-

Posts

380 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Boccherini

-

Ron, Anthony, thanks for taking the time to comment, I appreciate it. I would like to express my appreciation to all the contributors who made this project possible. It has been a challenging, valuable and enjoyable exercise, my skill set and levels are much improved. So, thank you gentlemen. Regards, Grant.

-

Proxxon MF70 opinions and accessories

Boccherini replied to Keith_W's topic in Modeling tools and Workshop Equipment

Keith, I purchased an MF70 last year through Chronos engineering supplies in the UK, even with the freight costs it was still several hundred dollars cheaper than anyone in Australia, I can't vouch for their current price. The service was good and came with tracking. Just needed to swap the plug on the power cord. The machine comes with 3 cutters, some clamps and a set of collets. In addition, I purchased the precision vice, dividing head and the adjustable chuck. The adjustable chuck is ok, not fantastic. Better to stick with the collets wherever possible.The chuck and collets will take drill shanks up to 3mm. I have purchased some additional Kyocera cutters (0.5 - 0.8mm with 3mm shanks) from My Tool Store in Qld. He provides a reasonable service, shipping/delivery is good. I have used the mill to make some blocks, the dividing head was useful to ream out the ends on some barrels. So far, the MF70 appears to be a useful tool. It is particularly useful if space is a problem, being easy to pack up and store. It is vital to bolt it down on your bench before using. Regards, Grant. -

Just caught up with your build....... looking very good, clean & precise. Lathe chucks: get both, you'll use them. Horses for courses. Regards, Grant.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

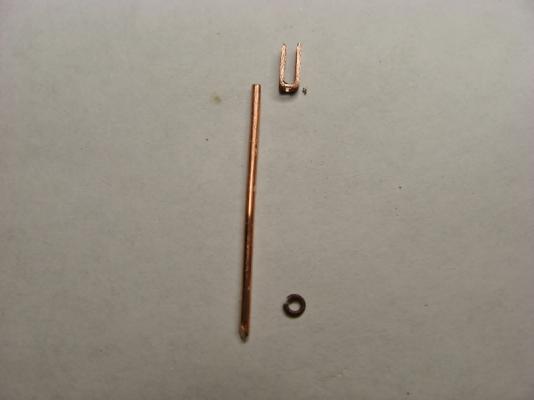

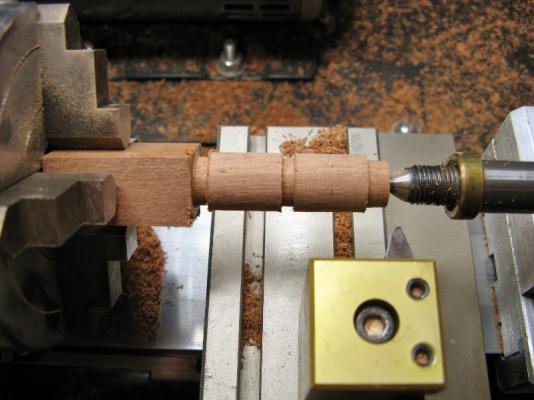

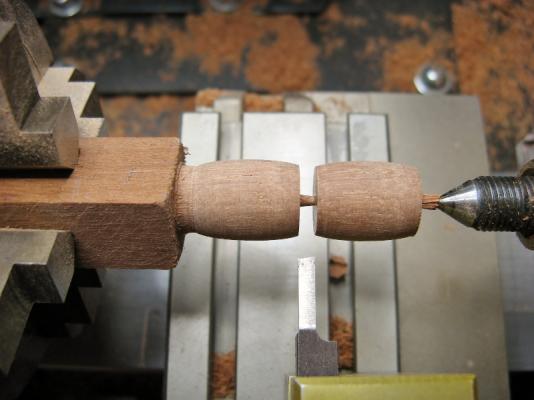

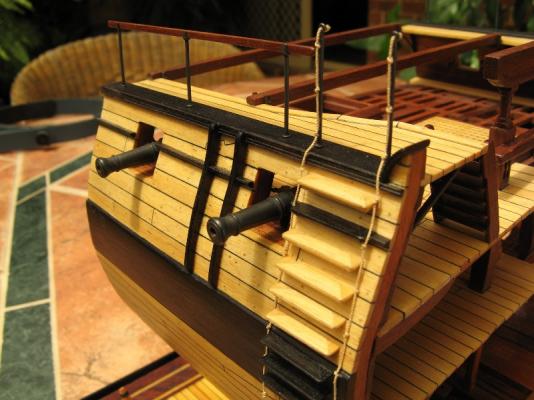

Mark & Christian, Pete and Wacko Wolf, thanks for your interest/comments. I'll be returning to my model of the "Harriet McGregor" from Underhill's plans, shelved due to loss of interest brought on by some mistakes made early in the construction requiring fiddly fixes that depart from the plans. I'm now ready (and better equipped) to deal with the results of my ignorance/lack of understanding and finish her. For general interest, here are some construction pictures for the stanchions, barrels and anchor. A word of warning, before soldering the ring to the stanchion, make sure the fit is tight. Any wobble will allow the ring to go skew when soldering. The entry rope stanchions have an eye soldered on top instead of the bracket. The barrels were turned from solid timber, I couldn't figure out how to cut the wedges required to show the staves. The ends were hollowed out to allow the installation of the barrel ends. I used paper strips for the hoops. The anchor was made from wood and sprayed. The method is in the MSW data base, I modified it slightly, the results were better than expected.

-

Rowan, if your are close by, this is where I obtained mine: Roy Alexander & Sons 8th Ave., Maylands. Nice bunch of guys. Regards, Grant.

-

Paddy, I used top and butt planking below the wales. The thickness of these strakes tapered down to the thickness of the normal planking below. Above the wales, the thickness tapered as the planks rose up to the sheer rail. I believe all the planking dimensions were from TFFM books. I don't explain myself very well sometimes, so I apologize if this is unclear. Pictures are better, I can send you a couple (or clutter up your log with them), to illustrate if you like. Regards, Grant.

-

Marius, you've been busy the last few weeks, quite a bit has been done. Nearly finished, a good looking model. I not sure I understand you corectly, but if you are looking for a decent draw plate, the Byrnes (Model Machines) one is top quality. You have my sympathy with regards to exchange rates and shipping costs (we cop it here), but the article is well worth the expense. Regards, Grant.

-

Paddy, Antony and Rusty, thanks for your comments. The gangways are in, along with the sheer plank. I decided to try something different with the drift rail, by producing a curved section instead of straight as indicated on the plan. The curved section is made up of 4 pieces of 0.5mm stock soaked in ammonia for about 5 minutes, carefully pulled into a curve around a former (18mm diameter), then clamped in place for 24 hours until dry. The pieces were then separated, pva glue applied and reclamped for another 24 hours. The result is a very stable, strong curved piece. This was cut in half, and shaped to provide the 2 sections required. I considered cutting these in one piece, but was concerned that they would either break during fabrication, or split some time in the future. There is a slight difference in the colouration due to the ammonia, this is not an issue, as I will be staining them black. Grant.

-

Thanks Ron, hope you rediscover your motivation quickly. I decided to fake the pins through the skid beams, one side from a slightly larger diameter with a shoulder filed onto it, the other was the correct size. Clamping the bracket in the manner shown provided a heat sink to protect the solder in the joint from melting and the crutch dropping off the bracket. I soldered the pins into the brackets thinking this would make the installation easier, not having to fiddle around trying to line up holes whilst glueing the brackets to the planking (with 5 min epoxy). There are also some dummy heads that don't go right through the brackets for the sake of appearances. The construction method has worked well, the brackets are very firmly attached and are not going anywhere, I expect they will get a few knocks prior to the gangways being installed. Grant.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.