JerryC

NRG Member-

Posts

71 -

Joined

-

Last visited

About JerryC

Profile Information

-

Gender

Male

-

Location

Millbrae CA

Contact Methods

-

Yahoo

ck_jrry@yahoo.com

Recent Profile Visitors

-

Canute reacted to a post in a topic:

1:22 Venetian Gondola - Amati

Canute reacted to a post in a topic:

1:22 Venetian Gondola - Amati

-

thibaultron reacted to a post in a topic:

1:22 Venetian Gondola - Amati

thibaultron reacted to a post in a topic:

1:22 Venetian Gondola - Amati

-

mtaylor reacted to a post in a topic:

1:22 Venetian Gondola - Amati

mtaylor reacted to a post in a topic:

1:22 Venetian Gondola - Amati

-

I have an Amati gondola in progress, it is an ongoing adventure. I also purchased a Gilberto Penzo gondola that I’m looking forward to. I think the Penzo gondola will be a lot easier to assemble.

-

JerryC reacted to a post in a topic:

Hello from Seattle - looking to buy a built ship

JerryC reacted to a post in a topic:

Hello from Seattle - looking to buy a built ship

-

JerryC reacted to a post in a topic:

Hello from Duluth, Minnesota - and request for direction.

JerryC reacted to a post in a topic:

Hello from Duluth, Minnesota - and request for direction.

-

JerryC reacted to a post in a topic:

New member with broken Ship in need of a professional restoration

JerryC reacted to a post in a topic:

New member with broken Ship in need of a professional restoration

-

Pitan reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

Pitan reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

CiscoH reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

CiscoH reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

CiscoH reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

CiscoH reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

Ryland Craze reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

Ryland Craze reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

skipper1947 reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

skipper1947 reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

JerryC reacted to a post in a topic:

A thoughtful verse

JerryC reacted to a post in a topic:

A thoughtful verse

-

Obormotov reacted to a post in a topic:

Spell Check

Obormotov reacted to a post in a topic:

Spell Check

-

Chuck Seiler reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

Chuck Seiler reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

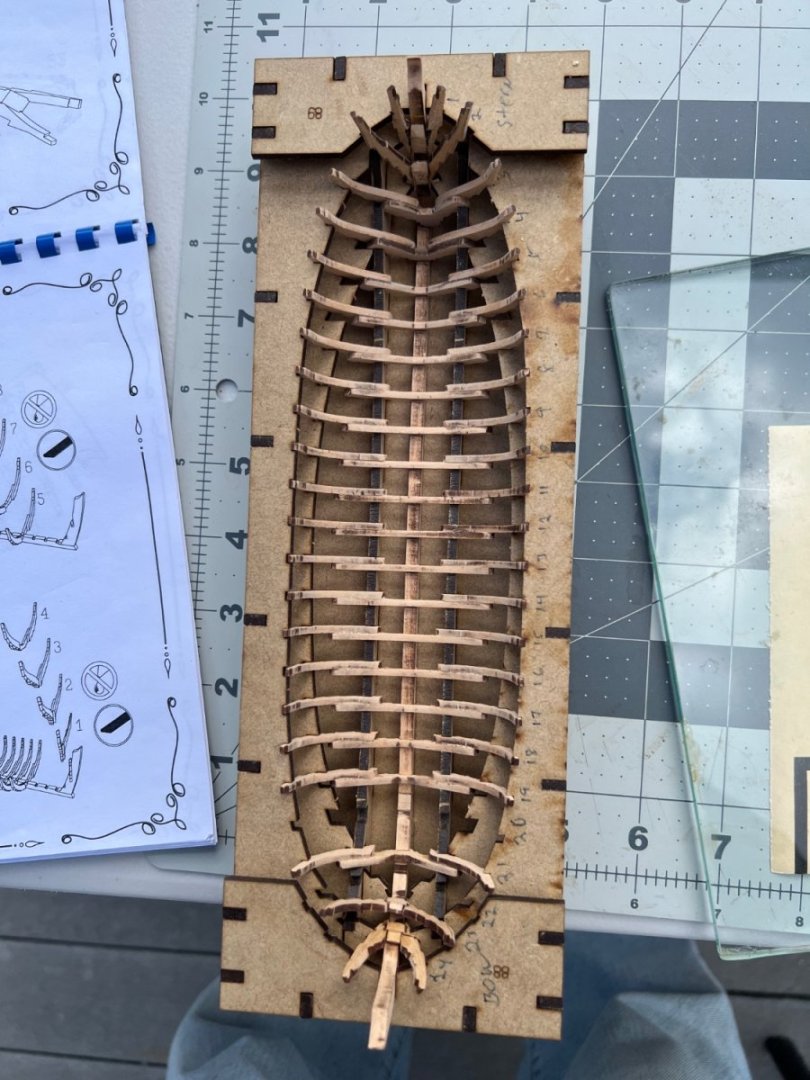

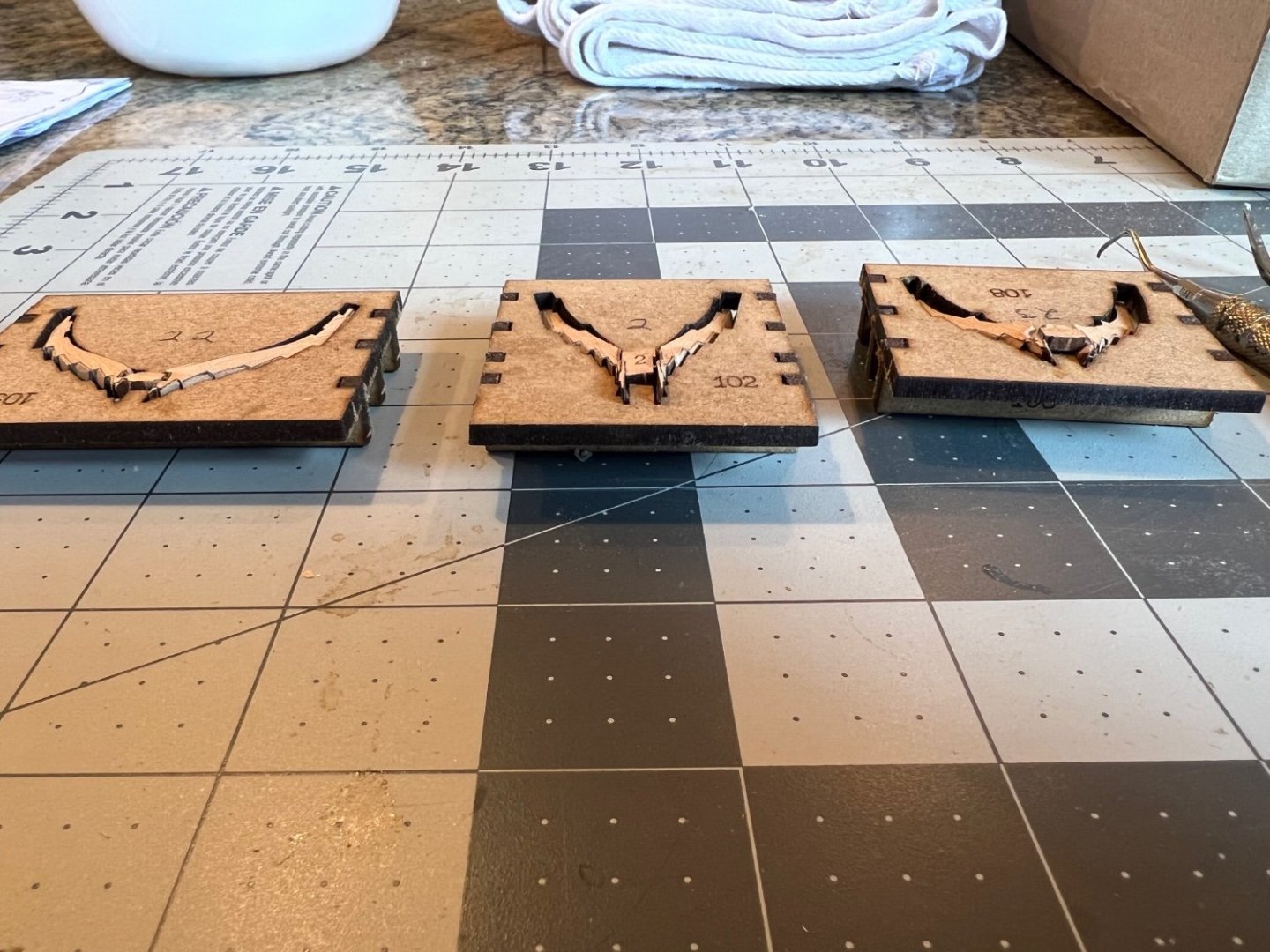

I’m still not moving forward. I’m in a bit of despair. I still cannot fit the bow and stern can’t frames to fit. I just joined jup with the South Bay Model Shipwrights. I’ll take the kit with me to the next meeting on the 13th. Hope to get back on track. I haven’t given up yet, but I’m disappointed with the way things,are going at the moment.

-

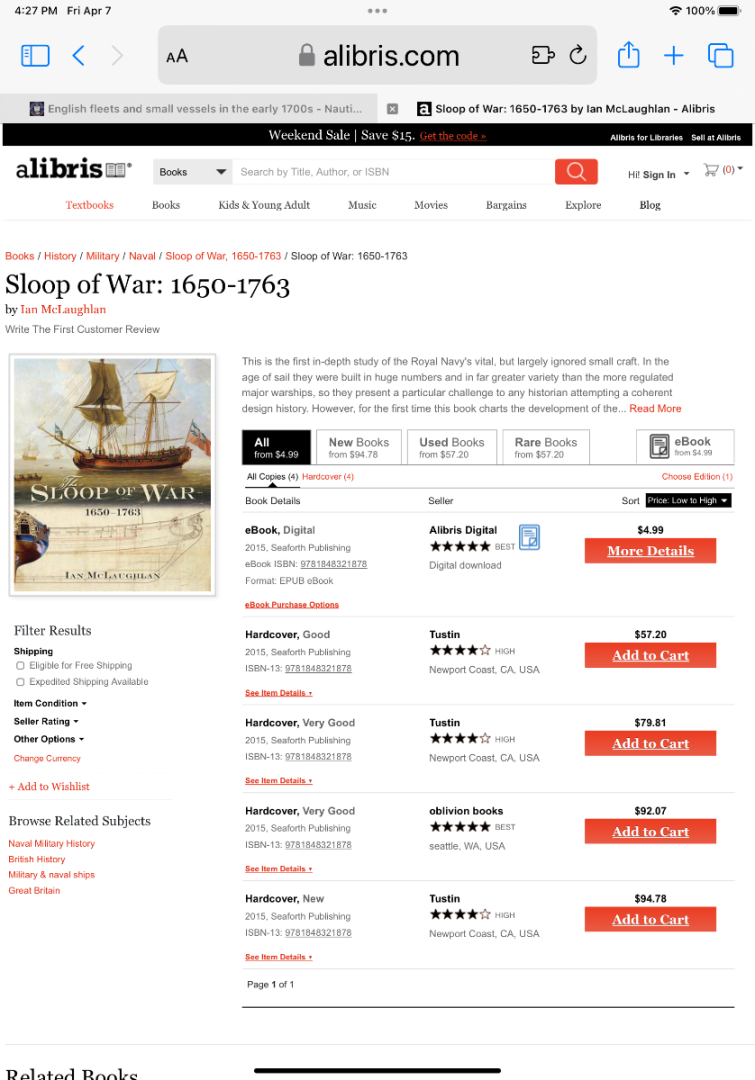

English fleets and small vessels in the early 1700s

JerryC replied to Dan DSilva's topic in Nautical/Naval History

-

I’m still wrestling with the cant frames. It’s slow going. It’s all put there together, take them apart, rinse and repeat. I’m learning as I go, which is a good thing since my order for the osberg ship is in the mail. The lessons I have learnt should make that assembly much easier. I also have been cleaning up a pair of Altec lancing voice of the theater speakers. Much more forgiving.

-

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

That sounds like different colors to me!

-

-

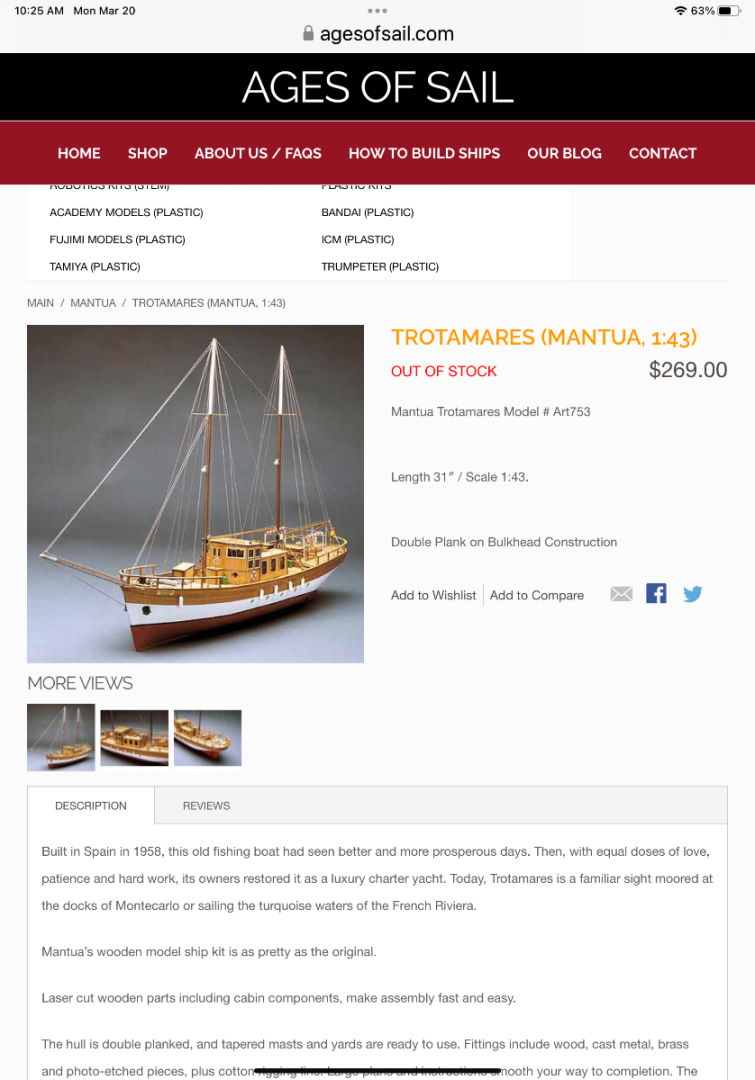

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

JerryC replied to James H's topic in REVIEWS: Model kits

I have one on order -

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

JerryC reacted to a post in a topic:

Captain John Smith’s Shallop by JerryC - Ships of Pavel Nikitin - 1:32

-

While waiting for frame parts, I’m assembling some other stuff. I’m getting the hang of it. There are a lot of subtle locating notches that require attentionI had disassemble this one twice i was aligning the pieces at the top and losing the notches.this one needed to be fixed three timesthis one still needs to be cleaned up and the hoops blackened and fastened. I think I’ll have to go and get some CA for that. I don’t think PVA is appropriate and epoxy would be too messy. I’m thinking of draining it walnut, only because I have a can of it sitting around.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.