-

Posts

184 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Hillsboro, Oregon

-

Interests

photography, motorcycling

Recent Profile Visitors

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

Macika reacted to a post in a topic:

Triton Cross Section by ChadB (Chach_86) - FINISHED

-

Landlubber Mike reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

Landlubber Mike reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

-

ChadB reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

ChadB reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

-

ChadB reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

ChadB reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

-

mtaylor reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

mtaylor reacted to a post in a topic:

USS Curtis Wilbur (DDG-54) by patrickmil - FINISHED - I Love Kit - 1/200 - PLASTIC

-

Hey Patrick, I'll be following along on this one! I served on the USS Barry (DDG-52) and had a friend on the Curtis Wilbur back in 99-03. We both worked on the AN/SPY-1D radar- those things that look like giant stop signs under the bridge lol. It looks like a fantastic kit! Chad

- 97 replies

-

- Curtis Wilbur

- I Love Kit

-

(and 2 more)

Tagged with:

-

Brig Eagle 1814 by bdgiantman2 - 1/48

ChadB replied to bdgiantman2's topic in - Build logs for subjects built 1801 - 1850

Hey Brian, Looks like a good start! I am pretty sure I have the drawings of my transom at home that I can share with you if it would help. Even if I don't I could take some measurements to help you out! I don't think I'd want to go through the process of trying to figure that all out again... Chad -

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

Nice looking jig and a very good start to your frames! You will find that the tolerances for your frames shouldn't be a huge issue on this build since the frames are all mostly square. I think as long as you can't see the black lines of the edge of the frame drawing then you have left enough. It can't be said enough though- if in doubt leave more! Chad

-

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

ChadB reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

ChadB reacted to a post in a topic:

H.M.S. Triton Cross Section by Ainars Apalais - 1:48

ChadB reacted to a post in a topic:

H.M.S. Triton Cross Section by Ainars Apalais - 1:48

-

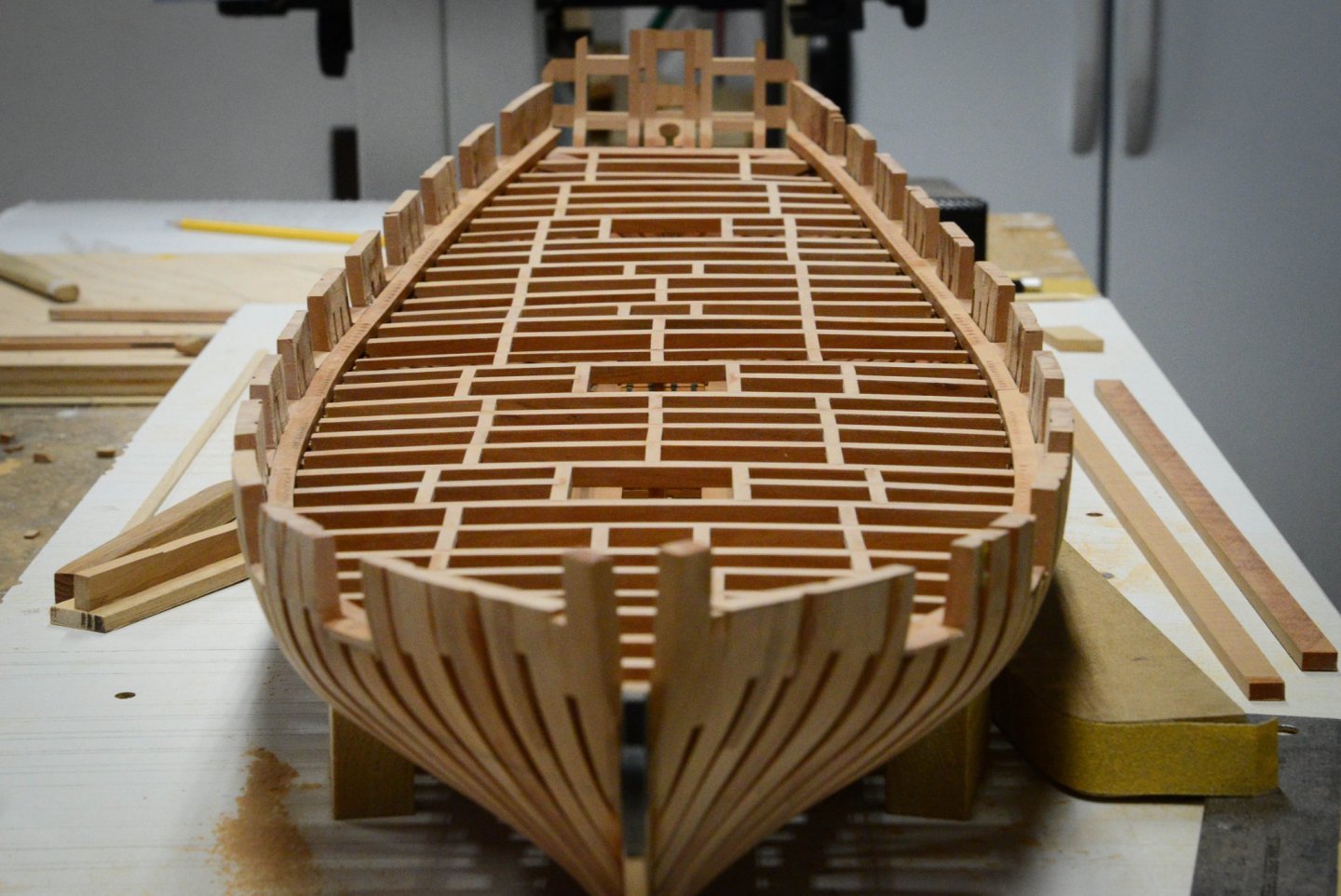

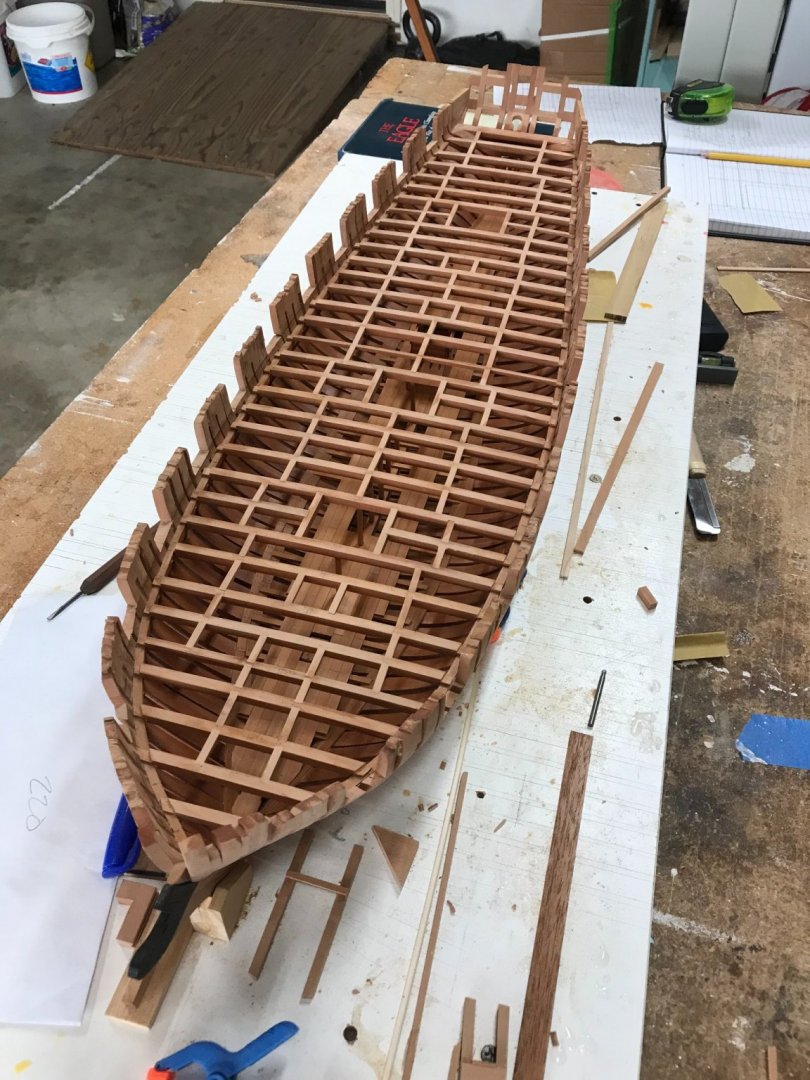

Brig Eagle 1814 by ChadB

ChadB replied to ChadB's topic in - Build logs for subjects built 1801 - 1850

Johann, Joe, John- thanks for the kind words! Not a huge update, but an update nonetheless. Waterways have been installed- they ended up being more of a pain in the butt than expected because of the need to drill out the cannonball divots and making them neat. I feel that similar to treenails, it would be easy to make them look incredibly sloppy if not lined up and even. I think I got it where I'm happy with it considering I don't have a mill. In the end I also am not a fan of cutting down the deck beam ends into a tab to fit between the clamp an waterway like I did. The idea is to make things easier but I don't know if it accomplished that and also made some of my beams a bit less sturdy. In the future I would notch the clamp and waterway as was done in the original ship. I also cut down my frame tops. When I made my frames I didn't leave enough wiggle room on top so a few were a bit under the correct height for the rail. My solution was to cut them all down 5mm below the rail height which is why they look a bit low. I will add a 5mm cap along the top that will just get covered up by planking and I figure make things a little more rigid anyway. Thanks for looking in! Chad -

Brig Eagle 1814 by ChadB

ChadB replied to ChadB's topic in - Build logs for subjects built 1801 - 1850

Schooners- thanks for checking in! Sorry I am just seeing your message now as I have been off the forums pretty much since my last update and nose down in decking or just enjoying the summer! Now that the rain has arrived back in the PNW I will most likely be getting back to work! JpR62, stuglo- thanks for the kind words and for checking in! Not a huge update and kind of a boring photo from my phone but deck framing has been completed. I am currently working on waterways. -Chad -

ChadB reacted to a post in a topic:

Scroll Saw or band saw... help me pick the right one.

ChadB reacted to a post in a topic:

Scroll Saw or band saw... help me pick the right one.

-

I've toyed around with the idea of doing this for quite some time and would love to do it when my kids are older and moving on with their lives (right now I want to give them all the time I can). I've slowly started tooling up for it and have been milling my own wood now, but want to get better because if I ever did it I'd want it to be the quality of the days of HobbyMill. I also have the added of benefit of having Gilmer Woods 20 mins from my house which would let me handpick the product. The major downside is that so far my back-of-the-napkin figures show that it probably leans more towards a labor of love more so than a profitable business. I wouldn't be looking to quit my day job but the time put in is time not modeling. Chad

-

Congrats! Your full build isn't too far behind! Chad

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Looks great! In my opinion, the quality of your work has grown quite a bit throughout your cross section and full build! Chad

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.