-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rfolsom

-

Cutty Sark by Keith B

rfolsom replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

Very nice work! I'm looking forward to your coppering methods... -

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad; you've seem to really master the porthole/mooring hole scratch build... I took the easy way out with my "non-elliptical" mooring pipes. Now I am doing the "hmmm" thing again... Very well done, my Friend!! ~Bob- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Coppering is looking excellent. Good to see your new posts... Well done! ~Bob

- 121 replies

-

- cutty sark

- artesania latina

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Very nice, Nenad. I may follow your lead on this...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

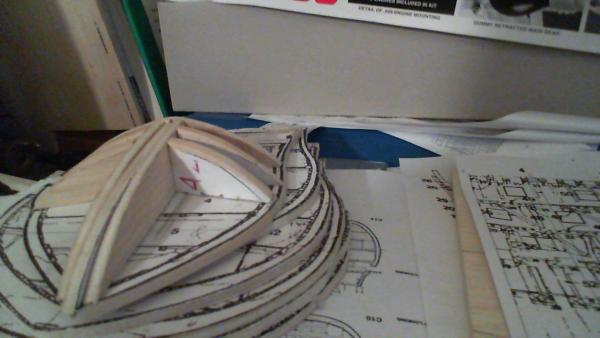

Your boats look great; Not cluttered at all... The kit's "bread and butter" method is very tedious, and inaccurate, if you are a stickler for scale. A POF approach, while very, very, time consuming is more rewarding, but I think you've captured the effect quite nicely. Don't sweat the small stuff... If you stick with the scale, these boats' hulls can be about as thin as an eggshell...

- 468 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

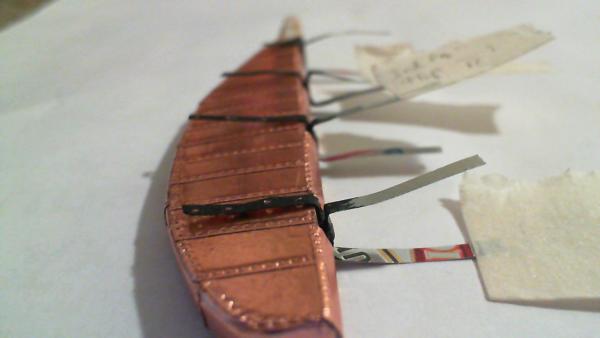

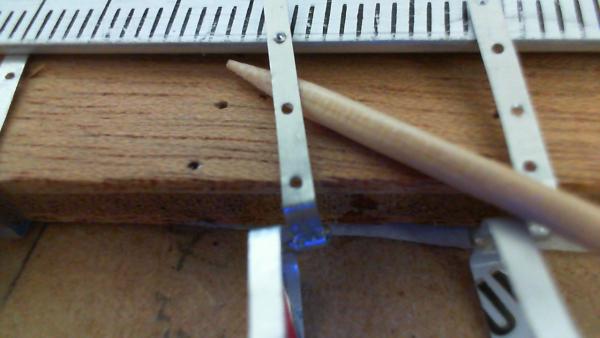

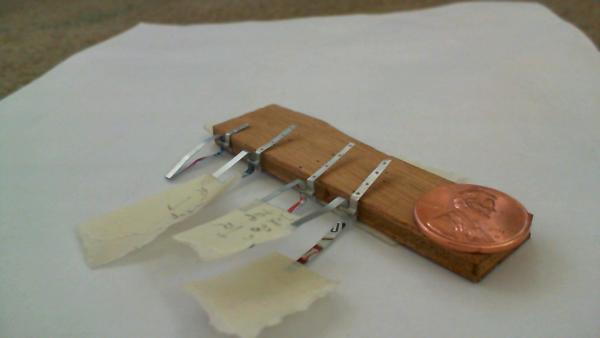

Ok. I started initial installment of hinges (semi-painted) to the rudder, using CA at the hinge points, but letting the ends free. Once dried, I will drill into the rudder through the pre-drilled gudgeon holes and affix the loose ends with small nails (hopfully NO CA). The sternpost gudgeons remain unfinished, as I decided to make the whole rudder/hinge assembly first, then fine tune how it meets with the ship. These will be evened up and trimmed to approx. 7mm, and drilled with 3 or 4 holes, for accepting the nails.

-

Thanks, Nenad; I'm doing paint testing... Marc, thanks for checking in, and it's great to hear from you again! Hope the new job is going well, and I hope to see some new posts in the near future... BTW, the Pig is well trained, and will be paying a visit to you in Virginia to inspect your progress... All the best, ~Bob

-

Cutty Sark by Keith B

rfolsom replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

Looking good, Keith; you'll be coppering in no time! -

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad; this is why I have not installed the whisker booms on the catheads yet. The cats as they stand, are pretty strong. I also will not install the boomkins until rigging is well under way... Bulwarks were bad enough to deal with when I was planking: ( 1. Plank a bit. 2. fix cracked bulwarks. 3. repeat...)- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

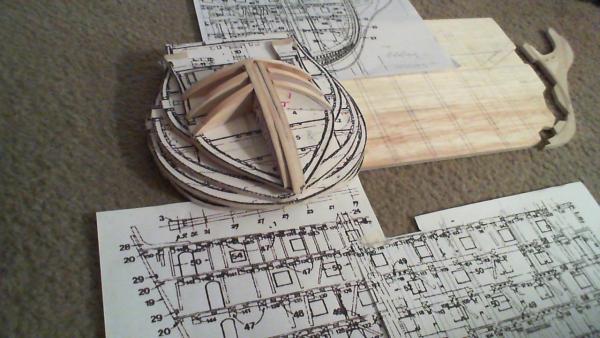

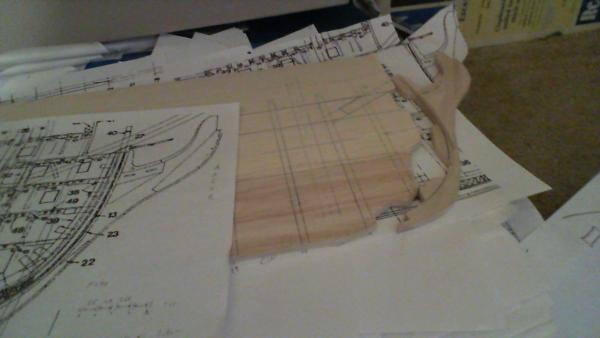

A little bit of work was done on the Vic. Rough cut a couple more bulkheads, and stared at the plans for awhile. Although I base this build loosely on Caldercraft, I've noticed many errors cropping up. The bulkheads are not lining up properly, so I'll be going completely to the AOTS. I've rough-cut many of the bulkheads, with AOTS templates affixed, but I'll have to re-draw the alignments on the keel; Caldercraft/Jotika is inaccurate.

-

Hello, Dale; thanks for looking in. I've been busy with the Cutty Sark, and there's so many Victory builds it's hard to keep track of... On the unfortunate side, I decided to completely scratch build the Victory's hull. I thought about tearing into your build, and taking the bulkheads, etc.(Decided not...). Anyhow, she's safely in my shipyard, as a model reference..

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Great way to organize your research, my friend. I initially cut some detail in "A, yellow" but filled it in. This is the area I'll be focusing on after the rudder.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by Keith B

rfolsom replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

Very nice work. And fiddly = detail! Looking forward to more light-speed progress.. Cheers, Bob -

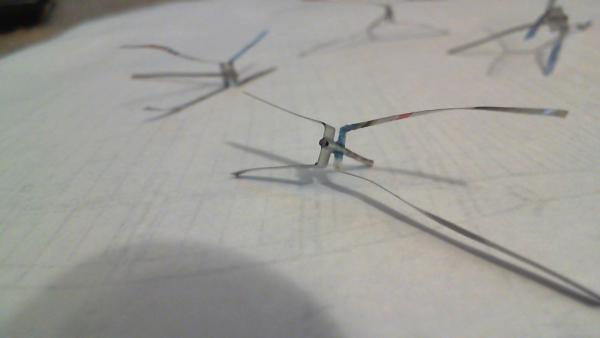

A little bit more work.. I have trimmed, drilled, and filed the rudder side of the hinges.. The ship-side gudgeons have yet to be finished. They are shown taped to the scrap piece of wood that I used for a drilling back. It also keeps them together and somewhat protected. I will simulate bolts with small lengths of 24 gauge wire. (0.51 mm). The holes are drilled with a 0.55 mm bit, which broke, so I'll be stalled until I pick up some more bits.

-

Keith; I was originally planning on epoxy for these, but since I didn't have any on hand, and these hinges do not actually support the rudder in my build, I tried CA and found it to be adequate. Lawrence, thanks for the kind words. I plan on using brass to fabricate all the yard and mast hardware, but that's a ways down the road, and my brass inventory is very limited. Also, my soldering equipment is not up to structural soldering; new toys must be purchased in the future...

-

Cutty Sark by Keith B

rfolsom replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

Looking good, Keith. I see hatch remakes for me in the future... -

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Very nice work, my friend! I really enjoyed the work on the detail for the rudder ring. Your ad hoc macro lens is very cool, too; It reminds me of the views from stereoscopic microscopes in college...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad is silent....... Perhaps just sitting back with a snifter of brandy or Scotch, looking at Her lines, and going ; Hmmmmmmmm......- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Thanks for the kind words, gentlemen. Nenad; I am in the process of determining the rivet/bolts for the gudgeons, but they will be present. I would like them to serve a structural purpose, (i.e. actually holding the gudgeons on) so I don't have to use any CA. Keith; The topgallant rail is here to stay, for better or worse, and I'm ok with how it looks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.