-

Posts

632 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Javelin

-

Great new project. However, I doubt the ship in the picture and the one in the painting are the same... I would rely on the painting more, since it clearly shows Columbia on the paddlewheel cover, while the picture doesn't really give a clue to the pictured ship's name....The superstructure with bridge on top etc, seems very different from the painting. Of course it could be an upgraded, later version of Columbia in the picture. The bottle is indeed not something an SIB builder would choose, since that long neck will restrict movement of any tweezer or tools you're about to use. Not very convinced on the ornamental top and bottom of that bottle. It looks like a good framing, but I'm somehow scared of those being a bit too empty and leaving the model appear too small for that bottle. You're "simulation" however looks good so far in that (or any other) regard. Looking forward to the way you'll handle the challenges posed by that neck.

-

You're welcome Ian, with regards to loading something like this, I believe they drive a car in, turn it inside, so the car front faces the stern ramp and drive it towards that ramp on the extreme port side or starboard side. The next car does the same and parks behind the first one. Third comes next and so on. Perhaps two lanes like that. Next lane I assume can stay without turning. During discharge the first two lanes, portside or starboard, can then drive straight out, creating space for the next lane to turn and then drive out. Not sure if that makes any sense.

- 24 replies

-

- ferry

- Europic Ferry

-

(and 1 more)

Tagged with:

-

Is the RCN weaponry, more specifically the SSM and RAM equipment supposed to be installed in these positions? The RAM not being centered I can understand, but I'd at least have expected the SSM (Kongsberg NSM?), to be devided between Portside and Starboard side?

- 49 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

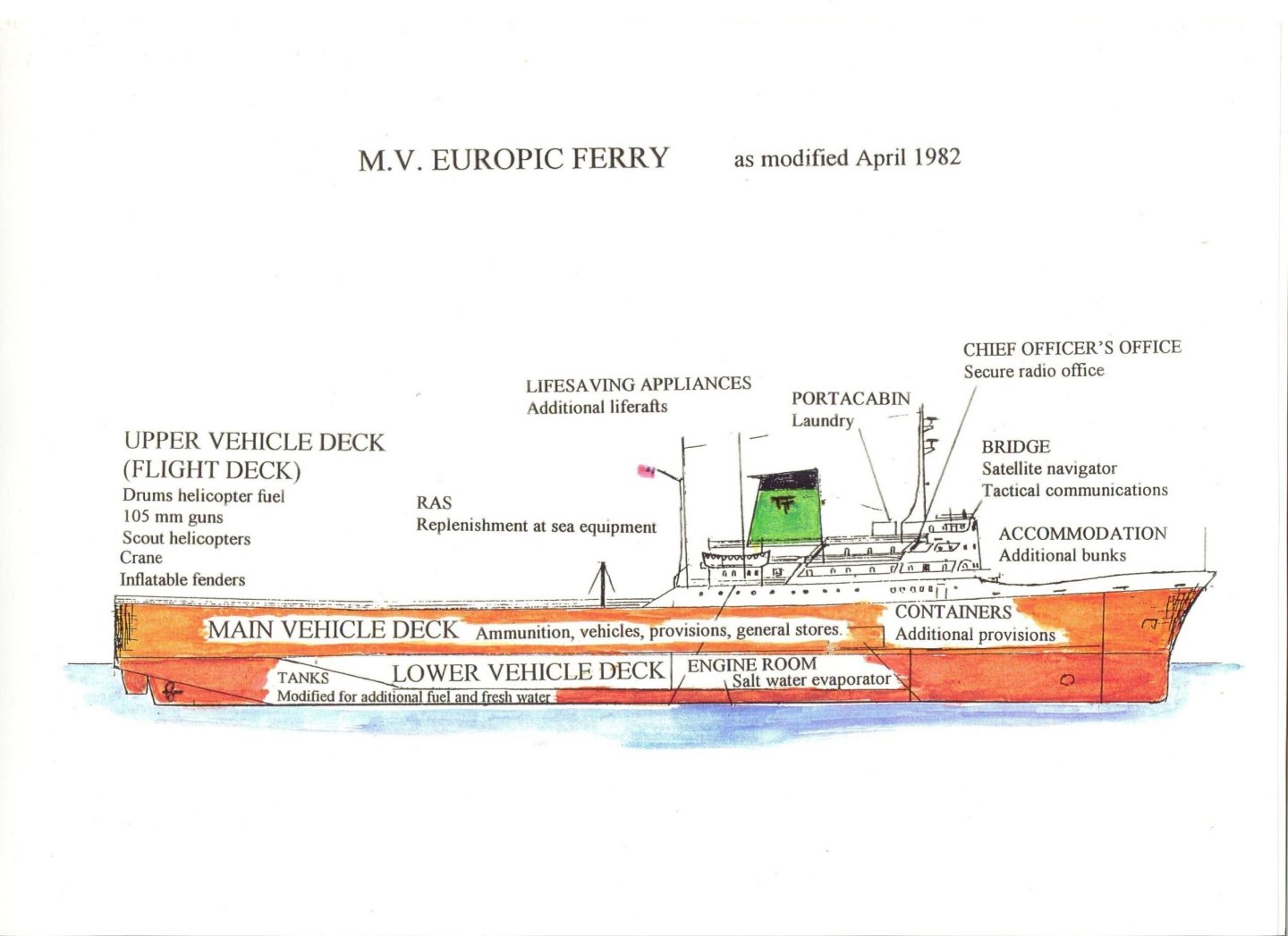

So I had a look around and it's pretty clear to me now. First indication is in this drawing (from: https://www.legasee.org.uk/veteran/chris-clarke/) In the above you can see the ramp on the main vehicle deck going down (starts above the word Tanks and lands below the L from Lower Vehicle Deck). It could apparently be hoisted up to close the main vehicle deck (I assume for a watertightness /safe freeboard reason). This can be seen on the General Arrangement plan as posted in some facebook page (you can view it without an account by searching it through google. Can't seem to link it here... As for the stern ramp, it works double. The vessel was loaded in 2 levels. The upper part of the ramp would hinge down and form a bridge to the upper deck, while the lower part of the stern door would hinge down and form a second bridge to the main vehicle deck. You can see the steel wires of the lower bridge hanging outboard on some of you pictures. Hydraulic pistons are normally used press such gates against a seal in the vessel hull to make it watertight. Not sure why they'd use those on the upper deck though. Perhaps a back-up of the wires? This double ramp is quite typical for ferries, but requires a specialised loading quay with an upper level matching or being adaptable to the height of the decks of the vessel.

- 24 replies

-

- ferry

- Europic Ferry

-

(and 1 more)

Tagged with:

-

Hi Ian, she'd have 2 masthead lights (she's more than 50m long), one side light on each side and 1 stern light. As for the platforms on the mast , as far as I can tell from the pictures above, I'd say the top one is an S-band (approx 3-3.5m long) antenna, while the other one is likely an X-band antenna (about 1.5m long). 2 radars are required, however the X-band is the only one that is really required (Search And Rescue Transponders /SART work on X-band frequency). The second radar may therefore be either an S-band or just another X-band. It is quite common for ferries and car carriers to have internal ramps between decks, be it permanent ones or hoistable ones. I'll have a look at some pictures of this vessel and see if I can figure something out.

- 24 replies

-

- ferry

- Europic Ferry

-

(and 1 more)

Tagged with:

-

Happy New Year and an excellent build so far!

- 211 replies

-

- Russo-Japanese War

- Mikasa

-

(and 2 more)

Tagged with:

-

She's gorgeous Bob. Happy you continued and eventually finished her. Love the cupboard too! Fits your varied collection well.

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

You've got yourself a follower now. Interesting subject, right down my alley! I do like the dark blue livery as well. But red's fine too, always makes for an eye catcher on the water. Curious where this will go, but I would indeed try to create some access to the front area. Some cleverly hidden and reinforced handles on that superstructure may help to prevent damage if you make it removable.

- 24 replies

-

- ferry

- Europic Ferry

-

(and 1 more)

Tagged with:

-

Fund raising

Javelin replied to Russ2025's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Made my donation today using the link. Didn't have any issues... Perhaps not an accepted type of card? -

Hi Paul, Ian, I indeed noticed he (offshore-vessels-drawings.com) was also selling the drawings and pictures for Viking Neptun (from her Eidesvik period) and used some of his pictures for details (like the swimming pool area and aft part of the accomodation). I do doubt he's allowed to sell these as ships drawings are normally quite confidential with notices explicitly stating that they can not be reproduced or used, disclosed or copied without either the owner or shipyard's permission... That is also the reason most companies are not very forthcoming with drawings towards modellers. Occasionally they are helpful and even eager to help, so it never hurts to try and ask.

-

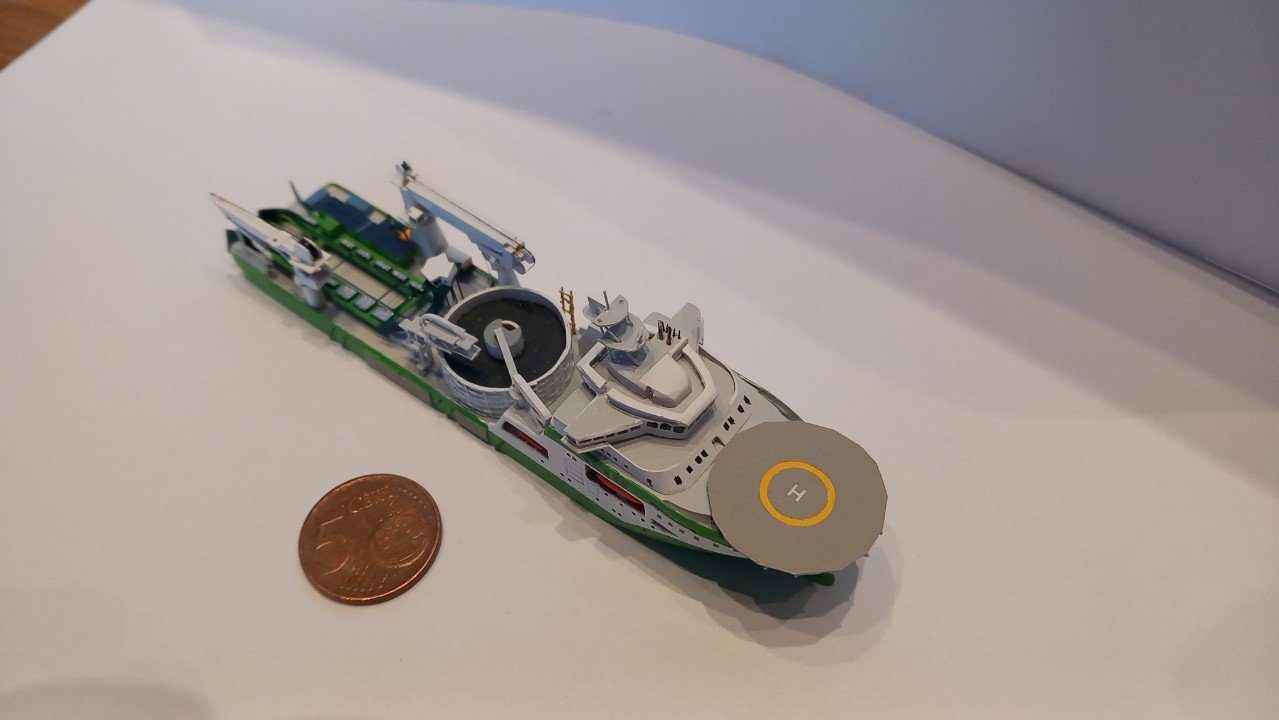

I was wondering about that too Keith, I guess people get sloppy or old over here 😁 @Paul Le Wol, I wouldn't get my hopes up. It's one of my typical preparations I do when I'm at sea. Since I'm unable to build onboard, I do research of ships and ideas at that time. Unfortunately I can't build each project in my limited holidays, so I end up with lots of projects and ideas in various stages of development that will never get built. The choice for VN in this commission at least allows me to use some of that past research, but 1/1250 really isn't my scale...

-

Although I didn't make any real eyebolts yet, I normally use copper or brass wire and turn it around a drill bit to make small round rings or eyebrows. If you use brass wire, it's best to use a 1mm or 1.2mm bit, when using copper a 1.5mm bit will do. You can experiment a bit on what goes best. The advantage of copper is that you can easily cut it with a knife and cut it very straight (I use a lot of copper wire from electrical wiring, since you find a lot of different diameters). They are of course weaker, so you have to be more careful than with brass.

-

Came in a bit late, but she is looking gorgeous!

- 110 replies

-

- san ildefonso

- occre

-

(and 1 more)

Tagged with:

-

Great subject, but quite a challenge at that scale! I assume you've seen this site and the rather rough drawing contains. https://www.granturismoevents.com/story-wallypower-118-the-coolest-luxury-yacht-in-the-world/ The site mentions 3.5t of fuel per hour for the gas turbine, that would make the bill "only" around $3500 per hour at regular MGO prices.

-

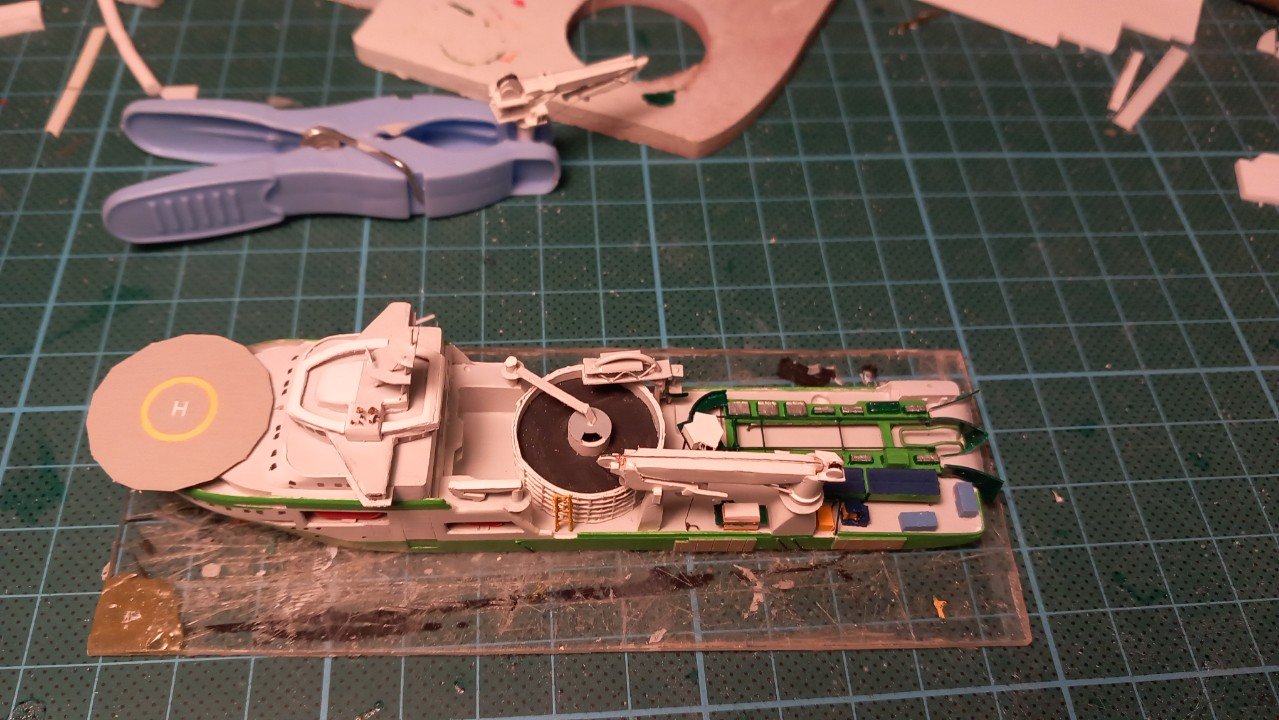

Thanks for the comments and likes. In all my haste to call this one finished, I actually forgot about the 2 large communication domes on either side of the bridge. I've made them from 3mm styrene rod inside my Proxxon and filed them to shape. As you can see, the second ship is also taking shape. @Glen McGuire, the only reason this build went do fast, was my preparation. I have been preparing a 1/100 scale RC build of this ship, which means I was familiar (and thought of solutions) with most of the issues I'd encounter by that integrated accomodation. Also having built a very similar cable layer in the past has helped to detail that installation with precious little info available. Although I have built a Trailing Suction Hopper Dredger before, I believe that Lange Wapper model may be more challenging. I've never been onboard of it and the dark green deck colour makes details on deck very difficult to see in pictures.

-

The item I sort of ignored is what I assume a loading tower for the carousel. I assume the cable comes in from deck (dark green bend near the deck) and pulled up over that loading bend over the edge of the carousel. Not sure if that tower can rotate inward and outward to follow the cable or not. Here's a shot of the ROV area. And with the first rescue boat in place. The auxiliary crane is being rigged and then it's time to round this one up.

-

I don't see any stupid questions here @Glen McGuire, but speaking of them, wait until I start my Sherbourne... 😂 The "New" ROV (Remotely Operated Vehicle) area is located just behind the big crane on portside. It's probably hired equipment since it's a blue A-Frame and it seems to be a habit in the offshore to rent this kind of equipment from specialised companies like Helix Energy Solutions or Reach Subsea. I simplified this equipment quite a lot compared to my 1/700 Living Stone. It's not very visible in this model and not worth hours of work to make each support beam and detail.

-

That is looking marvellous Phil. Very realistic in any case. Were there really ropes wound around those rings on 4 places? Just wondering since I'm from the reflective SOLAS tape era and don't know about Navy habits on this...

- 479 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Assembling a lot of parts now. This way it becomes obvious which parts I forgot to build 🤫 The crane is rigged with fly tying thread and the end is fixed to a tiny piece of copper wire inserted in the deck. They lash the real hook on deck as well to avoid swinging during sailing. The boats were glued to the davits to enable insertion in the recesses. Helo deck has its markings. I used my stencil cutter with vinyl to make the mask for the first time. Although the vinyl sticks a little too strong to my liking it did not have any bleeding nor did it tear out any paint underneath. Working on the ROV area as well as some details on starboard, the main item being a large curved loading arm for the carousel. I thought to leave it out (no idea why really), but it's a really visible item.

-

Since I was doing the last portholes/windows on the side now, I took a picture. In this case I used an upper and lower piece of tape. Normally this marker needs a porous surface (=paper). It does dry on the painted surface, but takes a long time to do so. Unfortunately it does appear to creep in and under the masking tape when the masking tape is left for too long. The result is visible in rather unsharp top and lower edges with occasional smudges. I might remove them with a knife tip. And finally finished handling and turning over that hull, so time to continue building up now. A bit to small to use a piece of railway track, so I'm using other relatively heave and stable objects. Nearly there now!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.