-

Posts

5,586 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

A new angle in precision sanding

wefalck replied to Arcticbeaver's topic in Modeling tools and Workshop Equipment

Edges round in which direction? -

Yep, with a bit of putty and a few tools, one can quite easily adapt commercial figures. However, 3D-printing in acrylic resins is the future. It may be worthwhile contacting sellers on the commercial platforms, such as shapeways, in order to see, whether they can/are willing to print their figures in different scales. While upscaling or downscaling over a large scale range may not be feasible for reasons of resolution, a change from 1/72 to 1/80 or from 1/87 to 1/80 should not pose a big problem.

- 276 replies

-

A new angle in precision sanding

wefalck replied to Arcticbeaver's topic in Modeling tools and Workshop Equipment

Wow, this is quite a price tag for those two tools, even though they look sturdy and well-engineered. If something melts or burns during machining, that means you are putting too much energy in a too short time-span into it. Reducing the energy helps. If you have a 220V/110V sander, you can reduce its rpms (and hence the energy put into the process) by running it off a dimmer, if doesn't have already a speed control. I also found that diamond tools work better on plastics (acrylic glass, polystyrene, etc.) than carborundum abrasives, so I am using diamond grinding discs on my micro-sander. -

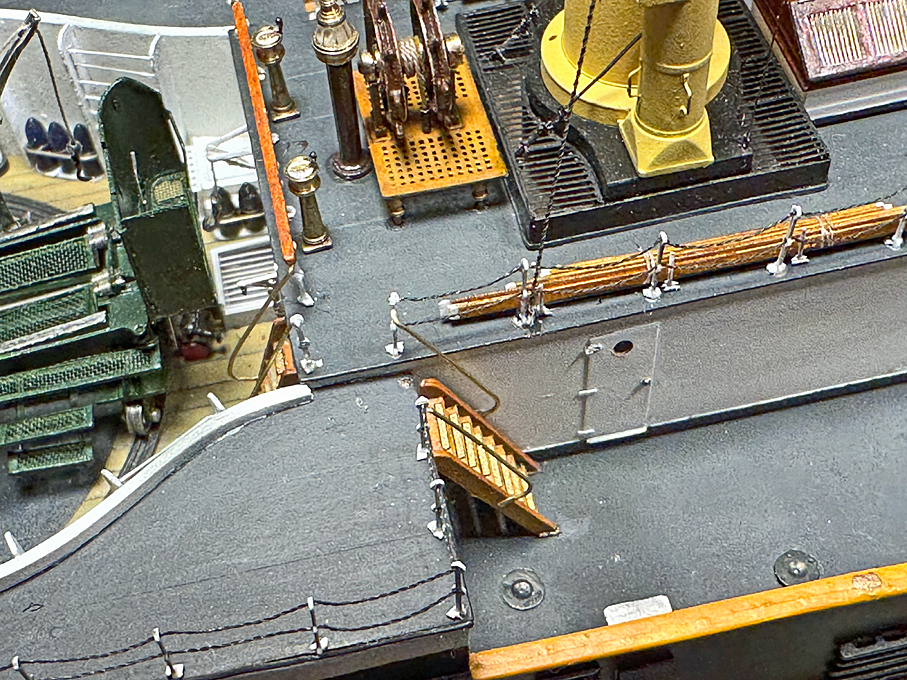

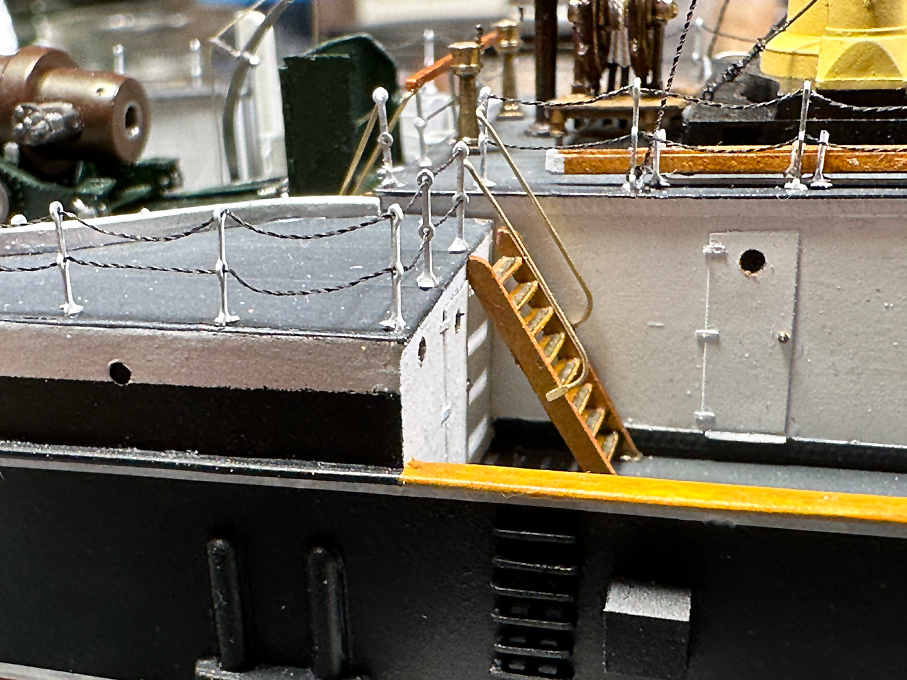

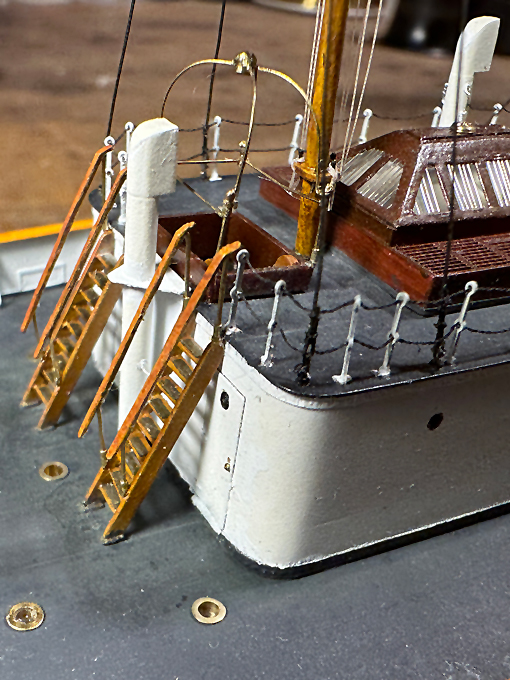

The last two weeks were spent travelling on business, to Stockholm (including a renewed visit to the Maritime Museum there 😉 ) and to Brussels. Friday and Saturday I spent at the information desk of Association des Amis du Musée de la Marine, which has been finally re-opened (see other thread on this). So, not much time in the workshop, but I still managed to complete the Banisters These banisters are flimsy matters so that I left them to the end as far as possible, still following the pattern to work ‘inside-out’ in order to not damage delicate items. The information is somewhat patchy as to what the banisters actually looked like. They are represented in the lithographs and on one or the other photograph, one can see parts of them. Basically, there are two types: bend pipe-work and straight stanchions located in sockets that support a wooden rail. As the metal parts are laid out in yellow on the lithography, they appear to have been made from brass (or bronze). One picture shows bare metal for the pipe-work. Hence, I decided to make them from bare 0.3 mm brass wire. At the moment this looks rather bright, but I assume that it will tarnish somewhat with time. The pipework ones were bent over a scale copy of the lithograph. The ends, where they attach to the stairs appear to have been flattened, which duly was represented on the model. For the ones with wooden rail at the end of the deckhouse, I cheated a bit and instead of having individual stanchions, I flattened the wire in the area of the wooden rail to have a support for it and bent the stanchions down sharply. The sockets were cut from 0.5 mm OD brass tube, which is a sliding fit on the 0.3 mm wire. The ends were milled down to the appropriate angle. The wooden rail was fashioned from two laser-cut strips of paper laminated together with varnish. With hind-sight, fashioning all parts from brass and soldering them together in a jig might have given crispier results. All parts were cemented in place with clear varnish. Overall, these quite simple parts took surprisingly long to produce. To be continued ....

-

... however, if you look at period photographs, very few people did wear Holliwood Cowboy-dresses and Stetsons. Bowler hats and the likes seem to have been more common, even in the 'West'.

- 276 replies

-

The German manufacturer Preiser (https://www.preiserfiguren.de/) used to have a small series of figures of around 1835 (to match a model of the first German steam-train) and a larger one for the period around 1900. They are in HO (1:87) scale and I have not checked, whether these series are still available. The closest in scale would be the British OO (1/76) scale and there are various manufacturers that make figures in whitemetal for the period around 1900, e.g. https://www.scalelink.co.uk/acatalog/index.html. In terms of quality (animation, detailing, etc.) they don't match the Preiser-figures though, which is partly due to the casting process, I suppose. The 1/72 softer plastic figures by HäT etc. (see http://plasticsoldierreview.com) are probably on the large side. But in the linked Web-site there is also an assessment of the 'true' scale for virtually all sets reviewed. Civilians though are far and few, as these aim mainly for the 'wargaming' market. True 'wargaming' figures in whitemetal would be too big and they are too chunky for my taste anyway.

- 276 replies

-

I wouldn't worry about the wood-grain not matching up at the joints. This would be quite common in this kind of craft, where they would have used what was available at the moment. Talking about woods: mango wood seems to be quite common as building material in certain (sub-)tropical regions. The dhow-builders in Tanzania/Zanzibar, for instance, use it extensively. Whith this kind of rough-and-ready working boats it is always difficult to strike the balance between precision in modelling and the somewhat rough look of the prototype. However, poor workmanship is difficult to sell as the rough look of the prototype ... the 'roughness' has to be also to scale.

- 181 replies

-

Does this mean that you filed to shape each individual link? I also noticed in your building log, that you shaped by filing the straps for the dead-eyes. Do you use some kind of template (like the file-buttons of ancient mechanics) or is it all free-hand? How do you hold these tiny and narrow parts during filing?

-

I would rather build everything myself, rolling stock as well as buildings etc. ... as I would perhaps go for a 1860s to 1880s subject, there is not much on the market anyway, a real niche subject. I have been looking over this site from time to time: https://www.carendt.com/micro-layout-design-gallery/. There are some harbour ideas as well, combining the best of our two worlds ...

-

In order calm down my ambitions as teenager, my father used to say that 1 sqm of model railway would cost 1000 Deutsche Mark. Considering inflation since the 1960s and translating this into imperial measures this amount to 100 $/£/€ per square foot today ... I have been repeatedly tempted, particularly around this time of the year, but space is a serious limitation, more than money.

-

How will you treat the hull as such? Perhaps, if the hull is going to be stained as well, the visual contrast between the supports and the hull will be less. Otherwise, to me they don't look so blotchy and such boats would look a bit rough anywhay, won't they?

- 181 replies

-

There was a colleague (sadly deceased last year), who turned this into a useful tool and made a small series of micro-meter fences for a group of people here. When I bought the KS230 nearly 30 years ago, the Böhler machines existed, but were not easy to get (no Internet sales back then), to see in the flesh, and at some stage the company went bankrupt, I believe. The other thing that then let me shy away was the fact that it uses 12 V DC motors - high speed, but low torque. Perhaps one could use the cast parts from the Böhler and upgrade with a decent motor ...

-

As you mention a tilting saw-blade, that is also something that I would have found useful at times (e.g. for cutting long mitres in certain pieces of joinery), but some people have come up with tilting/angled sleds (there are examples on YouTube for full-size machines that could be adapted).

-

I didn't spend another 300€ on the KS230 and I wouldn't. These modifications cost me less than 30€ I think. My problem is that I just don't have the space for an FET.

-

At the time, when the PROXXON KS230 was put onto the market (around 30 years ago), there was basically no alternative, at least on the European market. And still, there are not many alternatives for small table-top saws, other than the really cheaply made ones from the Far East. The PROXXON FET and similar ones are much bigger in size and price - the next one up would be small, but full-size circular saws I suppose. The KS230 was never intended to mill lumber, I suppose, but to allow (not so serious) modellers to cut pieces from softer woods. Of course, it can't cope with 5 mm oder more of hardwood. I fully agree, that its main weaknesses includes the rather wobbly fence that is only fixed at the front. Some 25+ years ago, when I bought my KS230, I installed an additional fence, that could be fixed at the back as well. This is not so easy, as the body of the saw does not allow access to the full length of the back edge of the table, which I consider a design shortcome. The other weakness is the width of the saw-slot that is too wide (to accomodate their carbide studded saw-blades). I actually, put a thin sheet of aluminium over the table with a zero-clearance slot for their thinnest blade. Perhaps the biggest weakness is that the saw-blade cannot be raised or lowered and there is no real 'improvement' that can change that. It is also rather inconvenient, but it presumably is a marketing thing, that the saw arbor is designed for blades with a 10 mm hole, which basically forces you to buy the blades from them. Standard hole diameters would be 8 mm or 16 mm (that is, if you are metric, of course). On another note, it would not be very difficult (and you don't need machine tools) to build your own saw with the different parts e.g. for CNC machinery that are now readily available from ebay et al.

-

It is essentially one of those ubiquitous 90W sewing machine motors.

-

The forum https://www.marine-modellbau-und-mehr.de/ is a bit special. The original owner was a rather strange character, he died a couple of years ago. The guy, who continues it, seems to continue also the rather selective admission policies. The policy seems to be to admit to the forum only people they know or people who have been recommended. As the original owner somehow didn't like me (though I never did anything bad to him knowlingly) and had apparently put me on a black list, the new owner didn't admit me either. When I tried to register out of curiosity under a false name and different email address, hiding even my IP address, I never got a response to my application. In summary, I don't think it's worthwhile to register there.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.