-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by HIPEXEC

-

-

Here's how I'm bending trim 1mm x 5mm planks for the curved bow pieces. After a 15 minutes soak, I placed them side by side in the jig that came with my heating iron. I placed some smaller plank pieces over the parts so as not to mar them with the clamps, then slowly increased the bend until they lay flat against the curve of the jig. Now they're drying. When dry, I'll cut & trim to fir, then glue them. This is my second try, since the clamps made marks on my first attempt.

-

No matter what general method you use to pre-bend a plank. Clamping it the exact spot you want to glue it while it's still wet, will give you a nearly net shaped plank for easy gluing. Look at my build of the USS Constitution to see some of the tricks I used.

Good luck...planking is not easy!

-

-

This is how I bend & shape & mount my fore toprail. It's two double 2mm x 2mm pieces bent & glued. First I soak the wood in clean plain water this time, then clamp them to the cutout from the false deck, which is close, but not net shape. Then I fine tune the bend in my jig. Then cut to fit with my miter box & glue. This piece was not pinned since it will have side supports to stabilize it

-

Great job so far. The Swift was my first build, so I can identify with what you're doing. I discovered using a sharp pencil to make deck nails on my current build. Many people look at them and think I actually nailed each plank. Nice Job!

Rich.

-

Thanks for the suggestion of Oxalic Acid. The bleach didn't work.

-

-

I made a "jig" with plastic coated nails that conformed with my hull shape. It worked pretty well. I fine tuned the bends by wet clamping the planks to the exact spot on the hull that they went. I'd like to see a picture of yours, though.

Rich

-

-

You'll be sorry if you don't have a straight frame. The whole ship will be off down the road. You have to be able to look at the ship from the front or back and see a perfectly symmetrical hull.

-

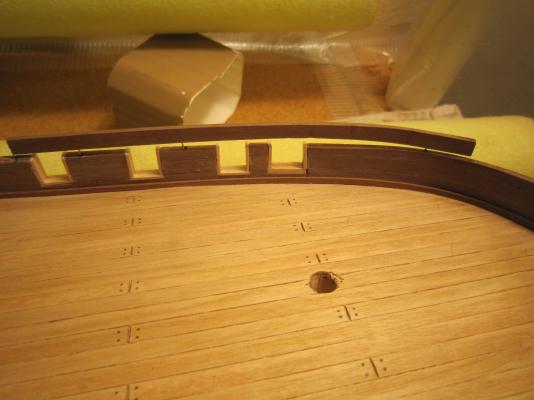

I'm slowly installing the rails & trim (pinned & glued) to the aft half of the ship. Constructo's use of 2mm x 2mm pieces, two across and three across, makes for interesting rails. I'll have to fill them in before varnishing. I'll start on the bow section next, but with its severe curves, It will be harder to trim. The bow stem fits pretty good, but that's because I worked on it for days right after I planked the hull.

-

-

I like running full length planks. It might be harder to do, but I like the finished look.

Rich

-

While I'm waiting for my trim to dry, I mounted the bowsprit and keel skeg and keel trim. I had pre-fit all these parts months ago when I was planking the hull, so it was just a matter of pinning and gluing. Constucto wanted me to put a blond keel trim on, but I like the matching Sapele that goes with the planks.

-

-

Those parts were not pre-shaped! They were just ordinary 10mm planks. You're right, it would have been easier to get the bend with a longer piece. Live and learn.

-

- patrickmil and augie

-

2

2

-

-

-

Now I'm trying to get net shape curves for the bow top rails. My jig only got me almost there, so I'm trying something new. I am using the cutout from my false deck as a jig and clamping the 2mm x 5mm planks to it in the exact shape needed. I soaked everything for 30 minutes.

As far as the 2mm x 10mm bow pieces go...I'm trying an extreme bending method. I'm using my heating iron jig and some vice clamps. I'll either break them or curve them. Time will tell.

-

-

-

-

While I'm trimming the aft toprails, I figured I'd stay ahead with the bow toprails. Wow! Trying to bend 2mm x 10mm Sapele that is harder than bending steel. At least steel is bendable. I only have to put a slight curve on them, but they don't seem to budge. The rest of the toprail is 2mm x 5mm and bends easier (not easy) the the 10mm stuff.

The 5mm stuff is being bent on the jig I built for planking the hull. The 1mm stuff is being bent on the form that came with by heating iron.

We'll see?

USS Constitution by Hipexec - FINISHED - Constructo - 1:82

in - Kit build logs for subjects built from 1751 - 1800

Posted

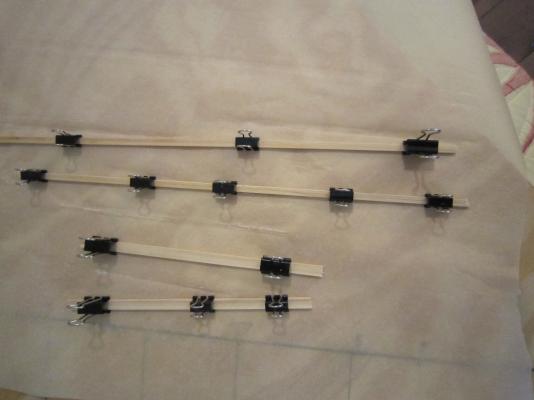

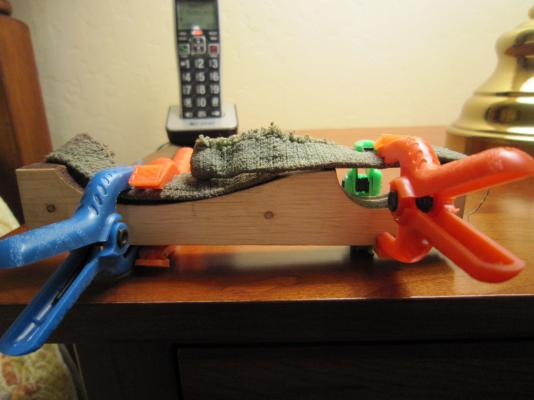

As I clamped some trim pieces today using clothespins, I had to laugh. So far I have used all these items in the picture to clamp various items in place. I've probably forgotten a few, but I can't imaging how many more I will employ by the time I am finished.