Paul Le Wol

NRG Member-

Posts

1,009 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

Jacques, those frames are looking mighty fine!

- 133 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

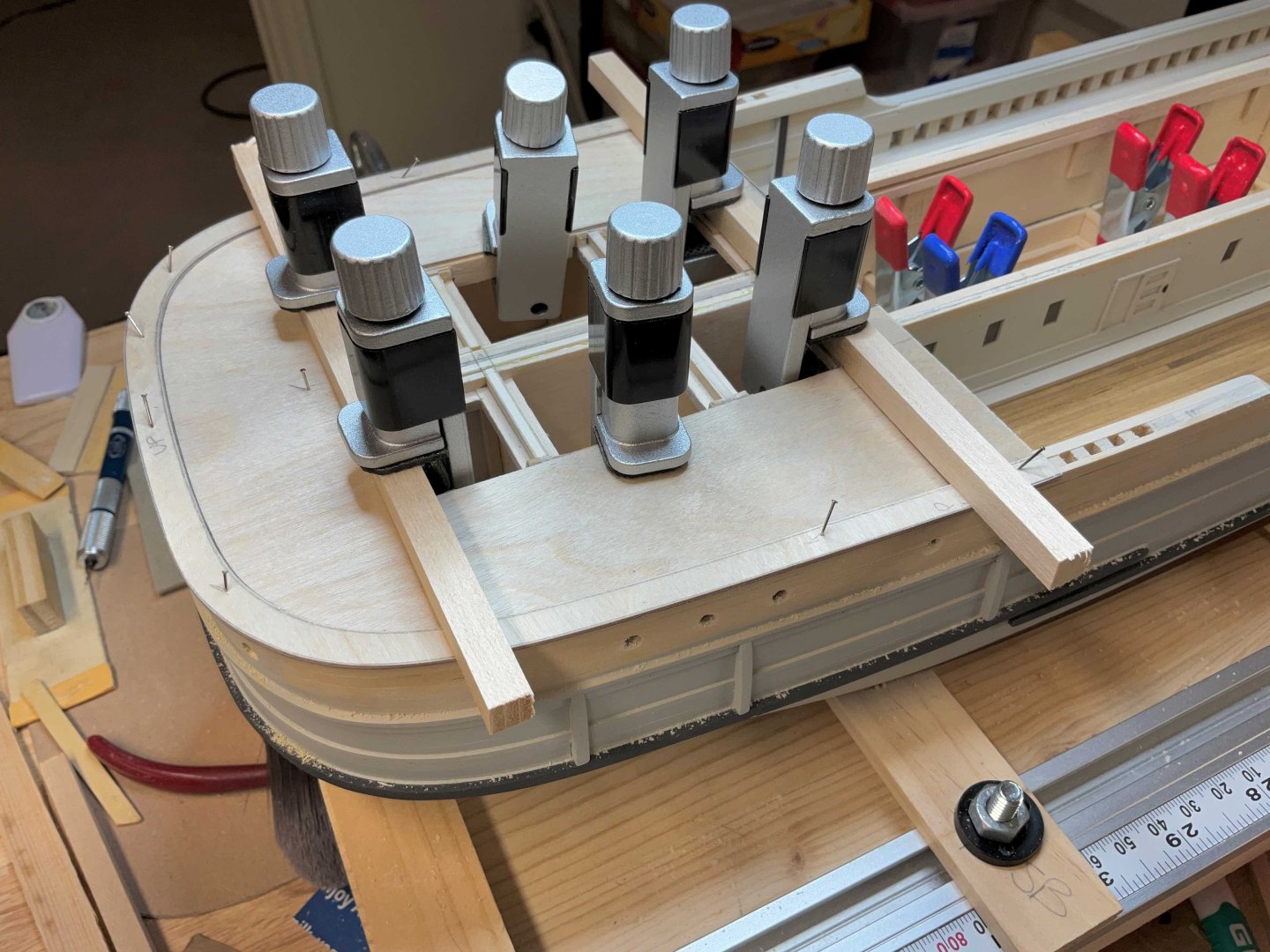

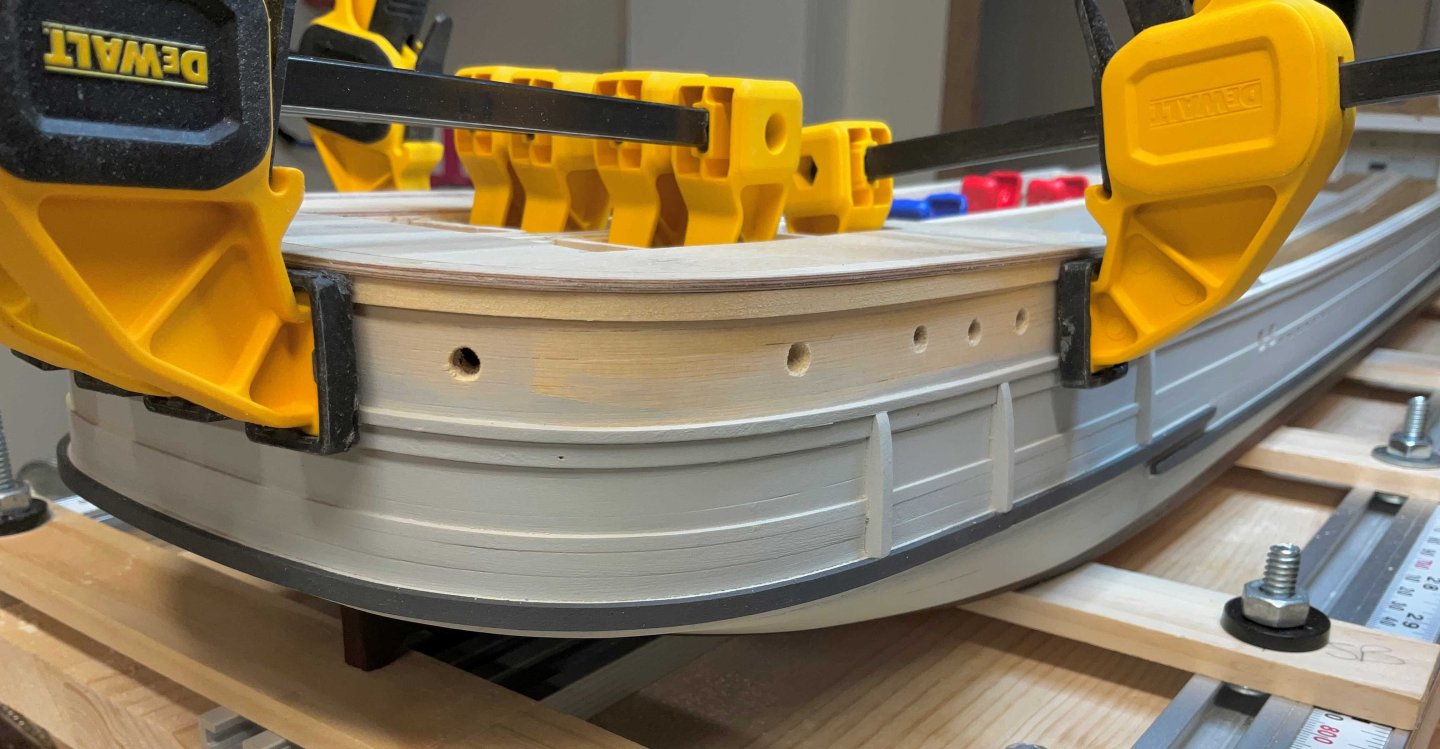

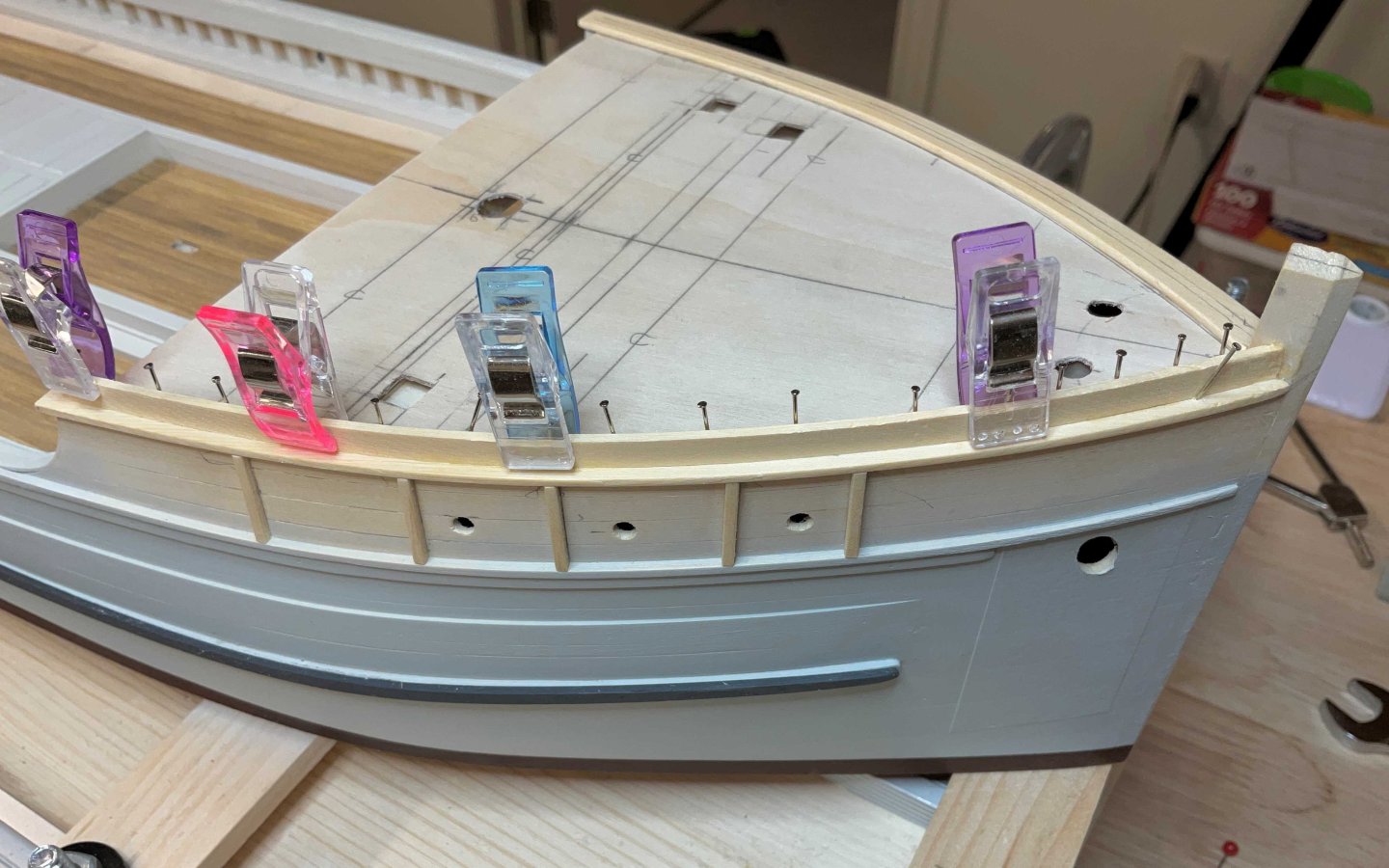

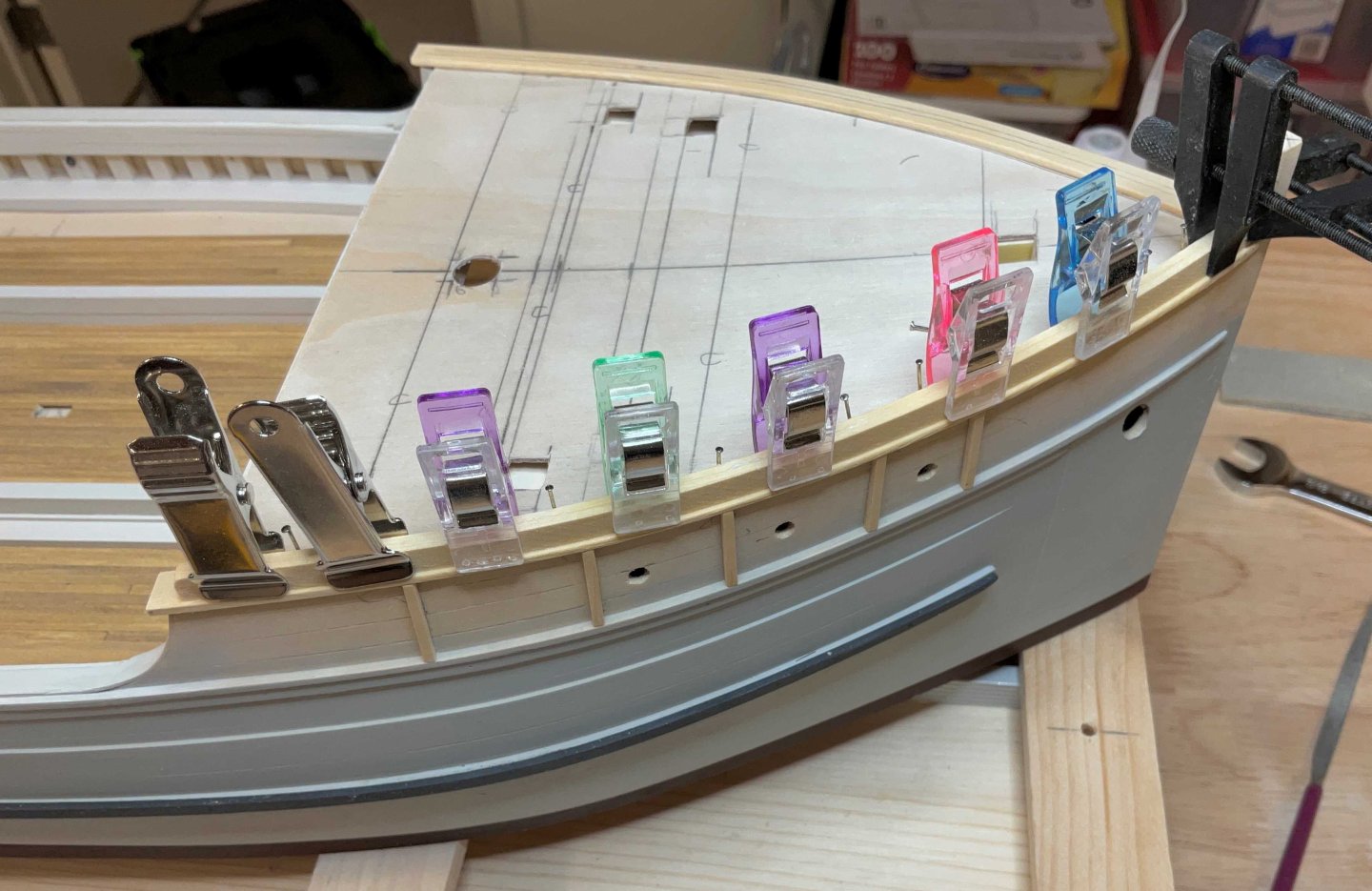

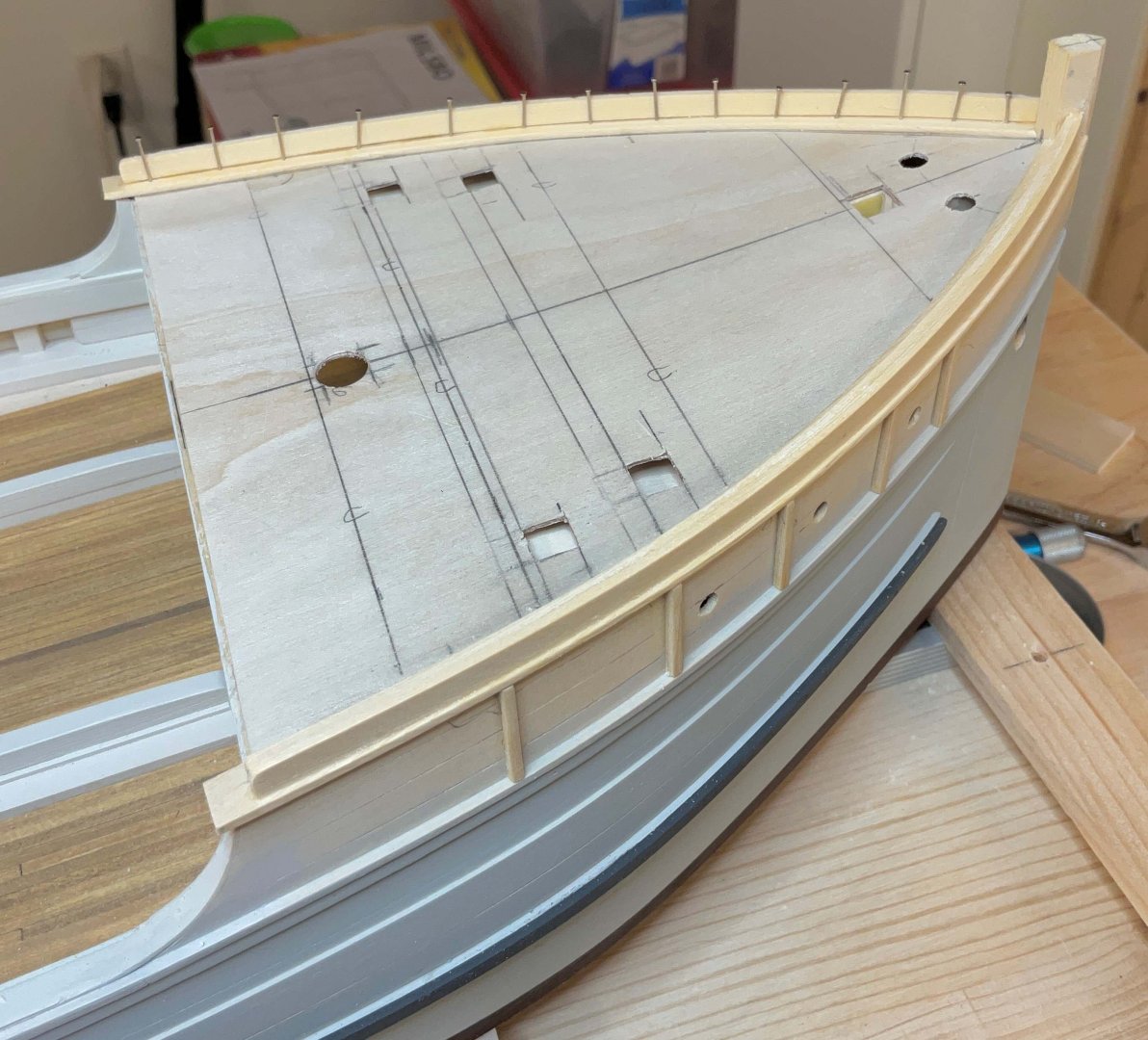

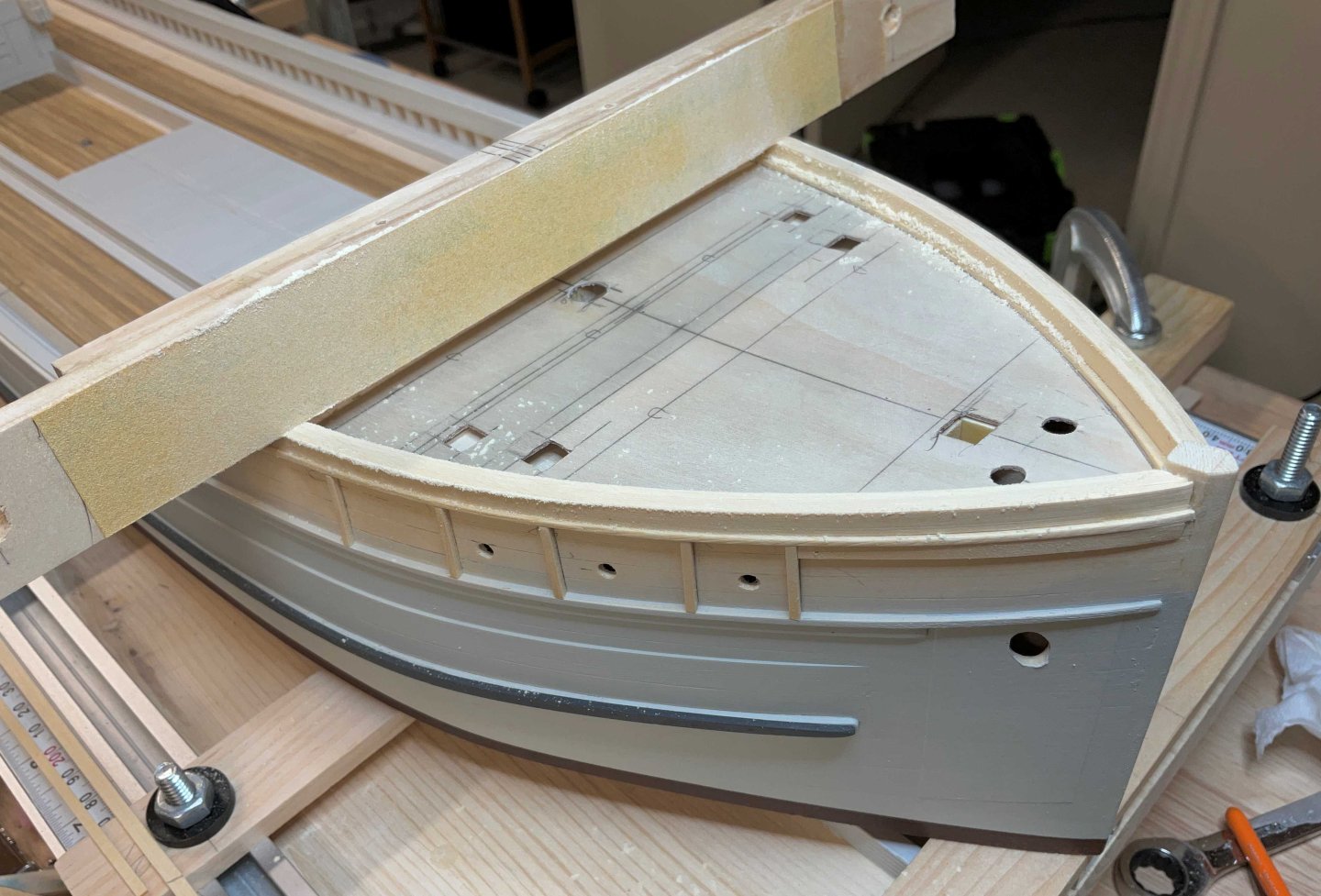

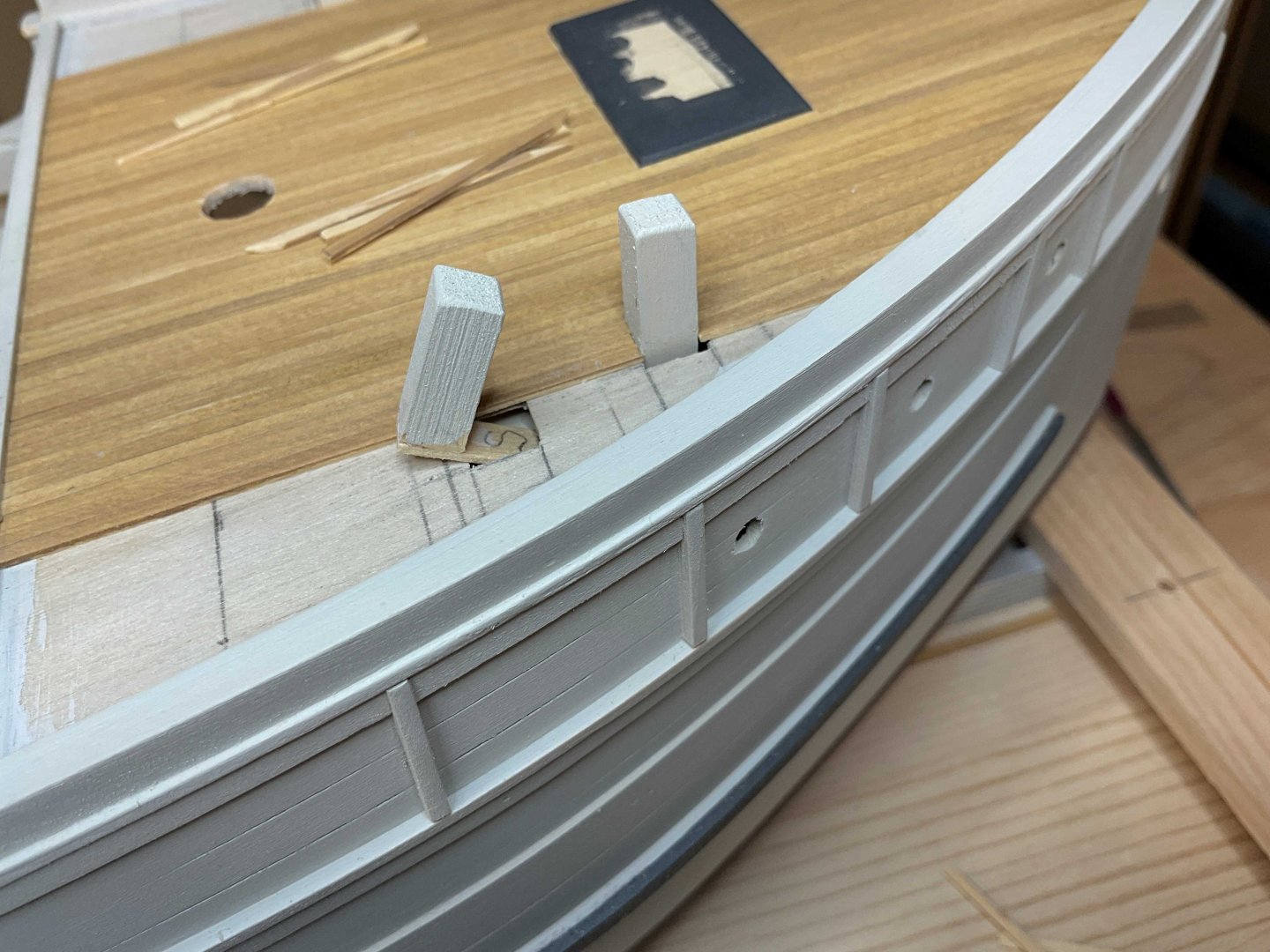

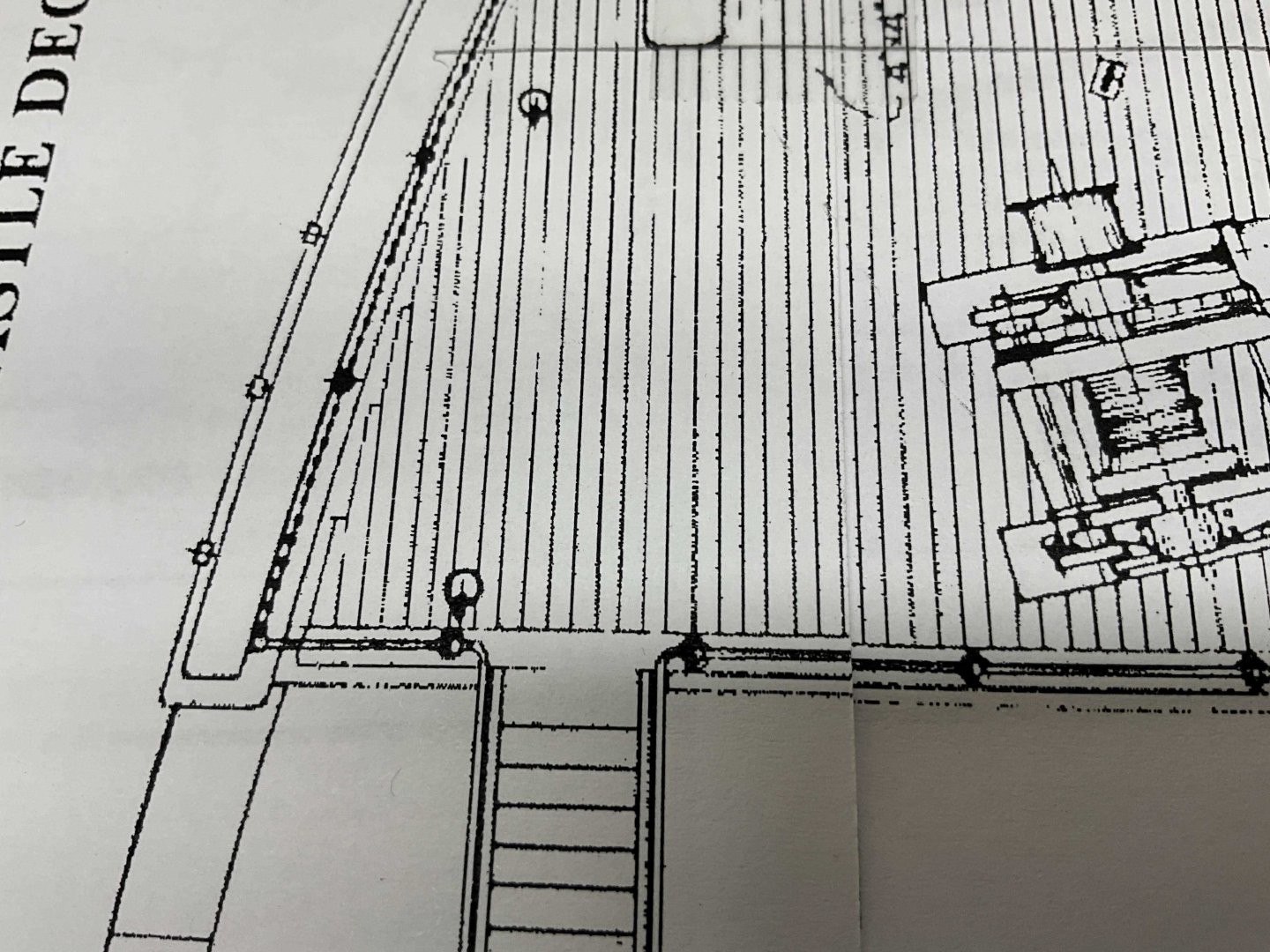

Hey Everyone, I hope all is good. Thanks to Everyone for the Comments and Likes. This update looks like more of the same only at the stern. I finished planking the forecastle deck. I managed to squeeze in 2 nibbed planks. The drawing shows 3 but because I'm using 5/64" wide strips instead of 1/16" wide strips everything gets thrown off a bit. The rough cut subdeck for the cabin deck was pinned to the hull and sanded back to within 1/16" of the bulwark planks using the small sanding block. The subdeck was then cut to accept the cabins and then glued in place. For the waterways a piece of 1/32" plywood was laid on top of the subdeck and the outboard edge of the subdeck was traced on to it. The outboard edge of the waterway was cut almost to the line and pinned on top of the subdeck. Then the inboard edge of the waterway was scribed on to the plywood using a compass stuck in a small block of wood that slid on the face of the bulwark planks. The inboard edge was cut and sanded back to the line and the waterway was pinned to the subdeck. Once everything looked okay the waterway was glued to the subdeck and the outboard edge was sanded back to the subdeck using the same sanding block The 1/32" x !/8" strip of wood that runs under the waterway was glued in place The coaming is made of two layers of 1/16" x 1/8" strips of AYC that were pre bent on the same mold as the rest of the stern planking. A line was scribed on the waterway to mark the inboard edge of the first plank and pins were inserted along this line. This plank was attached to the waterway with CA The outer plank was glued to the inner plank using white PVA After a bit of sanding the bulwark planks were painted Thanks for stopping by. The cabins are up next.

-

I have both of these tools and enjoy using them very much. On first use of the slicer it took me about 20 seconds to draw blood. Not the tools fault but my carelessness. I now keep a pair of tweezers handy to retrieve the cut pieces

-

Keith, that is a fine bit of micro-fitting!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Hi Steve, thank you for posting the photo of your beautiful Willapa. I hope to see more. I had noticed the metal attached to the corners in Phil’s photos but for some reason I thought that they were added when she became a museum ship. I appreciate the information about the hardwood corners. There may be a few things that I let slide but overall I will try to be accurate. ( something I am not known for 😀) . Thank you so much for your Comment, I appreciate it very much!

-

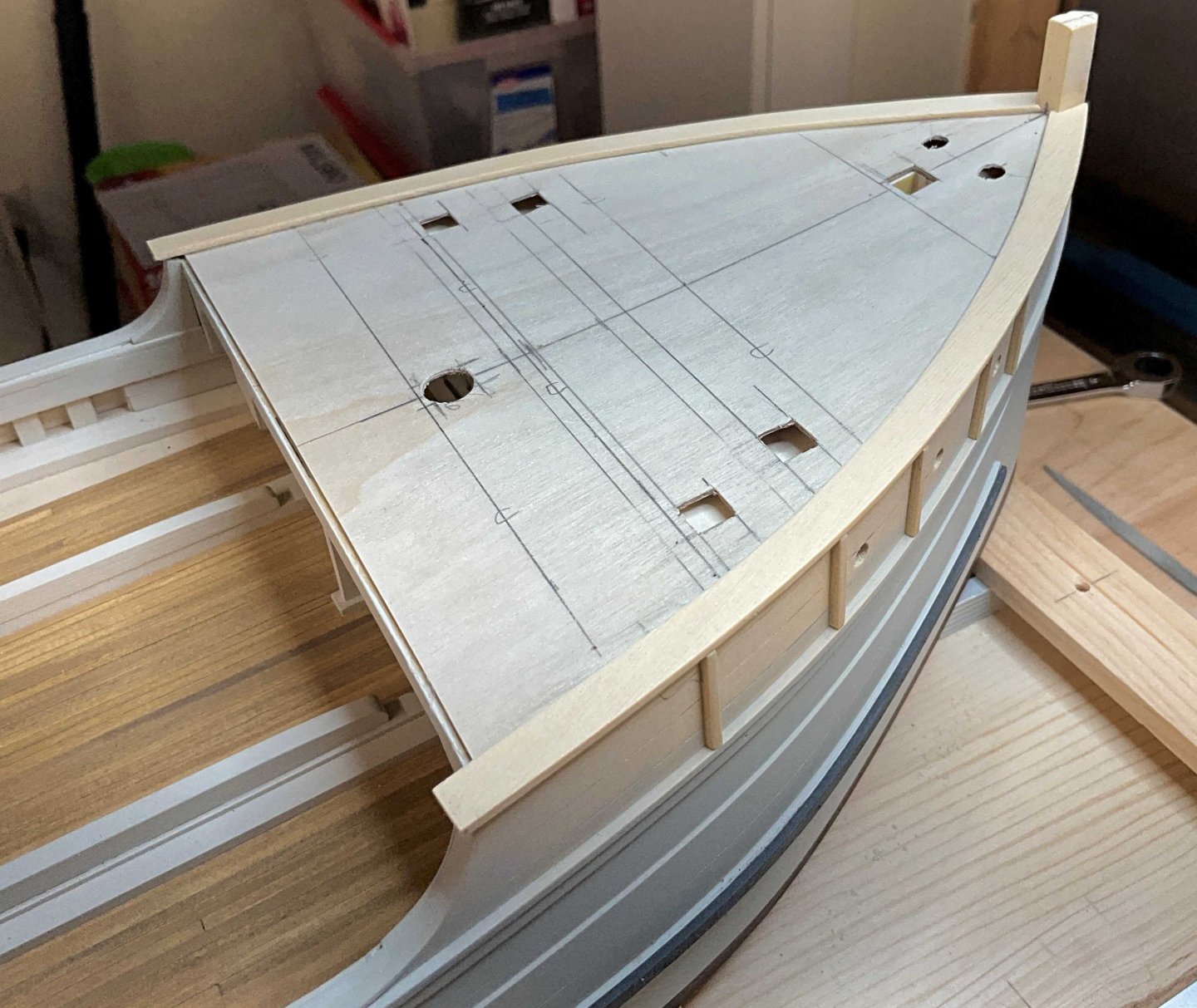

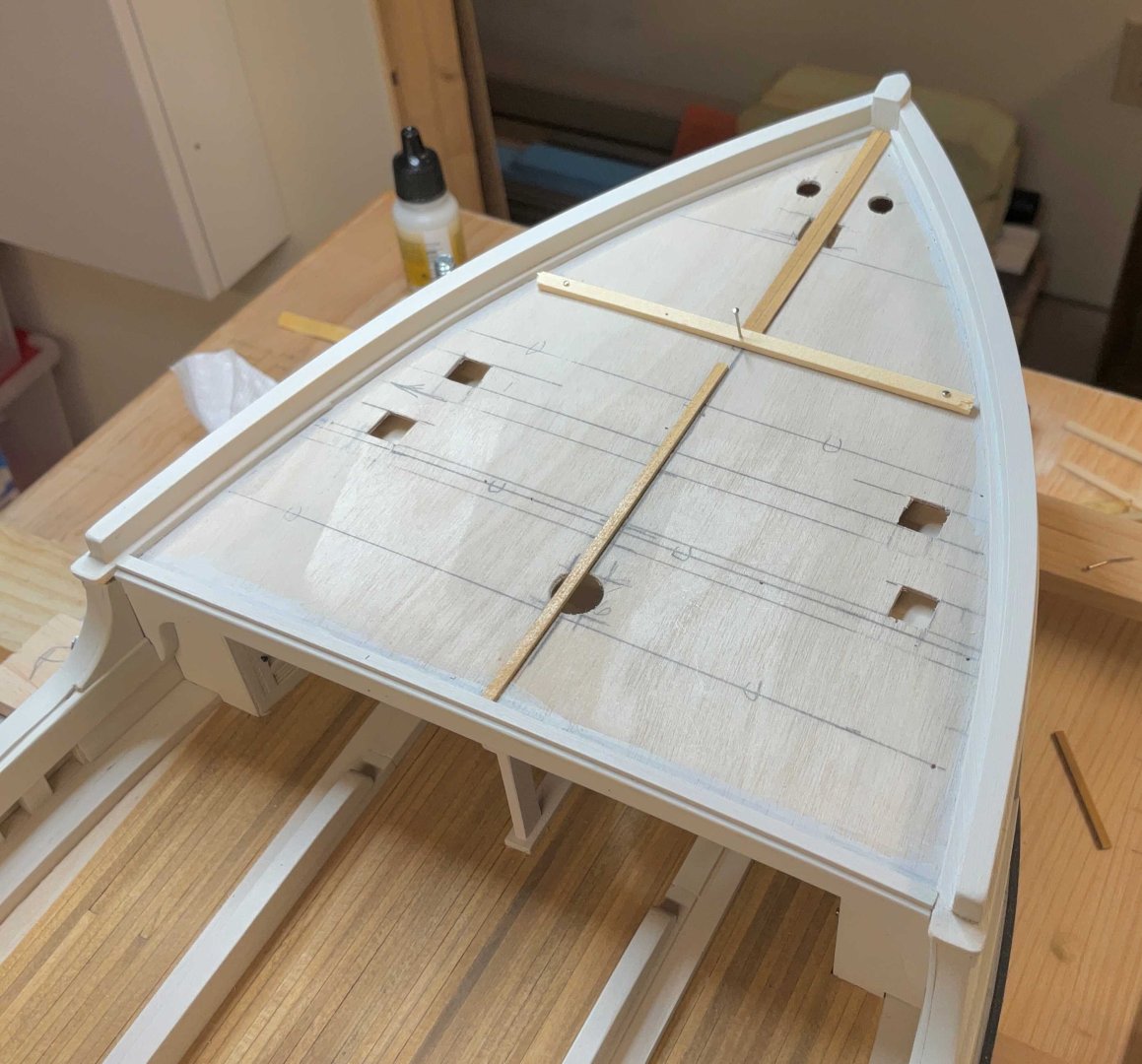

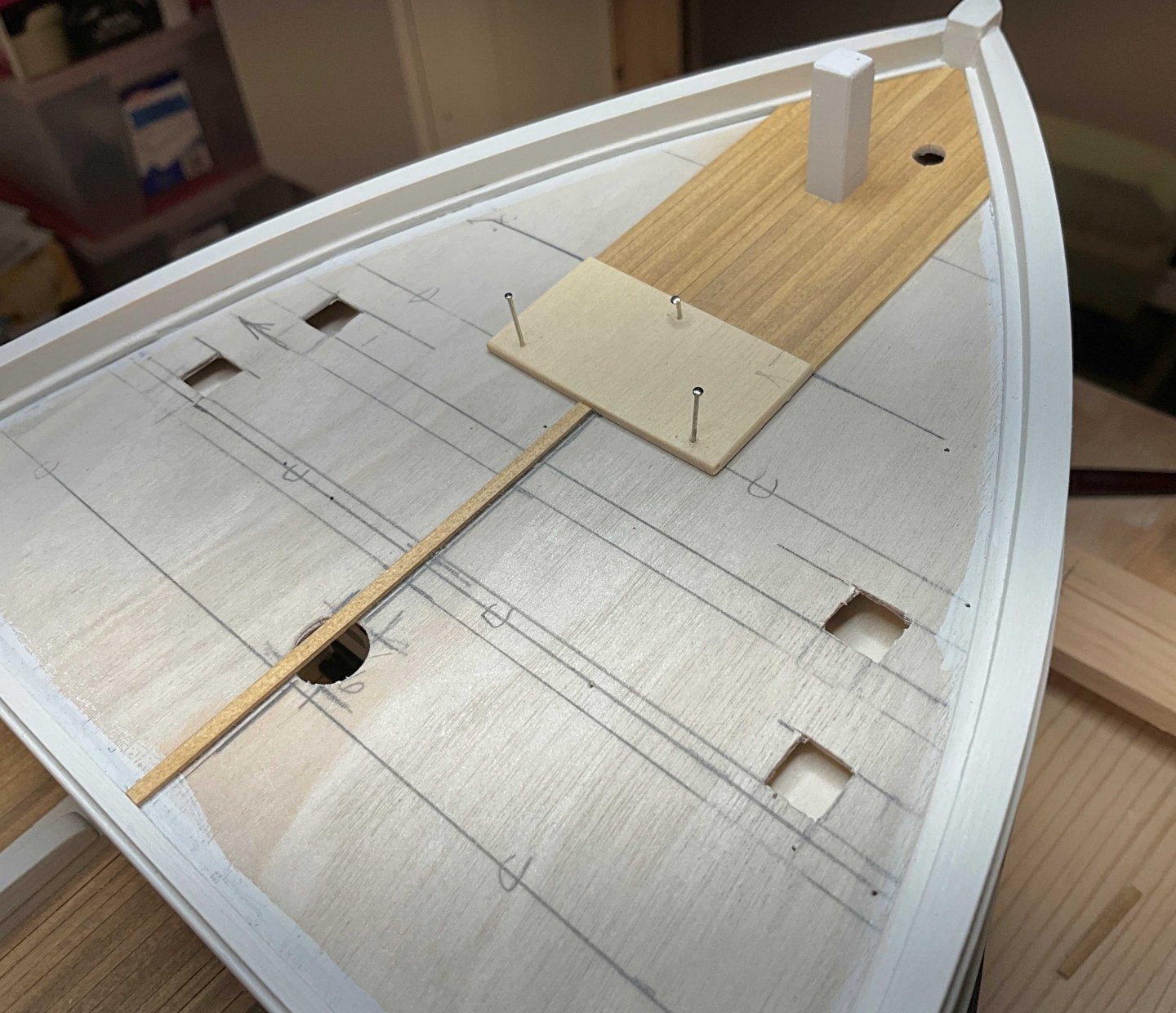

Hi Everyone, hope you are all doing fine. Thanks to all for the Comments and Likes! This update starts with the making of the waterways for the foc'sle deck. They were cut from a sheet of 1/16" AYC and sanded to shape. The coamings are made by layering three 1/16" x 3/16" strips. The waterways were scribed to show where the center plank is located and pins were placed to support it while it was attached with CA. The outer plank was glued to the center plank and the waterway with white PVA The inner planks were glued to the center planks and the waterways also with PVA. The thickness of the inner plank was tapered to 1/32" because the coaming gets narrower towards the aft end. I made a sanding stick long enough to span the deck and sanded the tops smooth The coaming across the aft edge of the deck was installed and after some sanding it went to the paint booth The deck planking was laid out to where it stops at the pad for the anchor winch. The 18" x 18" bitt slides into the hole that was left in the bulkhead former The planking from the winch pad aft and the forward planking didn't match in width so the next planks on either side of the pad needed a width adjustment. The smaller bitts port and starboard were the next obstacles. A small pad was glued to the bottom of these bitts to to help them sit vertically when they are glued to the horizontal bulkhead spacer just below the subdeck The last planks go and get all fancy. They will be covered in the next update Hope to see you then

-

Kevin, Mike and yourself did a great interview. Thank you

- 1,118 replies

-

Looking great Keith! Nice overhead shot

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Phil, great looking planking and nice modification on the #11 blade!

- 433 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.