-

Posts

383 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Boccherini

-

Silver Soldering Tools

Boccherini replied to bundybear1981's topic in Metal Work, Soldering and Metal Fittings

Jason, this is the torch I have been using for several years, it is works well for me. The flame is quite tight, so you have good control over what you are heating. They are also cheap, and readily available online. You just need a propane/butane refill can from Bunnies. It doesn't have auto ignition. Smith Little Torch is probably the best set up, but pricey. I cant justify the expense for the amount of use it would get. Silver solder paste is available from online jewllery suppliers, there are several in Oz. I 2nd Janos opinion of Mytool store, I'm another satisfied customer. Regards, Grant. -

Rusty, nice start. Are you cutting out mortices for the ledges or filing angled slots in the carlings? Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

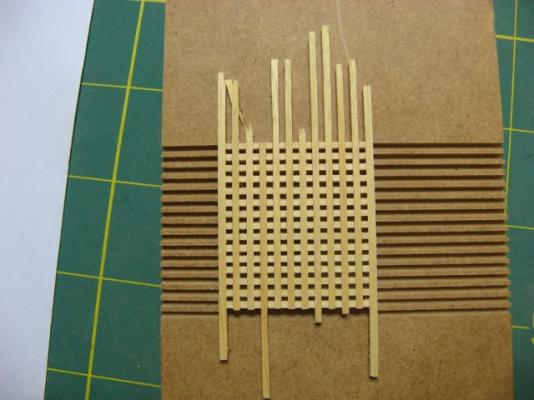

Joss, TFFM Vol 1 pp273/4, seems split gratings were not unknown. They made handling easier. I didn't have any problems with losing 'teeth'. Different timber? Two btw's: i) could you please give me access to the drawings, and, ii) how's the house extension progresssing? Thanks Pete. David, thanks for your interest. The mill seems to have been a good investment, and, as you say, it's not a financially debilitating purchase. Still coming to grips with what it can/can't do. The people I 'spoke' to prior to purchasing it assured me it would be adequate for modelling puposes. I'll know for sure in 12 months. Splitting the hatch worked out far better than I could hope, won't need to leave half the hatch open after all. Grant.

-

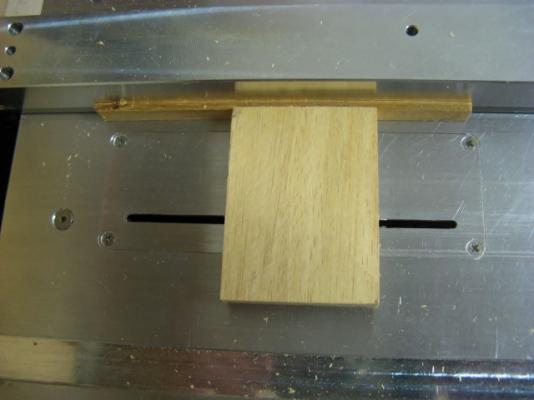

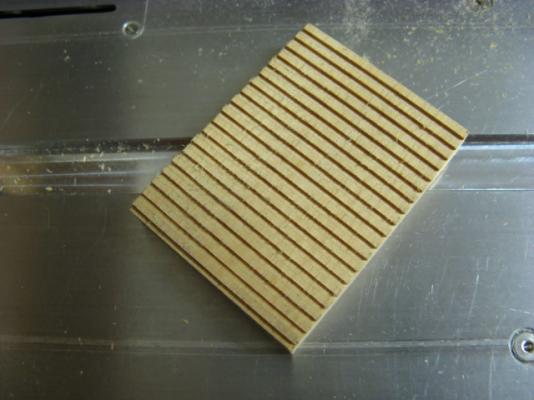

I have been putting off the hatch grating for some time, yesterday the desire to tackle this job came upon me. Being too lazy to build a jig for this, I used a spacer with the combined thickness of the saw blade and gap between the planks to cut slots the correct distance apart. The block was cut down to the correct width and the grating ledges cut off. The assembly jig and grating. At this point, it became apparent that my grasp of complex mathematical processes (addition, multiplication and division), was sadly lacking........aaaagggh! As Maxwell Smart would say, "Missed by that much." Shame the hatch opening isn't square. Another failure put down to haste and lack of careful checking when the carlings were put in place. The solution at present is to cut the grating in half, then make up a new half which will be left siiting on top of the grating in position, leaving half the hatch open. Grant.

-

Maso, I have used Birchwood Casey Brass Black (does the same job as Blacken It) without problem, obtained from one of the local gun shops. Regards, Grant.

-

Turning cannon's

Boccherini replied to garyshipwright's topic in Metal Work, Soldering and Metal Fittings

Gary, these are the cutters I used, and the end product. I used both ends of two blanks. They are showing a little bit of wear. Regards, Grant. -

Ron, I'm with Russ, it's easier off the model and less likely to damage anything. My x section is not a perfect match for the plans, so I marked out the position of the notches with all the beams pinned in place on the clamps (rather than using the plans to mark them). That way everything was in correct alignment. Regards, Grant.

-

Maury, you are doing a really great job. I spent some time 'twisting my pin vice' on the internal planking (Triton x-section), it was the least satisfying part of the build. Smart solution on your part. Regards, Grant.

- 324 replies

-

Echo by Rustyj - 1:48 - cross-section

Boccherini replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

Rusty, nice work. I'm glad you can keep it all separate in your head, I'd be struggling. The saying about struggling to walk & chew gum simultaneously applies to me. Regards, Grant. -

Maury, just went through your log, that is a good looking job so far. Congratulations. Regards, Grant.

- 324 replies

-

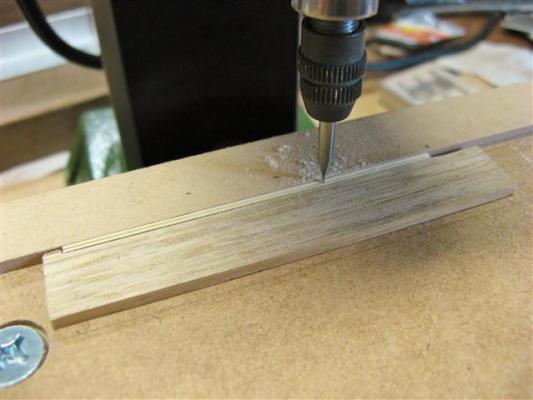

Thanks Paddy. There are ways of doing things without power tools, don't rush in buying stuff, do your research first. I have been gradually acquiring machinery over the last 8 years as my needs and ability increased. Having said that, they do make things easier. Pete, thanks. Yeah, looks like it's a good investment. There is a learning curve though, I didn't hold the first strip into the fence tight enough, it surprised me by climbing up the end mill. I also may have been trying to cut too deep, several shallow passes seem to work better than one deep one. Grant.

-

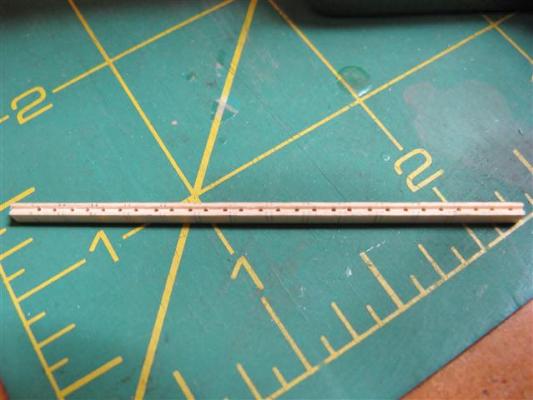

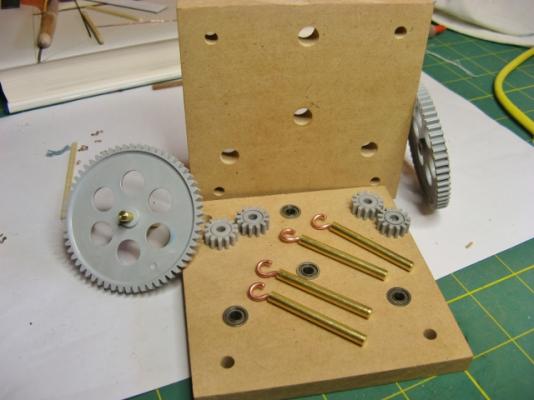

I recently purchased a Proxxon mill, this is its first time in use. The timber for blocks is lemon wood, harvested from a tree pulled out to make way for an extension several years ago. It is beautiful timber to work with, very close grained. I made a fence set up for the cross slide table to make things easier, the idea is not mine, but copied from a Russian build log from several years ago. A strip of timber has been cut to the right thickness and width, then a slot cut on the two sides for the sheaves and a light score on the two faces for the rope strops by pulling the strip through with a featherboard(?). The length of the blocks is marked on the strip with a small gap between them and the holes drilled to define the sheaves. This is a test strip to try out the technique, which seems to work quite well. The mill makes this work less time consuming. The blocks will be shaped by hand from here. There will be rope needed for the rigging, so I have started constructing a rope walk to manufacture it. Grant.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.