-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rfolsom

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

I'm very sorry to hear about your losses; please take care and know that my thoughts are with you, my friend. ~Bob- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Congrats to Princess; and belated congrats to everyone in your family for their education! You must be proud, and well deserved! ~Bob- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Always trying to plan ahead; the best I can do... I have no idea how to represent the scrollwork, other than photo etching. 15 years ago I worked for a circuit board manufacturer and everything I would need was at my fingertips; now, 800 miles away, I'll have to do it on my own. Photo etch is not my first choice, but I know the limits of my artistic skills, (nonexistent)... Anyway, much more paint, stain, and cut up aluminum cans to go before photo etch,..

-

Keith; I hope you're just kidding, Your build is looking wonderful! ~Bob

- 151 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

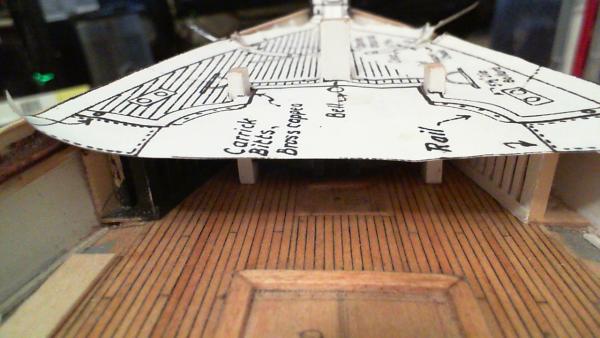

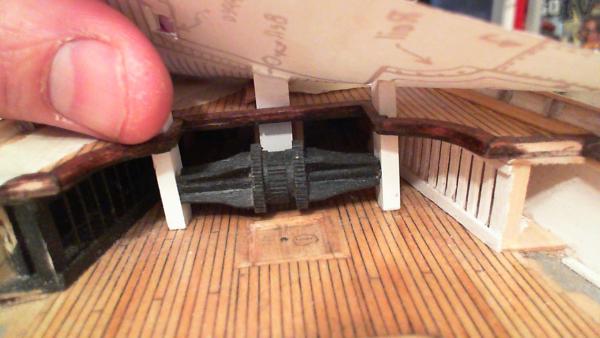

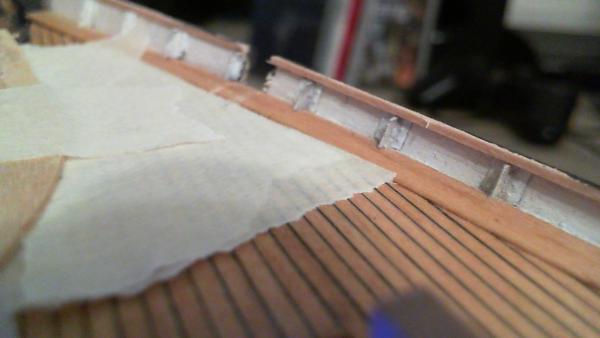

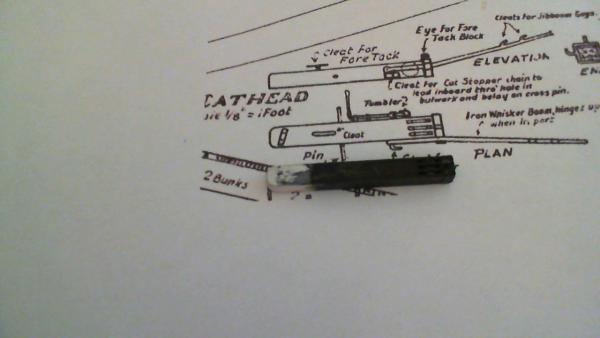

Progression with cathead fabrication cannot continue until I make the step to cut out the bulwarks where they fit on the ship. I affixed a template to the deck and used a razor saw to cut out the bulwarks. As I thought, the thin basswood broke on one side, but was an easy fix. These holes will have to be cleaned up before the catheads are installed. also, the masking tape and scrap wood shows where I protected the deck from my saw cuts. (Margin plank will be notched in this area.) Final photo shows my progress with the tumbler release handle for the cats... ~Bob

-

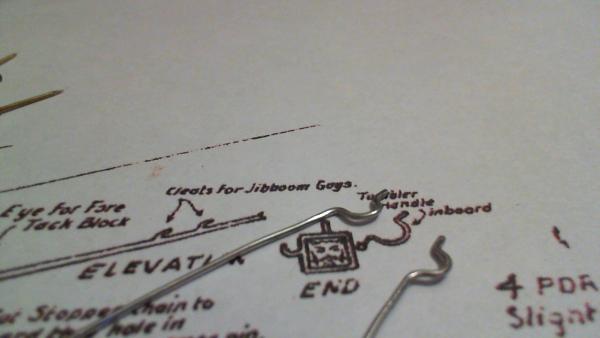

Thanks, Nenad; Campbell's plans are semi consistent with the actual ship... This goes for the cathead detail only... the 1/8":1' detail shows the cleats inboard of the pins; as in reality. His deck plans show the opposite; and indeed if you match the scale (from the same plan sheet!) nothing lines up. (Too much scotch for Mr. Campell that night, perhaps?..) Anyway, I'm done with diddling with this, so I'll be using the 1/8":1' plans; and adapting them as I see fit to the pictures of the actual ship.. Moving along...

-

Alright, CS Fleet; this is probably the #1 problem I can't get my head around... I'm working on the catheads, and I'm not getting any consistency between Campbell and the actual ship. Right now, I'm limiting my cathead attention inboards... There is a "pin" and a cleat that show up in radically different positions in regard with my two references (Campbell, and actual photos (courtesy of Lou). Also the taper of the cathead is not shown on the C. plans, but is evident with the pictures... This is the easy part... I still have to do the cat stopper tumbler and the whisker booms yet... SOS.. Which would be correct?

-

I wear a very convincing wig.. No railing pictures yet, but I made a small measuring stick based on Campell and went from panel to panel, sanding along the length of the bulwarks in order to get the proper height. Why I didn't do this before? I have no idea... (forest and tree scenario, most likely..) After this frustration, and while the new rails' stain is drying, I revisited my cathead prototype, decided it was o.k., and started another... These are the laminar pieces to replicate the sheave slots, that I have posted before..

-

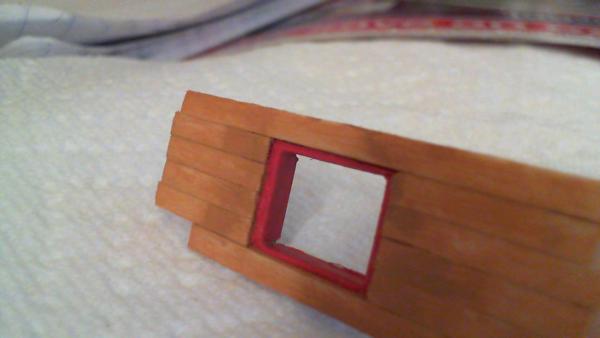

Final stages of the test port. Note no primer was used on the brass or wood, nor were many accurate paint coats, as this was only a test to see the contrasts and if the brass fittings would serve as an accurate liner substitute. (Hence all the dark splotches.) I'll keep this test assembly together to also test framing and inside bulwark planking when the time comes, then break it apart to retrive the brass frame...

-

Taking a break from fiddling with the bulkheads, I decided to dig into the 40+ year old fittings box. I'd pulled out these stamped brass gunport frames before; and thought to myself "what a shame I can't use them, they are the right dimensions." After revisiting, (Maybe this was the kits' intention all along) I thought about sandwiching them in between the bulwark strips and outside planking (bulwark strips don't exist yet; they'll be scratched from 1/32" sheet basswood, using Caldercraft scaled and modified to fit AOS). So a test had to be conducted... 106 of these stamped brass frames...

-

No fittings kit with my Billings' ; I bought all my (walnut) deadeyes.

- 151 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

Well, ... Internet provider was down for about a day and a half; at almost $80 per month I was very unhappy with that situation... So I took it out on the C. Sark.... I ripped off the t. gallant rails.. They came off very cleanly, actually.. now I can fix the scaling problem with the white panels. It's always a good idea, when you're away from a build for awhile, to stare at the plans for a good minute or two (or hour) to re acclimate yourself to the ship and plan your next move; or else you'll be tearing pieces (or your hair) out. ~Bob

-

What you do to one side, do to the other, in small increments, and remember each plank is a project unto itself... ( You can't torque the lower bolts of a Chevy head and then tighten the upper ones, right?.. warped head... Same principle with these models....

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

-

I'm not as experienced with this as many; but one thing I know, is "do one side, then turn it around, and do the other"; I do this with with deck planking, hull planking, coppering... It's a hell of an SOB to spend two months planking and coppering one side of the ship happily, and turn it around to find your work pulled the keel out of whack...

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.