-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

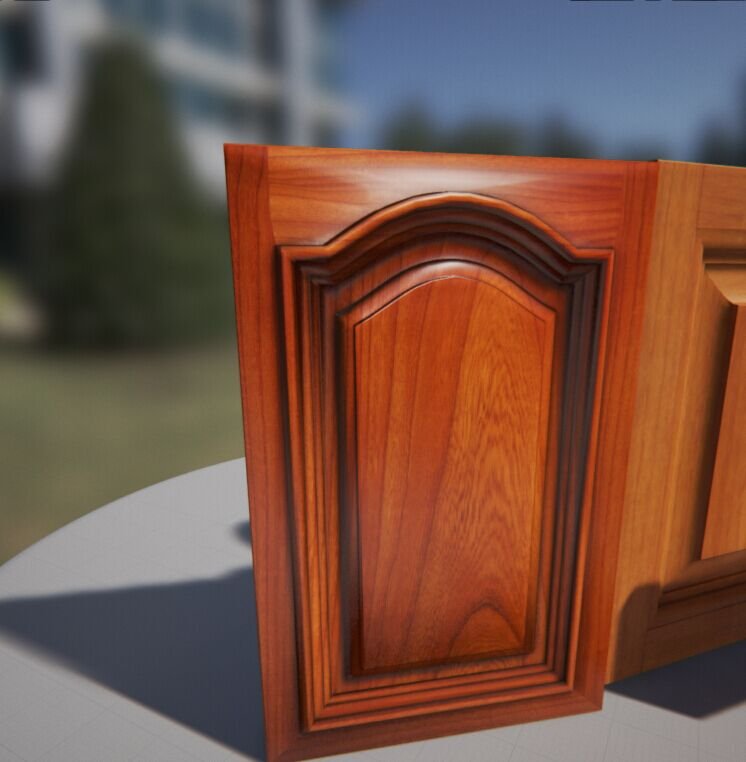

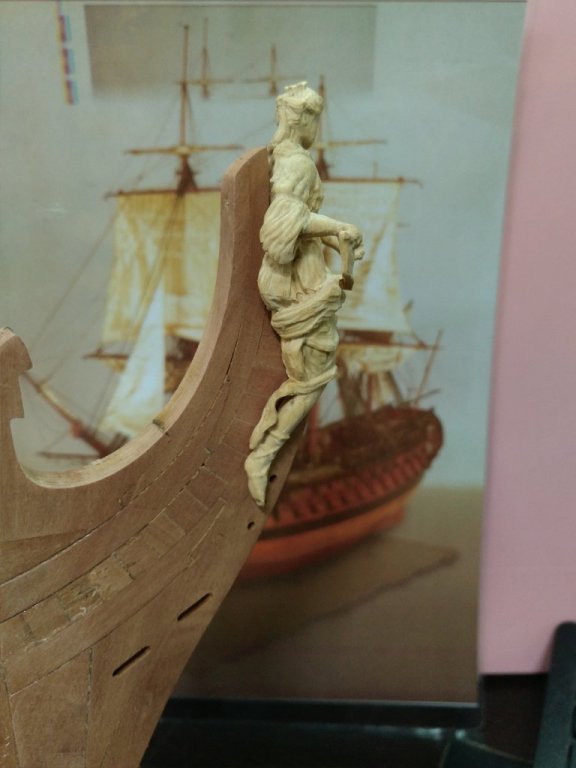

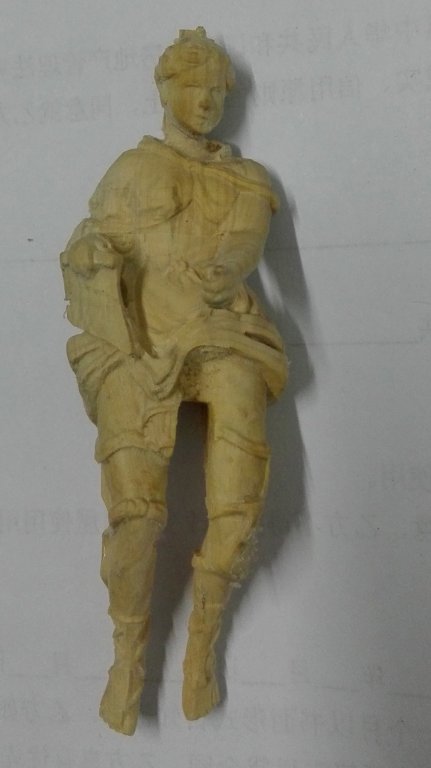

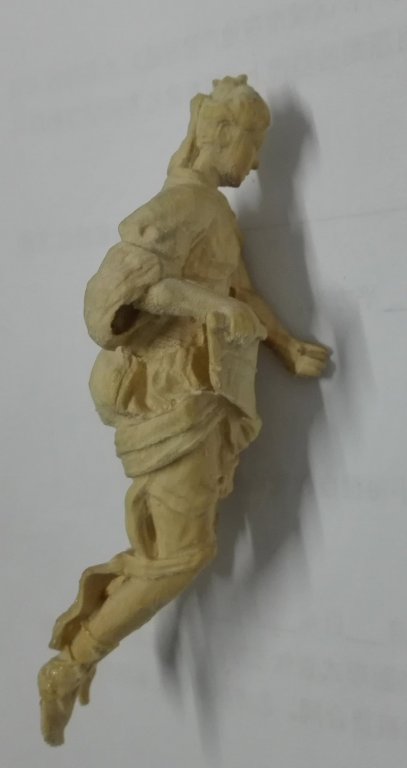

Thanks Hubac'sHistorian As a matter of fact, personally, I prefer to the ship model made by " pure hand", which is unique and more artistic. Maybe it's a more commercial approach to make ship model by cnc,It's like development kit-I try my best to reduce the manual and for a quicker process. That figurehead wasn't very successful because it's the first time made a human body by ZB, and first time make 3d sculpture by cnc.My current project will modeling figurehead in another way ,but by zb also.Why I make figurehead by CNC? Maybe you can not distinguish what it looks like-if i make it by hand. To do what you like is best,enjoy it and good luck! HJX

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Hi Hubac'sHist I took a cursory glance at your build log,I was immediately impressed by the magnificent 17th Century ships ,Exquisite relief, entirely of classical art.It is easy to match the perspective picture to your side view by photoshop-image morphing tool...I have just saw your build log,and i have 2 projects in-the-making...It's very easy for ZBrush to make this kind of relief--In the future,when I complete the two projects and would like to try this kind of "full sculpture" ship model - or just make the stern. Your project is very good, very historical and artistic,and you have great stamina, great work!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

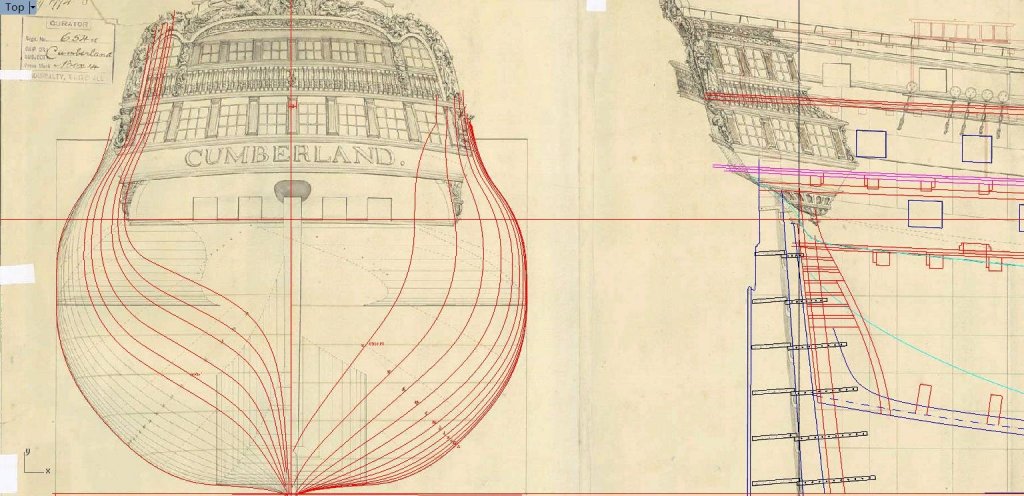

Yes druxey A project I'm going to finish and a project I'm about to start, and a project I want to do in the future, are all starting with NMM's original drawings. HMS CUMBERLAND 1774 I made the figurehead of L'ARTÉSIEN by ZBrush, which is the practice for HMS CUMBERLAND in the future.The first time I saw HMS CUMBERLAND was the background map of the forum, and I ’m very interested in it , but I have to prepare information and ship model knowledge. I personally think it's a little expensive- NMM Original drawings, about 60 pounds per one. I don't need so large size and I want to buy some more, It's better to have an electronic version(tiff or jpeg). The price is 20 pounds per one or more cheaper.

-

Another way is that you learn to use 3d/2d software. You can learn CAD + RHINO/ SOILDWORKS/UG,But I guess you have to study photoshop,I don't know how I can learn 3DMAX, CAD, rhino, silo, ZBrush, Vray, Mudbox, rhinocam, Photoshop, UE4,unity,DAZ...about more than a dozen,But these are self taught for 20 years,It seems unlikely that you will learn so much.I suggest you learn PS and CAD,Other 3D software models can be imported into CAD. As for the time you asked,It maybe takes more than half a year to make a 3D ship model.

-

If you make a 3D ship model with UE4, you'll operate it like a 3D game.You can even make virtual ship models in 3D virtual scenes. To build this 3D drawing, we first build the 3D model, and make the high polygon model and the low polygon model,Make UV,maps, normal maps...,Generally use 3DMAX and texture mapping software,then import model into UE4.Then programming, UE4 should be using C language and unity4, unity5 using C language .With the program, the scene is just as operational as the 3D game.

-

I also learned C++, because I like AI programming very much(Including CNC machining programming)the programme of figurehead processing, I have done it myself.UE4 is not so difficult(make shipmodel). I can do it at all - I'm not a professional programmer,but it takes a lot of energy.I estimate the demand for 3D drawings is minimal, so I have not see anyone doing it.

-

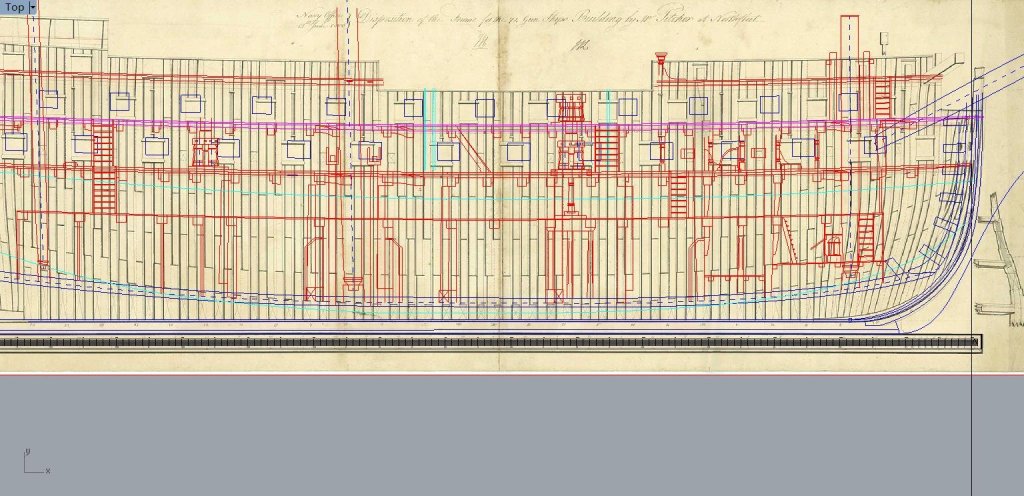

Hi Gaetan I have to use Google translator to communicate with you, so I will reply more slowly. I answer some of your questions all if I know. Your idea is feasible and can be implemented by games such as UE4 or UNIYT5.It seems that the two 3D game engines (or one of them) are free, but it's function is very powerful, looking at the result of them-it's the version 2 years ago. unity4 ,The result of unity5 will be stronger, the result of UE4 earlier version ,this is not the final rendered picture, this is a live picture! I once wanted to imitate Roger's collection and make a virtual ship model Museum,and made some 3D ship models.I have made some UE4 scenes, and tested the effect of wood material,shown as following: The ship model build in UE4 is close to the museum's effect,but I didn't go on with my idea, and I'd like to make a actual model-Because I want to learn the CNC milling machine operation, NC programming.

-

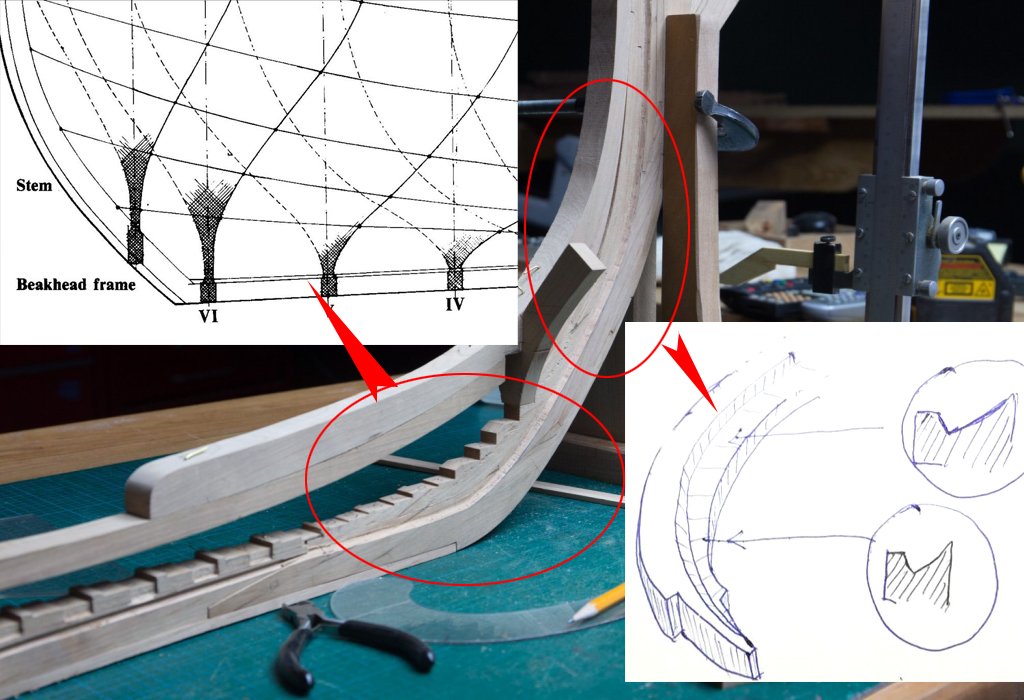

Thanks Gaetan Bordeleau I quite agree with you. As you said, developing a set of drawings is a huge project,so I never started the project yet. I have been thinking about how to reduce development time, improve the professional level of drawings, and quickly make model to validate the design.So I have been purchasing some specialized shipmodel books and drawings for the past two years,study other's build-log and look for opportunities to communicate with others-although my poor English restricts me.Then I thought of using numerical control(CN) to make shipmodel and improve efficiency and accuracy - though it was not" traditional" or "unorthodox",And I use french 64gun and flute zeehaen to do numerical control practice,CNC machining can be used to produce complex frames, keel, sculpture(figurehead) quickly , and the size is very accurate. Another way is to find partners, 2-3 peoples perform their duties,discuss the structure together, 1-2 person responsible for textual research and design, the other one responsible for making the model and verifying the design,it can reduce the development cycle. Ship model commercial development will also become very convenient,because my circle of friends including casting factory, wood processing plants, furniture factory, CNC machining,Desktop-CNC engraving machine factory, printing factory, foreign trade company...It's even easy to find some professional Carvers to make figurehead by hand.But the lack of copyright-copyright of ship model drawings.So, original development is necessary. Maybe business discussions here might be wrong.But even if only for hobby, to develop this set of drawings,I'm also looking forward to do it, because this is my hobby.

-

I bought this book last year. It's a good reference. Looking forward to make drawings of HMS PRINCESS ROYAL and shipmodel in the near future.But it require a lot of knowledge of ship model-Beyond my ability, so I am looking forward to developing this project together with somebody who have common desire and knowledge of ship model.

-

Current build

frame drawing and 3d model of HMS ANSON

L'ARTÉSIEN 1762 1:48 - 64 gun frame model by cnc -suspended for making drawing

-

Current build

frame drawing and 3d model of HMS ANSON

L'ARTÉSIEN 1762 1:48 - 64 gun frame model by cnc -suspended for making drawing

-

Hi Gaetan. I can understand your thoughts or needs. Make 3D models for a variety of uses, research structures/game/and drawings... At present, there are some free small software, you can import the 3D model, check to see the model from many angles, it's very useful to understanding the structure of the model.Better software such as UE4-a powerful 3D game development software that can even simulate real naval battles.It seems is free by developer(official).You can search it online and get authorization. But who will develop the 3D model?After all, this demand is very small, and team development is still not possible. As other members says,a good 3D model is no less than a real model.So, you can work with people who have 3D modeling capabilities. Now,I have give up making 3D virtual ship model instead of using 3D technology to make the actual one.Such as cnc

-

SOLEIL ROYAL 1669 by michel saunier

Jack H replied to michel saunier's topic in - Build logs for subjects built 1501 - 1750

Very spectacular and amazing -

Thanks Jeronimo,and thanks everybody. Maybe I will stop the buildlog for a while,I promised the request of a member to development of a private drawing of the frame and make its sculpture, including the figurehead. This is the last update of the production of the figurehead. After the figurehead is fixed, the support is finally removed. Remove the fixed softener... Finally, It's also need to be manually modified/polished and so on...

-

Thank you very much for your detailed introduction,I will do some improvement in your way.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

hi Mike Y I admire your ability to mill or polish the surface of wood,I'm amazing such a delicate model was made by hand.Do you have some suggestions for the selection and polishing of wood to me?thanks. hjx

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.61fdfb079121df2ed1e484ab69099f8f.jpg)

.thumb.jpg.7beccceff16c27320dd6806e97010c5e.jpg)

.thumb.jpg.efef85578d77ed7ad204bfb18c7d4810.jpg)

.thumb.jpg.b59a19cc56db782f47fce9943b63c90c.jpg)

.thumb.jpg.27e6c70fe53a2704651ba47d735e69b8.jpg)

.thumb.jpg.0a766ab1bf3289462aa57e4907996e4f.jpg)