-

Posts

4,379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

Thanks brother... And yeah I know the feelin' I've got so much useless junk floating around in my brain from researching subjects that strike my fancy from time to time that it all gets jumbled at times.... It was mid '43 when they started switching to Mark 13's on roll off racks .... As an aside, Kennedy, after the rescue and short medical leave was given command of PT-59, a 77' Elco that had been modified with no torpedoes, two 40mm's and four more twin .50's They were known as gun boats intended to handle heavier armored/armed shallow draft japanese barges they were beginning to encounter... His first action with this boat was the rescue of 50-60 marines from a swamped landing craft that was under heavy shore fire.... Reports say they made excellent use of those 40mm's silencing enemy shore batteries....... Getting sunk wasn't the only fame Kennedy was famous for, such just wasn't published cause Kennedy wouldn't allow it.... He thought the publicity over PT-109 was enough....

-

Ah brother, as I'm looking at the drawing on the instructions, port rotor has two stripes and the starboard rotor has three.... also the leading edge of all rotors is black even where the stripes are painted on, the stripes don't go completely around the rotor blades they are broken at the leading and trailing edges... Of course I could be wrong..... (but that is how it looks to me, maybe it's just my bad eyes)

-

Craig, looks like a good base, a suggestion? Add some blue washes to it, starting with a lighter blue over most of it and deepening to a very dark blue in the deep crevices, this will give the effect of deep water and the high point crinkles in blue green would give the idea of storm tossed water.... you can then top the crests with white to give greater attention to the wind driven nature of a chaotic seaway.... Wartime subs always seem to be surfacing in chaotic seas for some reason..... Just my opinion but it looks way too green for deep seas.....

-

Lapstraking the bow panels are you?, well we will overlook it since you promised not to do it again.... {naughty boy}

-

I'll research it again Lou, it's been a couple of decades since I last looked.... You see this is the thing about getting old, some memories fade or get mixed up.... Ballard found the 109's bow in 2002, he went searching for the stern but after striking out and running out of time he took a shot at the bow.... And yes he found it at the southeastern end of Blackett Strait near the entrance to Ferguson Passage...... Exactly where Kennedy reported the drift currents took him.... What they found was a torpedo, and a few feet away a torpedo tube still attached to it's training mechanism... (they had to crank the tubes outboard to fire them) Of course the 109 was the only lost PT boat reported in the area so they went nuts, as it was just laying right there in 1300 feet of water..... He was working with the Smithsonian on the project and beamed his film to them and they had a US Navy torpedoman, Welford West, who was aboard the boat that rescued them so that is as good an expert as you could have as to the equipment they were using at the time.... He identified it, (along with Navy torpedo experts) as a Mark 8 torpedo and a Mark 18 tube which was confirmed cause the training gear was still attached...... He also recounted that three months later their tubes were replaced with drop shackles which were easier to load and launch.... They tried to move it but couldn't as it was still securely fastened to something that was buried in the sand, but their penetrating sonar revealed that the object it is attached to is about 7 meters wide the correct width of an Elco PT boat at the forward torpedo tube... So the metal frames that supported the tubes remains but they were pretty sure the plywood hull is long gone....... Without actually pulling up a part with a serial number that can be traced there is some small doubt that it might not be the 109, but relying on movement & loss records of the period, the 109 was the only PT boat reported lost in Blackett Strait and it's exactly where it would be if it sank shortly after Kennedy reported leaving it..... In fact Kennedy reported the need to leave it specifically cause it was starting to sink... The Navy considers it the wreck of the 109 as does the Smithsonian, pulling up an artifact was rejected as it is considered a war grave...... So yeah, it still had the old style crank out torpedo tubes.... My bad....

-

Alright! In the teaching an old dog new tricks department..... Handling PE and the newer models with their tiny parts involves new techniques of assembly... I haven't done any PE on a ship model since my USS Olympia build of some 20ish years ago.... there was Toms MW and GMM and Eduard was still an upstart from europe concentrating on airplanes... the only way to glue PE was superglue and accelerator.... the parts were big enough to handle with small tweezers or surgical forceps...... My, have times changed, the parts are a lot smaller and PE has become much more refined and delicate... This requires new techniques and materials to do it effectively...... So back to the research, (that is my second hobby) and I've found a few sources on the most effective way to install PE on models.... And surprisingly, Greg's method of installing first and painting afterwards is actually the most widely used today..... Back in the past you usually painted first and then formed and installed, touching up the paint afterwards, not any more...... Nowadays it's install the surface details first then paint, fold first, then paint.... completely opposite from what I learned.... So in the effort to get with the program, I looked it up on the net and saw how easy they seem to make it out to be.... (yet to see if I can adapt to the new methods) But the first part is finding something to reliably pick and hang onto the parts and PE when installing them, and a glue that allows you to adjust them before setting up but still setting up rather quickly without the need for accelerators... Also giving a strong enough bond so the parts don't fall off at the first bump... So I picked up some Crystal FX positioner pencils and a Marvy Jewel Picker... the pencils are especially adept at picking up plastic parts, the the jewel picker at handling PE..... The jewel picker is an actual tool with two different size sticky tips with covers, recommended by a few friends in Japan who happen to be avid 1/700 scale WWII ship modelers..... The pencils are recommended by most youtube video modelers... (in any scale) The #1 consensus on which glue to use is Gator's Grip glue, talking with Kenny, (the guy who makes it) it was especially formulated specifically for PE and has since been adapted for tiny plastic parts..... I have ordered both directly from Kenny and it appears to be the leading PE glue advocated by the youtubers.... (although superglue is still advocated widely as well as PVA white glue) As soon as the glue arrives I'll be assembling the deck furniture and will be giving Greg's technique of installing first then painting a shot.... Makes me feel like a beginner all over again....

-

You have any plans on how your going to finish her? As built, (kit illustration) or as lost? She had a lot of weapons added to her upgrades, (not just the 37mm) like twin .50's from singles, shielded 20mm, initially built with torpedo tubes upgraded to roll offs, etc, etc before she was lost.....

-

It's why they developed polyurethane clear coats to protect the alkyd enamels underneath, but it didn't stop the enamels from deteriorating... eventually they developed urethane paints and from that powder coatings both of which are nearly indestructible.... Denis, they first blamed it on acid rain, cause that is where it showed up first, the acid in the rain was only a harbinger of what was to come, the acid weakened the surface cohesion of the paint carrier allowing the UV rays to attack the adhesion much quicker, eventually they started seeing it in the desert climates with no acid rain as well, that's when they learned they had to come up with something new.... Interesting that it coincided with the removal of lead additives to the paint, lead in paint was a compound to absorb UV rays and allow the carrier to last longer, much like preservatives in food.... Of course no one knew about the absolute toxic effect of lead.....

-

Paint chalking is where the paint is under intense UV light, (sunlight) and the pigments start to fade out and the carrier starts breaking down...... What it looks like is faded and almost pastel look to the painted surface color...... The surface itself in real life starts to fall apart the whitish bleached out pigment separates from the carrier which results in a whitish chalky surface tinted by what remains of the pigment in the remaining carrier that hasn't completely broken down yet..... If you rub your hand over the surface the bleached out pigment will brush off and of course leave your hand surface covered in the white powder.... (almost like powdered gypsum or heavy grained talcum powder) The surface where you brushed your hand over it will darken color wise as you have revealed more unbleached pigment..... Over time, this will turn the surface completely white.... (and it will completely fall off the surface) Modern paints usually take a few years to reach this state, this will happen with ALL paints over time..... Nature of the beast, true epoxies generally don't do this..... Unfortunately, the US Navy found out that 5-D paint, (which was blacker than black) in a heavy marine environment, would arrive at this state in four months.... It would start showing whitish patches and the paint would fade to a dark grey necessitating the repainting of the ships often, the ships were required to requisition and carry enough paint to have the crew completely repaint the hull at least once..... 5-S Sea Blue I believe also had this problem..... I do not know how they solved it with 5-N Navy Blue, (same base paint and tinting medium) but it seemed to last a lot longer, some ships it lasted for over a year. It would fade but retained it's color for a lot longer..... But that's what chalking was....

-

Read enough design reports on the US Navy and spring fashions to know it was a serious consideration for the BuC&R and a calculation made with every ship design.... Weight has always been a serious consideration vs weapons vs structure. Like the Gleaves class I'm building a 1700 tonner, the paint alone limited the amount of splinter shielding and then the antiaircraft weaponry..... but of course they really wanted a 2500 tonner but were treaty limited.... Most of the time, when a yard had control of a ship, they would sandblast down to bare metal and do a full surface prep before a repaint.... Which would last them about 4 months, after that, the crew was responsible for keeping it looking nice and shipshape..... Prewar, Captains were known to have lost their commands for failing to keep up their ships appearance..... And all it took was a comment from a senior command officer to move the gears.... One of the reasons US navy ships always looked in good condition... (and ship captains hated 5-D paint, it faded out and chalked up so fast that they would have the crew forming almost standing paint details to keep up) Even throughout WWII they still managed to keep their ships in reasonable shape paintwise.... I have to agree, the paint in those pics greg posted has the look of a hastily applied job.... The paint is peeling in sheets, that's definitely a lack of proper surface prep.... Greg, build your ships as dirty as you like, they are your ships.... last I'll say about the matter....

-

If that's what they are today, go for it.... I prefer WWII ships anyway, they have a cleaner look..... It probably isn't the paint, but the quality of the application.... The undercoats don't look like they were scraped or sandblasted at all.... The Navy has really changed since the WWII days....

-

Well, the fun has begun.... This is not my childhood model.... Dressing out the bow with the little, AND I MEAN LITTLE, parts and pieces is taking longer than I thought it would.... Each one of those bits on the deck are less than an eighth inch long six of them in that little space...... Closed sheaves...... (no more than a 32nd inch high) I remember when they molded these parts on the hull edge and all you had to do is clean them...... I can certainly see why 1/200 scale is popular..... a lot has changed over the last few decades.... Onward....

-

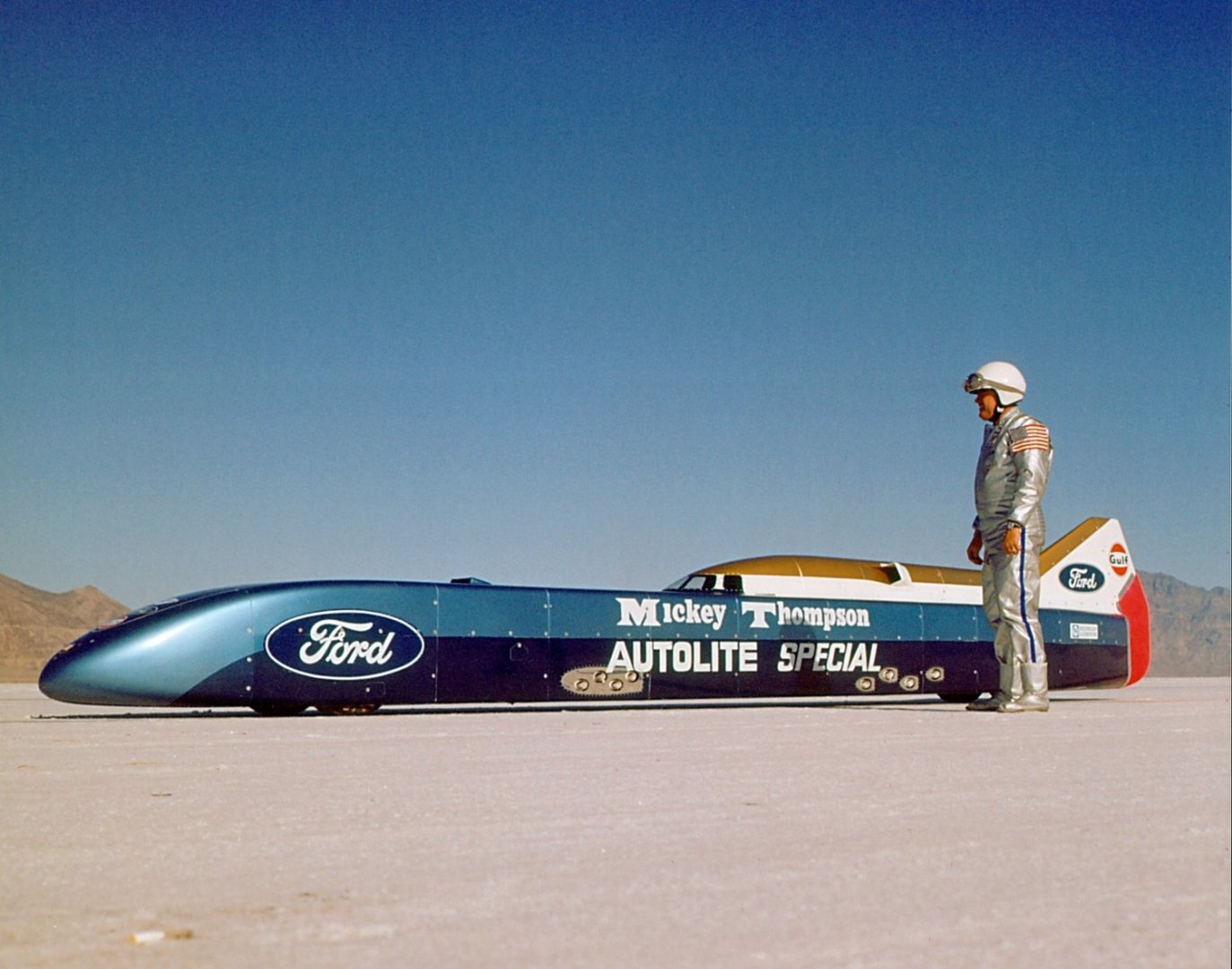

Micky Thompson, the legend..... Challenger I..... Thompsons second car..... Also known as the streamliner.... This car was retired when his chance to break the record was swamped when the salt flats were turned into a lake by a storm.... 50 years later Micky's son Danny took up the challenge and brought the car out of storage and rebuilt it..... It made a run of 450+ in 2018 and a return run which set the LSR for piston powered cars at 448.757 MPH which still stands today....

-

Hi Bruce, It was qualifying for the '67 Atlanta 500, he was the car owner/builder which was being driven by Curtis Turner... the #13 Chevelle..... As a driver he won 18 Stock Car/Grand National races A total of 57 wins, (mostly as a car builder/owner/crew chief) including and an indy race in '60, his driving career ended in '63..... Other little tidbits, he flew with the Flying Tigers in china, and piloted 52 mission over Germany in a B-17 during WWII..... He was a certified aeronautical engineer and held 9 patents for racing engine improvements...... He was a real down home country boy, but if you wanted to build a fast car, he was one of the few who actually knew what he was talking about....

-

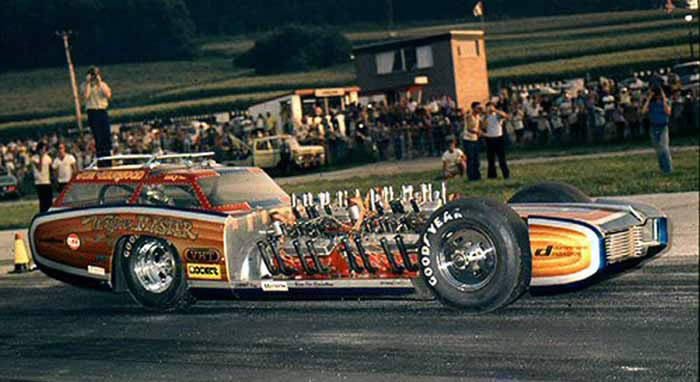

Yep, back in the day that is.. you could walk into any parts store and turn your 350 caprice station wagon engine into a 600 hp monster right over the counter..... (with a little creative machining, and knowing what you were looking for) I ran exclusively quadrajets on my chevy's, but then I knew what I was doing...... While the street racers were pumping holly double pumpers for their gassers, I was running a 1200 cfm quad...... For about two years Quadrajet built carbs for Ford who was fitting them for the 427 cobrajet..... It was worth 40 more HP when mounted to a throated and polished highrise 350.... Then there was the little application of a pair of waterpump pliers to a standard vacuum secondary quad to make it a mechanical constant opening secondary 4 bbl carb.... Nothing like twice as much gas into the intakes whenever you touch the pedal.... Back in my hotrodding days Smokey Yunnick was my hero....

-

Yep a 400 stroker, lose a little in the top end but almost double the torque.... (ie. never get beat off the line) Most races are won at the start..... That would surprise a lot of people.... Mine was a '73 C-10, Edlebrock tuned CJC 350 with 2.02 heads, hooker tuned headers, 4" collectors, packs, in an old grey primered forest service long bed stepside.. Was loud until the cops gave me a noise ticket... Then hung 3.5" turbo mufflers behind the packs, noiseless at normal throttle after that... 5.72 in the rear end, beat everyone to the 1/8th pole.... pull anything anywhere..... Put your foot in it sounded like SIR on race day.... That was a fun truck.... Everything was tucked up next to the frame rails so you couldn't see the 4" pipes ducking out from under the bed step..... The hot cars were the 350 ci monte's around here, with everyone thinking they were Big Daddy, or Don Pru.... they would throw an RV cam and dual exhaust in them with racing tires on cragars and think they had something special.... Took a lot of money off those boys till they learned.... Don't mess with the junky old chevy pickup...... Those were the days my friend....

-

Phew!!! Made it through that one..... The hull halves and decks are glued together... Doesn't appear that any twist developed.... Now I get a bit of cleanup and all those tiny fiddly bits that make up the deck furniture, bits, bollards, winches, turret rings and such.... They need to be installed so they are out of the way Onwards.....

-

Building a Medieval fortress - by Waitoa - Del Prado 1/87

Egilman replied to Waitoa's topic in Non-ship/categorised builds

Well I see the MSW Stone Masons Guild is taking off..... Gonna have to consider membership....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.0f8c4be69c27cd8d442c1cbe2ded94db.jpg)