-

Posts

741 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by schooner

-

8. Hull Planking This is not an easy planking job. The wide spacing of the frames make it hard to avoid bumps and dips. The large garboard planks make for an odd shape between the garboards and the deck edge - the fore and aft parts of the hull planks have to be tapered to fit. I still had to add some bastardized stealer planks of some odd shapes to get everything covered. If you have no interest in making this an RC build then you may want to consider adding some balsa wood blocks between the frames and then sanding them fair with the frames - that will give you more glueing area and probably a smoother planking job. I recommend that you put an un-tapered plank along the deck edge and another up against the garboard and then taper the remaining planks as needed, working from the deck edge towards the keel so that any stealers and odd shapes are at least inside the area that will get the “below the waterline” paint covering and ideally below the curve of the bilge so they will not be visible (or at least obvious). When I bought this kit I had hopes of leaving the hull planking above the waterline in a natural color like the photo in the catalog and on the box but when I tested the epoxy I’m going to use on the hull I had to change my plans - the epoxy dries into a semi-opaque reddish color. This allowed me to be more expedient than elegant in my planking since it will all be under a tough plastic-like coating and then painted. I did not have to soak the hull planks since there was almost no edge bending needed, the bow curve is gentle and the “twist” to get the aft end of the planks to lay on bulkhead #5 is nothing that can’t be handled with CA. After some filler and sanding it’s good to go: I deviated from the instructions in that I planked the stern area now because I want to get all the work below the main deck finished before I add the bulwarks. The stern planking was pretty easy, I did have to trim the 2 laser cut pieces that attach to the aft face of bulkhead #5 so that the stern plank butts would be flush with the hull plank butts.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

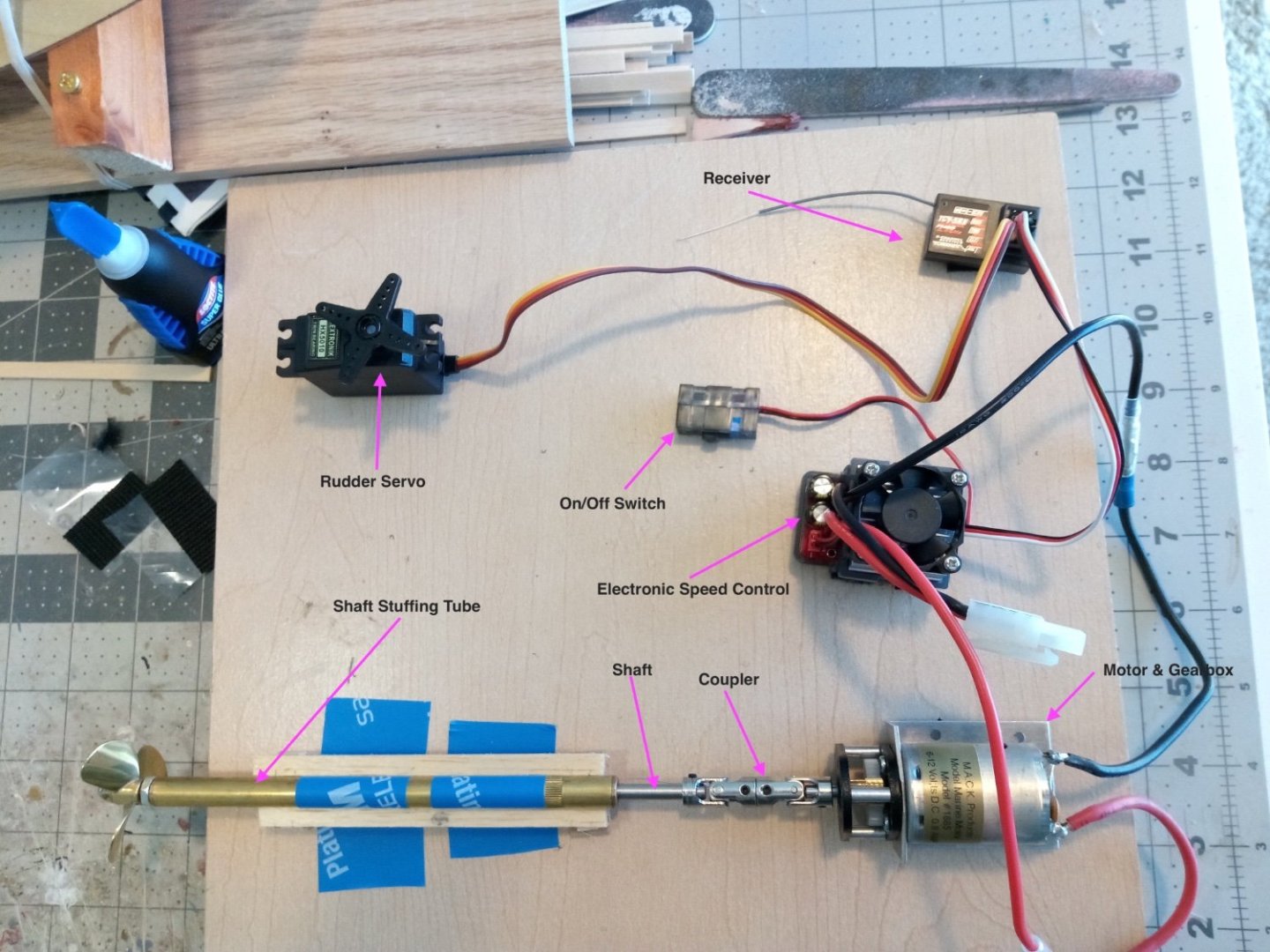

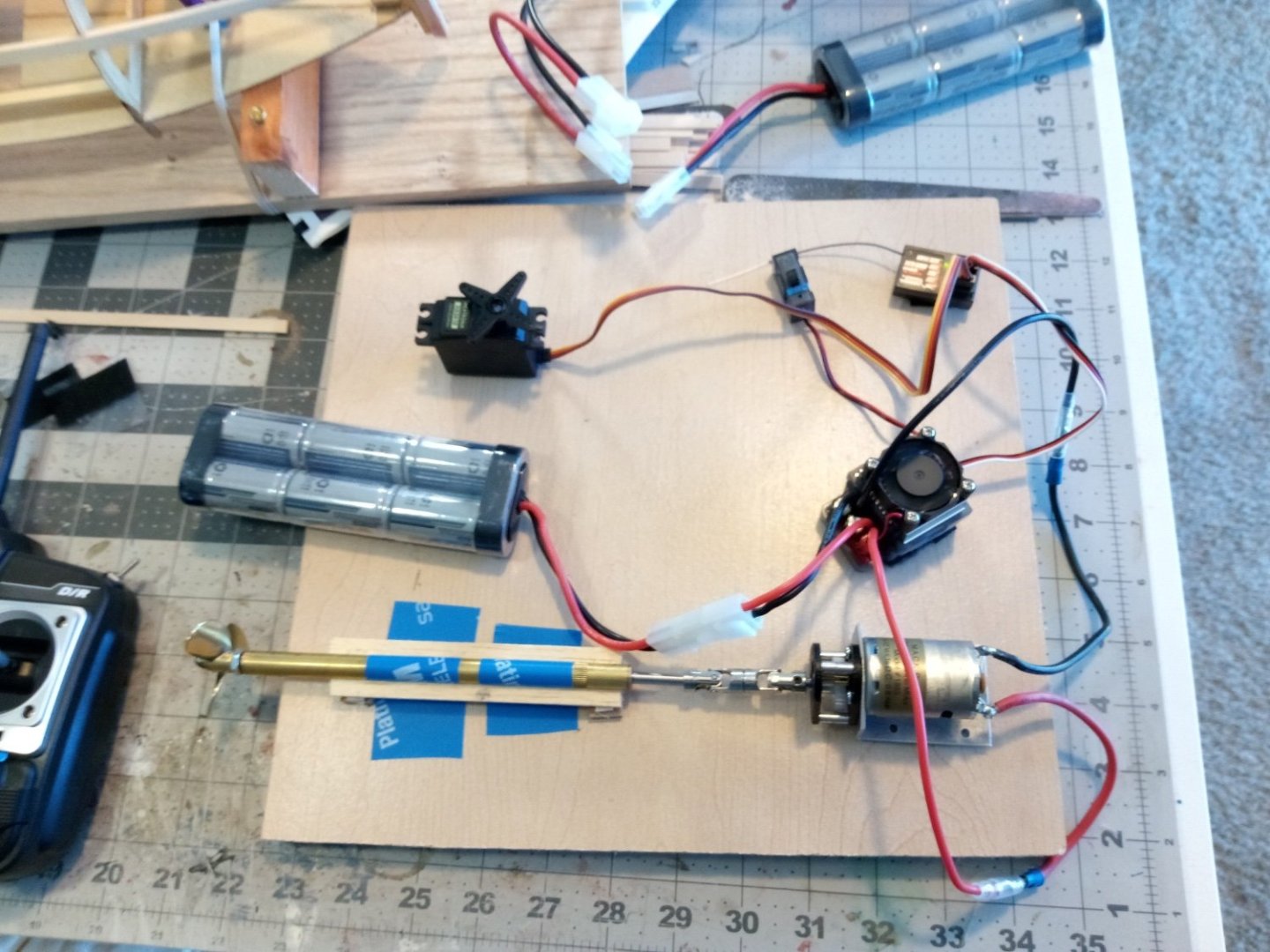

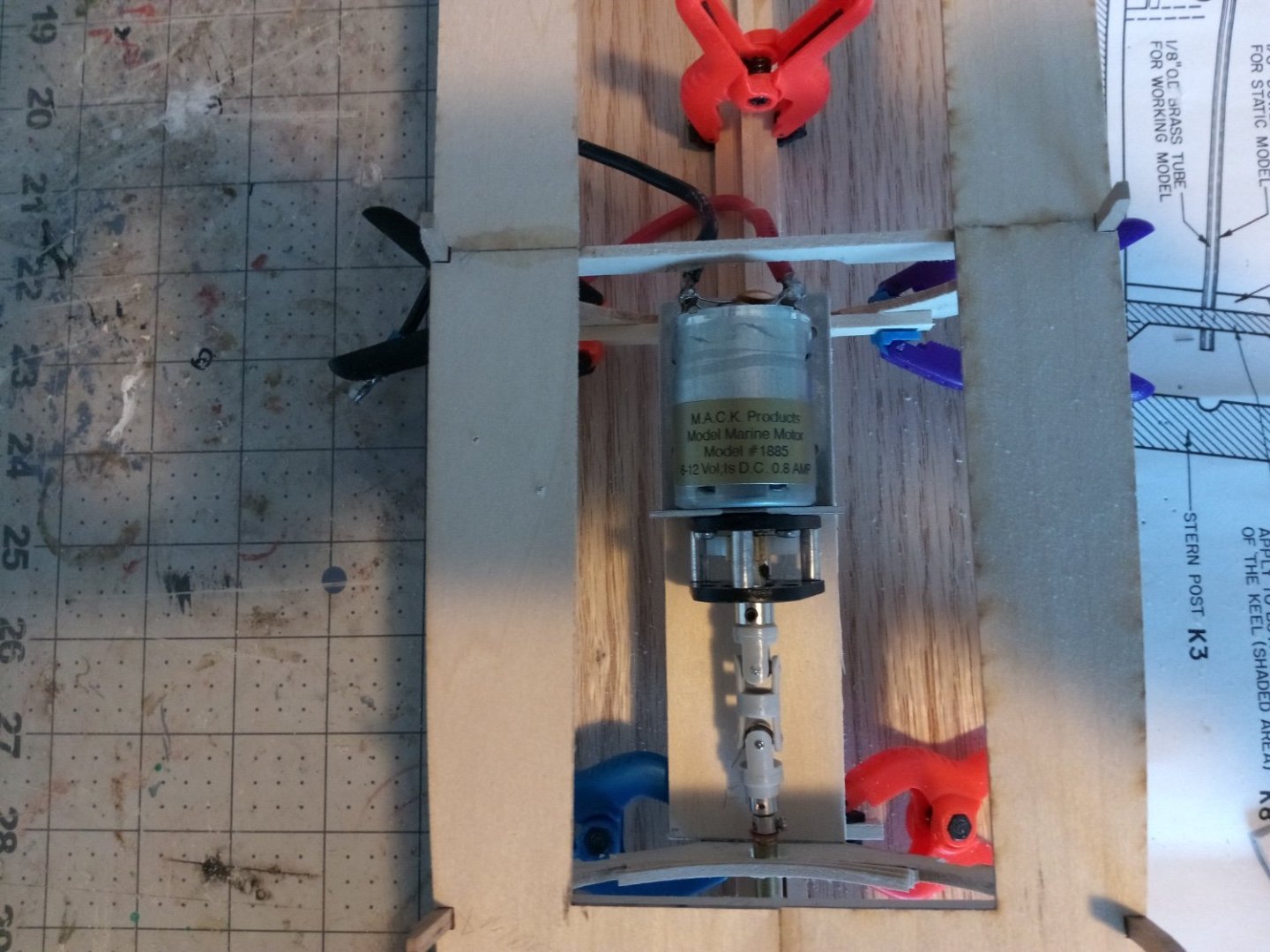

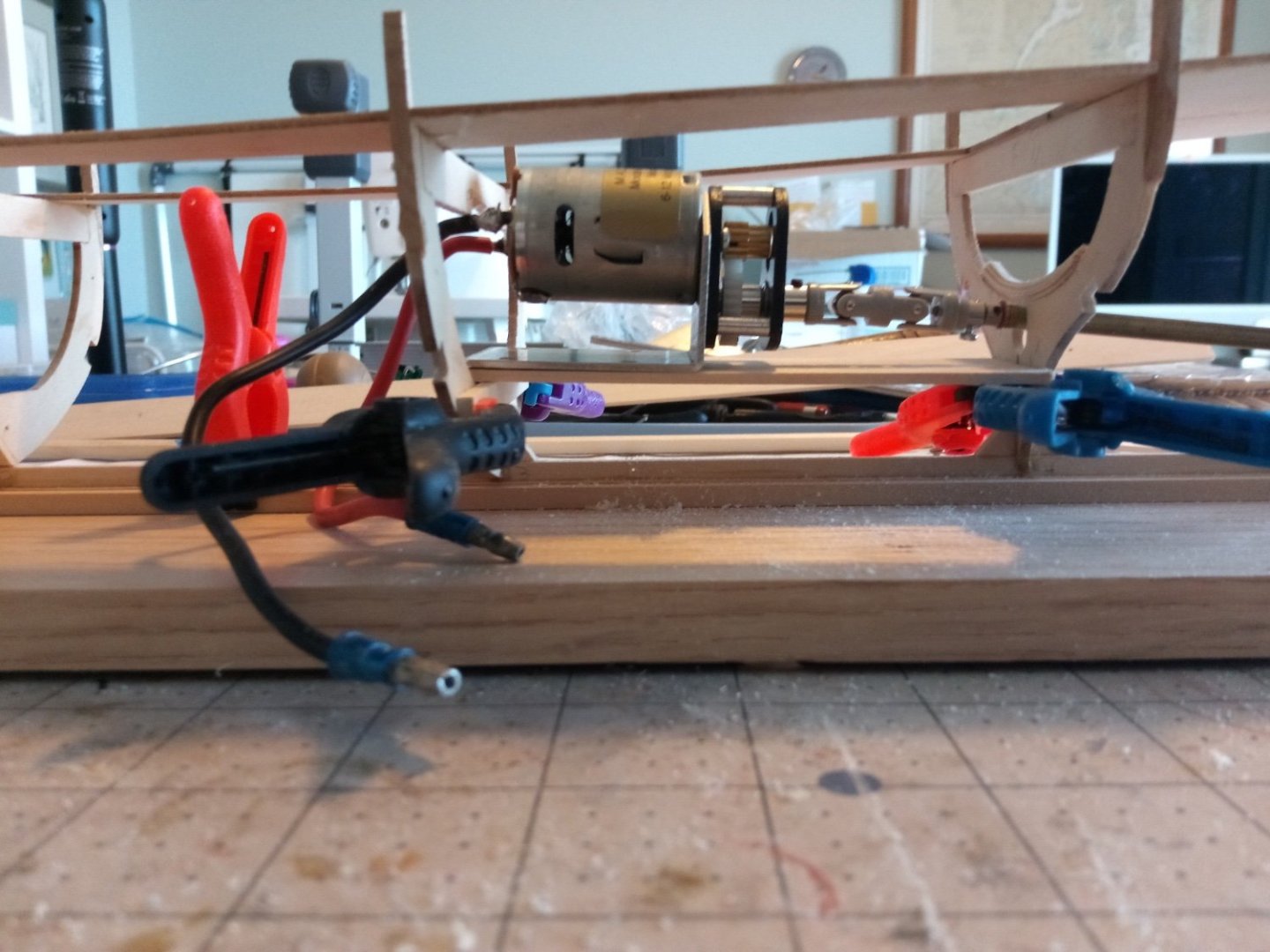

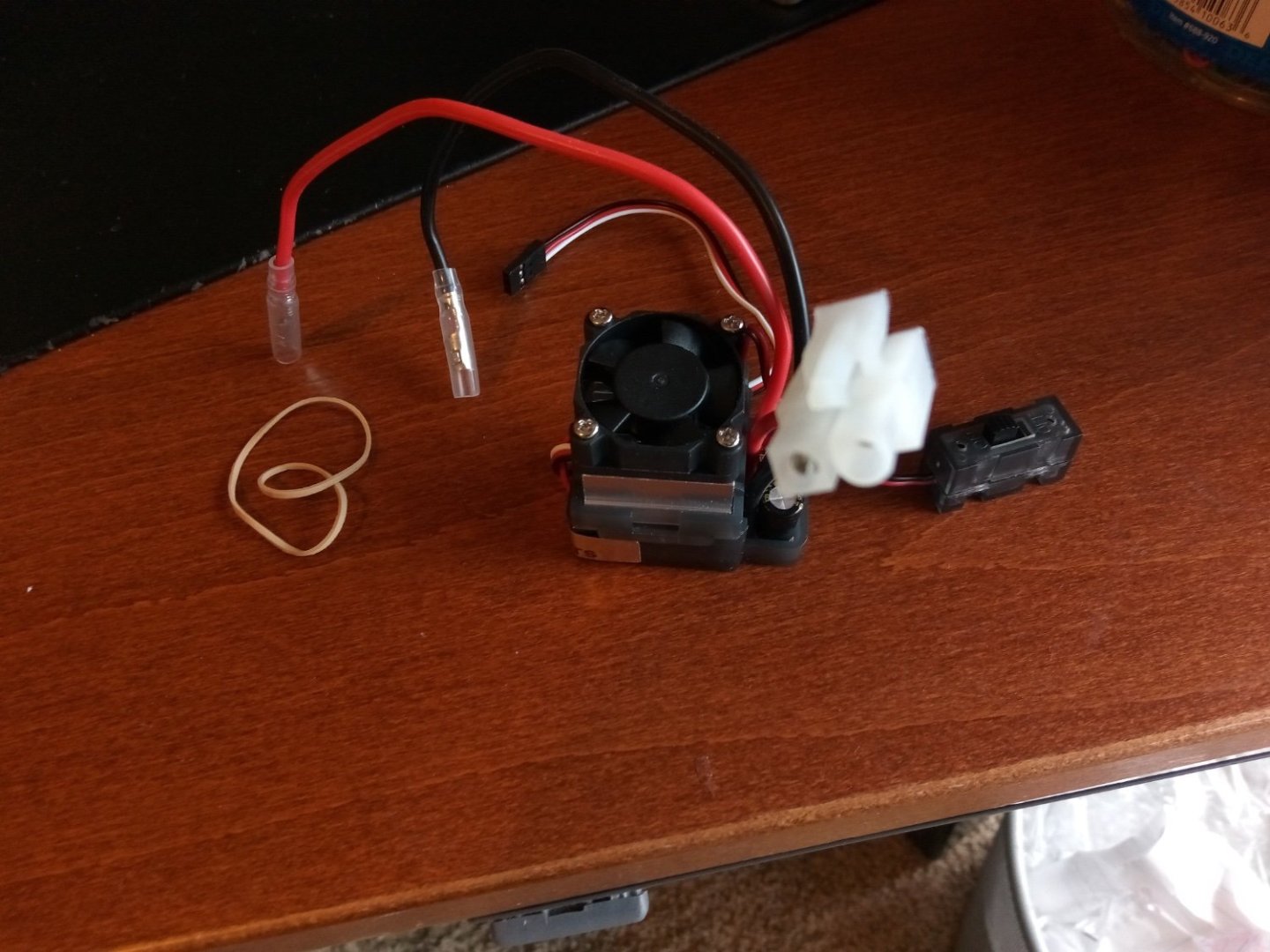

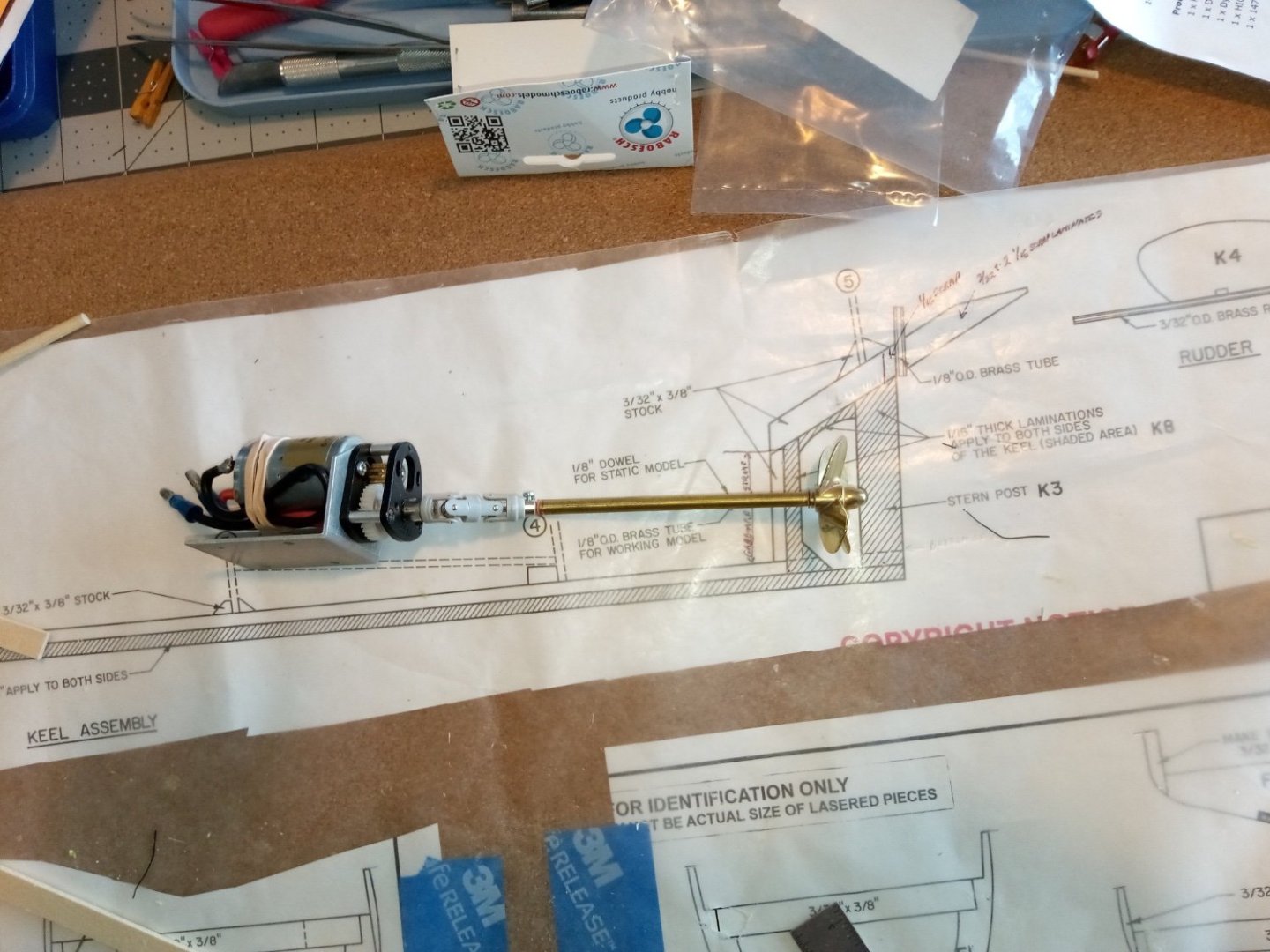

7. RC Test Run While waiting for the wood sealer and epoxy to be delivered I took the opportunity to figure out how all the RC stuff connects together and to give it an op test. Back in Post #2 I listed all the RC items I had ordered for this build. At that time I called the Electronic Speed Control (ESC) the “receiver” - that was incorrect. While examining the box that the control box arrived in I discovered a small item with 5 ports for cable connections and a short antenna - that is what is known as “the receiver, and important part of the RC rig. Here are all the parts hooked up, except for the batteries. Note that the shaft/stuffing tube shown here is the too-large one I originally ordered, the newer, smaller one is already installed in the hull: Here is everything with the addition of the batteries (1 of 2 shown): For the sake of anyone who buys the same RC stuff I did I’ll explain how the receiver is hooked up, hopefully saving you a lot of online research and trial and error. First of all this particular receiver is designed for RC aircraft so it has more slots than a boat will need The male connectors leading from the ESC and the Rudder Servo are not “keyed” i.e. they can fit into the receiver slots the right way, or the wrong way. All connectors like this have a black or brown wire, that is the negative or ground wire, and the connector must be inserted so that the ground wire is AWAY from the printed part of the receiver, i.e. near the edge. The ESC connector goes into the slot labeled “throttle” The Rudder Servo connector goes into bottom slot labeled “AIL” (for airlion), that will allow the rudder to return to the amidships position when the control toggle on the control box is released (otherwise you would never be sure where the rudder is and would have to make constant corrections). After connecting everything up, and charging the batteries I turned on the control box and then the on/off switch that will be on the model. After the ESC beeped for about 5 seconds (referred to as "pairing") I had throttle control of the shaft (fore and aft) and control of the rudder. The only issue was that when moving the throttle toggle in the forward direction on the control box the shaft went in the reverse direction (for a left hand prop like I have) but the control box has a reverse switch for each function that easily fixed that.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Glad to have you along Denis. If you have not been there already it might be an enjoyable trip over to Searsport, ME to see the BlueJacket display lobby of their finished models. Their Lackawanna is another attractive steam tug kit they sell, or if you decide to go the scratch build route you could get the plans (note: The Sequin kit does not have hulll form or lifts on the plans since it is a plank on bulkhead). Tim

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

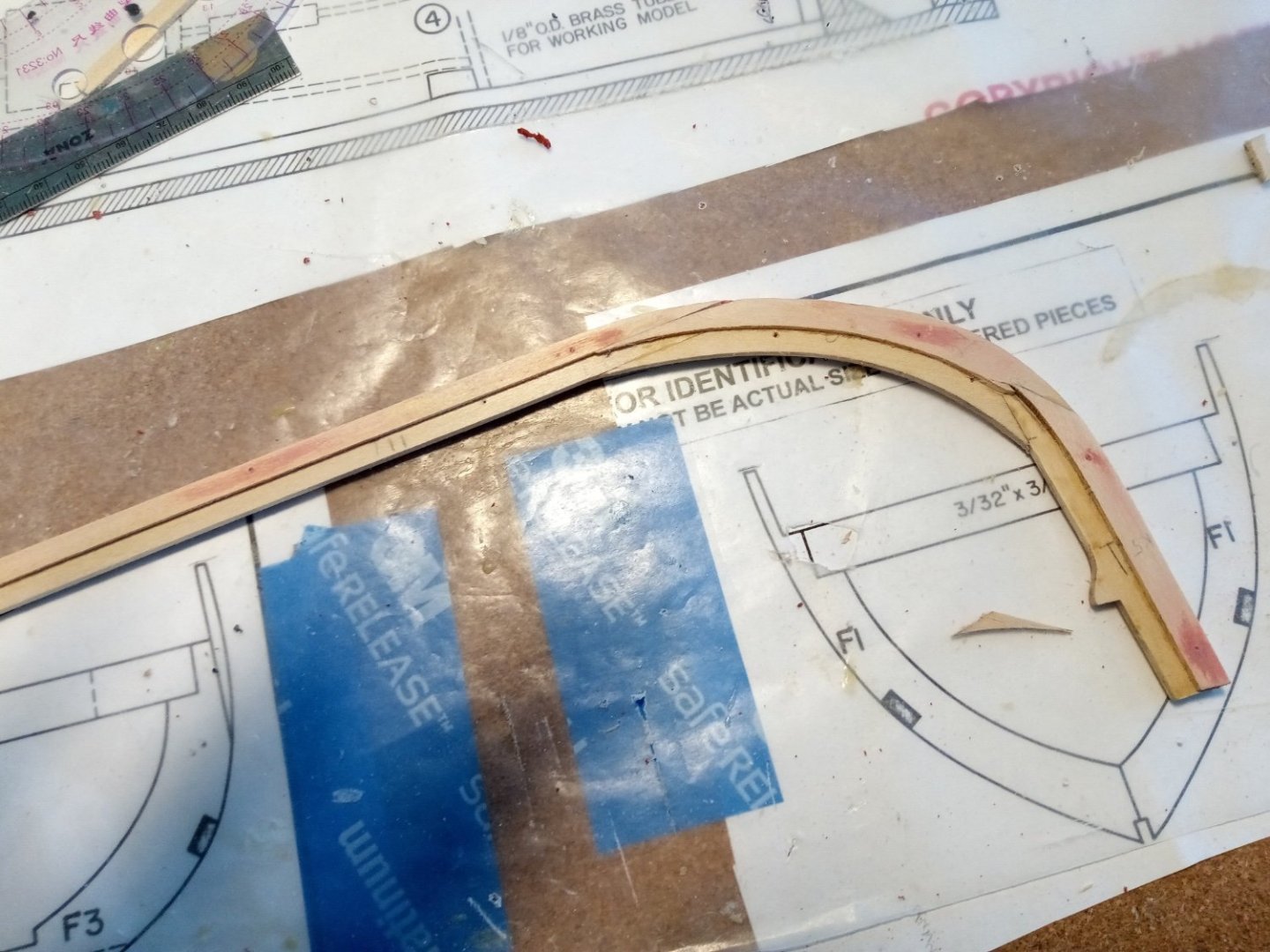

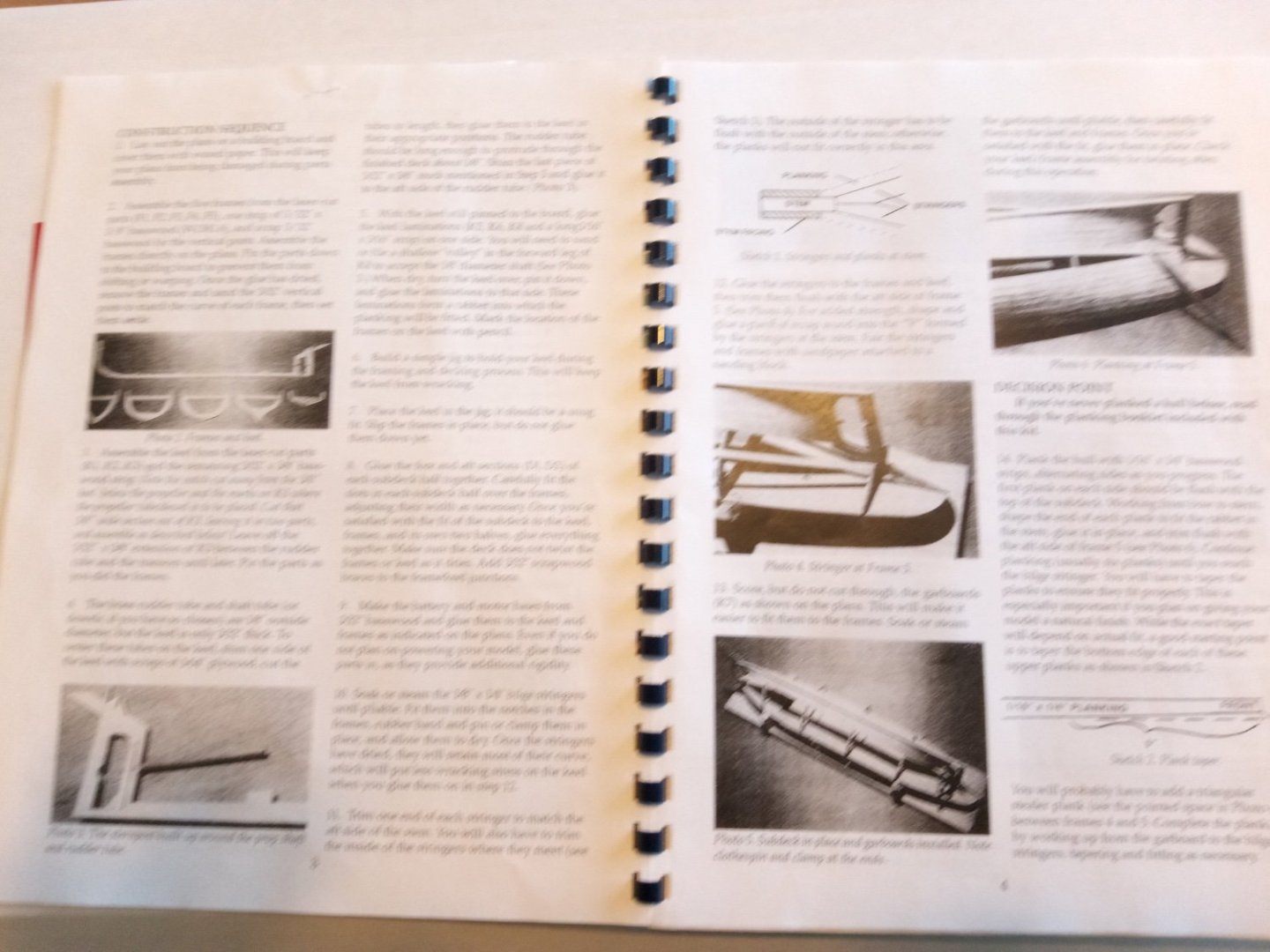

6. Bilge stringers and garboard planks The bilge stringers are 24” long which is an awkward size for soaking them so they will bend and twist to the shape of the hull. Fortunately one of the previous build logs had a good idea to handle this. You get a piece of 2” diameter PVC pipe and 2 end caps from your hardware store. You need the 2” diameter to handle the wide aft end of the garboard planks. Cut the PVC to 24” long and expoxy one of the end caps on: I added about 1/4 cup of ammonia to the tube, filled it with boiling water, dropped in both bilge stringers, put the other cap on and let it soak (in the vertical position) for about 10-15 minutes. The stringers were then clamped in place on the hull. The stringers would not fit fully into all the frame slots due to swelling so I clamped them as close as possible. I let everything sit overnight and when I unclamped them they had retained their curves and twists and the swelling had gone down: Before glueing them in place you have to trim the forward ends so that they sit up against the aft end of the stem but fully behind it so they do not get in the way of the planking which will lay on top of them (the instruction book has a good drawing showing this). Avoid taking off anymore length than necessary- there is only about 1/2” to spare. The instructions also recommend putting some scrap wood in the “V” between the stringers at the bow for better strength: The aft ends of the stringers were cut flush with the aft face of frame 5 and they and and the frames were then faired using a planking strip as a batten to ensure the planks would lay properly. RC After glueing them in place they, like almost all the rest of the wood inside the hull, got a coating of polyurethane. The garboard planks are provided as laser cut wood. RC I had to trim and file the stern post area that I had built up to accommodate the shaft and stuffing tube. I basically tapered the lower area under the garboard so that it’s bottom edge could fit into the keel rabbet. For those who do not modify their stern post this will not be an issue. The instructions recommend scoring the backsides to help them bend but 2 of the build logs reported problems from the wood splitting so I did not score mine - one of them split anyway but it’s an easy fix. Soaking for 15 minutes in boiling water and some ammonia and then leaving them clamped in place overnight worked well for these - they retained their complex bends and curves very well. The planks needed a little trimming at the bow and the lower aft corner to fit better but the design of the rabbets along the keel held them in place so well that little in the way of clamping was needed during the gluing. A little wood filler fixed the crack and the gaps near the bow (I could have trimmed the planks to eliminate the bow gaps but that would have broken the fair run of the top of the planks, making for a difficult area for the follow-on planks). RC I’m going to have to seal and epoxy the inside of the garboard planks and the interior areas of the keel before I add any of the hull planks or I won’t be able to reach in there. I’ll post about the sealer and epoxy I’m going to use when they get here from FEDEX.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Thanks Keith, glad to have you aboard. I remember spending some enjoyable hours looking through your Chris Craft build log and being amazed at the instrument gages! I live on a lake and someone here has the real life version of your model - its always great to see them out and about, adds a touch of class among all the jet skis and pontoon boats.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

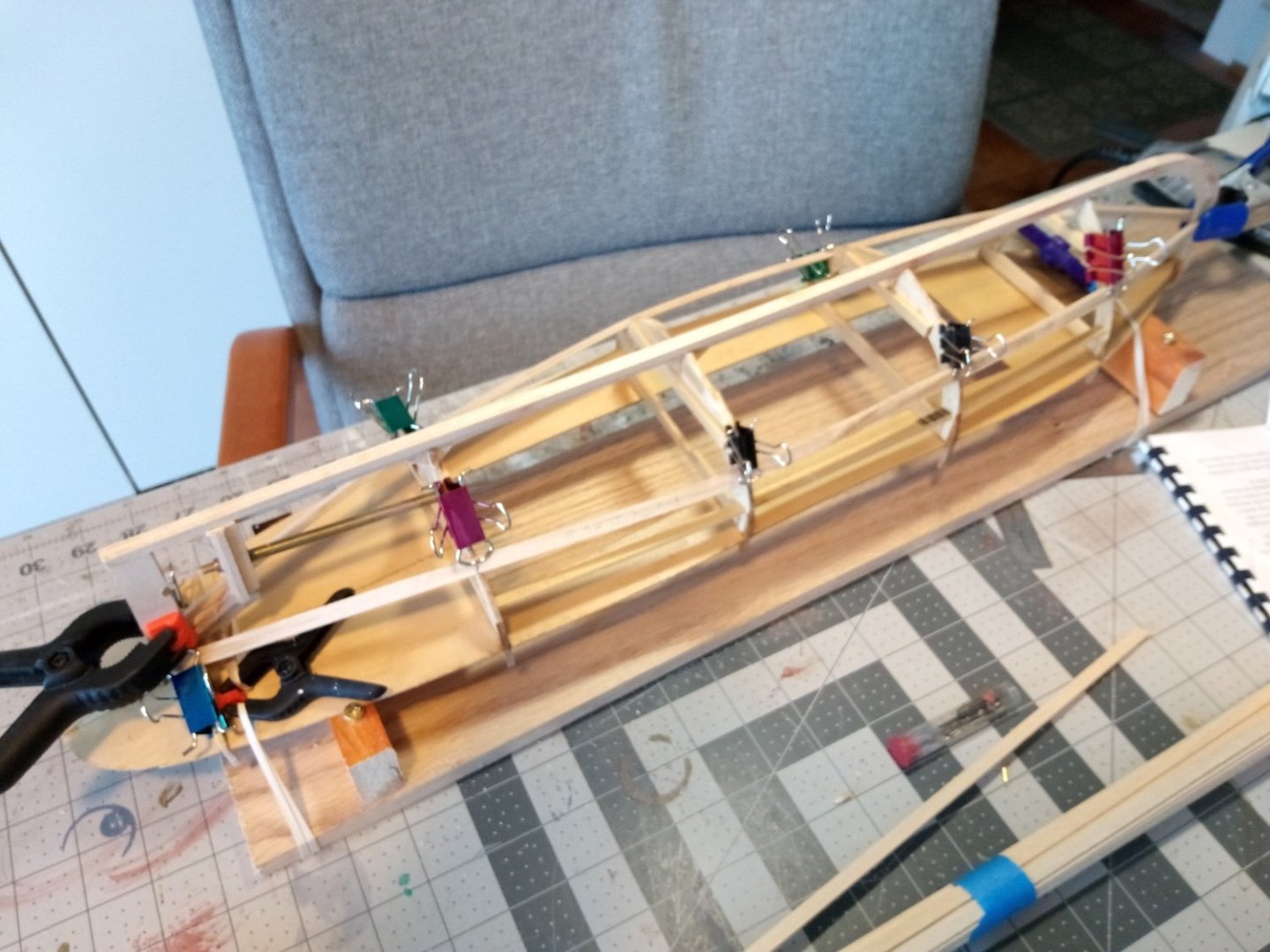

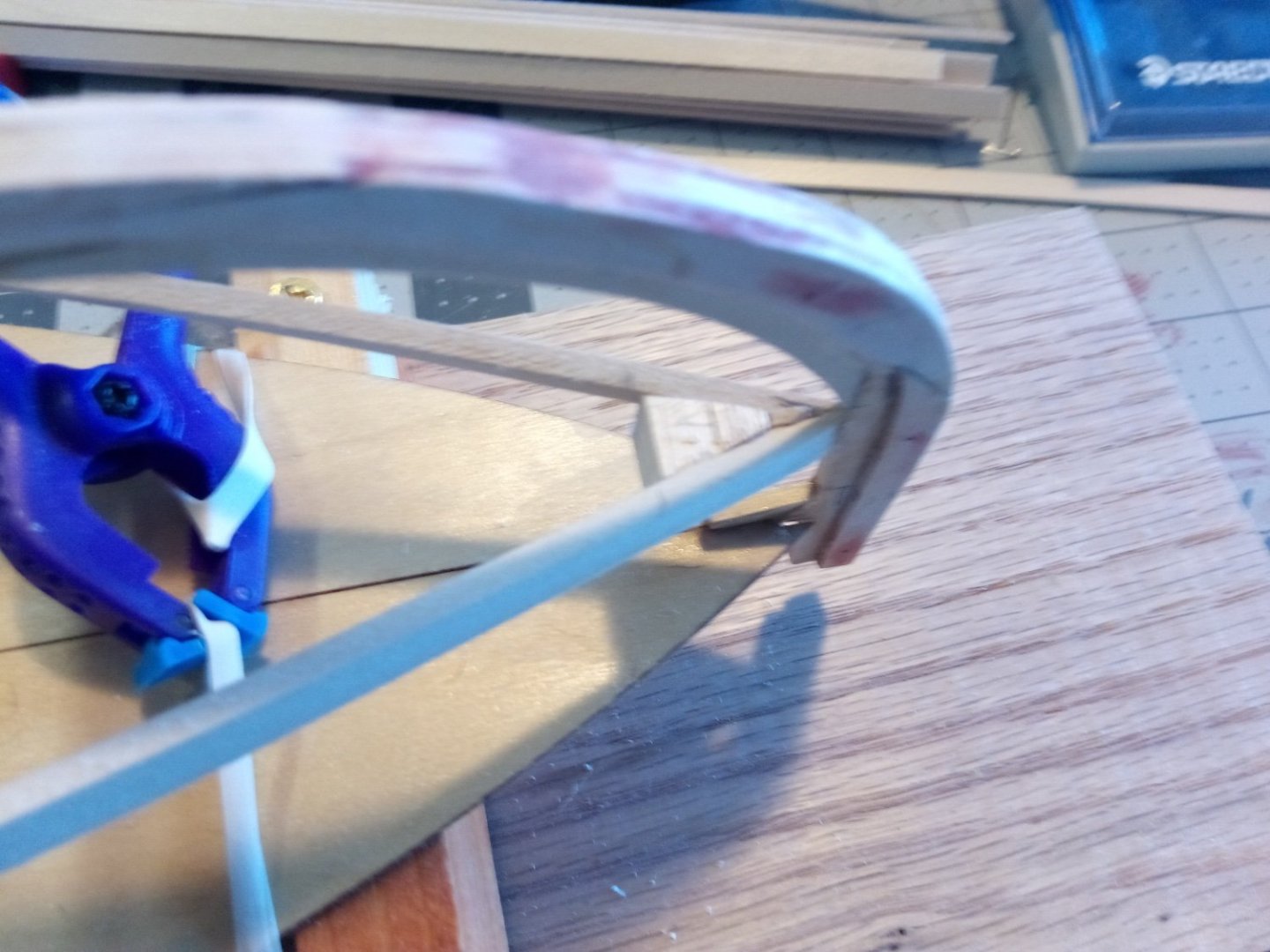

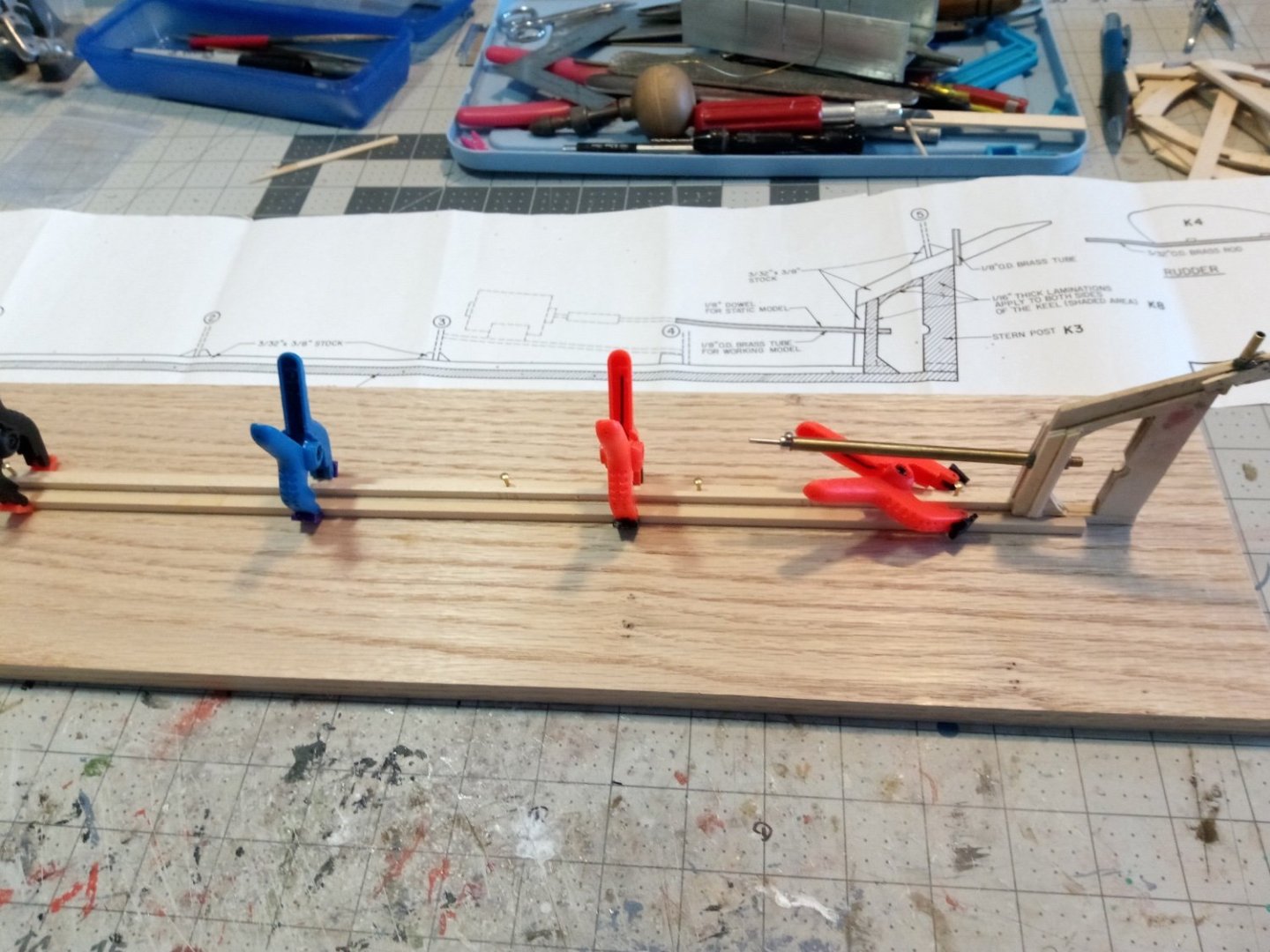

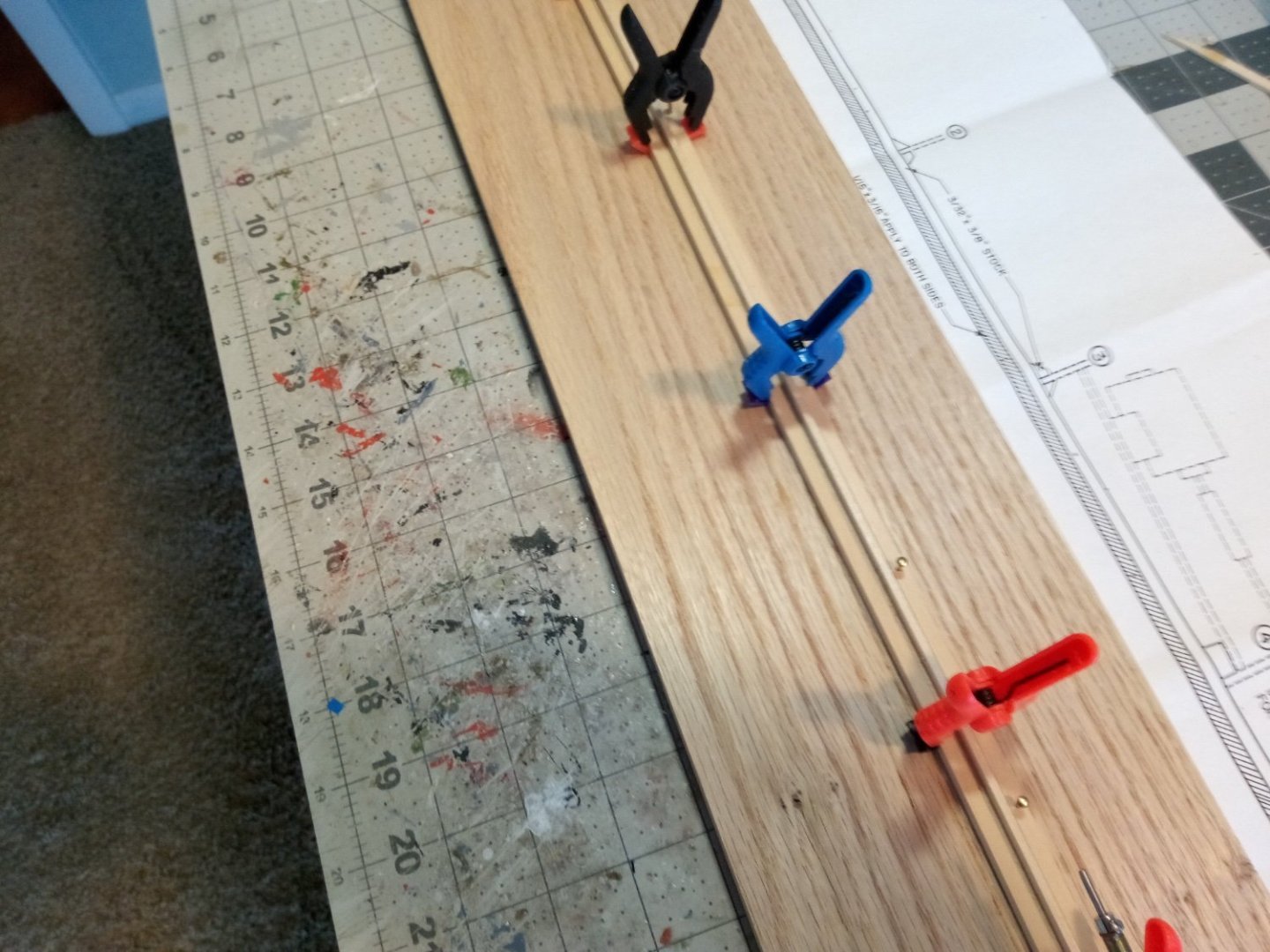

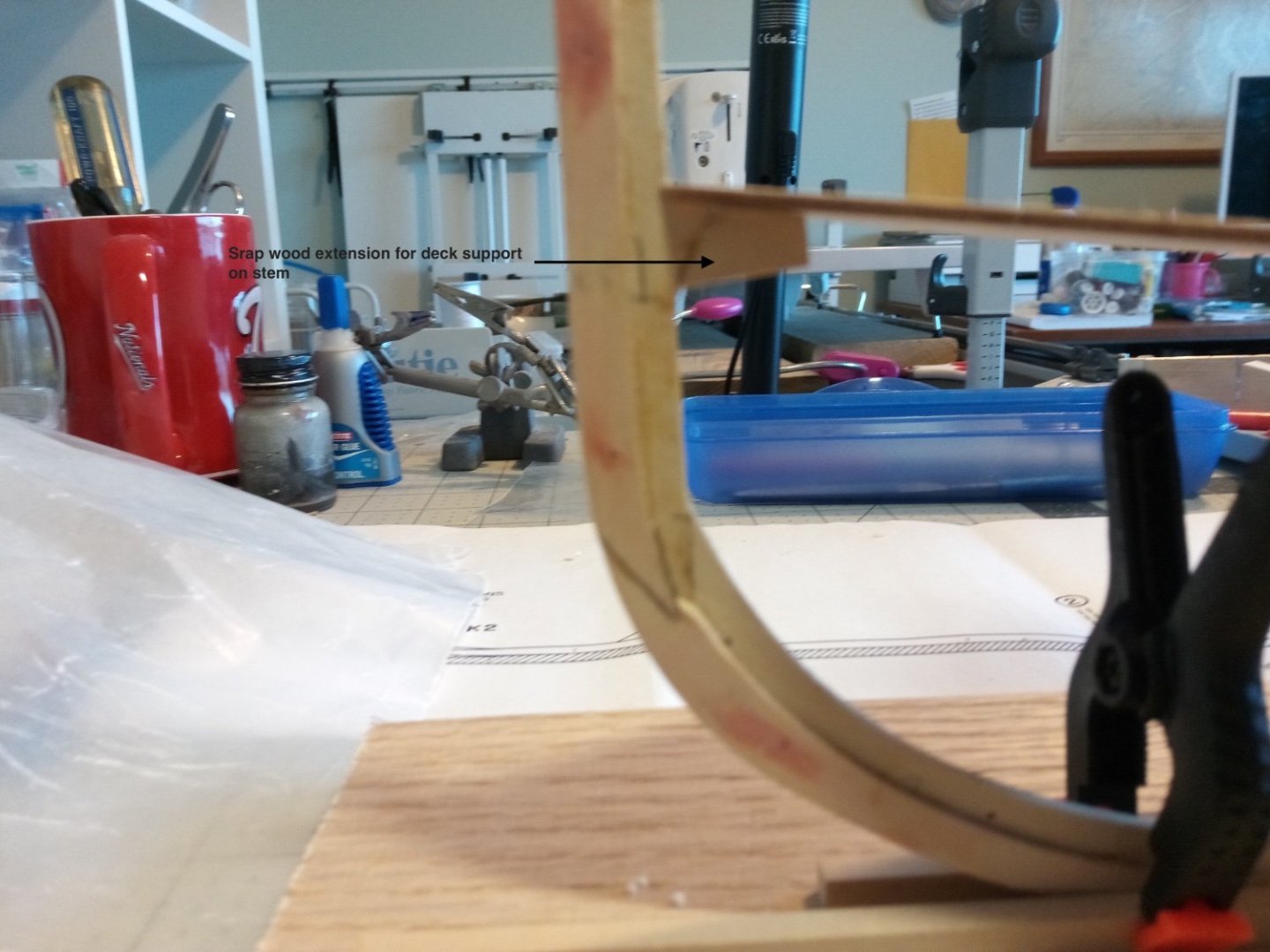

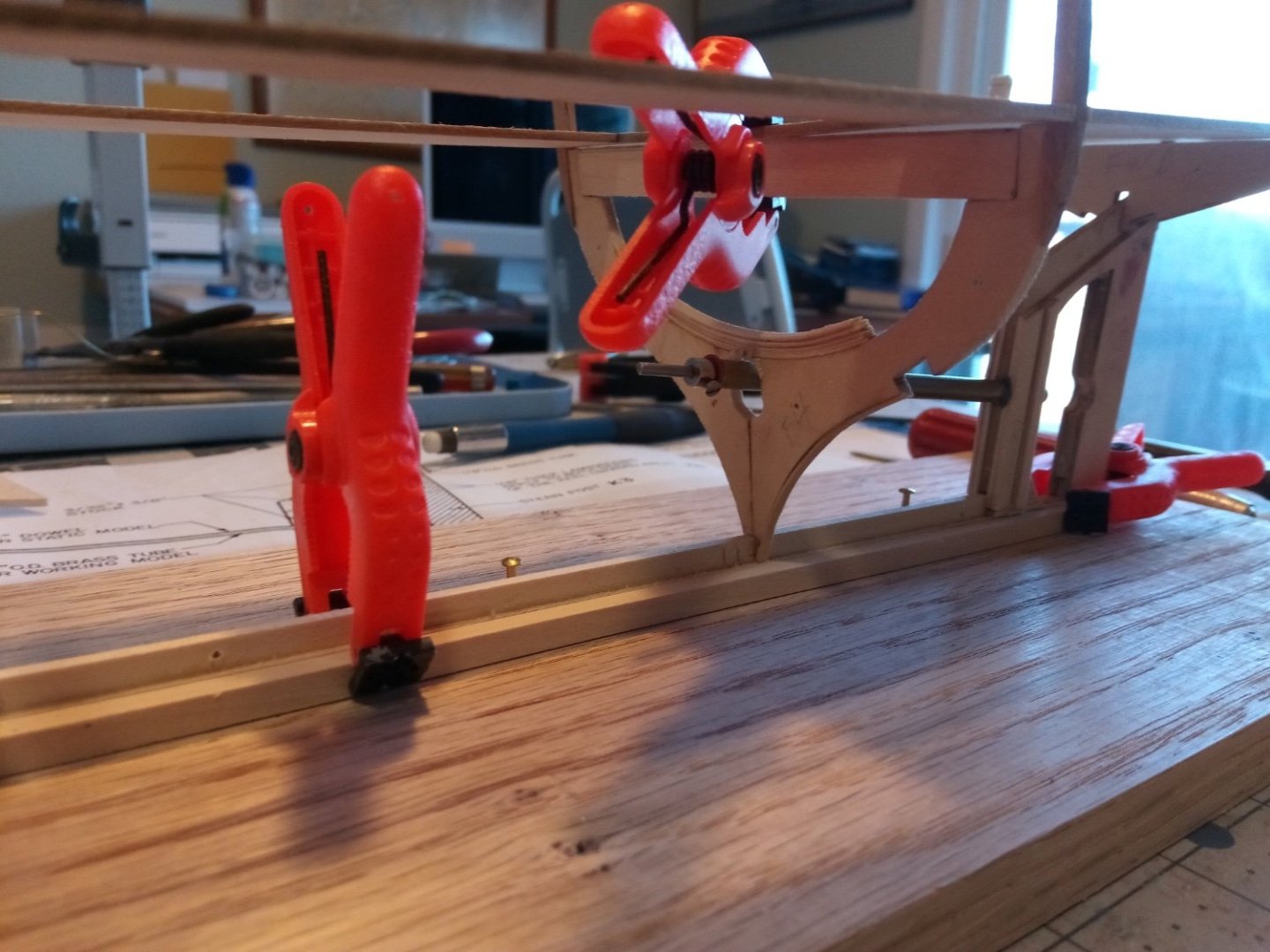

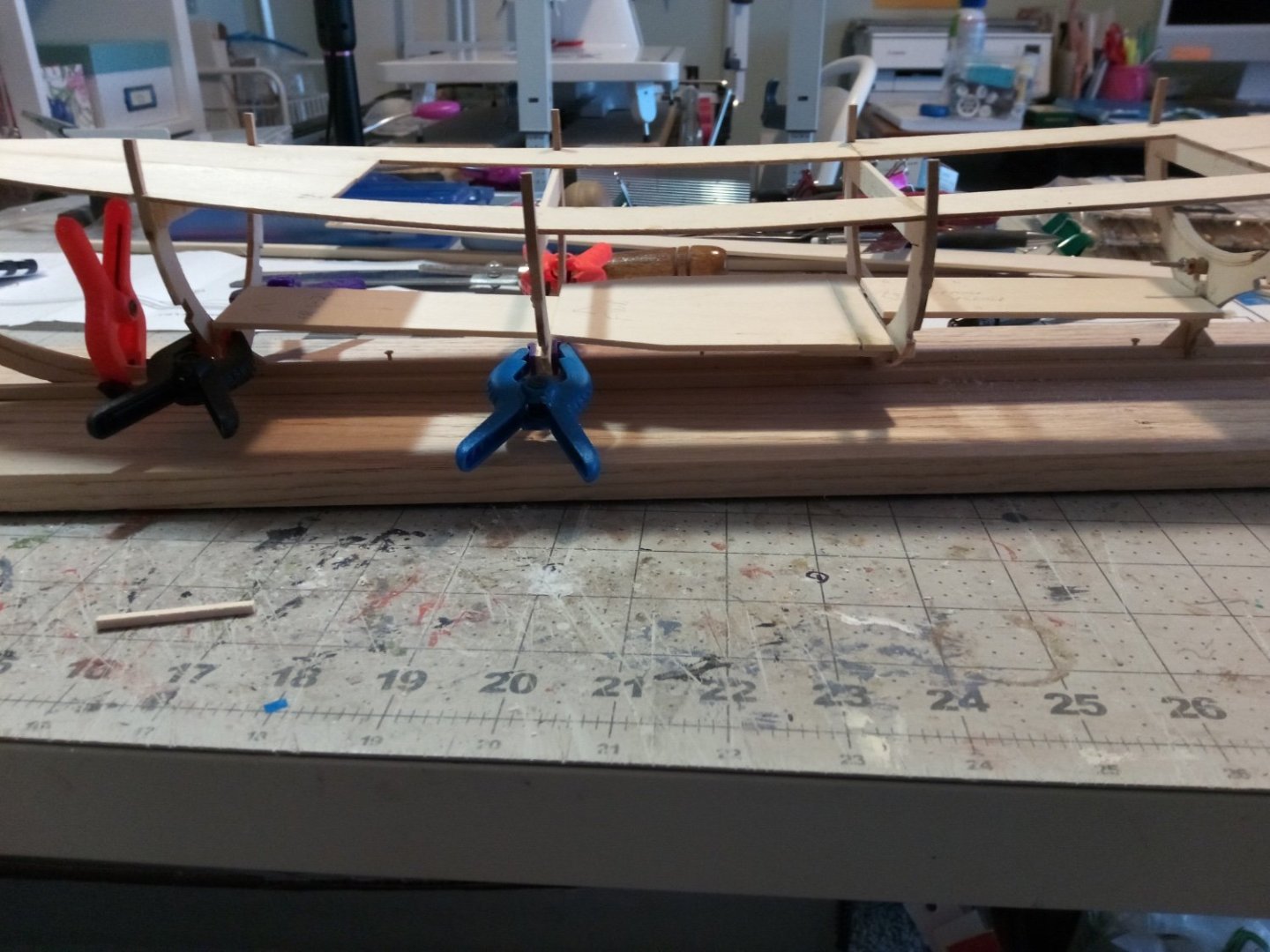

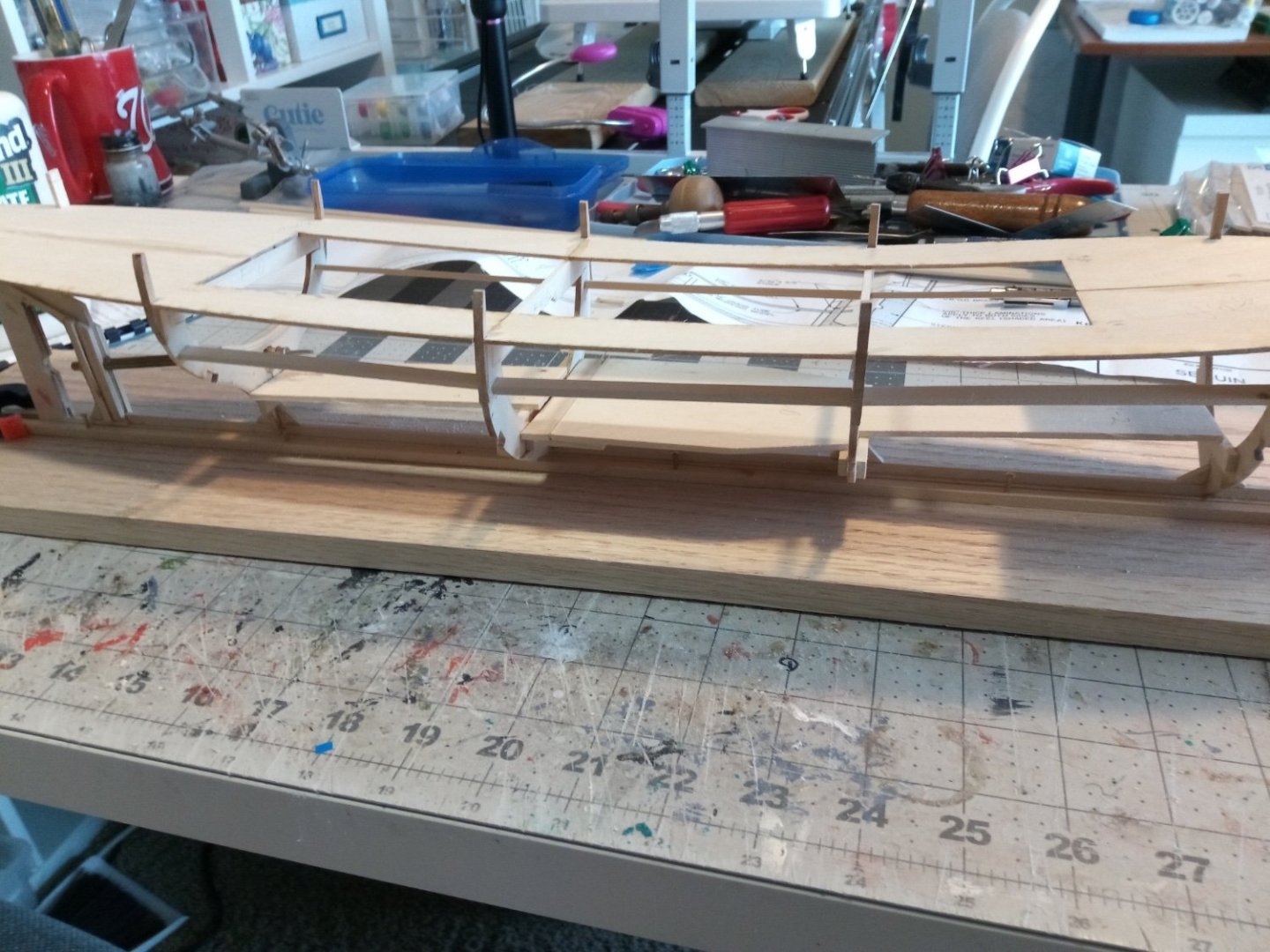

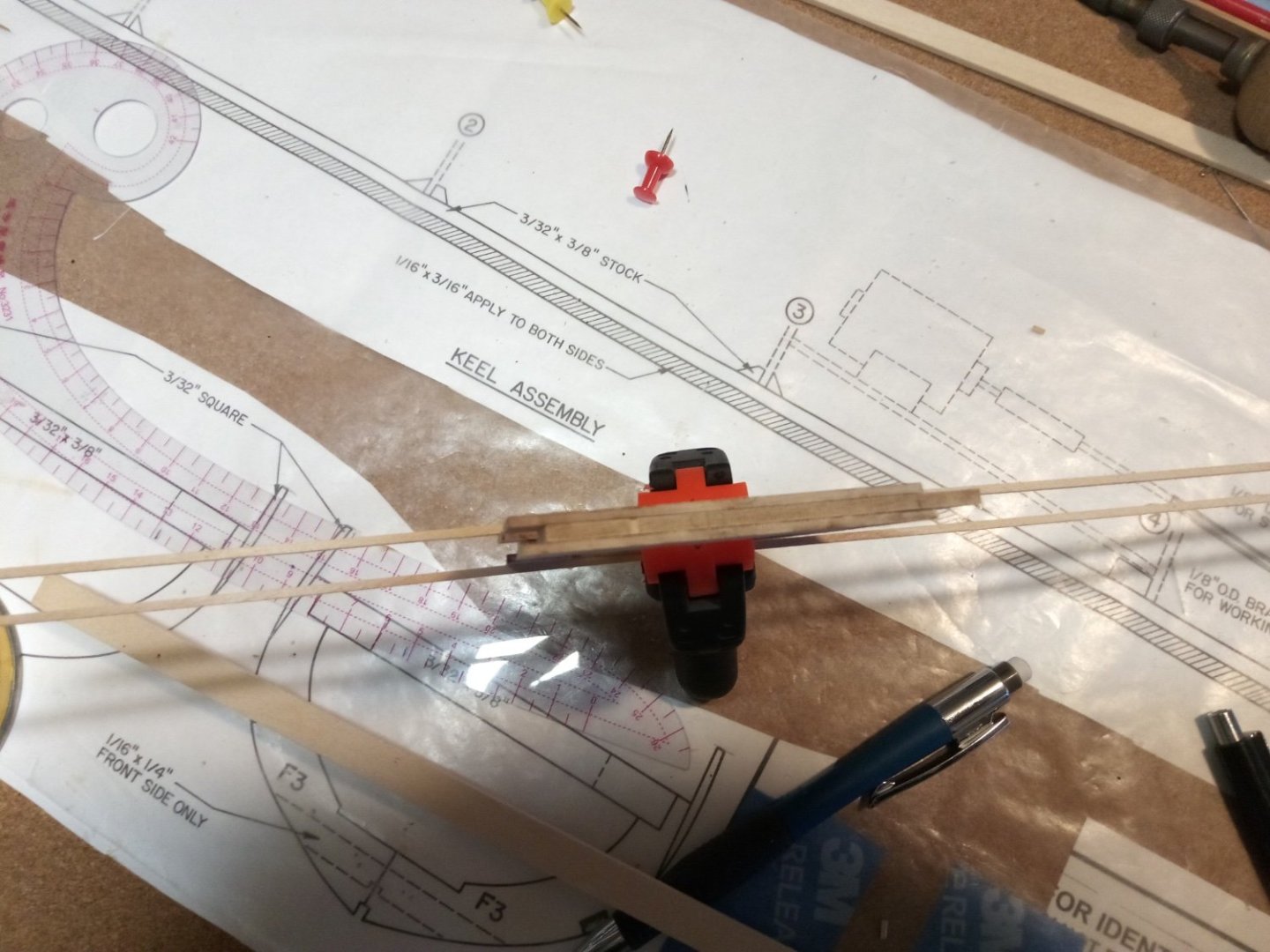

5. Assembling Keel, Frames & Deck I was pretty leery about this next step since the instructions call for dry fitting the keel, frames and deck pieces and then gluing them together. A photo on one of the SEGUIN build logs shows this step as needing a real rat’s nest of clamps, string and rubber bands to hold it all together. It actually turned out to be fairly easy because the plans are quite accurate - the slots in the deck pieces aligned perfectly with the frame extensions and the 1/8” hole in the after part of the deck pieces was right on top of the rudder post. First step was to make a build board that could hold the keel. Since the bottom of the keel is only 3/16” high there is not a lot of “meat” to grab onto so I used and idea from one of the build logs and nailed a piece of 3/16” square stock to the board and then clamped another piece on the other side of the keel. It’s pretty secure. I couldn’t get everything to fit on the first attempt so I worked my way from forward to aft, expanding a couple of the slots on the deck to better accept the frame extensions. My only problem is that my keel ended up being 1/8” longer than it should be so I had to add a scrap wood extension on the “shelf” on the aft end of the stem where the deck should rest. Here is everything dry fitted together: I had to further enlarge the hole in Frame 4 for the shaft. Since I had to enlarge it upwards I had to add some wood to the cutout area above it: I glued up the bow and frame#1 first. When that was dry I did each frame in turn. It went pretty well but when using one of the laser cut deckhouse sides to check the curve of the deck I found there was a problem. The stem was tilted slightly to one side because frame #1 was not level. After soaking the affected joints with water I was able to remove the Titebond III glue and redo the glueing in the bow area. This problem could have been avoided if I had some type of clamps to keep the stem and sternposts aligned - something to think about when designing your keel clamp. The next step is to add motor mount and the battery tray. As the instructions point out these should be added even for static display models since they help add some strength and rigidity to the frames. I added the motor mount first using the motor to get the proper alignment: I added the the tray between frames 2 and 3 per the plans and also added another between frames 1 and 2 ( I may or may not need it later for the batteries but it is easier to get it get it set up now). All of these mounts/trays are just dry fitted, I will not glue them in until after the hull is planked because they would block access to the inside of the planking and the keel which I will need to coat with sealer and epoxy. Since the trays will not be placed for a while I decided to add stiffeners between frames 1, 2, 3 and 4 that will hopefully strengthen the hull for the planking work: Now it’s time to remove the hull from the building board and invert it for the addition of the bilge stringers and the planking.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

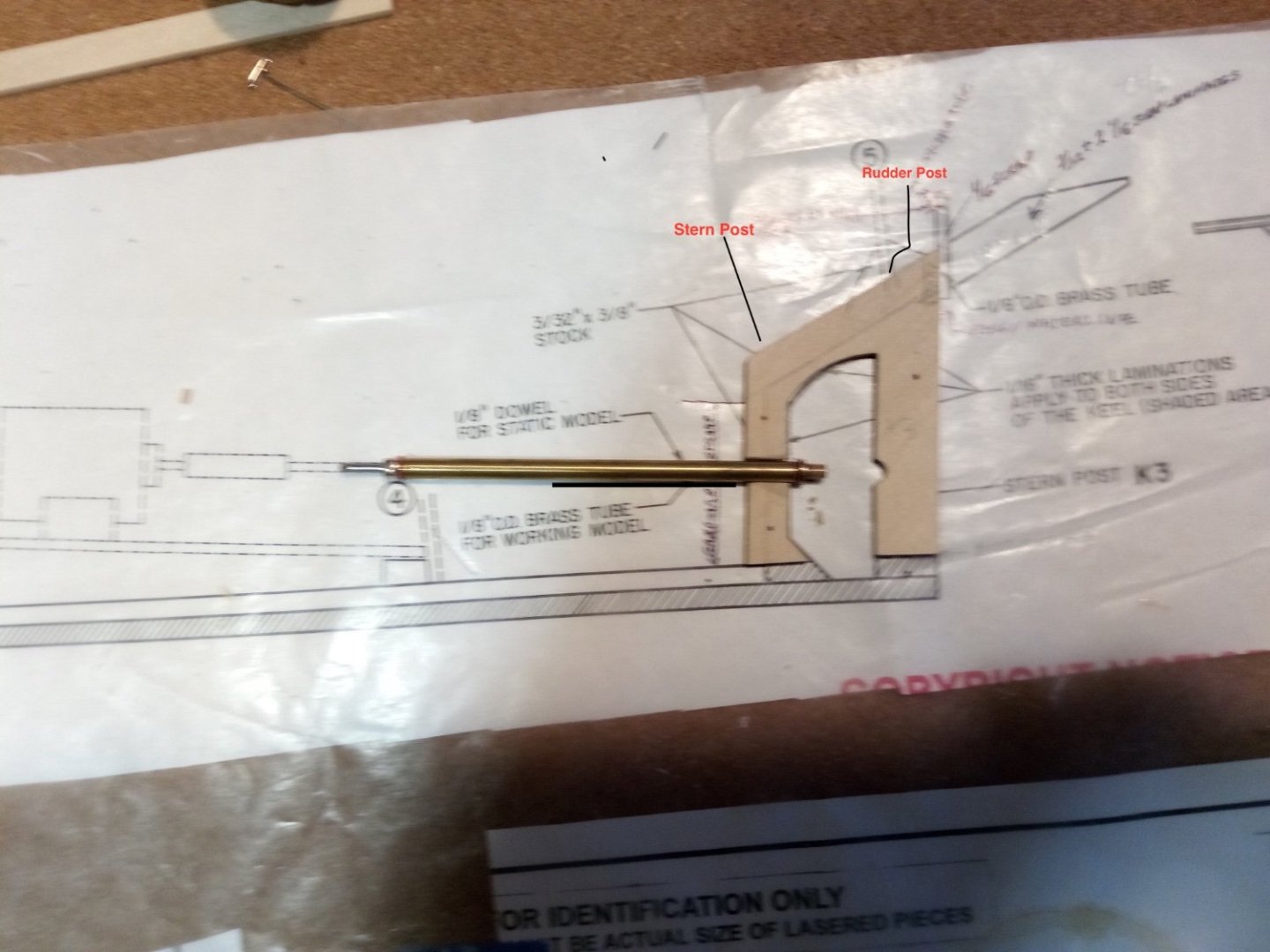

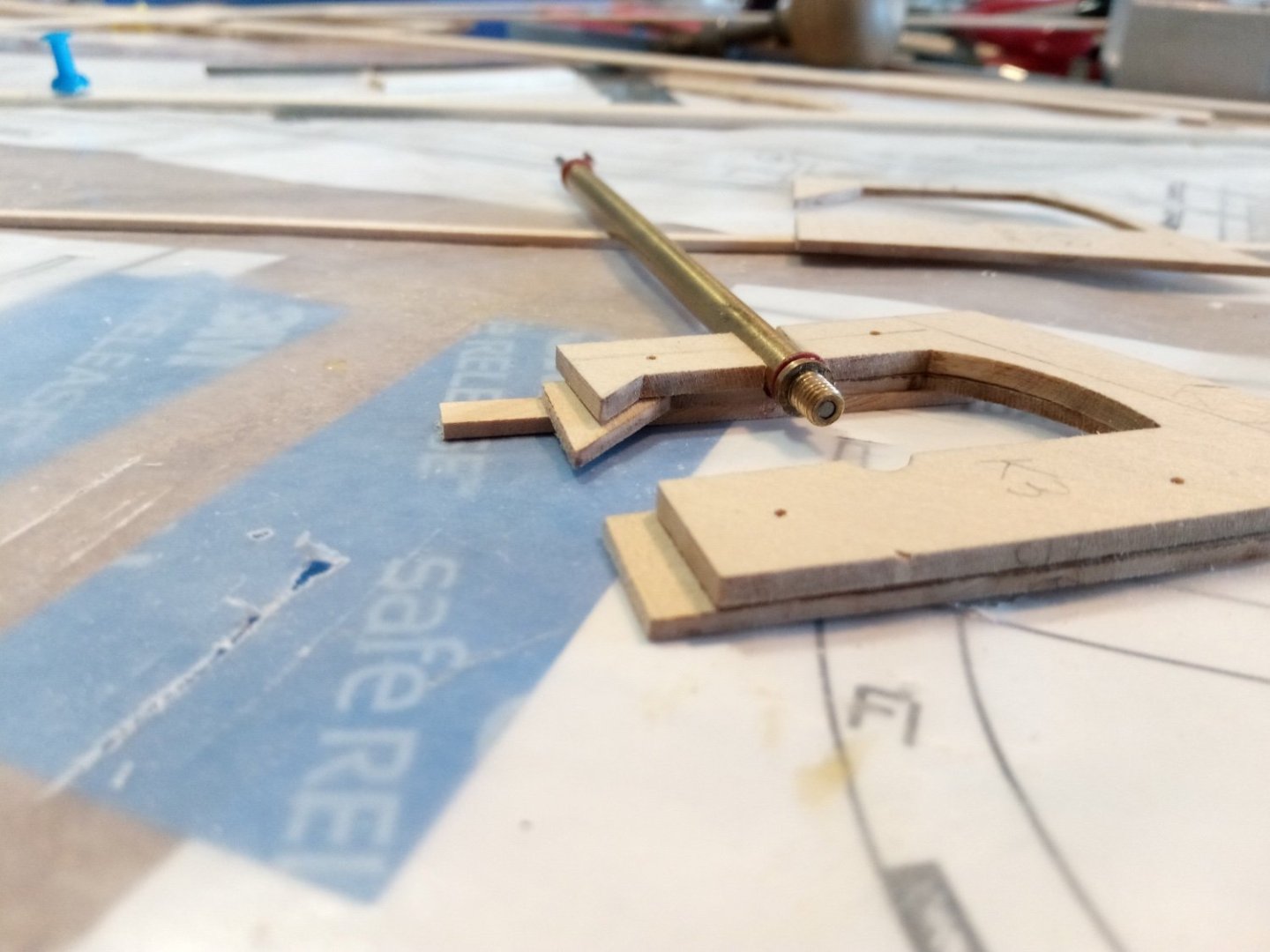

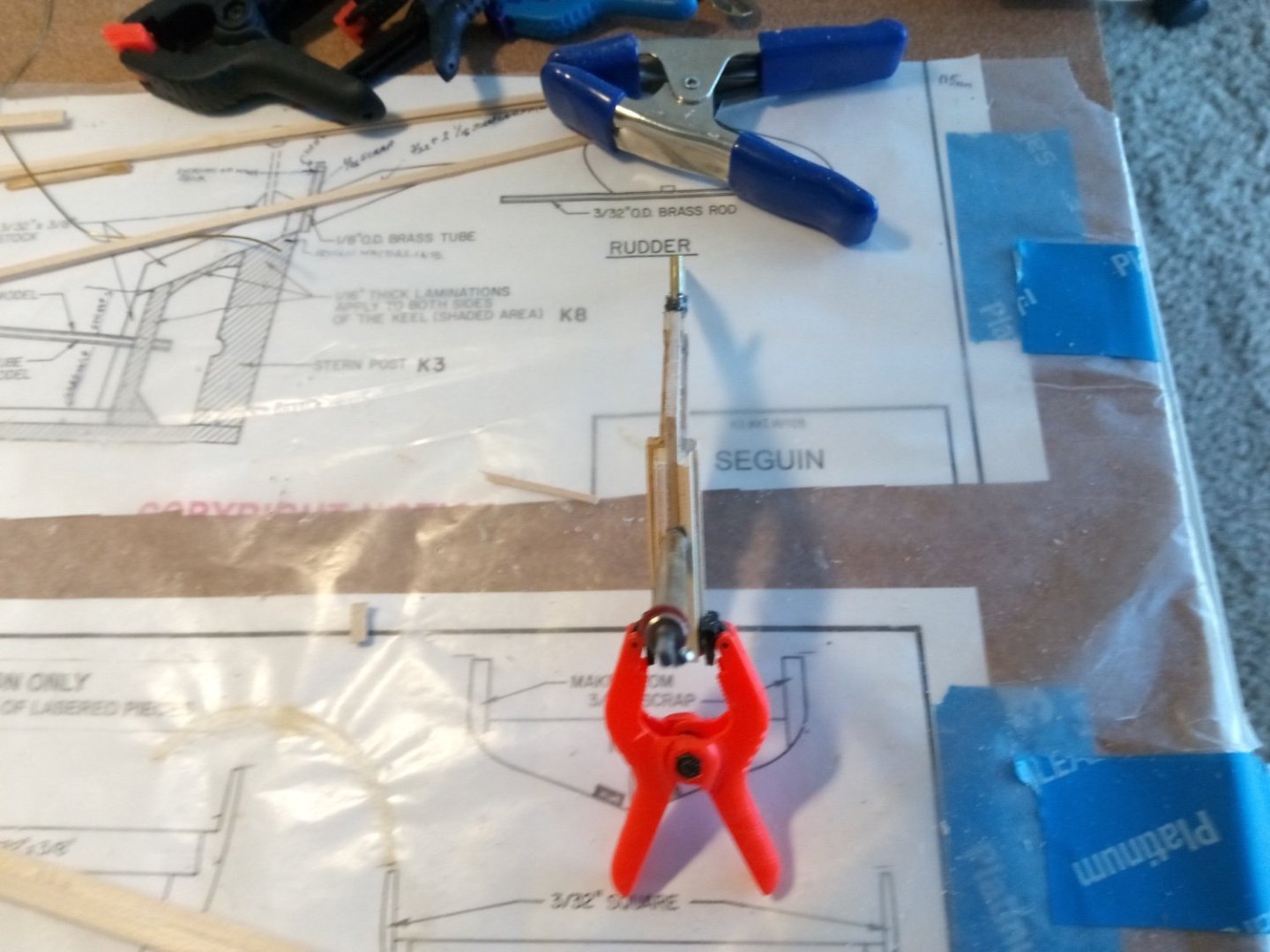

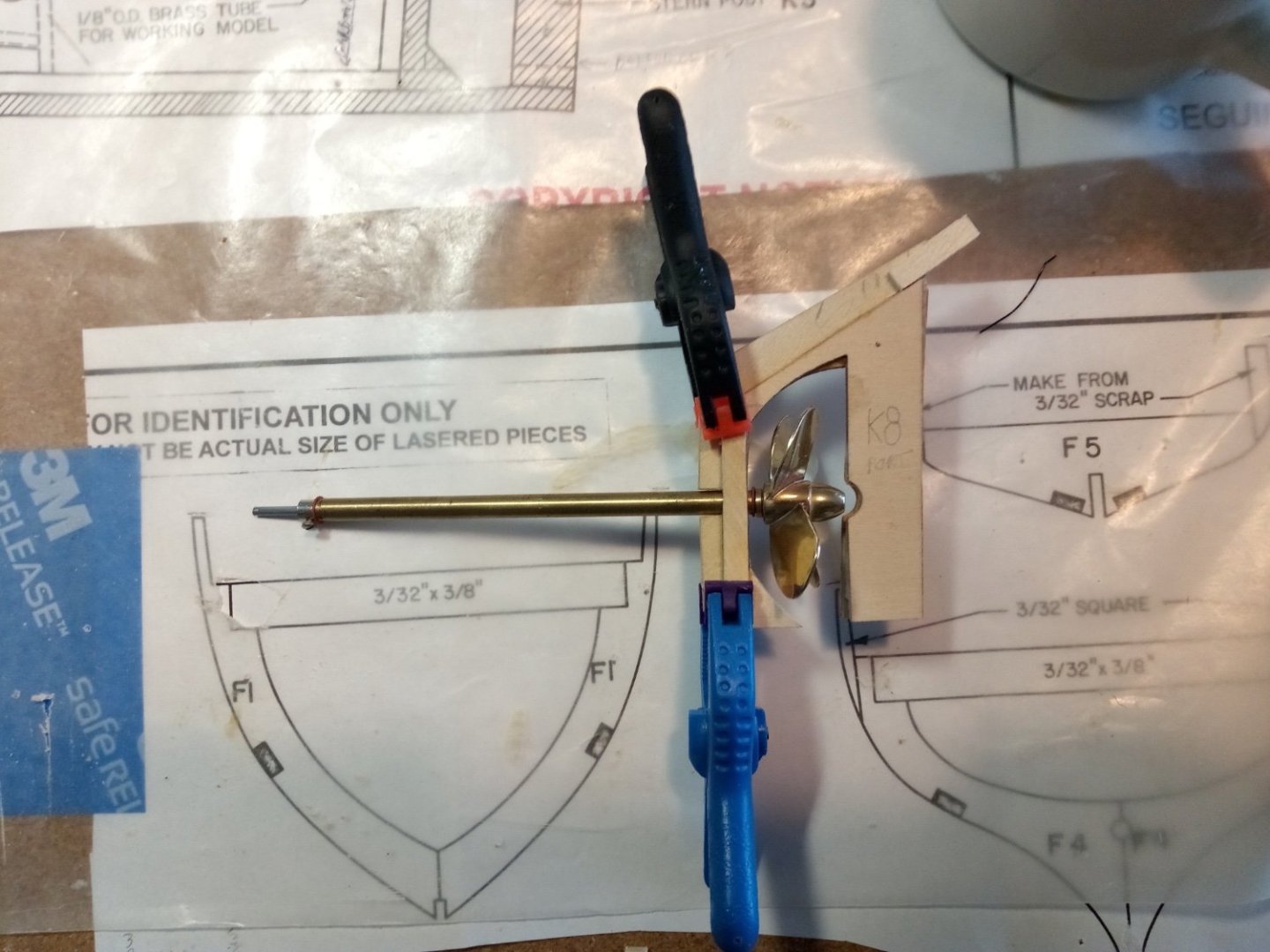

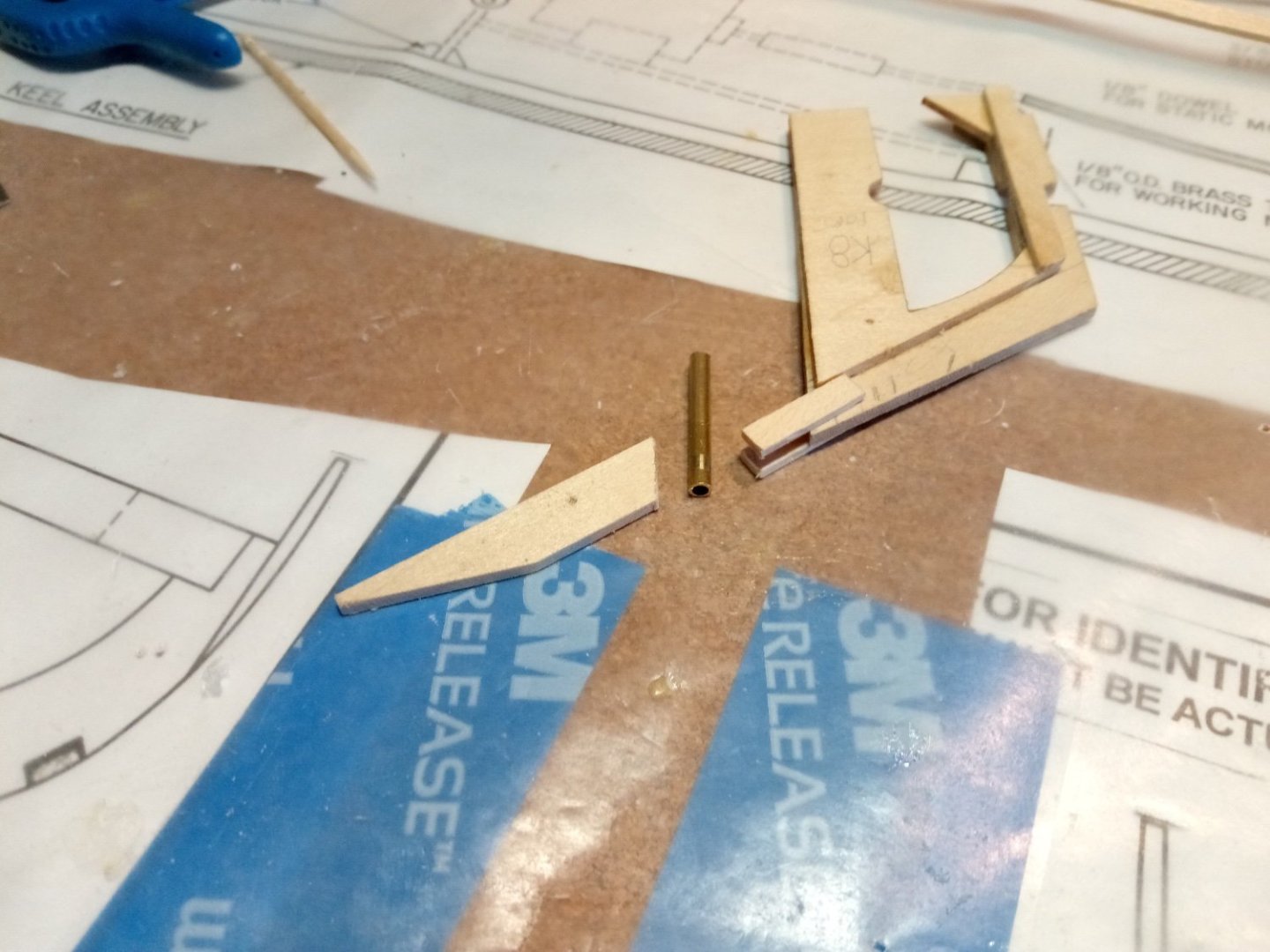

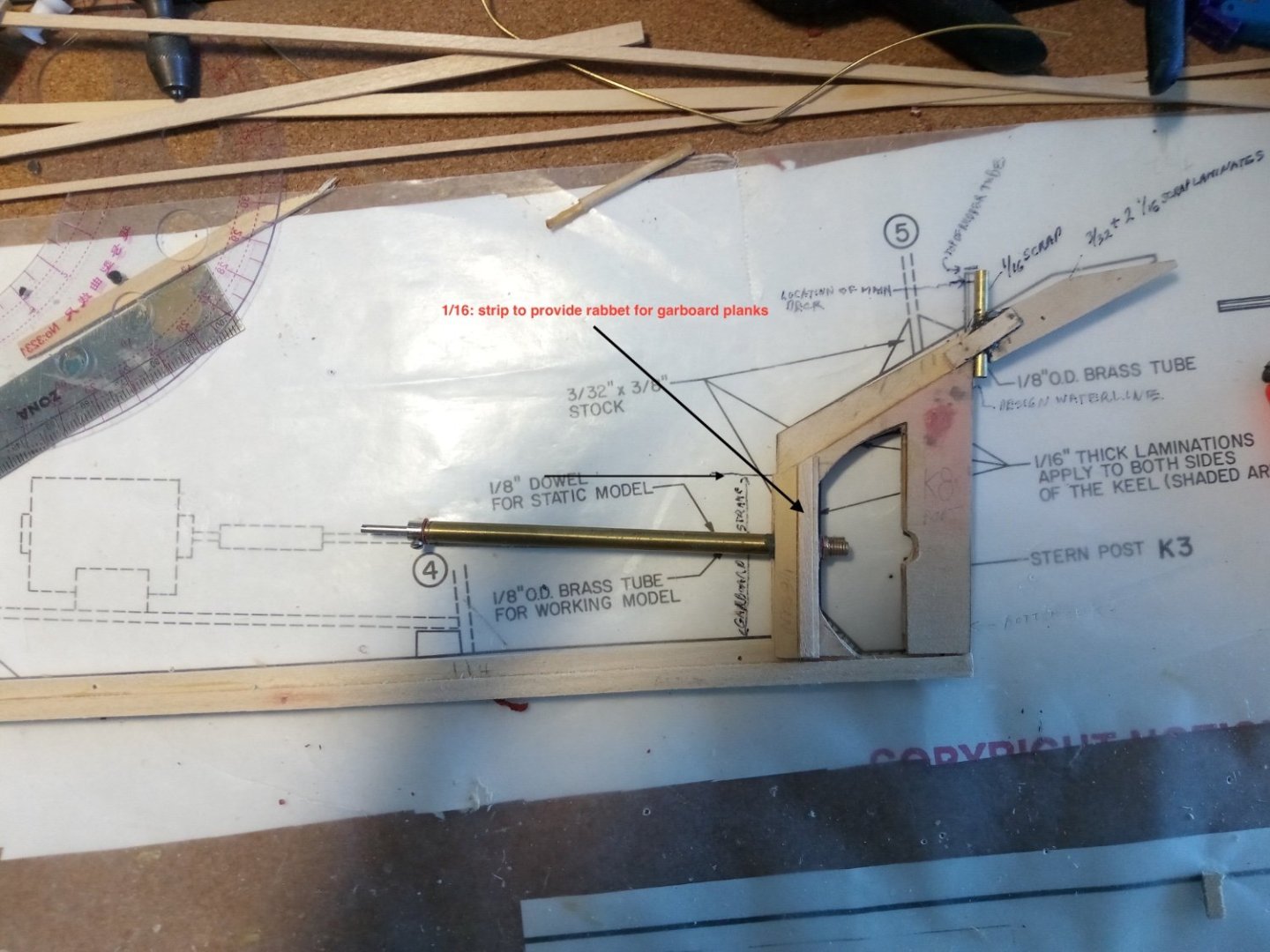

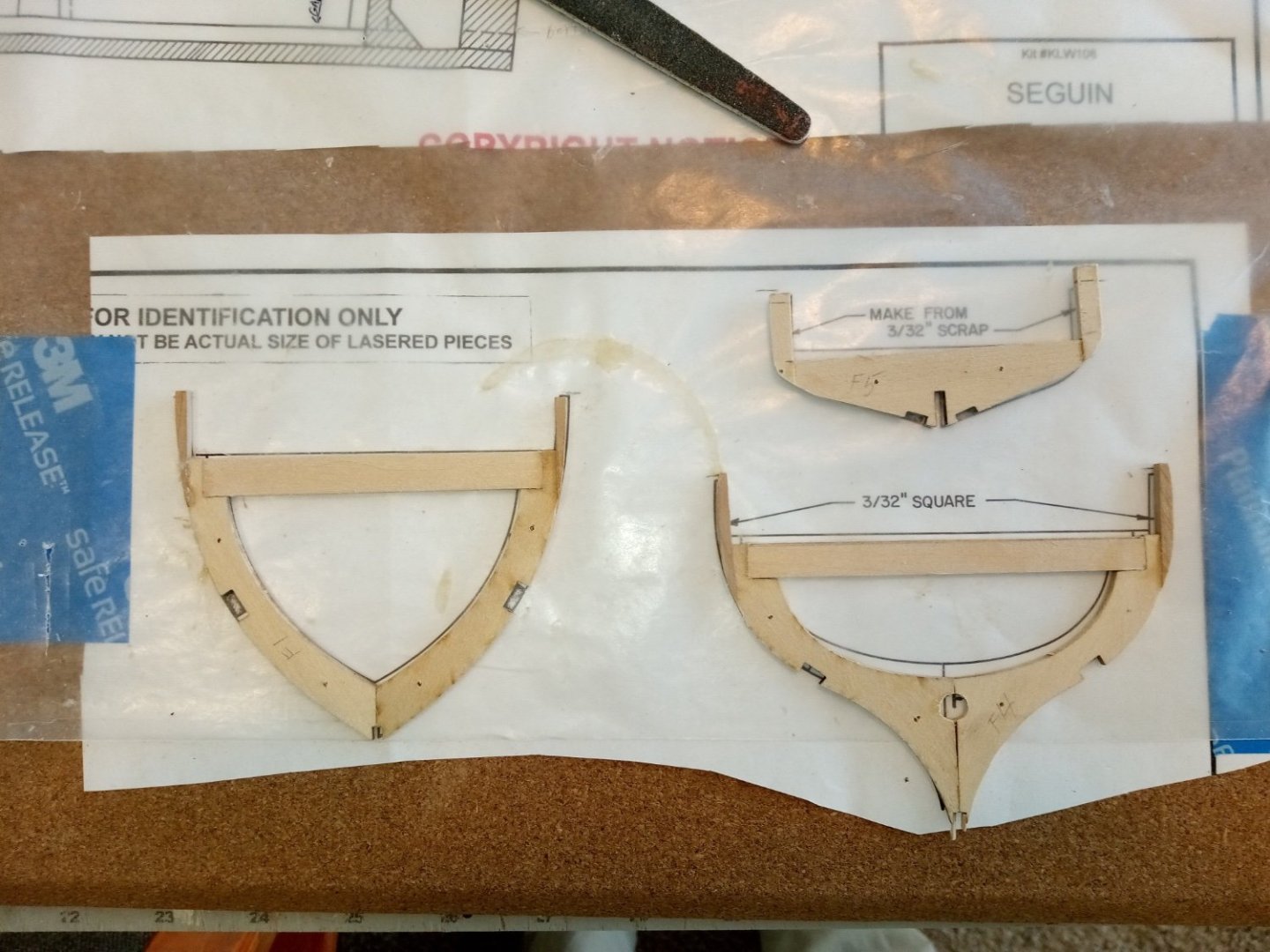

Thanks for all the likes ... 4. Assembling the Keel The single best thing you can do before assembling the keel is to take your glue bottle and put it out of reach. This is more complicated than it looks and you should assemble the jigsaw puzzle several times with pins until you are sure you have it right - and then do it again. I departed from the sequence in the instructions because I needed to make the stern post thicker to accommodate the 4mm diameter prop stuffing tube. Those who don’t plan on making an RC version can follow the sequence in the instructions - just be careful assembling the 3 laser cut pieces that make up the stern/rudder post area - the pieces all align on their aft edges but the center one (K3) extends above and forward of the 2 laminations pieces (K8), which in turn extend below the bottom edge of K3 to form a U-shaped area that will slide onto the upper (3/32”) portion of the keel. RC The first step is to cut out the slot marked on K3 for the shaft: I stacked the K3 and 2 K8 pieces that make up the sternpost to check their overall thickness and then laid the shaft on top of them to see how much extra wood there was, if any. There wasn’t enough (less than 1mm on each side) to provide strength for that hull penetration: I ended up adding 2 layers of 1/16” strip wood (1/8”” total) on each side of K3 and the K8’s for a total thickness increase of 1/4”and then filed the slot deep enough for the shaft to be centered on the centerline of K3: Before epoxing the shaft in place I followed the manufacturer’s (Deans Marine) suggestion and pushed a plug of Vaseline with a little water about 1/4” down into both ends of the shaft tube. Hopefully that will make it watertight. This shows the shaft penetrating the modified stern post: Before gluing everything together I made a fit check to ensure there was enough room to get the prop onto the threaded end of the shaft (there is, it just has to be tilted a little to get it in place) and that there was clearance for the blades to turn: Putting in the 1/8” tube for the rudder shaft was easy, no need to thicken the pieces in that area, I just added some scrap wood on each side to increase the glueing area for the tube and so that the wood extension aft of it had something else to attach to rather than just being edge glued to the tube: Here is the modified stern post resting on the main keel. I added a 1/16” strip above the original aft edge of K8 on each side to restore the rabbet edge that the aft end of the large 1/16” thick garboard planks will rest against: The main keel is made up of a long piece of 3/32” x 3/8” strip wood that has a piece of 1/16”x 3/16” strip wood glued along each side of its lower edge. The forward part of the keel is made up of 2 laser cut 3/32” pieces (K1 and K2) that attach to the main keel piece and have to 1/16” laser cut pieces (K5 and K6) that attach to its forward edge and that form a rabbet for the planking. I had to adjust K5 to get it all to fit: Next up will be attaching the keel to a build board and adding the frames and sub-deck.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

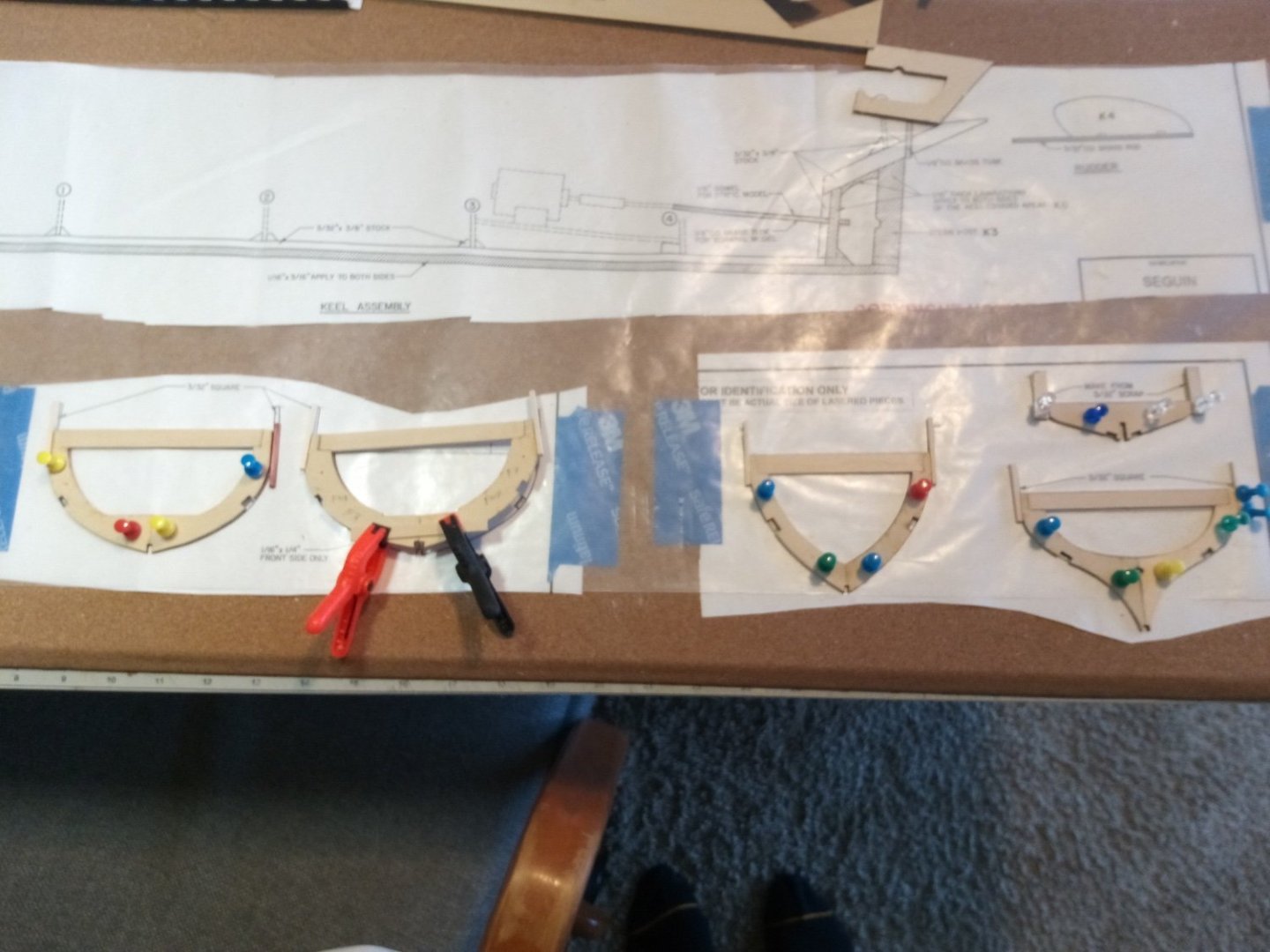

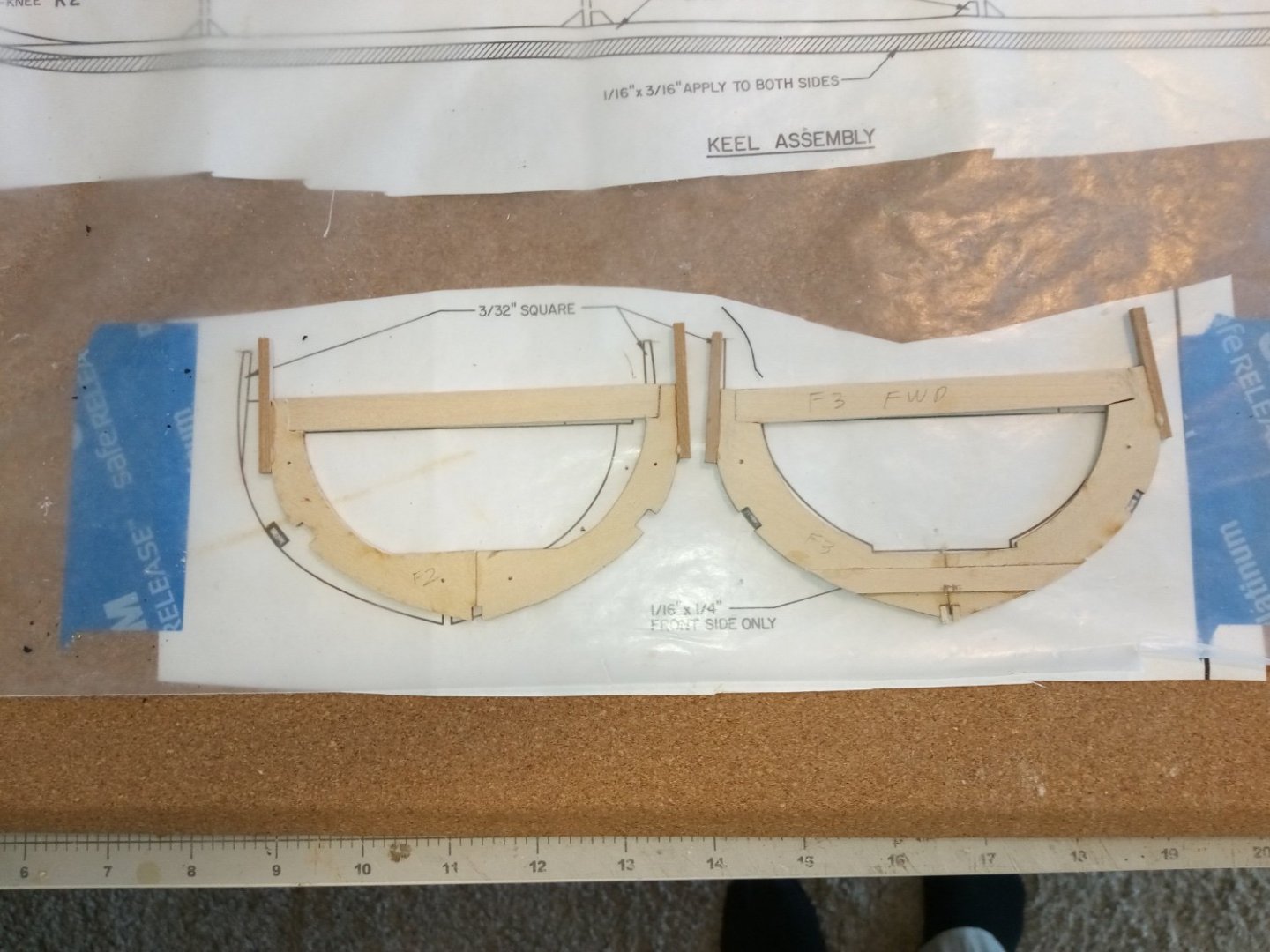

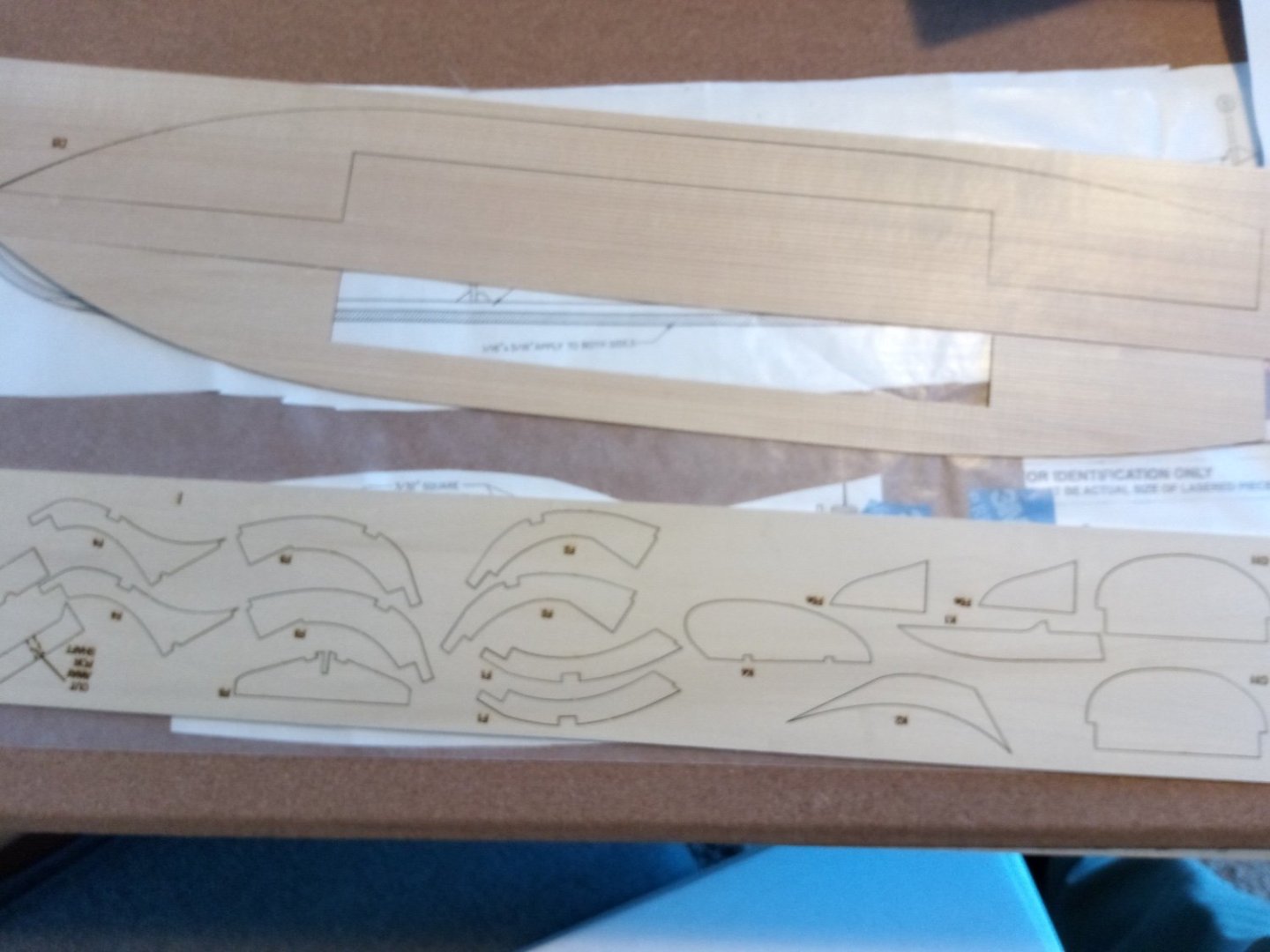

3. The Frames The assembly of the frames is pretty straightforward with just 3 “gotchas” that I picked up off of other build logs: As per the warning on the drawings, the laser cut pieces may not exactly match the dimensions shown on the plans (they are close, just not exact). Don’t try to make them match, just use the plans to figure out how all the pieces fit together. One builder reported a problem with the wood splitting when he tried to pin it to the plans. I wanted to avoid that so I drilled holes for the pins. Changing the depths of slots on the frames that fit over the keel will throw off the run of the deck My wife found a 3 ft long cork bulletin board at Michael’s Crafts that works well for pinning the frame and keel assemblies to the plans: The frames are easy to glue together. The plans/instructions call for using 3/32” square stock to fashion the extensions on each side that, along with about 80 similar pieces, will form the supports for the bulwarks. I decided to use mahogany for mine since it will make a nice contrast with the basswood bulwark planking. One thing to be aware of - the “slots” on the bottom of the frames that fit over the keel may vary in width, they need to be 3/32” wide to fit snuggly on the top of the keel. 2 of mine were too wide and needed filler material added, 1 was too narrow and need to be filed out, and the other 2 fit fine. Here are the extensions and the frame on the right has filler material in the slot: I recommend leaving the depth (height) of the keel slots alone. The frames will set the slope of the deck (which is significant both fore and aft) - if you change that the laser cut deck house pieces will not fit on the deck properly. The frame extensions were faired to the curve of the hull using a french curve and then sanded. Frame #4 has a hole for the shaft to pass thru, I enlarged mine quite a bit to allow the shaft to be aligned without interference (it would be a real pain trying to enlarge that hole once the frames, keel and sub-deck are in place). The last thing to do is to break out the 1/8” x 1/4” bilge stringers which are used in step 10 of the instructions. Check the fit of the strip into each of the slots on every frame and file as necessary. I found that the width was OK on about half of mine and the depth had to be increased on all of them - the stringers must sit at least flush with the top of the slot or the hull planking will not not lay on the frame properly. It’s much easier to do this now than when they are glued to the keel - some more filing will likely have to be done when fitting the stringers in step 10 but at least some of it will be out of the way. Next up will be assembling the keel.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

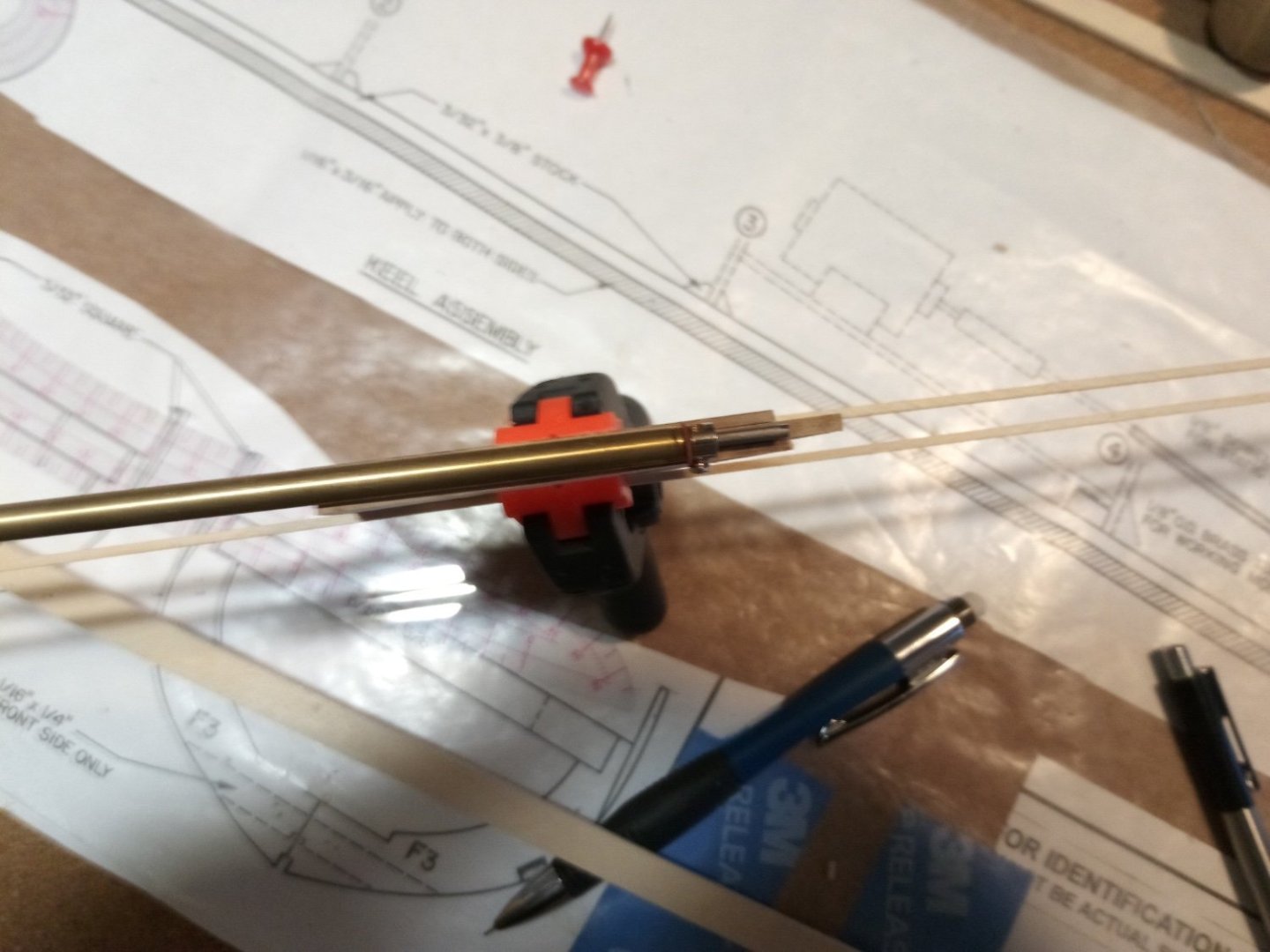

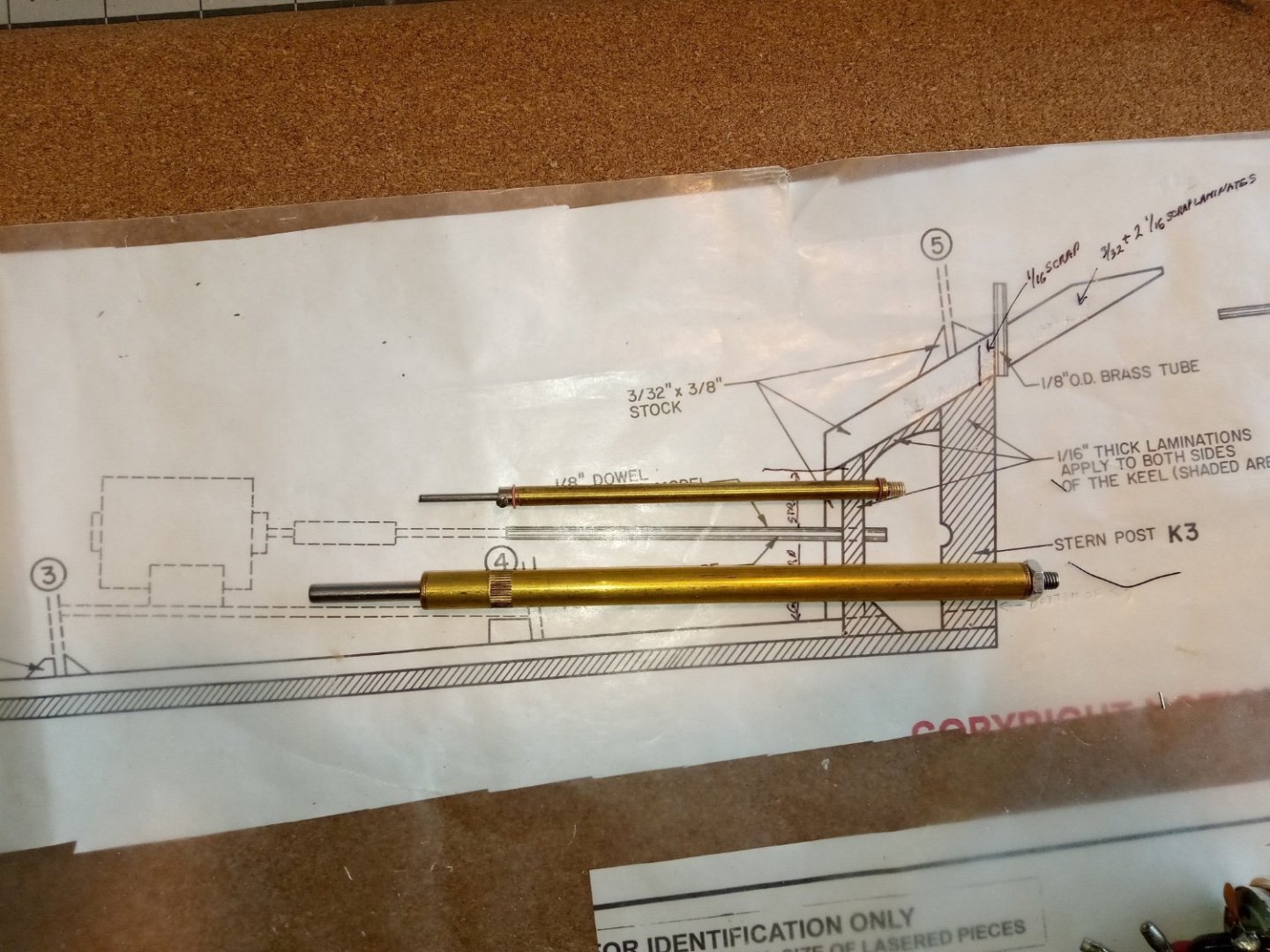

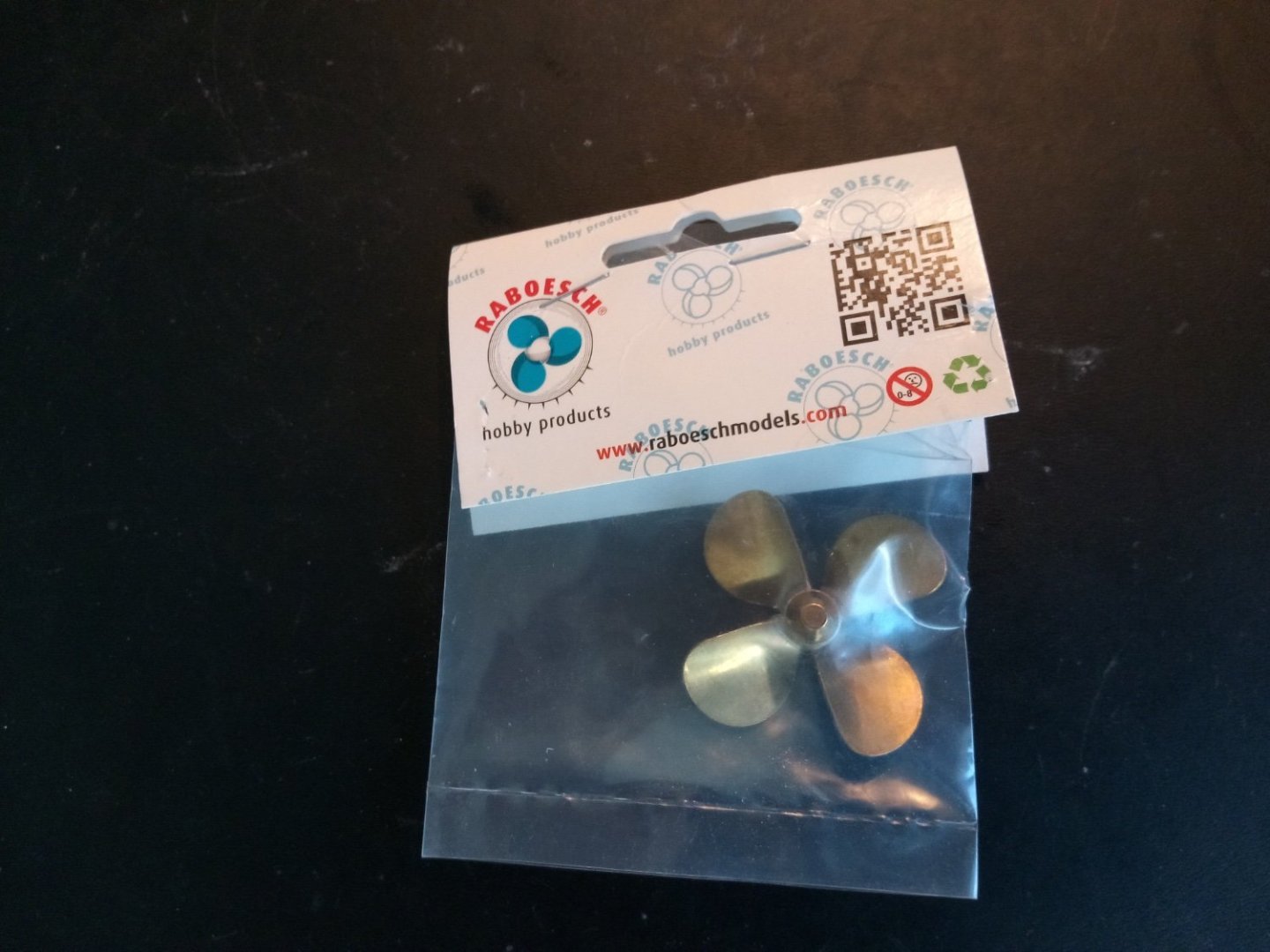

Radio Control: Parts and strategy For the benefit of those of you, who like me, have never dealt with buying and installing RC equipment I should start off by warning you this stuff can be expensive. That said, some of the more expensive items like the control box/XMTR, batteries, etc once bought will work with other RC builds if you should decide to keep going down this road. You may also be able to reduce costs by buying components from multiple dealers if you have enough RC experience to know what you are doing. I decided to order the RC stuff now because I cannot find any RC build logs for this kit. There are some out there for the Midwest Models SEGUIN (no longer in production) but that kit is about 50% bigger than this one, 3ft long vs 2ft. The tight confines on this kit made me leery of how (or even if) it was all going to fit if I did not have the parts at the beginning of the build. I will try to make it clear how all this stuff fits in there so you can delay buying the expensive items until near the end of you build. Given the high cost of the RC equipment and what looks to be a difficult build with a risk of not finishing it I recommend that you hold off buying most of the RC stuff until the hull is planked, waterproofed, and you are confident in completing the build. I will highlight the item you need to buy before starting the build. You will of course still have to do the waterproofing work as you go if you want the option of completing the build as an RC. Note from later in the build: I've edited this post after I started to install the RC equipment in order to simplify it - I've largely removed those items I bought but did not use and added some newer purchases. When I bought the SEGUIN kit up at the BlueJacket store in Maine, Nic (BJ’s owner), gave me a business card for a RC supplier who is familiar with the SEGUIN kit and could help me figure out what I needed to power it. After looking thru the kit I figured out that I really needed the shaft stuffing tube early in the build, which would determine the shaft I would use and the propeller. The supplier is Mr. Richard Kroll who owns M.A.C.K. Products Model Marine (www.mackproductsrc.com, (732) 870-2966). I went onto his website and found that he had a package of items listed as the power pack for the Seguin. I recommend you DO NOT buy the power pack since the included stuffing tube is 3/8” diameter and will not work for this kit which needs a 1/8” diameter stuffing tube, that in turn makes the supplied shaft, coupling and prop also unworkable. The power pack also includes several items you either do not need or can find better and less expensive version elsewhere. You can order the relevant power pack items individually. I recommend you order the following items from M.A.C.K. (or similar from online stores): #1885G Model marine motor and gearbox #7322T Electronic Speed Control (ESC). This is basically the “brain” of the set up. It receives commands from the handheld control box (XMTR), via the Receiver, receives the power from the battery packs and sends electrical commands to the motor for fwd/reverse/neutral. #7162 N-MH Batteries (2 packs included, only one is shown below and I could only fit 1 in the hull). I strongly recommend you use NiMh batteries and stay away from lithium ones. All the research I have done recommends charging lithium batteries outside, on a fireproof surface and even in containment bags because they can catch fire or explode if improperly charged so don’t mess with them. After I completed the hull I found that there was only enough room (and buoyancy) to support 1 battery pack. Turing FHSS 2.4 GHz Digital Proportional RC System (the hand held control box) (AKA the transmitter XMTR), it comes with a small 5-slot box with a short antenna attached, that is the RECEIVER. The receiver connects to the ESC and the servo (the receiver is not shown in this photo but is in the photos on post# 7) My search for a smaller diameter shaft and stuffing tube led me to the UK, specifically Deans Marine (deansmarine.com). They have a wide selection of shafts, couplers and props. After a lot of compare and contrast work I thought I knew what I needed and sent in the order. They were quick to come back to me to explain some of the items would not work together. That started an e-mail exchange with questions going both ways and photos from me. They were very patient and helpful and figured out what would work best for this build. Here is what I ended up ordering from Deans and I recommend you order the shaft/stuffing tube before starting the build because you have to place it early in the build. You don’t need the prop at this point but it is a great looking brass one that will look good even if you decide to go with a static display model. You can get the coupling later: 1) PR-18 shaft. It is 2mm diameter, the stuffing tube is 4mm diameter, which is only about 1 mm larger than the 1/8” called for in the plans - I can work with that 2) Nychrome EXL 2mm / 4mm coupler length 45mm (see 3rd photo below) 3) 147-16 45-L-4bl-M4 Brass Prop. It is a 4-bladed prop, left-handed, 45mm in diameter: The above 3 items from Deans ran me about 51 British Pounds ($62) including S&H Below is a comparison of the original shaft (lower) the replacement from Deans Marine (upper) and the shaft shown on the drawing: The new shaft will need to be shortened a little but it, the motor and the new Deans Marine universal coupling look like they will fit fine: I bought the following items online: 1) Battery charger for NiMh batteries. This one is cheap and easy - just plug it in an leave it for a couple of hours. You can find more expensive ones that will tell you when the batteries are fully charged. 2) For the rudder servo I found a lot to choose from on Amazon. I went with something called "Miuzei" MG90S 9g mini-servos. They come in a package 10 for just a few bucks. If it should burn out over time I'll have plenty of spares.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

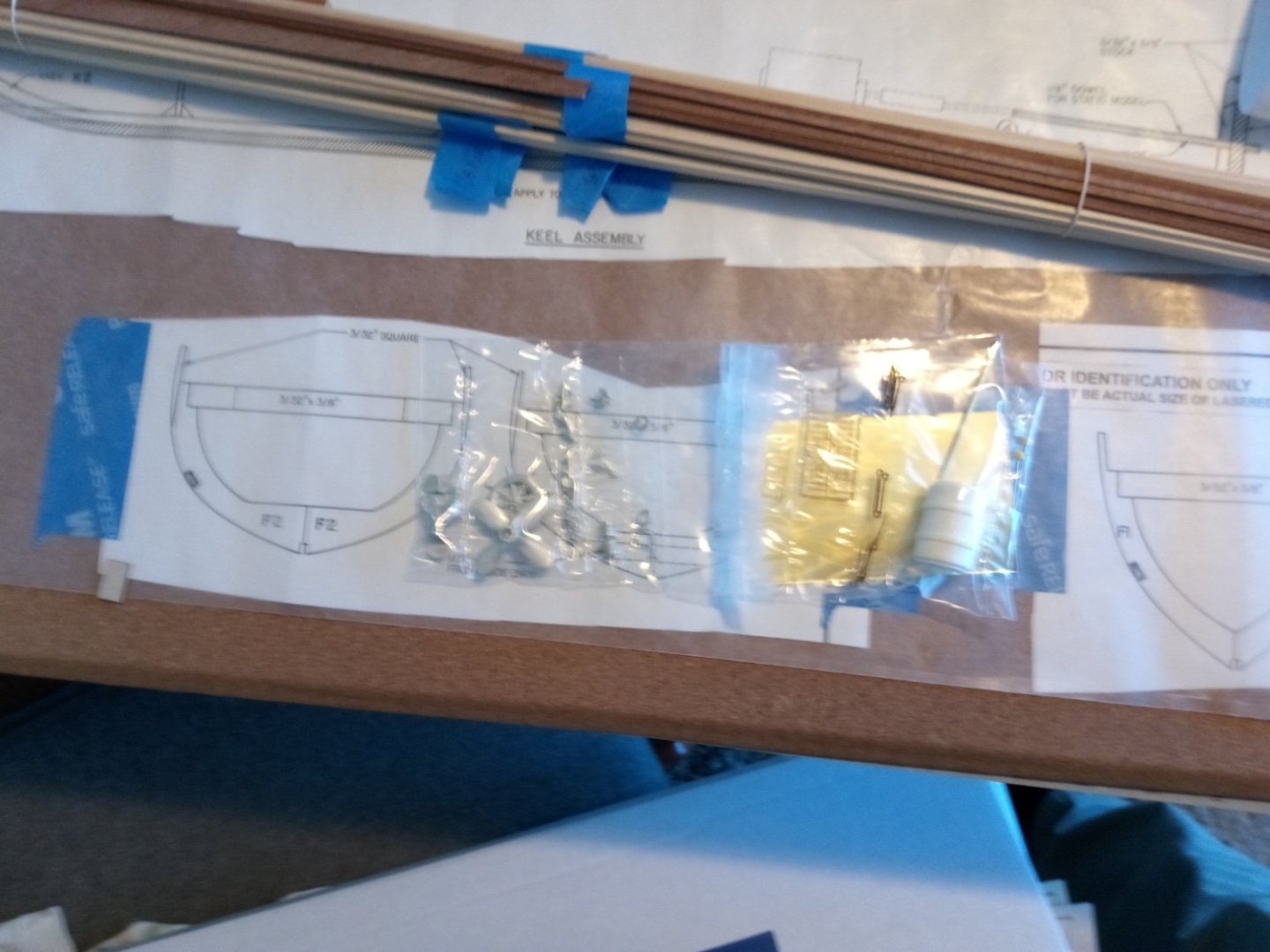

The Seguin From the BlueJacket website: “Historic wooden tugboat, 1884. Built in Bath, ME, the Seguin spent her first years towing wooden sailing vessels in the Kennebec River and towing cargo barges along the Atlantic coast. In the early 1900’s, she became a New York harbor tug, finally returning to an active career in Maine until retiring in 1967”. Why I picked this kit I’ve wanted to try my hand at a Radio-Controlled kit, and while there are far easier kits on the market for a RC first - timer I was really attracted by how good this boat looks, so that even if the RC side is a bust, it should still look nice on the shelf. Since this boat will be waterborne it will be a challenge to get her watertight so I will be leaping into fiberglass, or at least resin - I will have to decide that after the hull is planked. RC I will try to remember to put a green “RC” (like at the start of this paragraph) at the beginning of any paragraph dealing with RC or waterproofing related so that those not interested in those parts can eye-scroll past them. References: Build logs, websites and online forums Building the George W. Washburn: regroups.com>forums>boats>scale boats>building the George W. Washburn a decent build log of a Dumas POF steam tug similar to SEGUIN, has some decent waterproofing and RC info RC Deans marine.co.uk RC and waterproofing info scattered about RC Ship modelers.com>technical library RC info RC MSW build logs (not the SEGUIN) that have decent RC and/or fiberglassing info a. gjdale’s 1949 Chris Craft b.mtdoramike’s 1954 Chris Craft Build logs for the BlueJacket kit a. RC rcgroups.com>Seguin by ropanach b. Model Ship World, Seguin 1884 by RVCHIMA great log of a gorgeous build of this kit, if mine turns out half as good as his I will be happy c. shipsofscale.com >forums (note: anyone can view the site but the photos are thumbnails, if you register on the site you can click on them and blow them up to usable size) both of the logs below are useful for pointing out some problems to avoid 1) Seguin by anchorman 2) Bluejacket Seguin by pathfinder69 RC There is a ton of websites you can find by googling “rc boats” or “fiberglassing rc boats” of varied quality and usefulness but worth some time to look around and bookmark the ones you like. Books: RC in Model Boats by John Cundell. Has a photo of the Seguin on the cover (might be the old Laughing Whale kit) Decent book found on Amazon for about $8. About half the book is dedicated to less relevant things like the history of the hobby, how RC clubs work, high speed RC racing boats, etc but it helped give me a better understanding of what to think about when installing RC equipment What’s in the Box? The kit provides 2 large, clear sheets of plans and an instruction book There is an assortment of dowels, strip wood and name board stickers A set of paper flags A bag of Britannia metal fittings, some sheet brass and a little photo-etch brass There is a fair amount of laser-cut wood of various thicknesses and pre-scribed deck planking material There is also some very detailed laser cut wood of 2 different types of wood that give the deckhouse its unique look. Next post I will show the RC equipment I ordered for this build

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Amazing build!!! Although there are some other period kits available with stunning details, building them mainly consists of glueing and painting without anywhere near the amount of fabrication and scratch building needed to pull this off. Well Done and thanks for putting the build log together.

- 112 replies

-

- Bluejacket Shipcrafters

- Constitution

-

(and 2 more)

Tagged with:

-

Bob, I just found your log. I too am a total RC newbie. A couple of thoughts: 1) I have the same batteries and charger you do. Trying to understand the charger instructions drove me nuts - about 90% of them are devoted to keeping lithium batteries from exploding (which is irrelevant to the NiMh batteries we have). After multiple rereads of the charger instructions, multiple attempts to charge and a lot of bad language I finally got them to charge, although I never got the charging progress readout on the charger screen. I found that an early attempt to charge was defeated by a loose wire in one of the plastic connectors - your multimeter should help you with that if you have the same problem. 2) Figuring out that little receiver was another PITA (my receiver is different, it has 5 slots and my remote control box is way different). As Ian has told you, the brown or black wires go away from the printed area on the receiver. Another thing to think about when you get it working is do you want the rudder servo to return to the amidships (neutral) position when you release the remote control toggle? That is the logical way to have it but you may have to switch the servo lead on the receiver to the other empty slot to get that effect. 3) I can't help with binding issue - I got both the control box and receiver from M.A.C.K. (where your motors are from), the instructions said there as no need to pair (bind) them and they were right. If you got your receiver from MACK you might want to e-mail them - they have been pretty responsive for me. 4) There are a lot of RC online groups, some of them seem pretty responsive when people ask for help. I'd try to find one that allows you to post photos - that can save a lot of frustrating back and forth as they try to figure out what the issue is. Some sites that might be helpful: - modelerscentral.com - has a list of California RC boat clubs, one might be near you along with someone who could fix your problem in about 30 seconds (always good for your ego and self-image) - rcgroups.com - has lots of chat rooms and resources - shipmodelers.com - go to the tab for "model boat electronics", at the bottom of that doc there is a good diagram about how laying out your wiring can prevent interference problems (keeping the receiver away from the motors is just a start) Good luck, you've got a very nice looking build going there

- 296 replies

-

Great, great build and log! And a superb reference for the rest of us when trying to figure out rigging on masts. Thanks for taking the time to put all this together - it's one of my go to bookmarks.

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

This log is an absolute gold mine for how to rig period masts! Although the large scale of the kit helps, it is really your clear photos and explanations that make this the go-to place for some of the most difficult and least understood parts of rigging. Thanks for taking the time and effort.

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

Bold start cutting the hull in half! I had a great time building that kit as the USS Basilone. Message me and I can offer you a book on the Sumner & Gearing classes that I no longer need - has some good photos for detailing.

- 19 replies

-

- Putnam

- BlueJacket Shipcrafters

-

(and 3 more)

Tagged with:

-

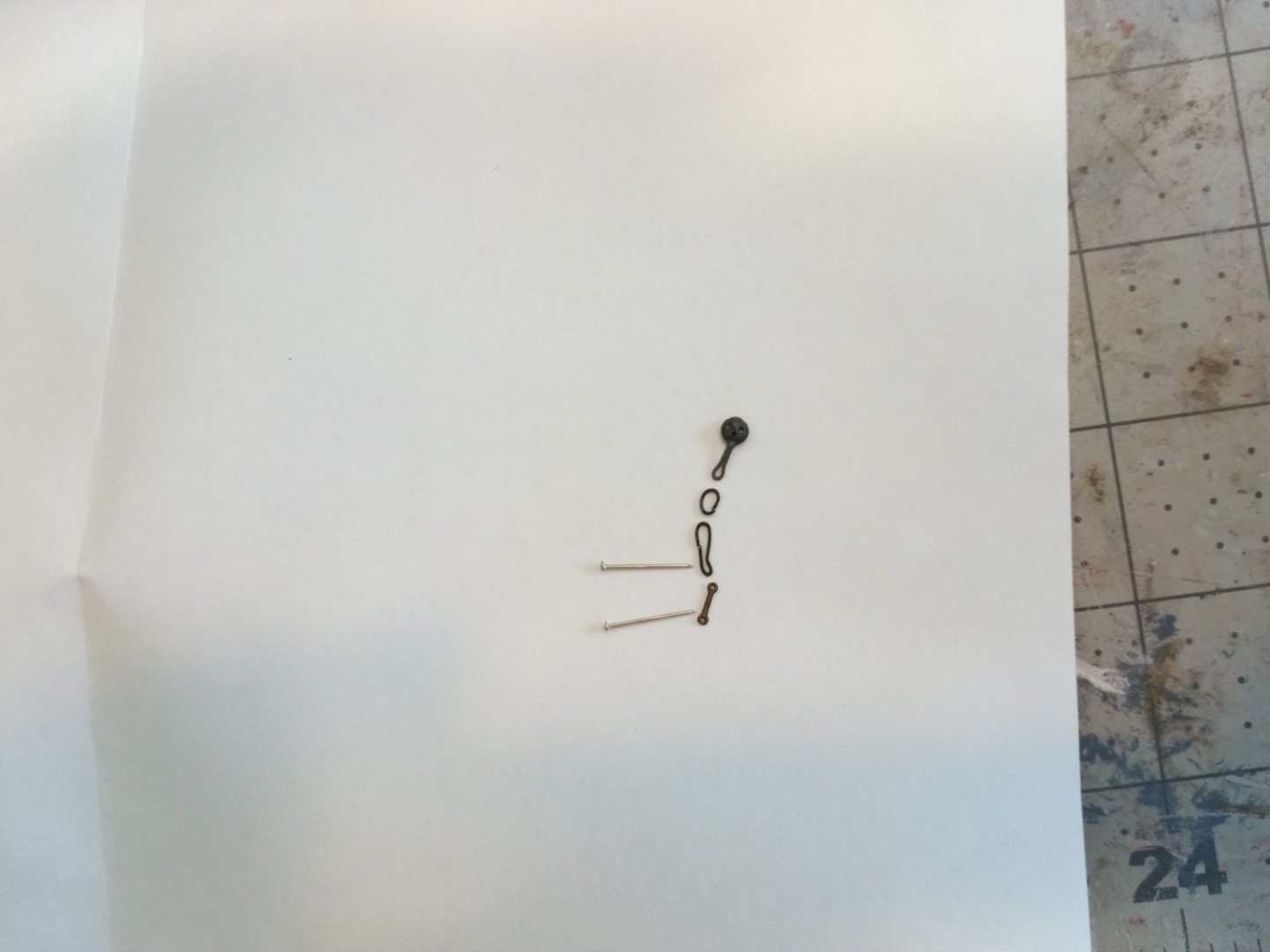

Deadeyes and Chainplates The deadeye/chainplate rigs consist of 3 or 4 parts (small deadeyes get 3). The kit provides Britannia metal deadeyes that come pre-stropped (thank goodness), the next part below them is the Mid-link, which are all the same size so it is easy to mass produce them by wrapping 24 gage wire 9 or 10 time around a dowel and then cutting them free and using pliers to bend them into more of an oval shape. The next part is the Toe Links, that took me the most time to make since for the large deadeyes they have to be custom fabricated out of wire so that the bottom of the last piece (the chainplate) can reach to or near the blackstrake which is the first strake above the wales. I was getting ready to fabricate the bottom pieces (the chainplates) I when was rooting around the bottom of the box and found the remnant of the PE fret and lo and behold there they were (the parts list does not break down the PE fret parts and when I inventoried the kit 2 years ago I had no idea what they were). Here are the 4 parts, along with 2 pins from the BlueJacket catalog (F0040) that just fit inside the chainplate holes. I cut all but the top 1/4” off each pin so I would not have to drill as deep. The orientation of the assemblies was determined by running a line from the mast top, across each deadeye and a pencil mark made on the hull just above the wales: The wire was fabricated by bending around pins and then shaping using pliers: Here’s the finished assemblies mounted on the model:

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

-

OK, I've been procrastinating long enough and need to get going on this build again. I've finished up the fighting tops. I decided to paint the top of the tops gray, as is done on the Constitution kit, I think it looks better and it makes sense from a practicality viewpoint since it makes all those trip hazards more visible than if everything was black on black: All the blocks have been added, more on the bottom than on the top. The kit provides britannia metal blocks but for small ones I find wood is easier to work with. Brittania looks better than wood since they are already properly shaped but I find it easier to strop with thread than with wire so this build will probably have a mix of wood and britannia blocks. The railings have been added. The netting is just tacked glued along the upper edge since it will have to be moved to accommodate some of the rigging like the stays: Note from later in the build: I ended up taking off the railings when I started the rigging - having them there just made things harder than they needed to be. I'll put them back on near the end of the build. Finally I ordered some swivel guns from the BlueJacket catalog. They are just dry-fitted here which is why they are a little crooked. I'll permanently mount them once all the rigging is done.

- 142 replies

-

- alfred

- solid hull

-

(and 2 more)

Tagged with:

-

Absolutely stunning work! I'm bookmarking this log as a reference for all future sailing ship builds. Congratulations and thanks for all the work in putting this build log together.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

Those extra details really bring it to life. Now you are going to have to invest in a new bookshelf worthy of displaying such a nice model!

- 100 replies

-

- pauline

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

It speaks very well of your work that it can stand-up to close up photography and still look great!

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.