-

Posts

380 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Boccherini

-

Rusty, congratulations on a fine looking model. Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

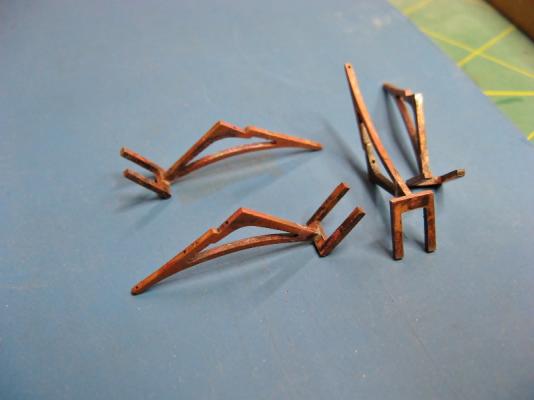

Just went through one of those periods where the desire to work on this project evaporated, didn't even look at it for 2 weeks. I'm over that now, the inspiration has returned . I have upgraded my gas torch, this one has built in ignition and aeration adjustment for the flame. A great improvement over the pencil torch. The brackets have all been trimmed back to the correct length, and the ends soldered on for the skid beams. These are still oversize, but will be trimmed back in the next step. I have started making everything slightly longer or thicker than required, having discovered it is easier to remove excess than add material or re make a piece. Grant.

-

Accompanied by the sound of teeth grinding and muttering under the breath. On a positive note......practice makes perfect. I developed the habit of measuring or making templates directly from the model, because of the previously mentioned difference between it and the plans. Saved some frustration. Regards, Grant.

-

Rusty, the cross secton has finished up very well, congratulations on a great job. Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Bob, neat job on the gun port lining, the planking is looking very professional. The top plank on the bulwarks needs to be rebated the thickness of the gangway planks, which are supposed to sit flush with the top of the frames. I made the same mistake, and spent a nervous hour carefully trimming the offending planks (on both sides) down to accomodate the gangways. Regards, Grant.

-

Rusty, good start with the brackets. My cross section and the plans don't always exactly agree, so I used a piece of timber across the deck resting on the gangway ledges to provide a guide for the underside of the gangway planking. This helped to get the correct angle for the brackets and eliminated the possibilty of them getting out of alignment. Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

The gangways are complete, I decided it would be easier to make them off the model, then install them complete. The construction sequence is pretty self explanatory (in spite of the fuzzy pictures, apologies). Clamping the first three planks was done in a jig, the rest of the joints were made by clamping to the table of the Byrnes saw (versatile piece of machinery). Grant.

-

Meredith, I have had a 10" Carbatec band saw for 10 or so years. It was originally purchased to cut deck planking, which worked out ok. The planks just needed a bit of finishing off on a thicknesser. It is now only used/set up for cutting larger pieces of timber down to a size the Byrnes saw can handle. I am using a coarse blade (4 tpi), which cuts hard wood easily. The cut marks are either hand planed off or removed with the thicknesser, or a combination of both. For what it's worth, I also have a scroll saw. Regards, Grant.

-

Re the "oops moment", this project has taught me to always make several more of everything that is required. The times I didn't, meant having to set up heights and jigs etc., all over again. It's a valuable lesson. Good to see you're on top of it. Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Rusty, the gun carriage components are looking very nice. Were the sides shaped individualy, or did you shape a block then cut the sides from it? Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Not quite as much progress has been made as hoped for, the Admiral desired a "galley" renovation, which has taken a bit longer than anticipated. All the brackets are tacked into place with contact cement to allow the marking of fixing holes and to make a template for the gangways. This will also allow me to accurately trim the lengths of the brackets so everything looks symetrical. Grant.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.