-

Posts

205 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wacom

-

Reading various post’s about rope making I see that DMC seems to be the cotton of choice for many folk. I am some what confused in that here in New Zealand DMC cotton comes in stranded packs used for embroidery and limited to 8 metre lengths. My question is does DMC sell it differently in the states or am I looking at the wrong stuff? Any help appreciated.

-

Steve, I struggled with this problem until the eureka moment arrived. Instead of trying to make 12 the same I realised that they are all different. I then used the template that Chuck provides and lined up my moulding with each template (one at a time) and carefully cut the angles. whilst my skill level is not up there with the likes of Chuck they are a lot better than all My other (too many to count) attempts. Hope this helps. Your work on the hull is outstanding.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks really good.

-

Tell me about it! I am the same stage Rusty and it takes lots of checking build logs, drawing and eyeballing to get them any where near. Love the colour of that wood😎

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Mike, your craftsmanship never ceases to amaze. An inspiration to us all, well done.👌

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for the info, this is just what I am looking for. Mark, I am aware of the differences but after much searching cannot find anything of use other than this book. No doubt some one will come along with fully dimensioned plans (I wish) I do believe that the smaller volume you mention is now incorporated into volume 4. Many thanks for your replies.

-

Can anyone recommend this book by David Antscherl? I am building the Winchelsea by following Chuck’s great instructions. It is my mind to look into the feasibility of rigging (at least to the main tops) this ship. Any help will be appreciated. I see the publishers also offer the plans and I was wondering if these include details of the mast’s, spars etc? Thank you.

-

Thanks guys for the comments and reactions, always encouraging to know Winnie is on the right track😇

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

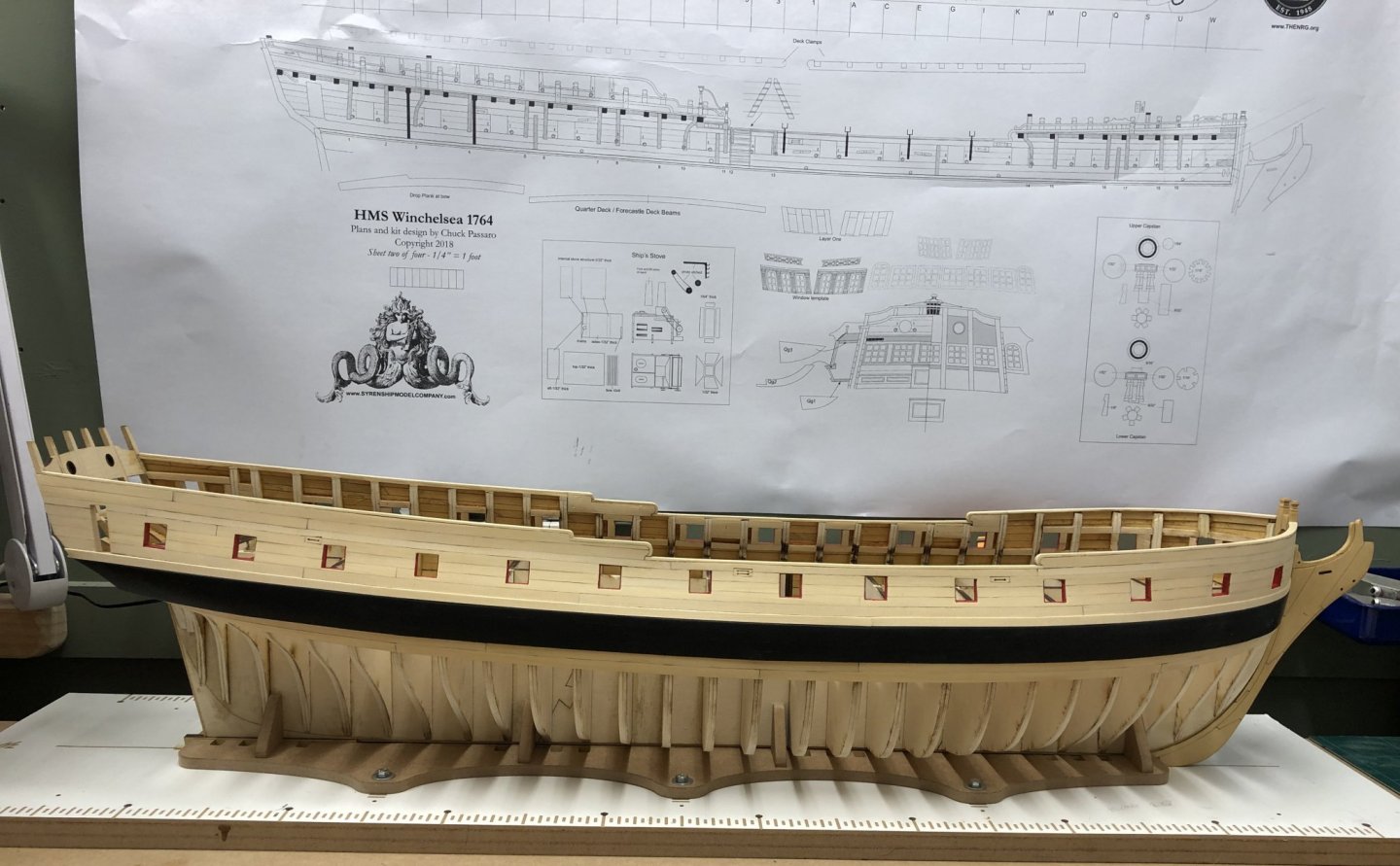

Finished Chapter Two. Some of the planks widths are "off" but I can live with the ship as she is so far. My thanks go to all you folk who are building Winnie, you are an inspiration to me and an encouragement when the going gets tough, thank you.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Run out best described as wobble, if the drill bit wobbles.. not good..no wobble.. very good. You can usually tell by eye if its OK. Sometimes if the bit wobbles, slack off the chuck, rotate the bit a little then re tighten chuck, this can help. Your drill press looks like a rebadged Proxxon Tbm, if it is then your chuck should be good.

-

Your skill at converting old floor boards into works of art is amazing. I bet there is some number 8 wire in there somewhere. Following with interest.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

Some of the best ideas are the simplest 😀

-

Proxxon flat sander accessories (BBS/S No28526)

Wacom replied to Bitao's topic in Modeling tools and Workshop Equipment

That looks like very useful tool, do you mind if I ask where you sourced the aly profile? -

Thanks for the comments and likes, every bit of encouragement helps 😋

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Finally some progress to report. As I mentioned in Jim’s log, I had the upper planking finished on both sides but felt the the finish on the planking and especially the gun-ports left a lot to be desired. After much thought I removed everything as far as the black strake and started again. This is my second attempt and although far from the standards set by so many others I am reasonably pleased with the way it turned out. I have also faired the inboard bulkheads. All that remains to do is touch up some small holidays in the paint work and apply a couple of coats of Poly to help keep it clean. Then its on to tick stripping and plank sawing. I enjoyed working on the two rows of planking below the wales so am hopeful I will enjoy this part of the build (at least there are no gun-ports to do)

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The parts for chapter three arrived this morning. Almost to good to use the fine detail is beyond belief. We are very lucky people to have Chuck not only showing us how to build this ship but also willing to supply the “tricky” bits too.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is beautiful Rusty, the Cherry looks great with the wipe on poly. Very inspirational.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.