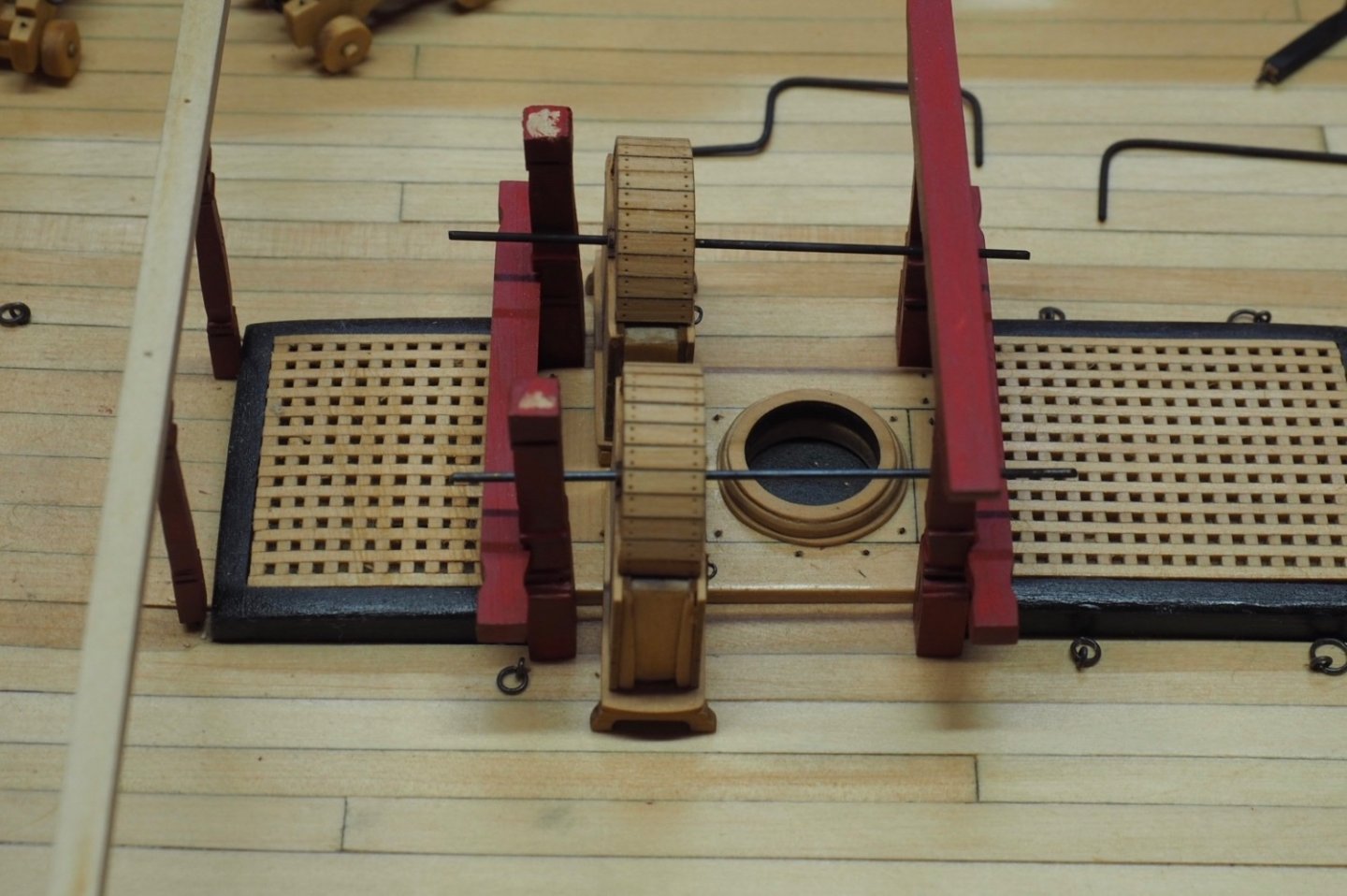

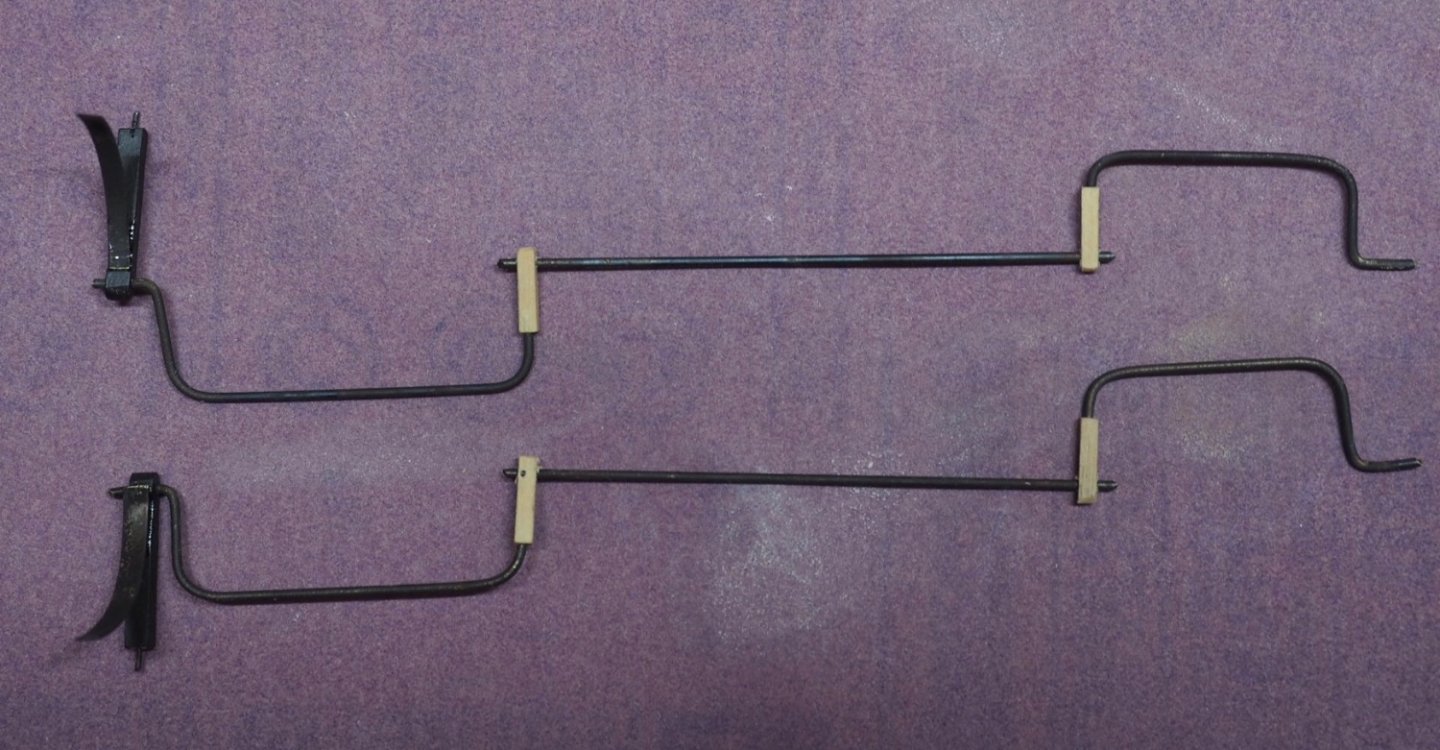

Thanks, Chuck, JJ, and Glenn. Chuck, I agree with you 100%. One think I didn't mention was that I pinned everything except the chain pumps. After I figured out how to get the holes drilled in the right spot using masking tape, I've been a pinning maniac. I thought about pinning the chain pumps, but decided the risk of splitting the feet was not worth any benefit. I'm certain they're not going anywhere with the 1mm brass crank rod holding them down. I'm away from home for work this week and looking forward to building the elm pumps this weekend after I get home. I have my 7-10-7 marks on the 3/16"x3/16" boxwood strip, so I can start filing right away.

-

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

Niagara by Alex-Ks1 - 1:7 Scale

Matt D replied to Alex-Ks1's topic in - Build logs for subjects built 1801 - 1850

8 feet long?! Wow! This will be amazing! I can’t wait to see your progress. -

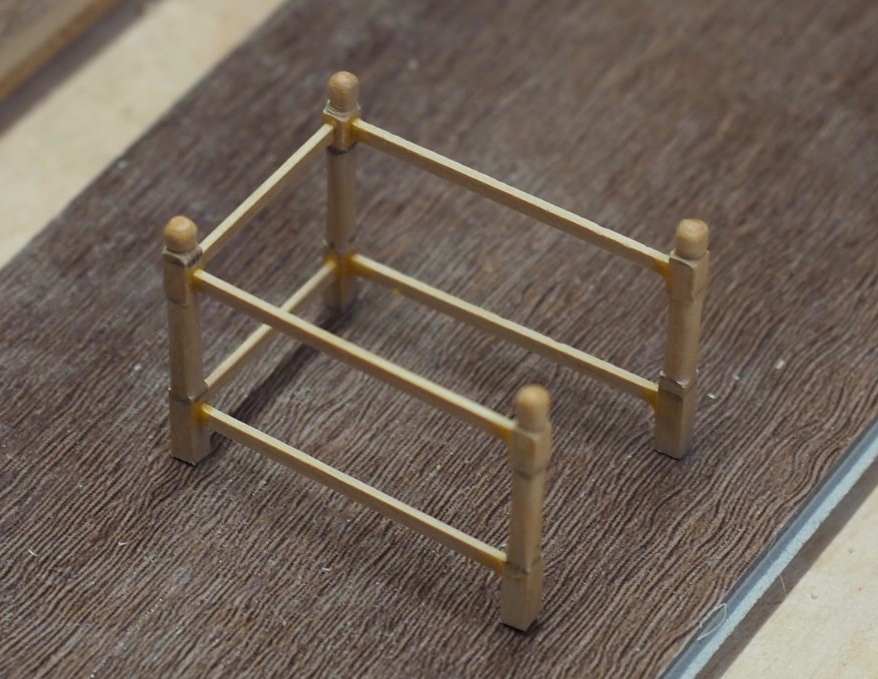

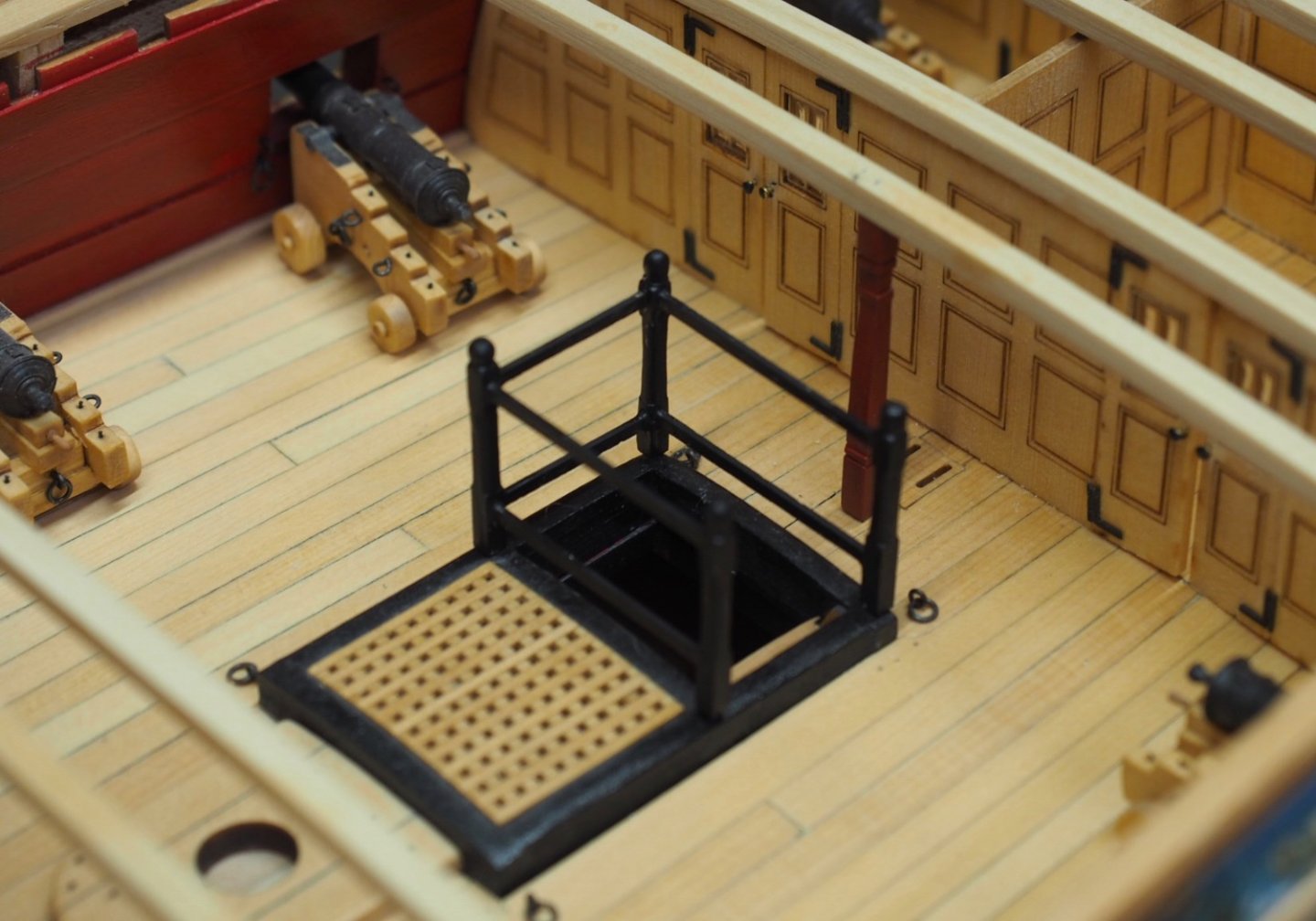

Here are a couple of shots of the railing around the companionway. I tried to do this exactly as described in chapter 7. Turning the stanchions was very easy using a Dremel tool and a small file. I glued it up using PVA. I expected it to be very fragile, but it’s surprising strong. I pinned it using 24 gauge steel wire. I’m pretty happy with how it turned out.

-

I think I have a problem with the height of my capstan. I can’t find a good view that shows how high above the quarterdeck beams the upper capstan should be. But I think mine is too high. I’ve carefully measured with my calipers and the top of the cog is 11/64” above the beam just forward of the capstan. Do any of you know if that’s too high as I suspect?

-

Welcome aboard the Winchelsea project, my fellow Michigander! You’re definitely not too late to the party. You will see that we have someone working in every chapter at this moment, which is pretty amazing if you ask me. So there are many sources of good advice for you. As Joe has already mentioned, birch plywood is potentially a problem. Do you mean high quality Baltic Birch? Or are you talking about the birch plywood that they sell at Lowes and Home Depot, which is only veneered in birch and is much softer inside? The former is much more like hardened blue steel appropriate for the hull of a battleship. Fairing it will be a really hard job. The latter is just about perfect for this project. My first hull attempt was with Baltic Birch. My second was with Home Depot birch.

-

The "window maker" glass looks really nice, Gary. I used Micro Krystal Klear for mine, following Bob's lead @rafine . I had already installed and enclosed the acetate on the outboard stern, just as you have described. But with the Micro Krystal Klear, I was able to carefully put it over top using a toothpick to spread it around just like you would in an empty frame. One advantage (in addition to having a look you might like better) is that it gives some degree of protection against breaking the window pieces later in the build. You might be able to test it on one of the extra windows from Chapter 3 by gluing an acetate window on and then applying the window maker afterwards.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, Rusty, and all of the likes, too. Chapter 7 has some neat stuff in it. But I'm a little freaked out by the beams. On the one hand, I can't wait to get them in and I love how they're going to look. On the other, I want to make sure everything is just right and the cannon are all very secure before I close her up. I'd hate to have to try to remove any of these beams down the road!

-

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

The New Up Arrow Button!

Matt D replied to Matt D's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

You’re the man, @James H! -

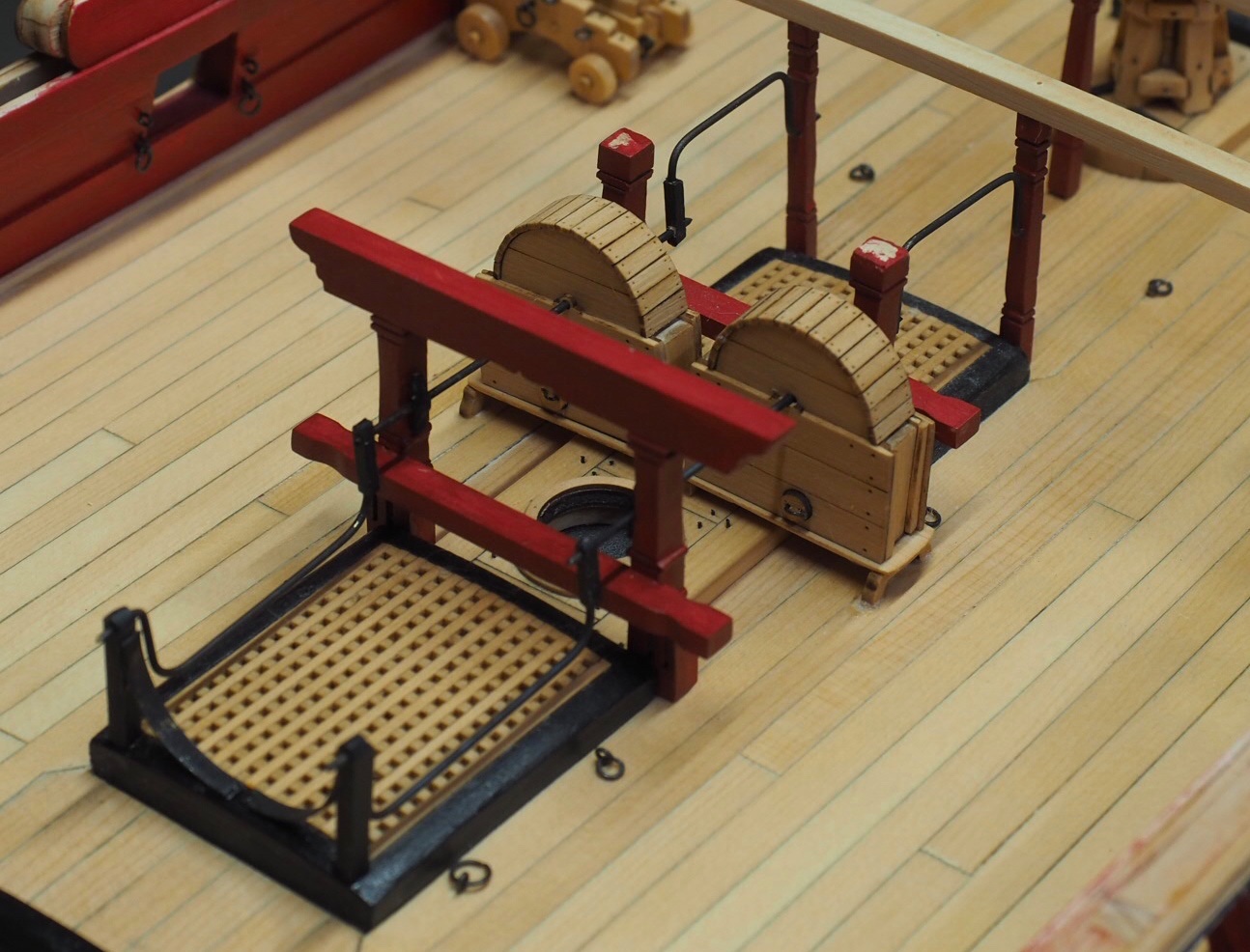

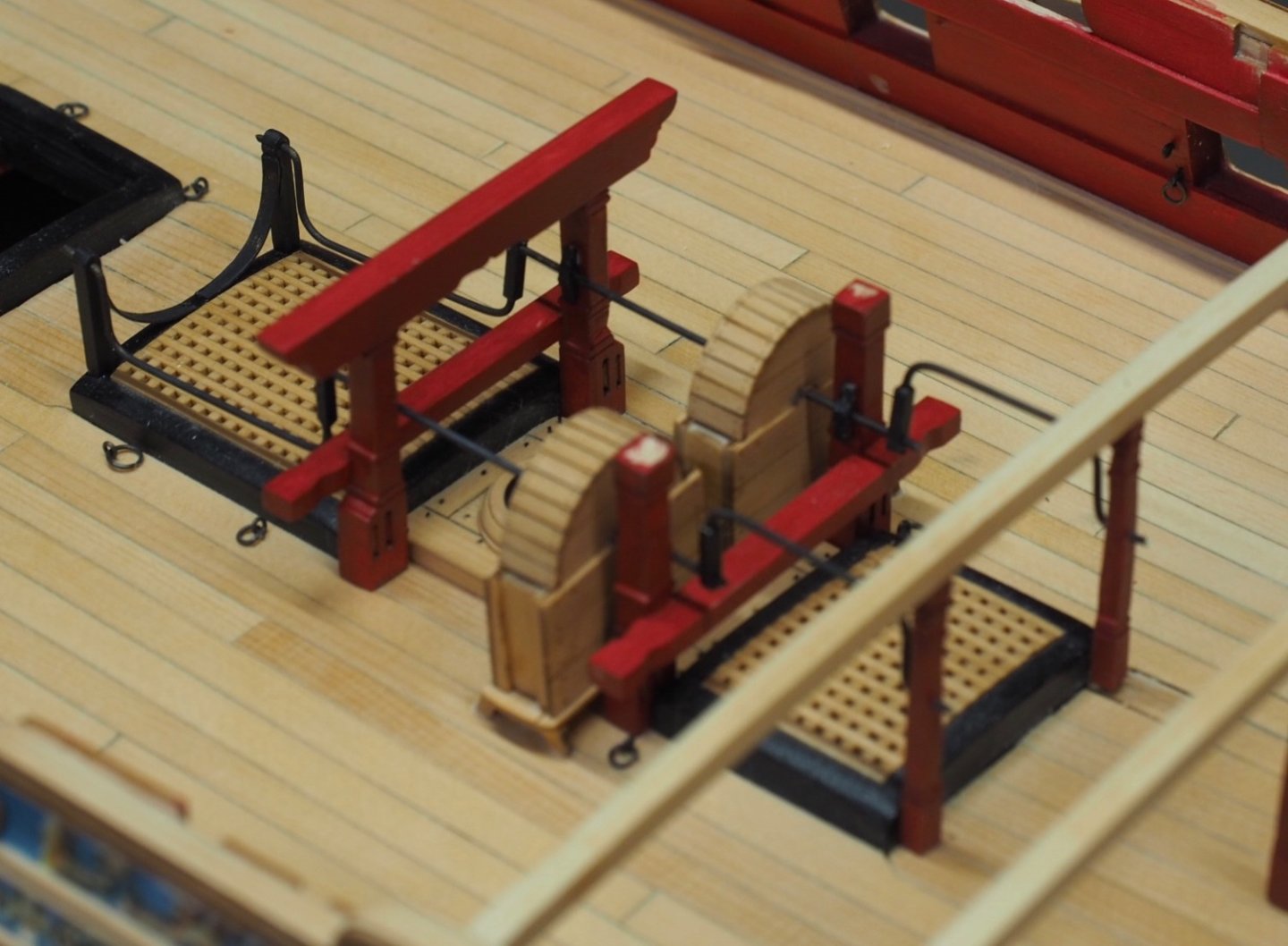

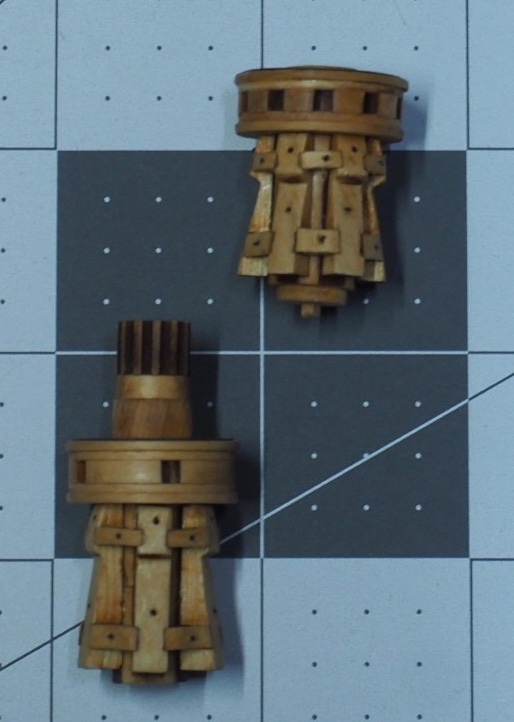

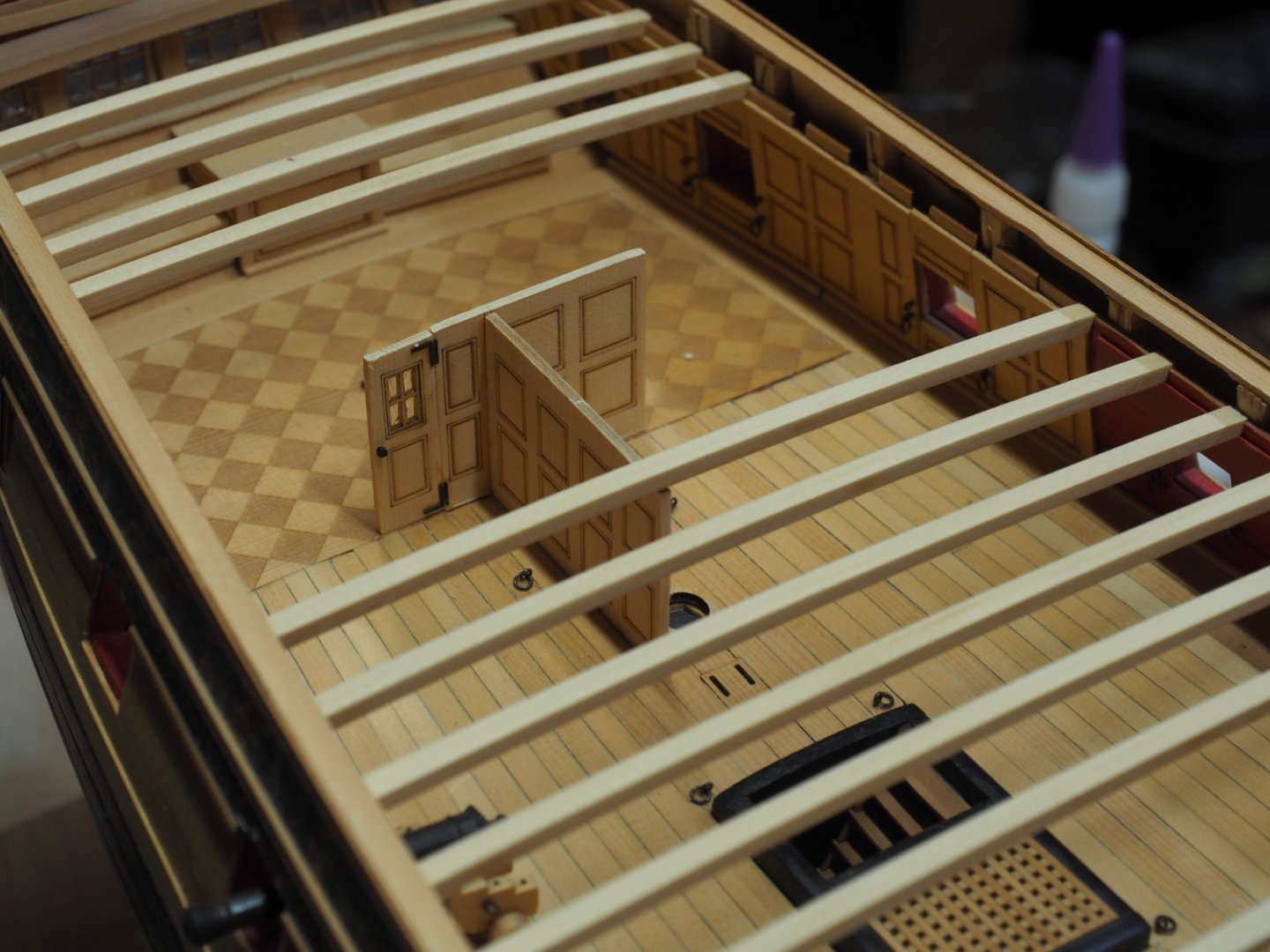

Where has the time gone? I’m working on chapter 7 and thought I’d add an update. I couldn’t help myself and had to start the chain pumps as soon as I received my chapter 7 parts. They’re not fully complete, but you can see that the bulk of the work is done. After that, I worked on the beams. Thanks to Chuck’s wonderful design on the deck clamps in Chapter 4, the beams are very easy to fit and align. With all of the quarter deck beams fit, I’m now working on the bulkheads. The center section of the aft bulkhead is not attached in the photo below. I have test fit and glued the fore to aft piece to ensure that aft bulkhead is vertical with respect to the model. I’d like to leave one door open in this bulkhead, but it won’t be either of the starboard side doors because I’ve accidentally glued the edges of those doors to the bulkhead pieces. I’ll try to be more careful on the port side. If you see those installed closed in a later post, you’ll know I was unsuccessful. Here’s a picture of a little project I did with my 15 year old son during the holiday break in the kids’ bathroom. These are new drawers in the vanity that fit next to the sink. The kids will each have their own drawer. He needed to do a project for a boy scout merit badge and I wanted to make their bathroom a little less messy.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.