-

Posts

502 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SiriusVoyager

-

It looks like you are off to a good start on your first model. Welcome to MSW!

- 19 replies

-

Finished the ratlines on the port side. Not much else to mention since it was the same process as the starboard.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Welcome to MSW!

-

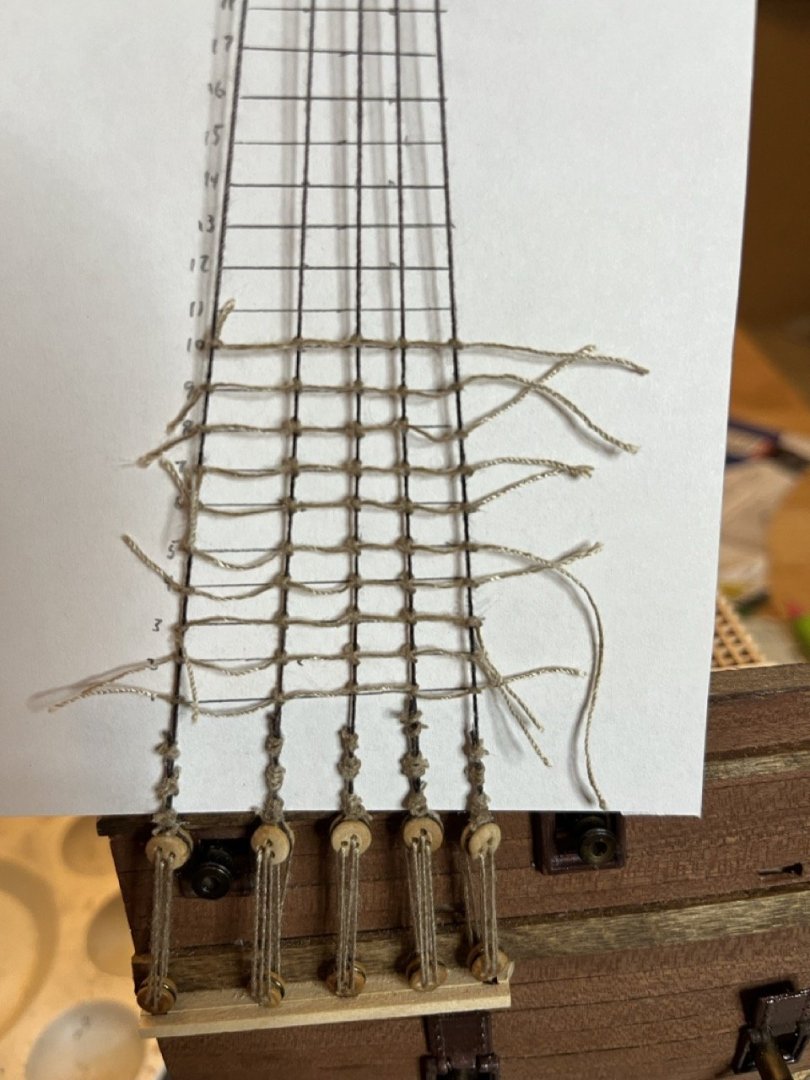

Starboard ratlines are now rigged. It took about an hour to do 10 once I got a rhythm going. This got me really good at using two sets of tweezers, one straight and one bent end, to manipulate the thread. I think my PVA needed to be a bit more diluted for a cleaner look.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Welcome to MSW!

-

Started the ratlines. 10 out of 60 done. They are a simple hitch on the outer shrouds and clove hitches on the inner shrouds. Once I got a good routine going on the clove hitches they went on fairly quickly. There is a touch of diluted PVA on each knot.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Thanks. I enjoy the rigging as well, at least what little I have done.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Very nice work Greg! The attention to detail and patience in your build can really be seen.

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

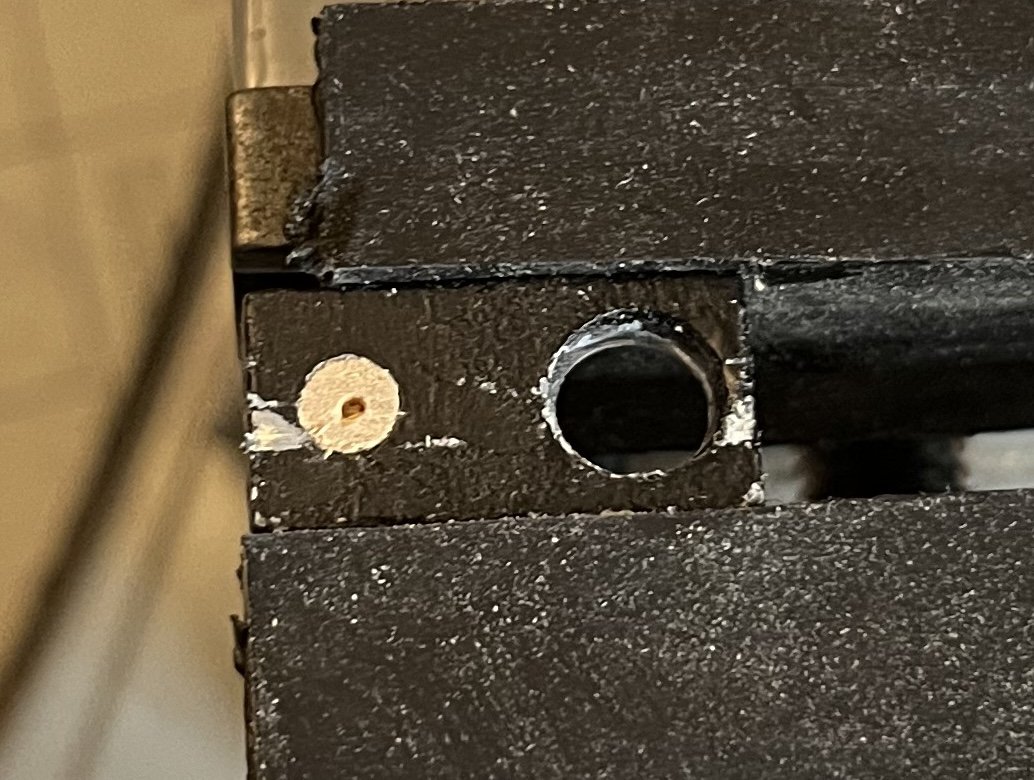

The instructions call for making the entire mast first. I learned after it was done that the lower mast should be made, then the shrouds so that they can be laid over the mast head. Once the shrouds are in, then the top mast can go on. This makes a lot more sense as the shrouds can really only be tied on around the mast head on a fully built mast. Next time I will make proper shrouds with lashed loops at the top. I also didn't realize that deadeyes were meant to be positioned in a specific way. I was able to turn most of them, but not all due to being glued in. Also for next time, I would make one [set] of shrouds and lanyards at a time so the others aren't in the way as much. I definitely need to work on my knot tying and lashing. It's done, but not very clean. With thread this fine though, I am not sure how to hide even a simple clove hitch. I used some wire spacing jigs to try and line up the deadeyes, but I don't think they will be perfectly even when done. Next time I will use a board and nail jig to make the all an even height. The first lanyards were relatively straight forward.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Welcome to MSW!

-

Hi folks, another newbie from the UK

SiriusVoyager replied to Graham_T's topic in New member Introductions

Welcome to MSW! -

Welcome to MSW!

-

Wonderful looking model! It would be hard to believe that it is made out of card if I hadn't seen otherwise.

- 146 replies

-

- Speeljacht

- Seahorse

-

(and 2 more)

Tagged with:

-

Very nice lobster smack! Now that you are done with the series, what is next?

- 37 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

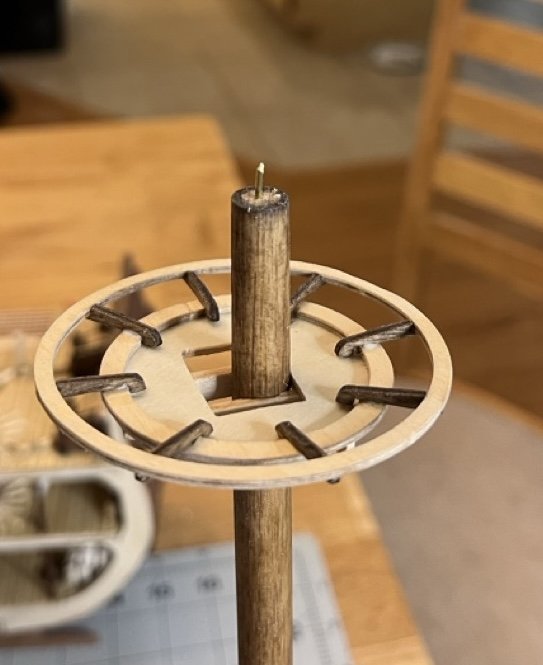

The next step is to assemble the mast. I think assembling the top after the trestle trees and the cross trees are fitted and installed would have been easier because the trestle trees needed to be shaped to allow the mast to fit though. One issue I rant into is that the instructions don't show how to put the caps on the masts. The holes clearly don't fit and there is no indication that you are meant to shape the top of the masts. I decided to shove a piece of dowel into the hole where the lower mast goes and cut it flush to allow the pieces to glue together. Getting the cap to stay in place long enough for the glue to dry wasn't working well, so I came up with another idea. Drill small holes in the mast and the dowel in the cap and use a small piece of leftover brass to connect them. This worked really well for the top mast so I repeated it for the lower mast. The mast fully assembled and installed into the hull.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

I gave that a try last night before I went to bed. It didn't seem to make any difference. I am just going to go with it as is. Once everything is rigged, I think it will be even less noticeable.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Even if your rabbet isn't quite right, I think it is good practice for more advanced models that aren't double planked. I plan on doing this on my next few builds.

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

I thought that that may be part of it. I was also thinking that uneven sanding could be to blame as well.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Stained the masts and yards. I was hoping to assemble the masts but they weren't quite dry so I will get to that in the morning. I am not thrilled that the stain is splotchy and uneven. I'm not exactly sure what I can do about that.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Welcome to MSW!

-

Revenue cutters don't get the attention they deserve. Your model looks great!

- 63 replies

-

- card

- Revenue Cutter

-

(and 2 more)

Tagged with:

-

I am almost done with my fifth model and I still make plenty of beginner mistakes. Just remember, you will always be your own worst critic.

- 12 replies

-

- Lowell Grand Banks Dory

- first build

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.