-

Posts

741 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by schooner

-

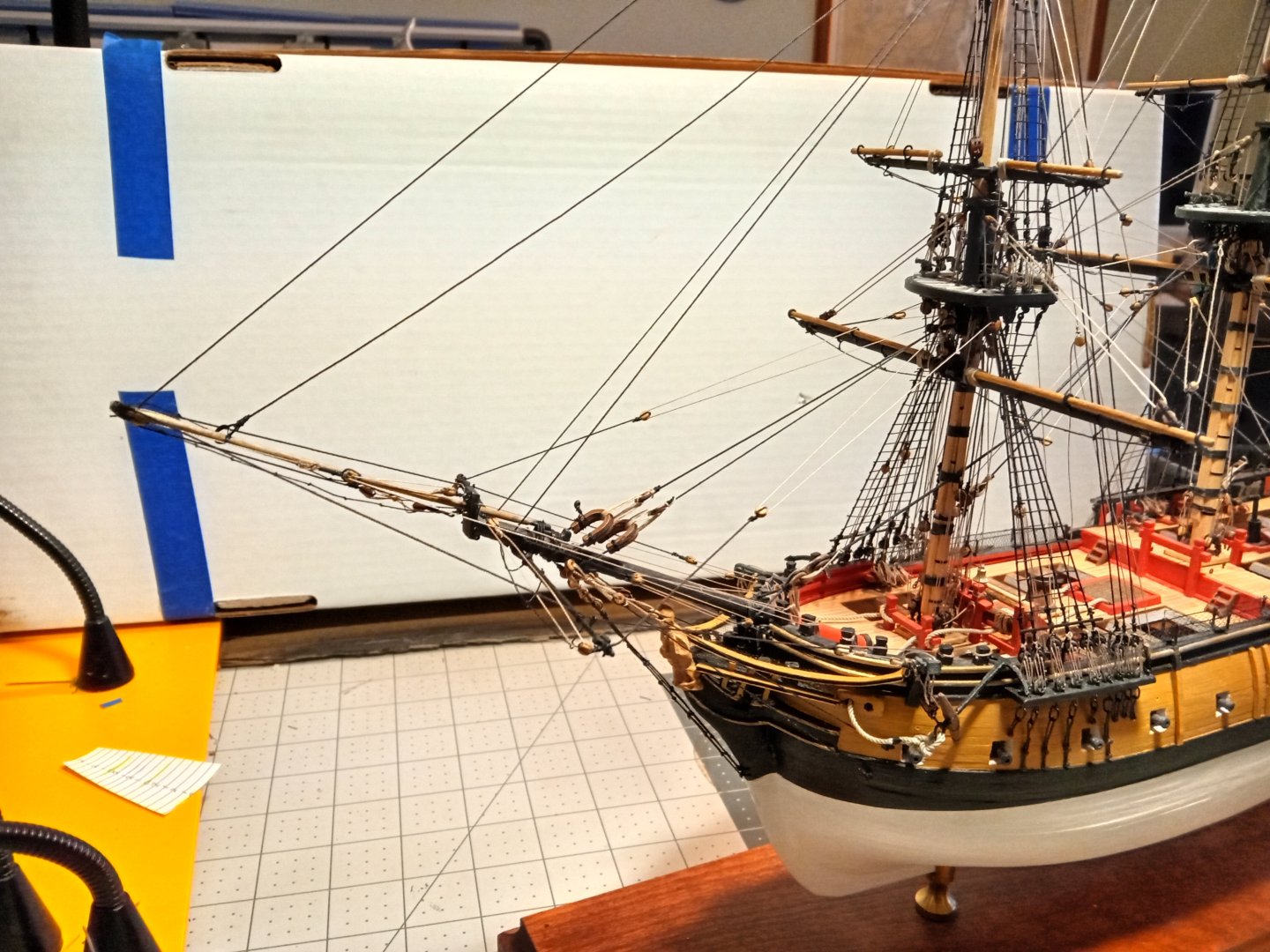

Thanks for the kind words. Just one more photo to show what attracted me to this kit - I wanted a fully rigged 3-master that would fit on a bookshelf. Well, it does!

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

-

Hey Jim, Shaping solid hulls is always an adventure (I've done 6 of them so far from BJ). But as you have obviously figured out already there are few unrecoverable errors at this stage. By adding wood where needed, and some filler (as long as it is not too thick to avoid problems with curing/drying) you can redo almost anything. I have not done the Connie but it looks like your fix on the stern may well work. Perfection is always nice but for the hull, simply keeping things symmetrical and avoiding anything odd-looking should be "good enough" because if you get this build finished everyone who sees it will be fixated on the masts, rigging and the deck details and any minor flaws in the hull will never be noticed (even by you). Keep plugging away.

-

Thanks for all the kind responses and the likes.

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

-

Nice work Avi! I'd like to make one suggestion regarding mounting the guns on the gun deck. You should consider pinning the carriages to the deck with a piece of thin brass rod. When moving the hull around as you get into the rest of the build you will unavoidably push several guns out of place. If you can, you may want to extend the length of the rod so that it passes thru the cannon barrel and carriage and then into the deck. Trying to remount the guns once the upper deck is in place can be a real pain, as I know from experience.

-

I'm at the same point in the build as you. I think the idea is to place the top of the batten along the middle laser line then check for any weird bends, adjust as needed (and as little as possible) to get a fair line then mark the bulkheads where the top of the batten touches them (the batten can then be removed). That line will be where the top of the 3/16" high sill pieces sit. Doing it that way ensures that the top of the sill pieces sit as close as possible to being 3/16" above the transverse parts of the bulkheads which the deck planking will sit on. If they do, then the stacking of the 1/16" thick planking, plus the 1/16" thick waterway, plus the 1/16" thick carronade swivel brackets (pg 46 of the instructions) will leave the top of the swivel brackets even with the gunport sill, thereby centering the carronades in the gunport and level with the deck. That's the theory anyway, for what it's worth.

-

Finally finished The display case base arrived from BlueJacket so it’s time to take some final photos and put this one to bed. It has been a challenging but enjoyable build.

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

-

I agree with Phil about gluing the stropping lines around the blocks. If you don’t some of your blocks may “roll out” under tension, probably in the worst locations for trying to fix them. You don’t need much glue, just a little on each side if the block. Rounding off the edges of the blocks will make them look more realistic. The blocks from Syren look great but the Model expo blocks can be improved with a tumbler or by filing down the edges (tedious but not too bad if you do them as you need them.)

-

I too was worried about snagging the bowsprit/jib boom but I clipped a piece of bright orange tape near the end of it and it's visibility served as a warning/reminder whenever I was reaching anywhere near that area.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks Matt! ----------------------------------- Step 31 to completion The last step is to select and prep the oars. The kit provides 2 complete sets - one of PE and one of pear wood. I went with the pear wood. Sanding the char off these delicate pieces and then sanding all 12 of them so their cross sections would have a more rounded appearance ended up taking more time than any other step in this build. I did add copper paint to the blade tips per the instructions but did not follow the recommendation to partially paint them in white. I left it off since American warships of the Napoleonic War period seemed to have a lot less decoration/ornamentation than the RN. I’m not sure if that was a matter of preference, Navy Department parsimony or just no need to keep crews with too many embittered products of the press gang busy with fancywork rather than sitting around plotting mutiny.🙂 Final Thoughts: I’m very pleased with how this kit turned out. I may build Vanguard’s 18 ft cutter to hang on the SYREN’s stern davits when I get to that point in the build. Although the build logs made this kit look a little intimidating I found that clamping each hull plank in sections with my fingers until the glue set made that part of the build surprisingly easy This was more fun than I thought it would be - the kit is well designed, the instructions are very good and the materials are great

-

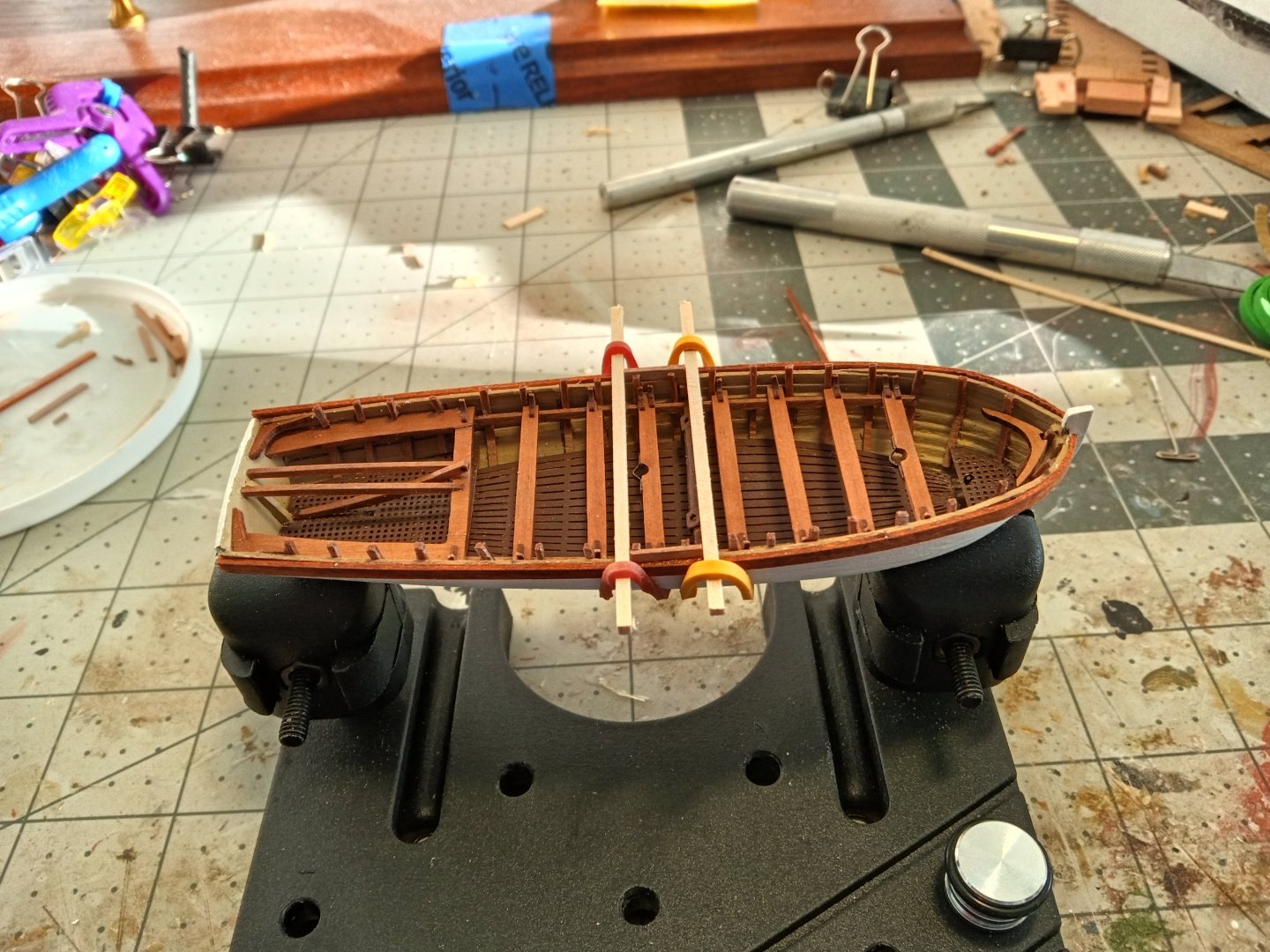

Steps 24-30 The stern sheets assembly went in after a little trimming to fit the shape of my hull, followed by several other laser cut pieces.My kit did not have the overhead plan referred to in other build logs but an email to Vanguard got a quick response with it attached so I was able to determine the placement and spacing of the seats (and the oarlocks later.) Getting the seats parallel to each other and perpendicular to the keel wasn’t hard using this clever jig from post #10 of Clark’s build log (I had to clamp a temporary stern post to the transom to give the jig something to rest against) : There are 20 TINY laser cut knees for the seats (2 per seat except for the 2 that have the mast support brackets - they get 4 each). The rib extensions were all trimmed to a 1mm height and the davit supports added to the stern sheets: The instructions said you can cut the tiller off the rudder because “a separate arm” is fitted in the boat. The arm referred to is the davit associated with the kedge anchor handling. I’m no expert but I think the davit and the rudder is an “either - or” proposition - if the davit was deployed overhanging the transom then rudder had to be unshipped (the boat would then have to be maneuvered with just the oars). I put the davit in what seems like a logical stowage position. The kit does not provide a windlass which the other part of the handling equipment so I scratched one using the instructions for the SYREN’s boat (available online from Model Expo - select the kit and look for a tab for “instructions and parts list”) The rudder is made up of laser cut wood sandwiched between 2 PE pieces that include the mounting plates for the gudgeons and pintles. Since I plan on stowing the rudder in the boat I cut the plates for gudgeons off and glued them to the transom along with 2 eye bolts. I used some stained basswood I had on hand for the wales. The hull exterior was painted white. There are 2 different ways to handle the gunwales, add them as one long strip from stem to transom and then cut or file the oarlock slots, or install them in sections. I went with the sectional approach because I thought trying to file the oarlocks might be more than the thin edge-glued wood could stand up to. I found some strip wood of the width I wanted for the oarlock openings and moved them around as a guide for cutting the sections:

-

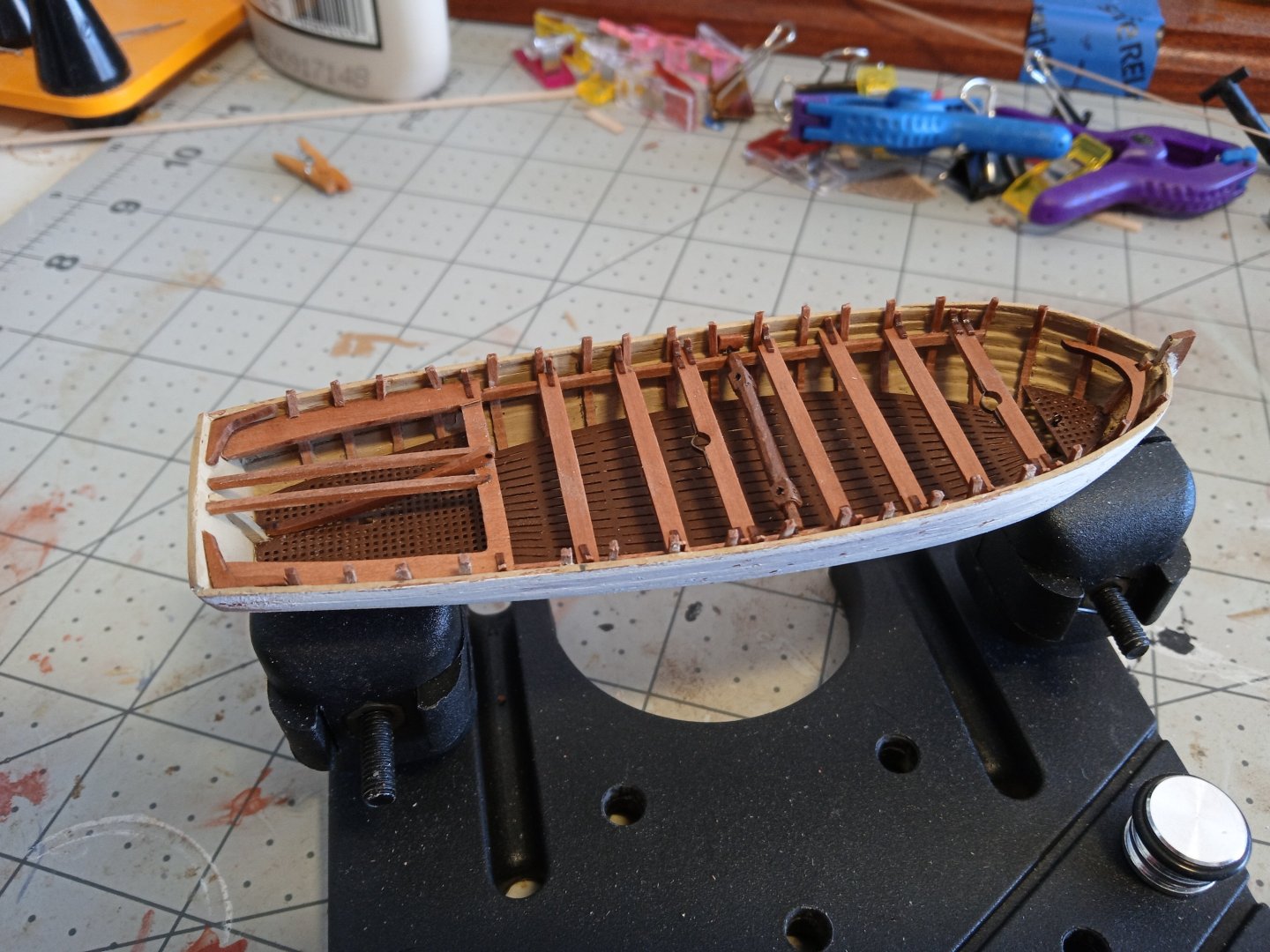

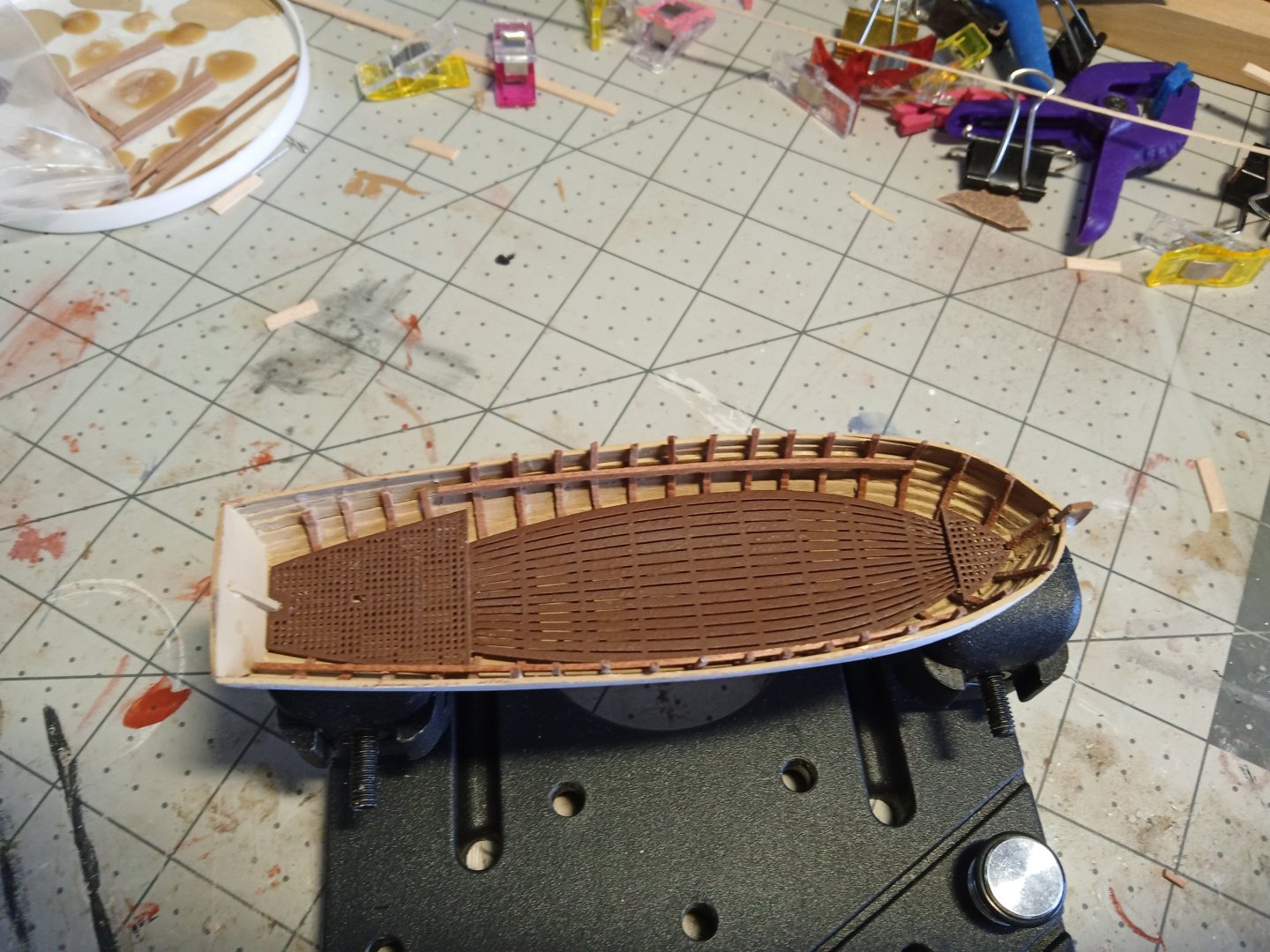

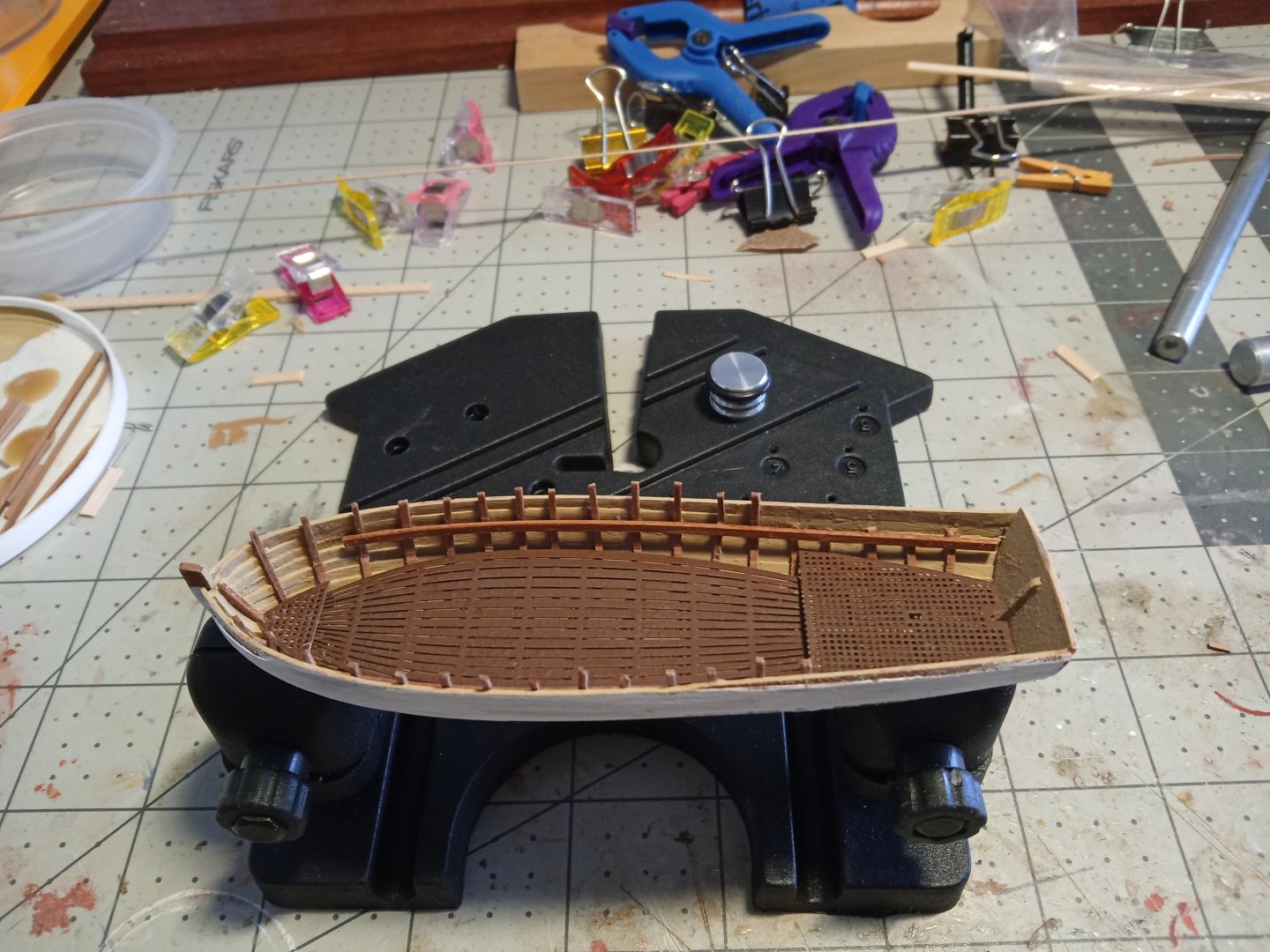

Installing the ribs and seat supports Steps 19-23 - There was enough filler bleed thru in the plank gaps from my first few planks that I did not feel comfortable leaving the interior planking bare so I painted it with some acrylic tan. - The ribs went in pretty easily after soaking. Following the recommendations on several of the build logs I trimmed the tops of the ribs leaving about 1-2 mm above the sheer strake to help position and support the garboards/washboards/oarlocks when those go on. The seat supports went in without need of soaking, they were placed 3mm below the top of the sheer strake using some 3mm strip as spacers. The photo etch floorboards and gratings were sprayed with Tamiya Fine Surface Primer and then sprayed with a dark flat brown spray paint, I wanted to avoid brush painting them since the holes are so small it would have been easy to clog them up even with thinned paint. As can be seen in the photos below on the port side I cut the seat supports to end about 4 ribs forward of the transom per the instructions. When test fitting the after stern sheets assembly I figured out that it would be easier to install it if it could rest it on the seat support strips so I left the support on the starboard side long enough to reach the transom. That also helps ensure that the stern sheets sit level with the thwarts/seats. The ribs and seat supports were given a coat of poly which looks good on the pear wood. The exterior of the hull has a coat of primer on it.

-

Hey George, I've used those scribed decks several times and you can get a pretty invisible seam between them. Now that you have the char off push them together and using a pencil carefully mark the areas where the halves touch and sand a little in those areas, recheck - remark - sand a little more. Eventually you will have the halves making contact along their entire length. Don't get carried away with the sanding and stay away for power tools. If you look carefully at the edges of both halves before you start you may well be able to plan your sanding such that the halves meet either right on a prescribed plank seam or at least with a seam that looks like the prescribed seams. Don't sand away an entire plank width chasing a seam though or your deck may end up too narrow. After you are happy with their fit and are ready to glue them to the sub deck I suggest you use epoxy to do it. CA sets up too fast and you may not get everything aligned before it does. Wood glue (PVA) has a lot of water in it and speaking from personal experience with these scribed decks the moisture can cause them to swell and buckle. If you end up with a spot or two that you are not happy with that would be a great place to put some rope coils to cover them up.

-

Cleaning up the hull and removing it from the jig Steps 13 - 18 Prior to removing the bulkheads and hull from the baseboard I applied my preferred filler to the hull exterior and sanded it smooth: After the exterior of the hull was smoothed up it was time to remove the bulkheads from the baseboard which was easy to do (another reason not to glue the bulkheads in). I followed the directions and cut away the “bridges” that connect the tops of the bulkheads, here the first few on the left have been clipped: I used needle nosed pliers to twist away the vertical sections of each bulkhead from its connecting point with the base, which remains attached to the keel and will serve as the base of the floor boards and gratings. By using PVA and trying to avoid getting all but the slightest amount of glue between the bulkheads and the planks they all came out without any problem: The hull at this point is pretty fragile and needs to be handled with care until the ribs and seat supports are installed.

-

Steps 8-13 Planking the hull The bulkheads were faired with a sanding stick and a file with the beveling checked with a planking strip I had some basswood strips of the same dimensions in my stash so I used them to try out planking methods. The bass wood is a little more forgiving than the pear when it comes to bending and I planned to use it near the keel if I ran out of pear The planks are so thin that the laser cutter did not need to spend any time cutting them out so there is no real “char” typically found on laser cut wood but there is a thin, crusty veneer on the edges. I didn’t know if that would interfere with the glue adhesion so I sanded the edges - it was quick and easy to do with a sanding stick I tried 2 different bending methods: soaking the wood and letting it dry on the jig and using Amati’s Form A Strip Plank Bender: 10-15 minutes of soaking in warm water was enough to allow both the pear and basswood to bend enough for the sheer strake. One of the build logs pointed out that since the rabbet at the bow is a slot that has to be used by both the port and starboard planks that marking the plank tips so you don’t put them into the slot over half way will prevent problems (good catch) The Amati plank bender worked well on my un-soaked basswood strips, they curved coming out of the bender. Perpendicular “squeezes” yield a nice curve whose radius is determined by how close you space the incisions. Angling the incisions yields an edge - bent curve. The plank bender also worked with the soaked pear strips (I didn’t think they would stand up to the bender while dry) so I’ll combine both methods; soaking the pear and letting it dry on the jig and then using the bender again to adjust the bow curve if needed so only minimal clamping is required. The directions recommend glueing with wood glue (PVA), not CA, since when the hull is removed from the jig the bulkheads will be removed by twisting them out of the hull with pliers (exciting!) Where to apply glue is not as clear. Some of the build logs glued the first plank to all the bulkheads and the following planks just to the edges of the previous planks, some build logs seemed to glue the planks to all of the bulkheads. Both methods seem to work except for one that used CA who had some plank damage (holes) when removing the bulkheads. I’m going to go with using a little CA at the stem and transom and PVA for edge glueing. If any PVA squeezes onto the bulkheads it should be minimal. After the sheer strake planks were in place I tapered the remaining planks from the 3rd bulkhead going forward, removing about 50% of the plank width by the time it had reached the stem. Clamping the planks is a challenge. The other build logs show some innovative methods but I only have some clamps made from binder clips. After the first couple of strakes I figured out a method that worked best for me: 1. Add PVA along the previous (installed) plank from the forward tip to the 3rd bulwark 2. Add CA to the tip of the plank 3. Install the plank and hold it in place with my fingers for about 90 seconds 4. Secure the aft (unglued) part of the plank with a binder clip and let the glue dry for at least an hour 5. Add PVA along the remainder of the plank edge and CA at the transom seating point and hold the plank in place for 90 sec, add binder clip and let the glue dry for an hour. - After adding 6 planks from the sheer towards the keel I started tapering the aft ends of the planks - I should have starting doing that with the 2nd plank, given how much smaller a radius the transom has compared to the bulkheads. After adding 8 planks I added a plank along the keel Almost done… I did not break any of the supplied planks but there are only 2 left over, and you will need those for the gunwales, so be careful in handling them. - The port side is done and as can be seen below there is still a sliver of a plank to be added to the starboard side: That remaining sliver of space brings up a point. Some of the other build logs have shown that with sufficient skill/experience some “traditional” planking techniques like drop planks, stealers and spilling can be used on these planks; I just could not do much beyond tapering. By starting from the sheer line and working towards the keel after adding 8 planks I had moved “under” the turn of the bilge and all the remaining planks would be out of sight in almost any display of this model. That, and the fact that I plan on painting the exterior, makes the fact that my final planks have some very unrealistic shapes (i.e. pointed ends and thin widths) is not a big deal. I hope to leave the interior of the boat unpainted and even then I hope to be OK since the unrealistic planks will be out of sight under the floor boards and gratings. Thoughts on planking: Not surprisingly my technique and results improved with practice. My first couple of strakes had some gaps that were not apparent when just clamping with clips vice fingers, and one or two strakes sit higher than their neighbors but after that my seams tightened up. When I do one of these kits again I plan on buying a similar size POB lifeboat kit from Model Expo, shown here, and use it to practice my technique in parallel with the Vanguard kit. The ME kits are not nearly as well engineered or detailed as the Van kits, the directions can be poor photocopies and all the wood is basswood but they are inexpensive, only about 1/5 the cost. There are a couple of build logs for them on MSW here and here. Planking this kit ended up easier than I thought it would be. With some practice, such as having a ME kit to practice on, I’m confident that next time I could do a planking job that is good enough that I could leave the hull exterior unpainted. Unlike some of the other build logs, I did not attempt to add a scale garboard plank on this one but next time I may give it a shot

-

I managed to totally screw up the bread and butter 25 ft launch that came in my Model Shipways SYREN kit so I had to look around for a replacement. I came across several build logs for Vanguard Models’ ships boats here on MSW, all of them are in the 1775—1800 kit section (links below): 18th c Ships boats by Blue Ensign 22 ft Yawl ships boat by Johngr 24 ft Launch by Clark The above logs are excellent references for dealing with these delicate kits and the builders’ craftsmanship produced some stunning work. If you, like me, are a ham-fisted wood butcher whose main ship modeling tool is bad language then maybe my experience might help persuade you to take a chance on one of these kits. A couple of points: - If you would like to see what is available from Vanguard Models go to their website and look under “model kits” then click on “ship’s boats”: - I should mention here that Vanguard also offers several boats as 3D printed resin and wood versions that look much easier to build than the all - wood versions. They can be found under “Fittings and Accessories.” That is going to be my fallback choice if this build does not work out. There is a build log of one: 26 Ft Launch by Blue Ensign - Vanguard Resin/Wood small boat Model - 1:64 scale - My kit did not come with instructions because they are available for download from the website - Vanguard Models accepts PAYPAL and my order arrived remarkably fast, quicker than I’m used to from many vendors here in the US - IMPORTANT: Because of the small scale involved both the pear wood and the MDF jig pieces are VERY fragile. During every step you should move carefully and avoid putting any pressure on anything - if you sand and file so that parts fit together without any pressure then you will be OK. It’s doable - it just takes a little longer than you may be used to. From here on out if I refer to a step number it is the step number from the instructions Steps 1 and 2: Setting up the framing jig Carefully remove the MDF pieces, the keel and transom. Note that there is a rectangular piece next to the keel - don’t separate them - it is a temporary support (I did, not realizing what it was, but was able to tack glue it back in place) The directions recommend not glueing the bulkheads to the base. I did not even though most of the build logs did. I’m glad I didn’t because when I tried to fit the keel it would not fit into any of the bulkhead slots. I was able to remove each bulkhead from the base and individually fit it into the keel off the base with some filing. The bulkhead slots were too tiny to file so I filed the thickness of the keel below the slot until each bulkhead fit down into the keel so its top was flush with the top of the keel (only 1 or 2 need a little adjustment to the vertical slot surfaces). Once done the bulkheads were reinstalled in the base and the keel fit snugly into place and all of the bulkheads were secure in the base without need of glue. Steps 3 - 7: Glue the keel and transom into place with diluted PVA Cut out the 2 bow planking patterns L15, bevel their forward edges and glue them in place At this point I recommend you reinforce the stem and the transom so they do not break off during fairing and planking. I used some scrap wood glued to the base that supported them in both axis: Photo 1

-

As far as nameplates I have had good luck going to local trophy shops - they can make anything you want, metal or plastic, and usually for less than you would spend online.

- 32 replies

-

- Bounty

- Constructo

-

(and 1 more)

Tagged with:

-

One trick to make flags look more realistic is to sandwich a piece of aluminum foil between the two sides with its dimensions just 1 or 2 mm less than the paper dimensions. Add a piece of the halyard line along the folding seam and then glue the 2 sides together. When the glue is dry take 3 or 4 wood dowels of different sizes (1/4 inch and smaller). Taking the 2 largest dowels pinch the flag along a line between the bottom inboard corner and the top edge a little way away from the top inboard corner and bend/curve the paper around the outboard dowel. Move the dowels to the outboard edge of the curl and repeat going the opposite direction. Keep alternating using successively smaller dowels until you get to the bottom outboard corner of the flag. The aluminum foil will help the curves or folds maintain their shape. If you are not satisfied then flatten out the flag and try again using different dowel pairs and different starting locations. With some practice you can make flags that look like they are in a stiff breeze, a light one or hanging limp in a calm. You can see what I did by clicking on the below link to my Sequin build, the flags are in post #54. Keep up the good work, you have a great looking model.

- 32 replies

-

- Bounty

- Constructo

-

(and 1 more)

Tagged with:

-

You are doing a great job - hard to believe it is your first model. As far as rigging goes, the Mary T. Is about as simple as it can get. I recommend you search for other build logs for this kit and see how they tackled it. The “Shop Notes” section on this site does have a section for rigging but there are over 60 pages of topics so it might take a while to find a particular topic. Keep up the good work.

- 30 replies

-

- Mary Taylor

- solid hull

-

(and 2 more)

Tagged with:

-

Almost done…. The rigging is finally done. Now all that is left to do is fixing any cannon barrels that got pushed off their carriages, adding the gunport lids, the quarterdeck railing cloths, adding the boat to the transom davits and mounting the model on the display case base when it gets here from BlueJacket.

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.