-

Posts

3,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Dan Vadas

-

-

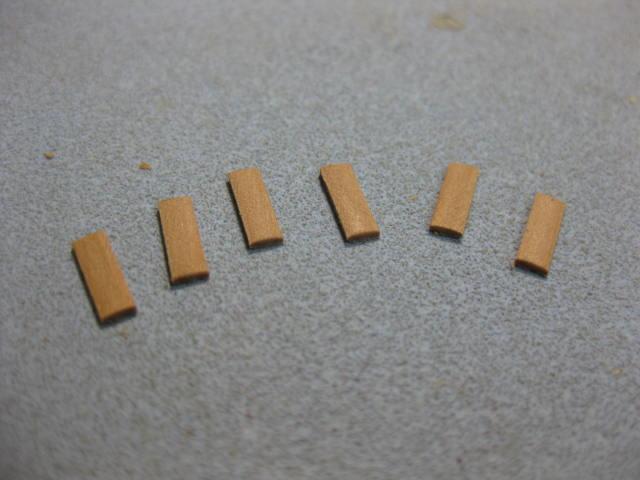

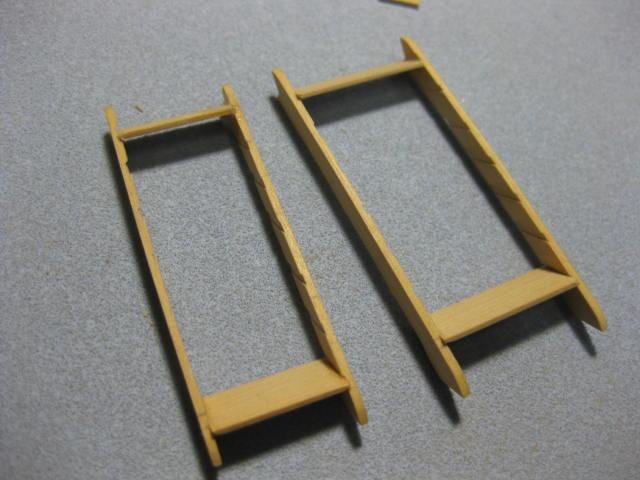

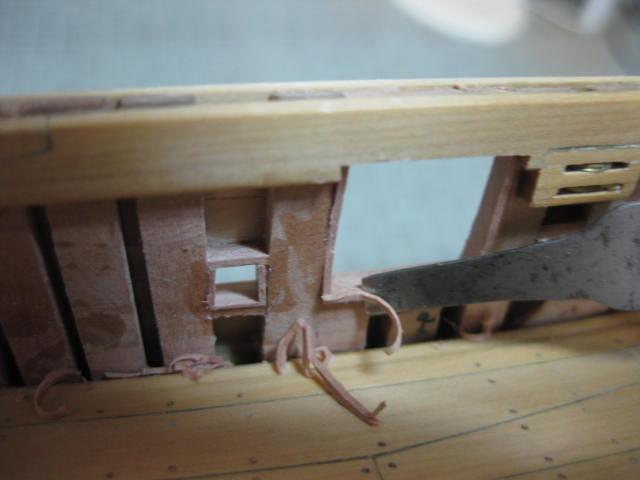

Bucklers

The Bucklers are covers for the Hawse Holes to minimise the entry of water. There are two types - "blind bucklers" which were used when no anchor cable was in use, and "riding bucklers" which fit fairly tightly around the anchor cable.

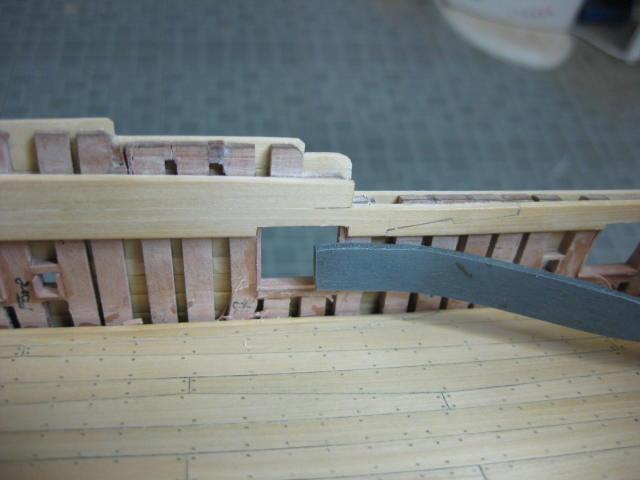

They are supported by removable Cants each side, which are morticed into the Bolster below and the Upper Deck Breasthook above :

-

- Mirabell61 and Jorge Diaz O

-

2

2

-

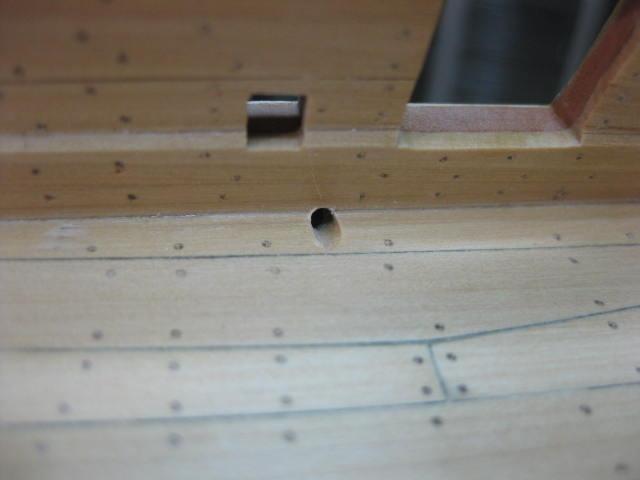

Hawse Holes Finishing

The Hawse holes were now filed out to their finished dimensions. Both sides needed to be filed out to accommodate the Hawse Linings :

They are lined with Oak (dark pear on the model) in Barrel Stave fashion - this protects the surrounding framing from damage and is relatively easy to replace when they wear. I'm showing this feature on the port side, and "lining" the starboard side with poly tubing to simulate copper sheathing :

The appropriate size drill bit came in useful to check that the angles were correct :

-

-

-

-

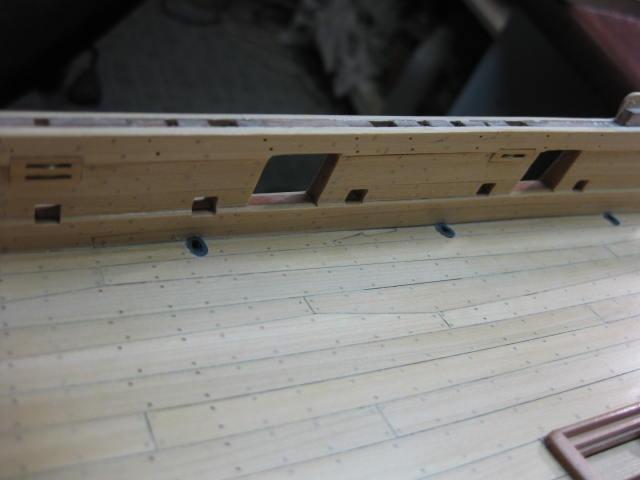

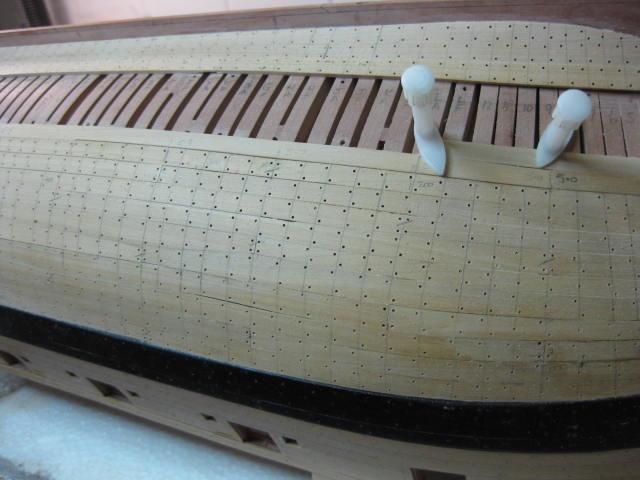

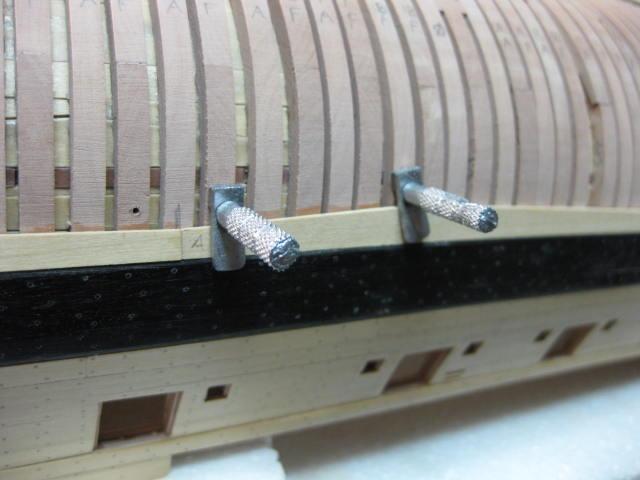

Scuppers

The Scuppers drain the upper deck. They are cut into the Waterway and angle down outwards to exit through the Black Strake :

To simulate the Lead scupper Linings I used "Evergreen" polystyrene tubing - 2mm for most, and 2.5mm for the Hawse and Pump Dale scuppers. I heated the end of the tubing gently over a gas flame and then pushed it onto a cold piece of brass sheet to make the flange. These were done in two pieces meeting in the middle :

After fitting all the scupper linings I painted them Lead Grey :

- Jorge Diaz O, john2013 and Mirabell61

-

3

3

-

-

- kiwiron, Jorge Diaz O and Wishmaster

-

3

3

-

-

-

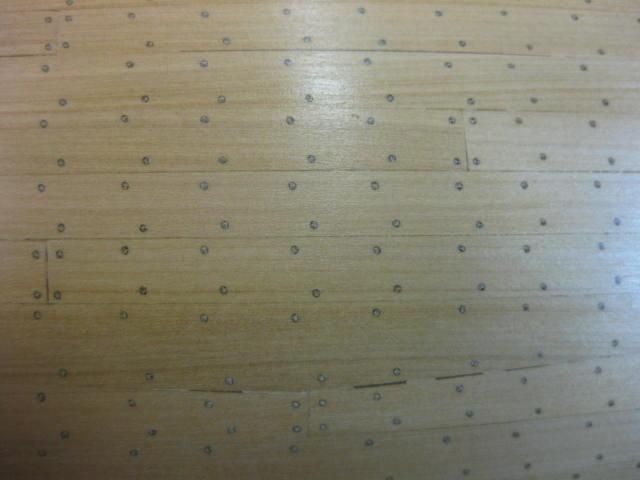

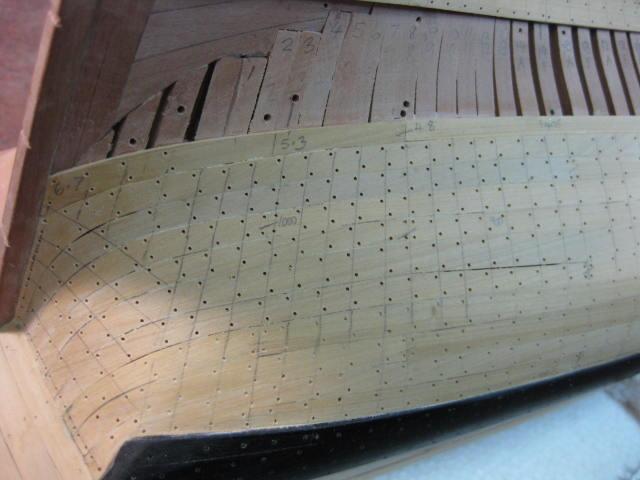

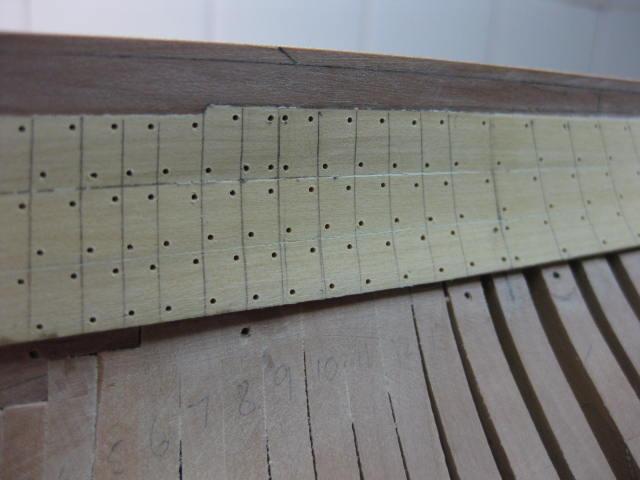

Top and Butt Planking

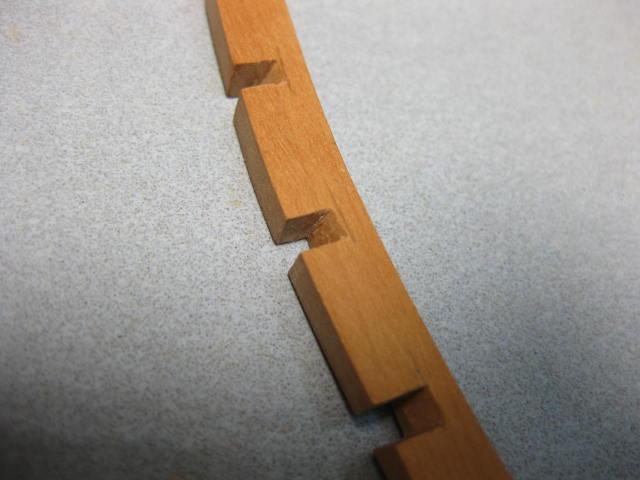

The first six strakes of planking beneath the Wales are worked in Top and Butt fashion :

The aftmost plank beneath the Wales has a very sharp bend and is also wider than most other planks to fit around the end of the lower wale. The card template alongside it was used to get it’s shape :

-

-

Garboard Strake

The Garboard Strake is the first to be fitted when planking the lower part of the hull :

The forward end of the Garboard Strake ends just after the point where the keel starts to rise. It’s upper edge is virtually straight, with the edge that sits in the keel rabbet tapered to follow the rabbet :

-

-

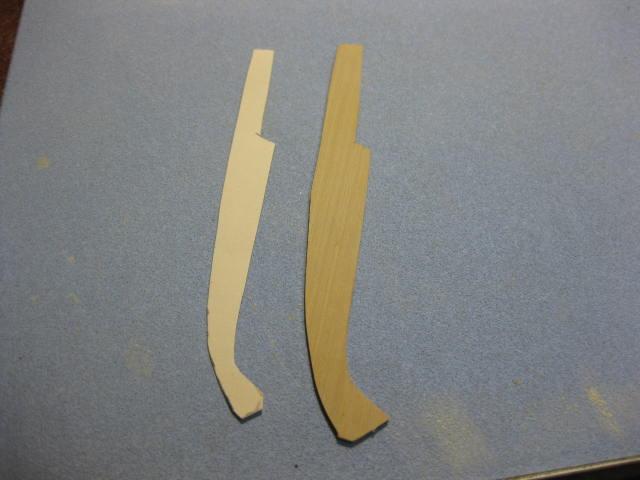

Helm Port

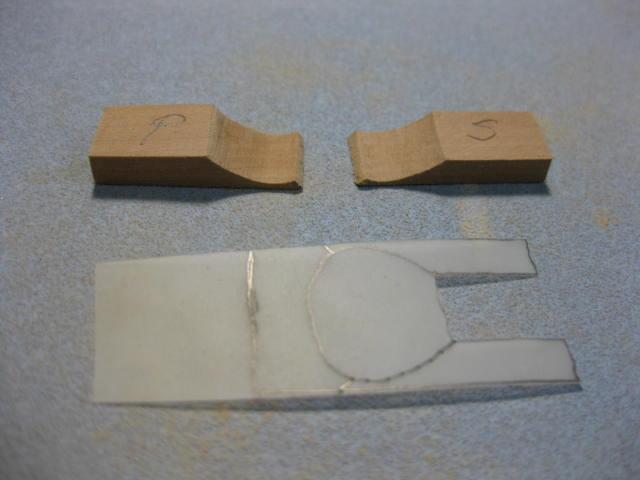

To work on the Helm Port the ship was removed from it’s work base and inverted on a board covered with expanded foam for protection :

The two inboard pieces of the Helm Port were cut roughly to shape using a Mylar template, spot-glued into the framing and marked out for their final shape against the frames :

They were removed again and sanded to the marks :

The outboard piece of the helm port was made in similar fashion, glued into place and final sanded :

-

-

-

Spirketting, Quickwork and Inside Sweep Ports Trimming

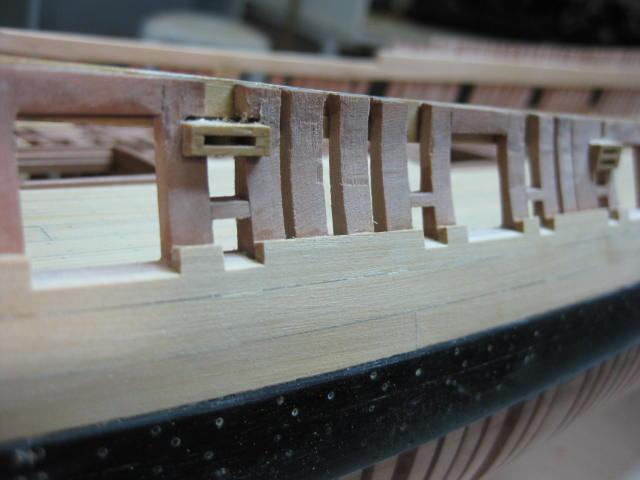

Note the steps between the Spirketting above the Waterway and the Quickwork above it, and also the one above the quickwork where it meets the String in the Waist. There is a chamfer on both steps :

The Fixed Block is flush with the String but stands proud of the Quickwork :

Trimming the top of a Sweep Port with the long sanding stick :

-

Port Stops and Sweep Ports

The upper planking at midships. A scarph joint in the Sheer Strake can be seen, also the Fixed Block below the sheer strake :

1 ½” thick Port Stops are fitted to both sides and the bottom of the Gun Ports :

The Sweep Port Stops are 1” thick :

The inside edges of the Stops are first trimmed with a chisel-point Xacto :

and finished off with a Riffler File :

-

Topside Planking

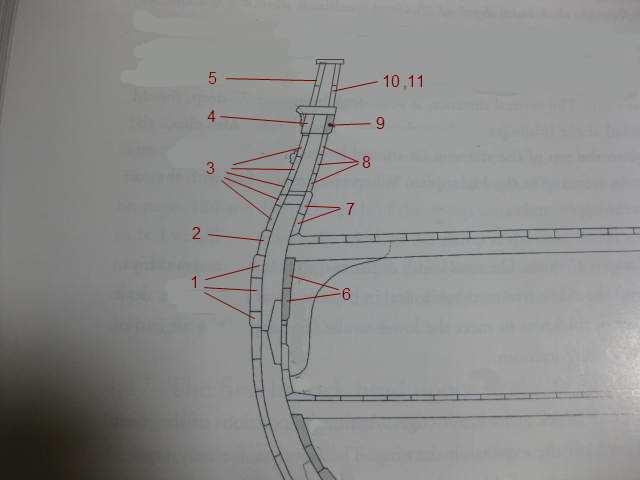

Below is a description of the External Planking from the Wales up, and the Internal Planking from the Upper Deck Clamp with the thickness of each :

External

1. Wales 4 ½”

2. Black Strake 3 ½”

3. Stuff of the Topside 3 ½” thinning to 2” at the top

4. Sheer Strake 3”

5. Plank upon the Drifts 2”

Internal

6. Upper Deck Clamp 4” thinning to 3” at the bottom of the Lower Clamp

7. Upper Deck Spirketting 3”

8. Quickwork 2”

9. String in the Waist 3”

10, 11. Quarterdeck Bulwark Planking 2 ½”

Where a strake would be less than 5” wide at a Port the lower strake is “worked” up to the lower sill of the port :

Trimming of the Gun and Sweep ports begins with a razor saw cut in each side of the port :

The bulk of the waste is removed by carving it out from the centre with an Xacto knife :

A long sanding stick is used to level the planking at the bottom of the port sill. This stick reaches across to the starboard port to ensure the correct level :

The Sheer Strake is “worked” above the Ports in similar fashion to the lower strake :

-

-

Ebony Wales and "Dummy" Treenails

This is my first attempt at using Ebony - a VERY dirty and difficult timber to work with.

The Wales are the thick planks just above the waterline - they are 4 1/2" thick. Bending Ebony of the required thickness without cracking it took a LOT of soaking - up to 4 hours per plank near the bow - and even longer to let them dry on the hull after clamping before actually gluing them on :

Treenails were simulated in the ebony with a piece of sharpened 0.5mm ID brass tubing held in a Pinvice. Blackened brass "bolts" were later fitted at the butt joins :

-

Quarterdeck Clamp and Transom

The Quarterdeck Clamp sits atop the Lower clamp - the extension of the String in the Waist. Note the extension piece above the Quarter Light :

These pics are out of sequence from the Counter Timbers post. This is the Quarterdeck Transom - the quarterdeck has a significant roundup of 6" at it's widest point and the transom follows this roundup although it's obviously not as high over it's length :

HMS Vulture 1776 by Dan Vadas - FINISHED - 1:48 scale - 16-gun Swan-class sloop from TFFM plans

in - Build logs for subjects built 1751 - 1800

Posted

Upper Deck Breasthook

Fairly self-explanatory .......