-

Posts

6,652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

The eye-bolt to which the the throat-block hooks may be a through bolt and have some sort of eye underneath from where the line starts with which the sail is lashed to the gaff. Also, half-hitches at each eyelet keeps the line better in place.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

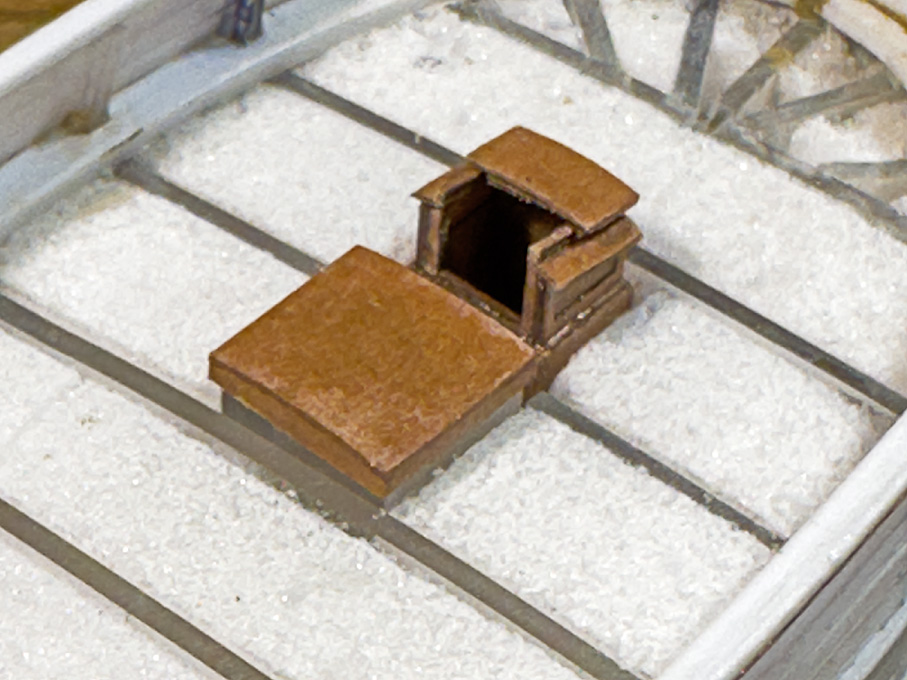

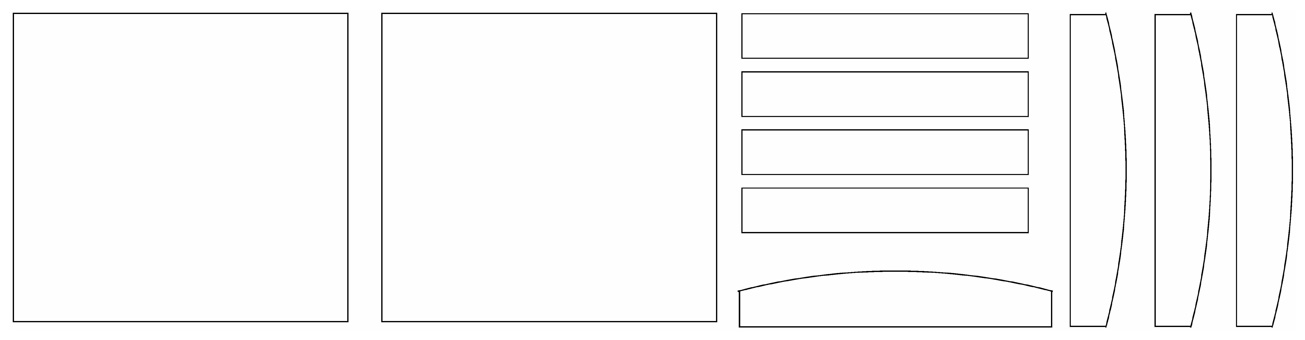

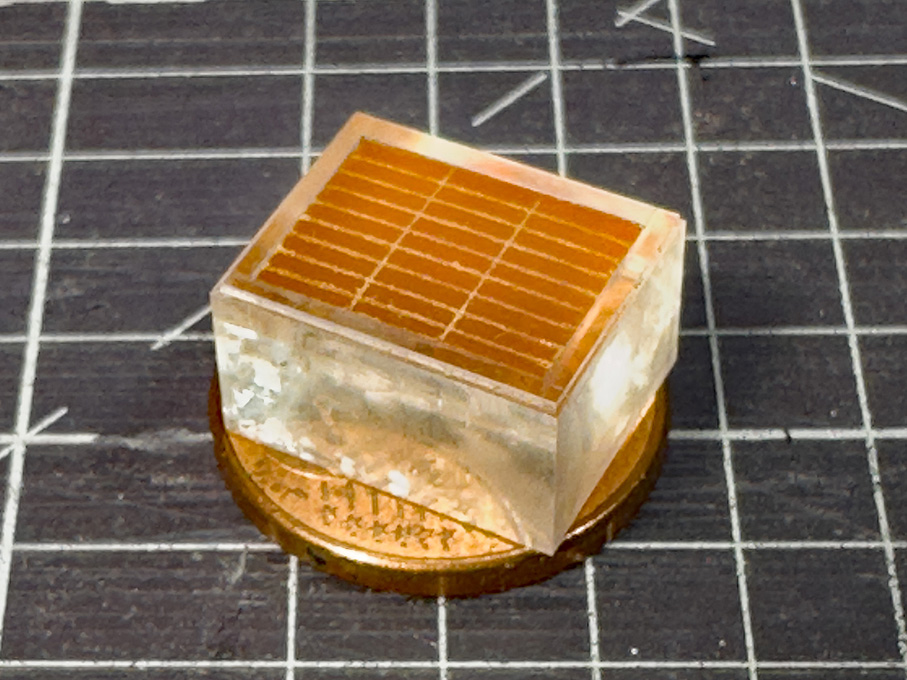

Again, I managed to eek out a bit of time for the workshop between travels and addressed myself to the Parcel Hatch The ’parcel hatch’ is a common feature of such trading-smack type vessels and proved access to the cargo hold before the mast. As the name indicates, this space was typically used to store general cargo, while the main hold was used for bulk loads, such as bricks or coal, or grain in sacks. The laser-cutting template for the parcel hatch lid This hatch will be shown closed and therefore a ‘core’ (the actual hatch including the coamings) was milled from a piece of acrylic, while the lid was built up from laser-cut parts. I could have milled the two parts in one piece, but milling the camber of the lid would have required a more complex set-up. On the real thing lid was made to fit over hatch like the lid on a box. These hatch lid was tied down with two iron straps, the ends of which slipped over eye-bolts in the deck, to be secured to them with cotter-pins presumably. As these parts will be painted in a different colour from that of the hatch and have to fit tightly, they will be made and fitted later, once the hatch is installed. The parcel hatch and crew companionway provisionally deployed To be continued …

-

Looking the thing, you are on the right track! I think the lanyards should be rove about three times through the thimble, keeping in mind that the steel shrouds are much stronger than the rope. I use something like dilute nail varnish (the acetone solvable one, not the acrylic variety) for keeping coils in shape and place. I prefer a solvent-based varnish for that, because one can soften it with a drop of acetone, if the 'rope' doesn't comply yet. The problem may be that it leaves shiny traces, but if it is rather dilute it may be not so serious and can be corrected with some matt acrylic varnish.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Think it would also make sense here in principle, as ELBE/ELBEN operated in strongly tidal waters, where touching sandbanks and the like may take place frequently. Talking about that, I wonder, whether she was really coppered. Most vessels that would only operate in home waters around the North Sea and the Baltic did not need to be coppered, as Terredo navalis had not penetrated through the Channel yet. Today, the situation is different, with T. navalis being found around the Wadden Sea island already.

-

If you look carefully at the sheet provided by the supplier, you will notice that there are vertical lines separating the plates, these should probably face to the rear, as the 'tiling' would begin at the stern and continue forward with the plates overlapping each other a bit. Similarly, the coppering would begin at the bottom and progress upward. Keel and sterm/stern would be done last, the rationale being that these areas would be most at risk and plates may need to be replaced more frequently.

-

Sorry, the Versailles reference went into the wrong forum and thread - to many things going on at the moment. In the building thread mentioned above there should be historical photograph or two that shows the drive arrangement on GJØA.

-

I just checked the pictures of GJØA that I took, when I visited the museum in 2019. However, at that time non gypsie-chaindrive was rigged though some chain was wrapped around the deck-winch. BTW, I may pop over to Versailles, but as I am between travels, I am not sure I will really manage.

-

Look for a building log on the Norwegian GJØA, I seem to remember that she used a chain drive from a petrol engine to the spill/winch.

-

I think that it would have been a chain-drive. Leather belts would break, if humid and frozen. I have never seen belt-drives on ships, but chain-drives seem to have been fairly common at a time before electrical direct drives became the norm.

-

Glad to have been of service ... As to the robands vs. continous lacing, I have seen both used on the same sail. I didn't check on the photographs, but was the foot of the sail actually tied to the boom? On vernacular craft sails were often loose-footed, as this allowed tricing them up quickly and thus take the pressure out of a sail e.g. in an emergency. Whether and how a sail was tied to the boom may also be depending on whether the boom was used as a cargo derrick. Robands may be easier to untie than to unravel a continuous lacing.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

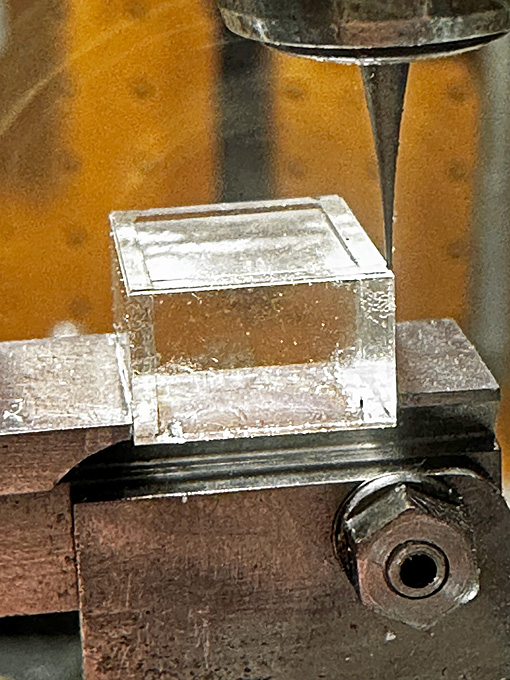

In spite of a week's travel for business, I managed to get done a part: ********************* The Main Hatch The main hatch will be shown closed, so I could revert to my usual technique of milling it from a solid piece of acrylic glass. In fact, the piece forms a core and as sharp corners for the recess into which the hatch covers fit is needed, around it strips of 1 mm acrylic glass were cemented. This arrangement was milled to size and shape as shown previously. To make it visually more interesting a quarter-round cove was milled into the outer edge with a 0.5 mm ball-burr. In real life, this would also prevent the wood from splintering, when hit by something during loading. Milling a quarter-round cove into the coaming of the main-hatch The cover was assumed to be in three parts, each planked with short lengths of plank. The cover is made from a tight-fitting piece of bakelite paper into which the planks were engraved, as was done for the deck-planks. Making hatch and cover in separate pieces allows to paint it with sharp edges. The cover will be simulated to be natural wood. The main-hatch with the cover inserted Eventually, the hatch will be fitted with clamps for the battens to tie-down the canvas cover. That will be done at a later stage to avoid damage during fitting the part into the deck. To be continued …

-

In any case, don't iron sails already treated with acrylic paint. The paint is not heat resistant. Otherwise, I ironed silk-paper slightly humid with a wool seeting or so between two thin cotton towels. Keep the iron moving, it is easy to 'brown' the paper ...

-

Pretty cool tool: drilling positioner

wefalck replied to CPDDET's topic in Modeling tools and Workshop Equipment

The problem is, that it only works for the set of diameters provide in the tool ... -

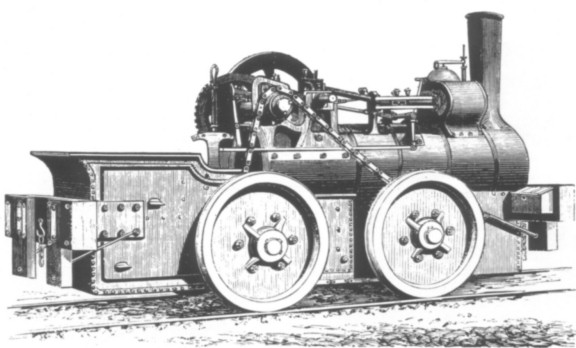

Aveling & Porter converted a couple of their traction engines for use on rails in the RN Dockyards. There is a preserved one in Chatham: https://newsite.dockyardrailway.co.uk/?page_id=89. The wheels are driven by chain from the crankshaft.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Machining bevel gears it not trivial and one needs a pretty massive 'universal' milling machine or shaper and a dividing head for that. However, by 1900 it would not be uncommon to see bevel gears of some sort on steam-engines. For instance, they were used since the later 1860s or so to drive the rope-drums on ploughing engines. Also, they became increasingly common in engineering due to the budding automotive sector, although there initially chain-drives were used. Chain-drives were used on (sailing) ships for instance to power winches from a centrally placed IC engine, but also in stationary industrial applications powered by steam. From the modelling perspective, one could turn a cone and file the teeth for bevel gears. You can buy them down to 0.3 modular, but that would be still too coarse for your scale. For chains, one could try to find a so-called fusee-chain as used in certain types of clocks/watches, but I have no idea of prices.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

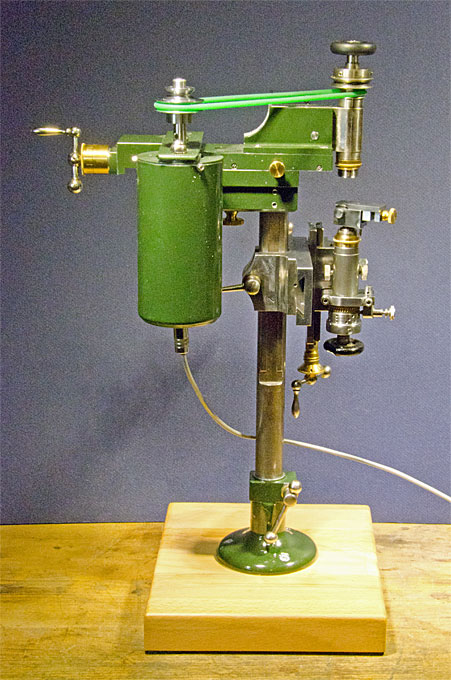

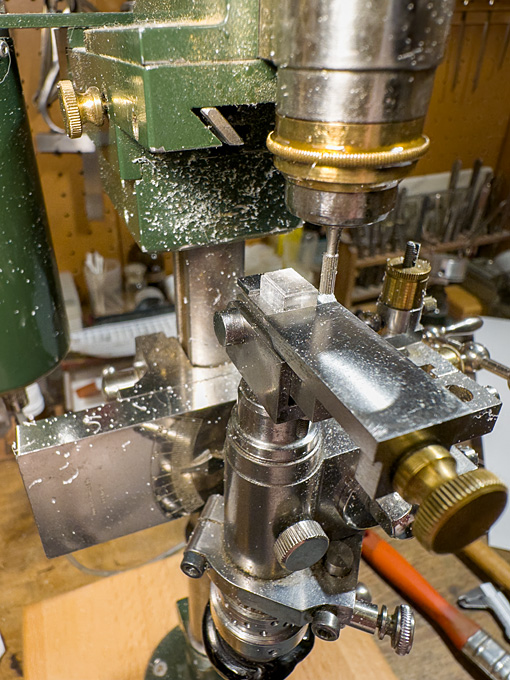

Well, it's a vintage milling machine that never was: https://www.maritima-et-mechanika.org/tools/micromill/micromill.html. The key mechanical parts came from antique watchmaking lathes. https://www.maritima-et-mechanika.org/tools/micromill/MF-V1.mp4 The miniature vice is shop-made: https://www.maritima-et-mechanika.org/tools/attachments/attachments.html#Micro_vice

-

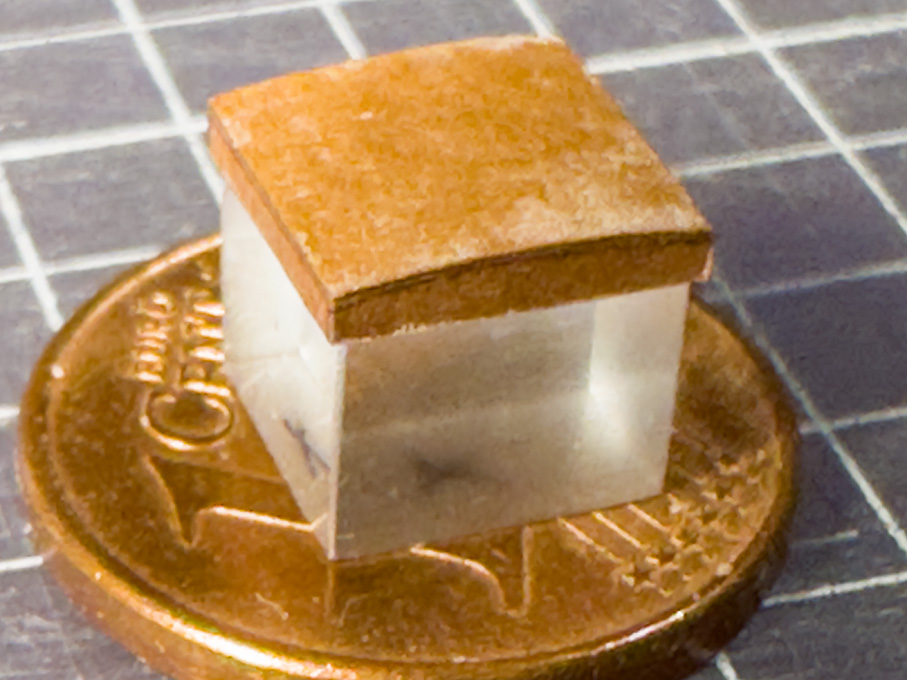

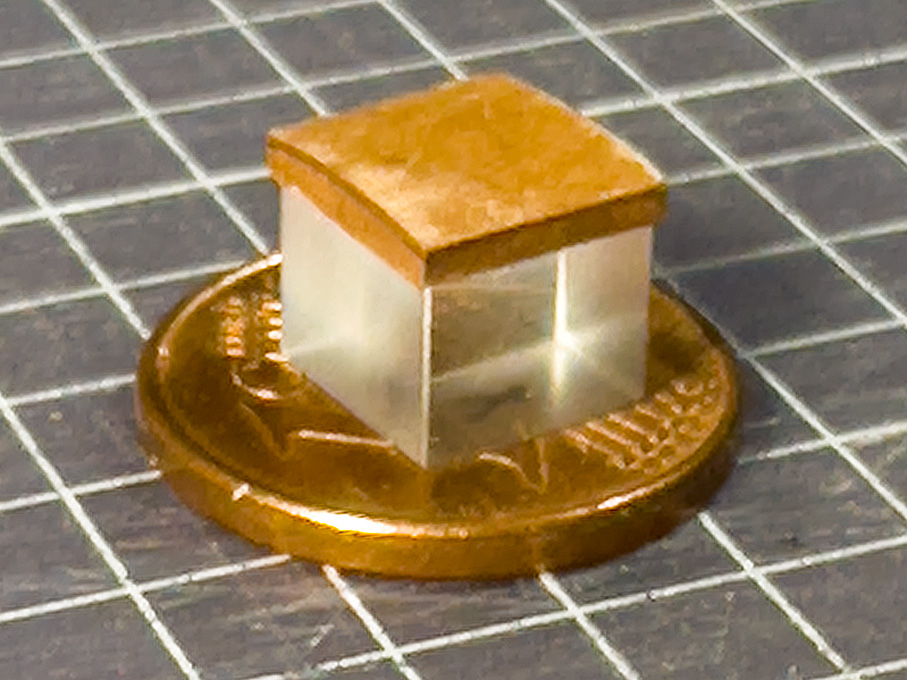

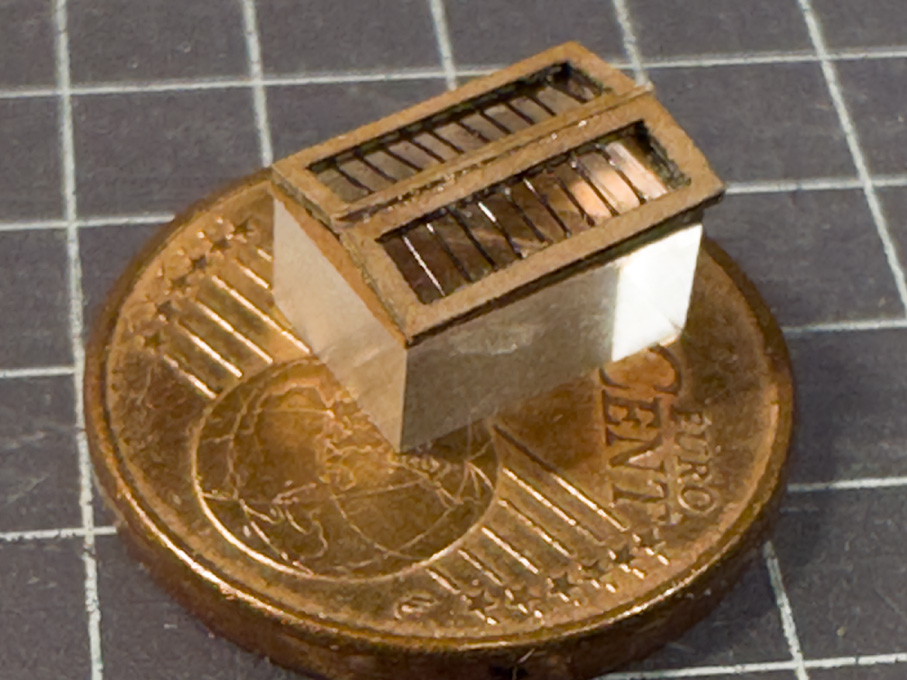

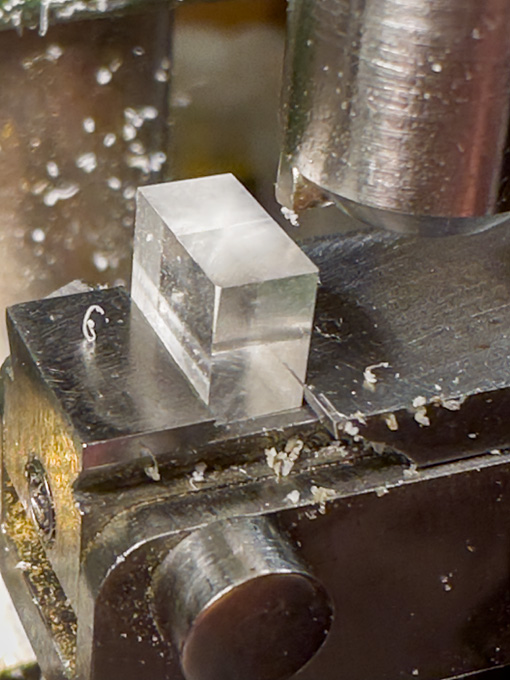

In between business-related absences from home, I managed to progress a little bit ... **************** Cabin Skylight As noted previously, the cabin skylight is a somewhat perilous position, but nevertheless contemporary drawings and some old models indicated, that they were of relatively lightweight construction. The actual construction is somewhat conjectural, but it seems that the hatch was covered by frame into which glass-panes were insert. Over this, there is a shallow roof-like structure with protective iron bars. In this arrangement, the glass-panes are not actually insert into the roof-like structure, but are at some distance below. The effect is, that even in the event that the iron bars are bent, the glass would not be touched. It also conceivable, that in the Baltic not real glass was used, but rather muscovite, which would be obtained by trade from Russia. In the event of very bad weather, the roof-like grille presumably could be replaced by a plain hatch cover. Milling to shape of the acrylic glass core for the cabin skylight This structure was built up in my preferred way, that is around a core of acrylic glass. It was milled to size from scrap piece of acrylic glass. For the ‘glass’ surface, I was able to use one of the original - as manufactured - surfaces, so no polishing was required. The high-speed milling with a fly-cutter a low feed-rate left almost transparent surfaces. Milling to shape of the acrylic glass core for the cabin skylight Milling of the recesses for the laser-cut frame parts The parts for the roof-like structure were produced again with the laser-cutter from Canson paper. The structure was to be designed in two parts, namely the frame attached to acrylic core and the two roof halves with the grilles, to allow painting. During painting the horizontal pane will be masked off and the roof halves painted separately. In order to ensure equal spacing of the ‘bars’, the roof was built up from three layers with the middle layers having notches. This layer was lacquered onto one of the outer layers and the ‘bars’ attached with drops of varnish – quite a fiddly bit of work and I am not entirely satisfied with the result. In the past, I made such parts from surface-etched brass and this seems to have worked better, but I didn’t want to set up everything for etching just a couple of small parts. Basic structure of the skylight, waiting to be painted and finally assembled I prefer to defer painting to the late stages of the building process in order to avoid handling the painted parts as much as possible, so construction of the skylight stops here for the moment. To be continued …

-

You mean by drive-shaft and bevel gears?

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.